Research Progress of Air-water Interface Stability in Food Foam

System

Xinghui Wu

1,2 a

, Mingjie Xia

1,2

, Shufang Cao

1,2

, Wenqi Cai

1,2

, Li Li

1,2

and Lina Yang

1,2,*

1

College of Food Science and Engineering, Bohai University, Jinzhou, 121013, Liaoning, China

2

Grain and Cereal Food Bio-efficient Transformation Engineering Research Center of Liaoning Province, Jinzhou,

121013, Liaoning, China

*

Corresponding author

Keywords: Foam System, Polysaccharide Hydrocolloid, Interfacial Stability, Surfactant.

Abstract: The foam dispersion system is widely used in many kinds of food processing fields and give good texture and

sense for food. This paper summarized this formation mechanism, the effect mechanism of internal factors

(surface tension, surface viscoelasticity) and external factors (temperature, pH, surfactant, ionstability) on

stability of foam system, and the progress of effect of polysaccharide hydrocolloids co-regulating protein on

stability of foam system. The aims was to provide theory support for developing natural surfactant and obtain

expected foam texture in food system. In order to promote the application of polysaccharides hydrocolloid

surfactant in the field of foam food processing.

1 INTRODUCTION

In daily life, the macro behavior of many foods, such

as their stability, rheological properties and structure,

is related to the state of structural units. As one of the

most common structural units in multiphase food

system, the foam system plays a vital role in beer,

inflatable candy, ice cream, baking products and other

foods. The foam system not only gives the superiority

of food organization structure and appearance, but

also benefits chewing and food flavor transmission.

At the same time, the