Analysis on Energy Recovery Efficiency of Oily Sludge Gasification

Ziyi Wang

a

and Zhenbo Wang

*b

College of New Energy, China University of Petroleum (East China), 266580, Qingdao, China

Keywords:

Oily Sludge, Pyrolysis Oil, Pyrolysis Gas, Char.

Abstract:

The harmless treatment of oily sludge is a long-term and arduous task. It is always a hotspot that is worthy of

discussion for how to maximize the utilization of oily sludge and control the pollution to the lowest level. In

this paper, the CO

2

in waste gas from oily sludge combustion is reused by gasification to produce syngas rich

in CO and H

2

, so as to reduce CO

2

emission and realize efficient recovery of oily sludge energy. The effects

of gasification temperature and dosage of gasification agent on the gasification efficiency of oily sludge were

investigated. It is found that with the increase of gasification temperature and dosage of CO

2

, the energy

recovery efficiency and the yield of CO are greatly improved. It is found that the CO production can be greatly

increased when the temperature reaches 900 °C, while the CO

2

/oily sludge ratio will not significantly affect

the experiment result when it exceeds 2.

1 INTRODUCTION

1

As a kind of representative by-product of

petrochemical industry, oily sludge treatment is

imminent (Gong, Du, Wang, Bai, Wang, 2019);

(Gong, Du, Wang, Sun, Fang, Wang, 2019); (Gong,

Fang, Wang, Li, Li, Meng, 2020). According to rough

statistics, the production of oily sludge exceeds 5

million tons only in China (Gong, Liu, Wang, Wang,

Li, 2020). Moreover, the existence of toxic

substances such as heavy metals, PHCs and PAHs

undoubtedly increases the difficulty of oily sludge

treatment. On the other hand, oily sludge also

contains a considerable amount of energy. If

reasonable methods can be used for energy recovery,

it will greatly promote the development and

promotion of oily sludge treatment technology.

Therefore, there are new requirements for oily sludge

treatment, that is, based on realizing the harmless and

reduction of oily sludge, to achieve the efficient

recovery and utilization of energy as far as possible.

Among many treatment methods, combustion

treatment method is the first choice because of the

characteristics of fast treatment speed, strong

adaptability, thorough treatment, etc.

However, the application of combustion

technology for oily sludge treatment is difficult to

solve the problem of low energy recovery efficiency,

a

https://orcid.org/0000-0003-3591-5940

b

https://orcid.org/0000-0002-3055-961X

and the impact of a large amount of CO

2

emissions

from the combustion of a large quantity of petroleum

hydrocarbons is also negative.

Therefore, it is of great significance to discuss

how to achieve efficient energy recovery and CO

2

emission reduction of oily sludge.

Gasification has great potential although it has not

been widely used for oily sludge treatment at present.

Using CO

2

as gasification agent can reduce CO

2

emissions, as well as realize the recovery of oily

sludge energy products, which is an ideal treatment

scheme. In the report of Guo et al. (Guo, Xiong, Che,

Liu, Sun, 2021), due to the existence of CO

2

, the

formation of CO increases with the increase of

temperature, while the formation of NO

x

and SO

x

is

inhibited. Michel et al. (Michel, Rapagna, Di

Marcello, Burg, Matt, Courson, 2011) investigated

the effects of gasification technology and the results

showed that the content of H

2

and CO account for

45.89% and 24.35% 880 °C, respectively.

In particular, the combination of gasification

technology and combustion technology is more

hopeful to realize the low-priced and thorough

treatment of oily sludge.

In this paper, the gasification experiment of oily

sludge in a fixed bed reactor was carried out, and the

effects of temperature and gasifying agent dosage on

the composition and distribution of gasification

Wang, Z. and Wang, Z.

Analysis on Energy Recovery Efficiency of Oily Sludge Gasification.

DOI: 10.5220/0011207500003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 355-360

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

355

products were investigated, which provided basic

theory and data support for the large-scale promotion

of the technology.

2 EXPERIMENT AND

MATERIAL

Oily sludge is collected from Liaohe Oilfield,

Liaoning Province, China. The basic physical and

chemical properties of the samples were tested as

ASTM method D482-87, and the results are shown in

Table 1. In order to facilitate the follow-up

experiments, the original oily sludge samples were

dehydrated at 105 °C by oven and segmented to the

size of less than 5mm.

Table 1: Basic physical and chemical characteristics of PS.

Data

Proximate analysis

ad

(ad. wt%)

A 48.53

V 49.76

FC 1.71

Ultimate analysis

ad

(ad. wt%)

C 53.78

H 8.32

S 0.96

N 0.39

ad: air-dry base; *By difference; A: ash, V: volatile

matter, FC: fixed carbon

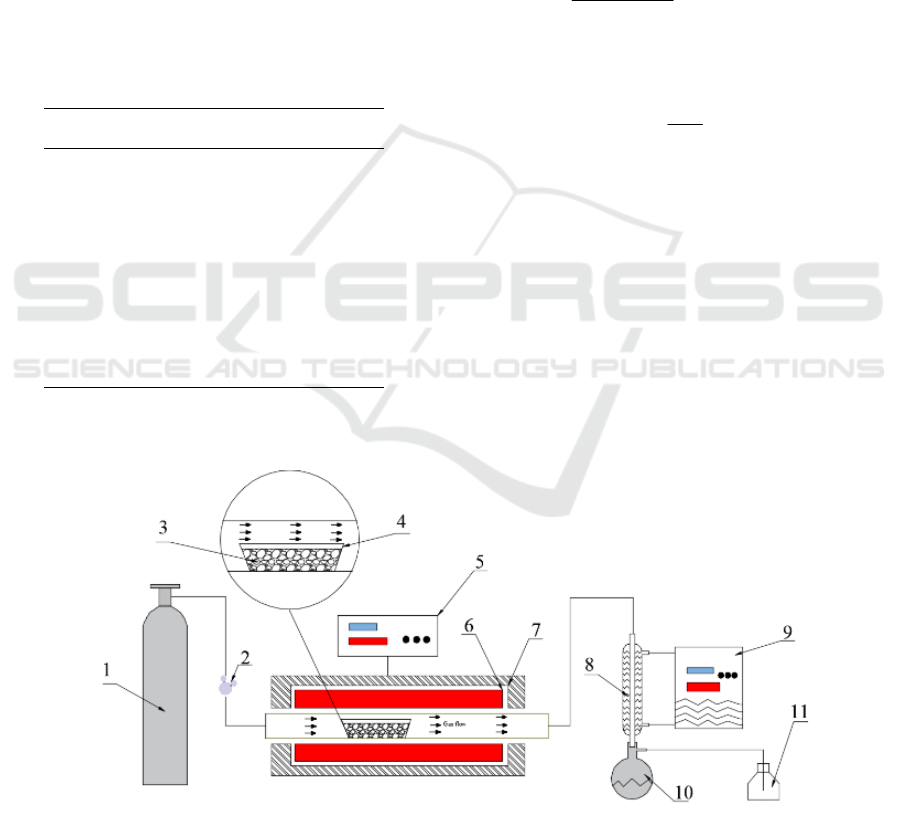

Gasification experiment was carried out in a fixed

bed reactor as Fig.1. N

2

was injected as carrier gas

and protection gas at a rate of 40 ml/min to produce

inert environment and CO

2

is used as gasifier. The

effect of gasifier on gasification process is tested by

adjusting the amount of CO

2

flux. 4g of LSOS

samples were taken in each experiment and placed in

corundum crucible. Temperature and CO

2

/oily sludge

ratio (R) was set as 500/600/700/800°C with R=1 and

R was adjusted as 0.6/1/2/2.5 at 800°C, respectively.

The gasification experiment was determined as 25

minutes, during which the CO

2

and N

2

were injected

stable. The actual amount of CO

2

is shown as Eq. 1:

2

2

22.4mL/mol 1000mL/L

25min

OS i

CO

CO

mn

Q

M

×

=××

×

(1)

The yields of gasification char could be calculated

as Eq.2 and Eq.3.

=100%

c

c

os

m

m

η

×

(2)

gc

=(1- ) 100%

η

η

×

(3)

m

c

—Weight of gasification char;

m

os

—Weight of oily sludge sample;

η

c

—Yield of char;

η

g

—Yield of syngas.

The syngas was collected with aluminum foil gas

bag. The composition of gasification syngas is

detected by GC-456-Gas Chromatograph detector.

1. High pressure gas cylinder 2. pressure reducing valve 3. sample 4. crucible 5. heating furnace temperature controller 6.

heating wire 7. furnace body 8. condenser tube 9. condenser tube temperature controller 10. flask 11. gas recovery device

Figure 1: Experiment flow chart.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

356

3 RESULT AND DISCUSSION

The application of incineration technology for oily

sludge treatment not only can recycle the energy

contained in oily sludge, but also can realize the

thorough treatment of oily sludge. However, a large

quantity of hydrocarbons contained in oily sludge

will produce CO

2

during combustion. In order to

reduce CO

2

emission and recover as much as

possible, combustion waste gas can be added into the

gasification process as gasification agent in a certain

proportion to produce high calorific value syngas rich

in H

2

and CO, which can be used as industrial raw

material to create certain economic value. Therefore,

as an important part of the treatment process, the CO

2

gasification characteristics of oily sludge need to be

further investigated.

3.1 Effect of Temperature on

Production Yield

High temperature environment provides energy for

the gasification of oily sludge. Organic components

in oily sludge are cracked to produce small molecules

of gaseous organic matter. The non-decomposable

components and inorganic substances exist in the

form of char. Different from the combustion process,

the gasification process of oily sludge is always in the

endothermic state, which means that in the

conversion process, the external energy needs to be

continuously input for the gasification process. As

one of the key parameters, temperature is an

important basis to measure the energy input in the

treatment process. Especially for large-scale process,

it is very important to determine the optimal

temperature. The influence of temperature on the

treatment effect is mainly reflected in two aspects: the

energy recovery rate and the composition of gas

products. The effect of temperature on the yield is the

most intuitive. Generally, high temperature

environment is conducive to the decomposition of

organic components, and the increase if temperature

can promote the recovery of organic components. For

the gasification process of oily sludge, organic

components recovered in the form of syngas have

higher recycling value. In Fig.2a, the ratio of oily

sludge to gasifier was controlled to 1, and the

temperature change and energy recovery ratio were

studied separately. In the environment above 600 °C,

more than 90% of organic components can be

recovered even without oxygen and other oxidants.

However, when the temperature is raised from 600 °C

to 900 °C, the yield of gas products has not been

greatly improved. The yield of syngas only increased

from 45.5% to 47.9%.

From the perspective of energy recovery, the

energy recovery rate of oily sludge increased by

about 5%. This feature shows that for oily sludge, a

substantial increase in environmental temperature

has a positive effect on energy recovery, but the

increase is no longer obvious when the temperature

exceeds 600 °C, even the energy input is far greater

than the energy output, which is not in line with the

economic balance.

However, the yield of the product is often not a

single determinant, and the influence of temperature

on the product composition is also crucial. For the

gasification product, only syngas and char residue

and oil phase production are lack. Therefore, the

calorific value and purity of syngas determines the

value of products. Especially CO and H

2

are the most

ideal components.

45.5

46

47.5

47.9

54.5 54 52.5 52.1

600 700 800 900

0

10

20

30

40

50

60

70

80

90

100

Yield(%)

Temperature(°C)

Char

Syngas

88

89

90

91

92

93

Recover rate(%)

Figure 2: Recovery rate yield of syngas and char of LSOS at 600/700/800/900°C.

Analysis on Energy Recovery Efficiency of Oily Sludge Gasification

357

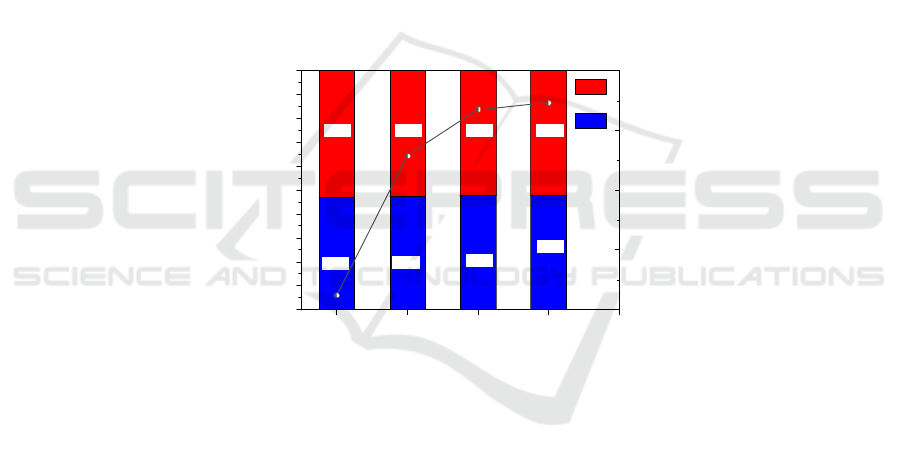

3.2 Effect Of Gasifier Dosage on

Gasification Effect

Since the gasifier will participate in the specific

reaction, the amount of gasifier often has a significant

impact on the yield of the product. The CO

2

/oily

sludge ratio (R) was adjusted and the product

distribution of oily sludge was investigated.

According to Eq. (1), the injection volume of CO

2

is

set as 24/40/80/100ml/min, and the corresponding

product distribution is shown in Fig. 3. It can be

found that the injection amount of gasification agent

has a significant impact on the gasification effect of

oily sludge. Although the effect is far less than that

caused by oxidant, the gasification of oily sludge is

limited when the amount of gasifying agent is

relatively low, resulting in incomplete gasification

reaction and the low yield of syngas. Nevertheless,

the planned recovery rate of oily sludge has reached

a very high level, that is, the recovery rate has

exceeded 91%. With the increase of R, the gasifier is

no longer the obstacle of syngas formation, and the

syngas production increased slightly. With the

increase of R value from 0.6 to 2.5, the yield of

syngas increases from 46.92% to 47.75, showing an

obvious upward trend. However, the increase of

gasifying agent will not increase the recovery of

product without limit. It can be clearly seen from

Figure 3 that when R increases from 0.6 to 2,

increasing the ratio of gasifying agent again will not

increase the yield of syngas, and will basically remain

at a high level. At this stage, the energy recovery

efficiency is above 92%.

Although it is to combine CO

2

gasification and

combustion treatment of oily sludge at present,

excessive CO

2

injection is meaningless. Excessive

CO

2

injection may also cause heat loss and energy

waste. Therefore, it can be preliminarily determined

that when the R=2, it can meet the processing

requirements and obtain a better processing effect.

46.92

47.51

47.73

47.75

53.08 52.49 52.27 52.25

24 40 80 100

0

10

20

30

40

50

60

70

80

90

100

Yield(%)

Temperature(°C)

Char

Syngas

91.0

91.5

92.0

92.5

93.0

Recover rate(%)

Figure 3: Distribution of gasification productions of LSOS with different R.

3.3 Effect of Temperature on Syngas

Composition

The gasification products of oily sludge mainly

contain char of gas and solid phase. Syngas, as a

target product, composition greatly determines the

economic value. As can be seen from Fig. 4, the

composition of syngas is extremely complex. In

addition to the target products CO and H

2

, there are

many kinds of impurity gases including methane,

ethane, ethylene, propane, propylene, isobutane, n-

butane, trans-2-butene, butene-1, isobutene, cis-2-

butene, isopentane, n-pentane, C5+, etc. In syngas,

CO and H

2

account for 21.89% and 21.01%

respectively, which are the main components of

syngas. The proportion of methane, ethylene and

other small molecular hydrocarbon products is also

quite high, accounting for 22.35% and 19.41%

respectively, which is equivalent to the production of

CO and H

2

. Although there are many kinds of other

impurity gases, the proportion is quite low, most of

them are about 1%, which can be ignored. This

phenomenon shows that in the process of

gasification, the purity of gas products is quite high,

which has a very positive impact on the subsequent

recycling. By comparing the gasification effect with

the previous pyrolysis study, it can be found that there

is a certain gap with pyrolysis (Wang, Gong, Wang,

Li, Liu, Tang, 2021); (Wang, Gong, Wang, Li, Liu,

Tang, 2020). There are not only differences in the

form of products, but also obvious differences in the

composition of products. For pyrolysis in inert

environment, the syngas is mainly composed of C1-

C6 components and H

2

and CO only occupy a small

proportion. By adding CO

2

as oxygen donor, the

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

358

composition of CO and H

2

in the product greatly

improved. In Fig.4, the ratio of CO and H

2

increased

greatly and the proportion of miscellaneous gases

decreased significantly. In particular, the gas ratio of

C5 and C6 decreased significantly.

1.13%

21.01%

21.89%

6.73%

19.41%

4.2%

22.35%

Methane

Ethane

Ethylene

Propane

Propylene

Isobutane

N-butane

Trans-2-butene

Butene-1

Isobutene

Cis-2-butene

Isopentane

N-pentane

C5

C6+

CO

H

2

Figure 4: Main syngas components at 600 °C.

In the gasification process of oily sludge,

temperature and R, as important indexes, not only

affect the product distribution, but also the product

composition. The results show that the proportion of

C3 + in syngas composition is low and does not meet

the expected goal of the experiment. Therefore, this

experiment focuses on CO, H

2

, C1-C3 components.

It can be seen from Figure 5 that when the

gasification temperature is only 600 °C, the yield of

each component is at a very low level. When the

temperature rises to 700 °C, the yield of each

component does not change significantly. Only the

yield of CO increased significantly. When the

gasification temperature was further increased to

800 °C, the CO production increased significantly,

but it was still at a relatively low level. The

composition of syngas changed obviously when the

temperature increased to 900 °C.

The composition of syngas is affected by

temperature and can be divided into two stages.

When the temperature is lower than 900 °C, the

increase of temperature has little effect on the

increase of components, and CO

2

cannot fully

participate in the gas-phase reaction. Organic

components tend to recombine freely in high

temperature environment to form gaseous products

with small molecules. Due to the participation of

CO

2

, the difficulty of the reaction is greatly reduced,

and the chain breaking and recombination of organic

components can occur at low temperature. It is worth

noting that when the temperature increases from

600 °C to 800 °C, the proportion of C3+ in syngas

decreased, even disappeared.

At present, the common views on the production

of H

2

and CO include CH

4

+2H

2

O→4H

2

+ CO

2

and

C + 2H

2

O → 2H

2

+ CO

2

(Zhu, Zhao, Fu, Yang, Li,

Yuan, 2019) and Boudouard reaction (C+CO

2

↔2CO;

ΔH=172 kJ·mol

-1

) which is proceeded spontaneously

in the forward direction to produce CO above 973K.

Therefore, when the temperature rises to 900 °C, the

production of CO increases by leaps and bounds.

While due to the lack of water and energy input in

low temperature environment, the yield of H

2

is

difficult to reach a high level. This conclusion is

consistent with the experimental results.

When the temperature was maintained at 800 °C,

the effect of syngas composition was investigated by

adjusting the amount of CO

2

. Overall, the increase of

the amount of gasifying agent has a certain effect on

the increase of the yield of each component.

Especially for CO, when the gasifier is increased

from 1 to 2, the yield is more than twice as high.

However, when R further increases, the increase of

CO production is not obvious. When R>2, the

increase of the amount of gasifying agent will not

have a great impact on the yield of the product.

0

10 0

20 0

30 0

40 0

50 0

60 0

70 0

Yield/mL

600?

700?

800?

900?

CO H

2

CH

4

C

2

H

4

C

2

H

6

C

3

H

6

C3+

Figure 5: LSOS syngas composition at different

temperature.

0

100

200

300

400

500

Yield/mL

24mL/min

40mL/min

80mL/min

100mL/min

CO H

2

CH

4

C

2

H

4

C

2

H

6

C

3

H

6

C3+

Figure 6. Syngas production composition.

Analysis on Energy Recovery Efficiency of Oily Sludge Gasification

359

4 CONCLUSION

The gasification treatment of oily sludge has short

treatment cycle and high efficiency, which is an

excellent treatment technology with good prospects.

The results show that the effect caused by the

increase of temperature is more significant than that

caused by the increase of gasifying agent dosage.

When the temperature is increased from 600 °C to

900 °C, the CO production is increased by 4 times,

while when the temperature is increased from 600 °C

to 900 °C, the CO production is increased by 12 times

while the effect of temperature on H

2

production is

not obvious. The increase of gasifier will also

increase the yield of H

2

, and the yield of H

2

is nearly

doubled when R is increased from 1 to 2. The syngas

obtained in the environment of high temperature and

sufficient gasifier is rich in H2 and Co, and the

impurity gas content is low. It is a gas product with

high calorific value and high added value. It has a

good industrial application prospect, which lays a

foundation for the promotion of oily sludge

gasification technology.

ACKNOWLEDGEMENT

The research was supported by the State Key

Laboratory of Pollution Control and Resource Reuse

Foundation (No. PCRRF19023), Natural Science

Foundation of Shandong Province (No.

ZR2020QE199), Key Research and Development

Program of Liaoning Province (No.

2020JH2/10300099) and Fundamental Research

Funds for the Central Universities (No.

18CX02150A).

REFERENCES

Gong Z, Du A, Wang Z, Bai Z, Wang Z. Analysis on

integrated thermal treatment of oil sludge by Aspen

Plus. Waste Management 2019;87:512-24.

Gong Z, Du A, Wang Z, Sun Z, Fang P, Wang L, et al.

Reaction Kinetics of Oil Sludge and Microalgae Co-

Pyrolysis. Acta Petrolei Sinica Petroleum Processing

Section 2019;35(2):312-9.

Gong Z, Fang P, Wang Z, Li Q, Li X, Meng F, et al.

Catalytic pyrolysis of chemical extraction residue from

microalgae biomass. Renewable Energy 2020;

148:712-9.

Gong Z, Liu C, Wang M, Wang Z, Li X. Experimental study

on catalytic pyrolysis of oil sludge under mild

temperature. Science of the Total Environment 2020;

708.

Guo S, Xiong X, Che D, Liu H, Sun B. Effects of sludge

pyrolysis temperature and atmosphere on

characteristics of biochar and gaseous products.

Korean J Chem Eng 2021;38(1):55-63.

Michel R, Rapagna S, Di Marcello M, Burg P, Matt M,

Courson C, et al. Catalytic steam gasification of

Miscanthus X giganteus in fluidised bed reactor on

olivine based catalysts. Fuel Processing Technology

2011;92(6):1169-77.

Wang Z, Gong Z, Wang Z, Li X, Liu J, Tang C, et al.

Pyrolysis performance and kinetic analysis of oily

sludge. Journal of Thermal Analysis and Calorimetry

2021.

Wang Z, Gong Z, Wang Z, Li X, Liu J, Tang C, et al.

Pyrolysis characteristics and products distribution of

petroleum sludges. Environmental Technology 2020.

Zhu X, Zhao L, Fu F, Yang Z, Li F, Yuan W, et al. Pyrolysis

of pre-dried dewatered sewage sludge under different

heating rates: Characteristics and kinetics study. Fuel

2019;255.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

360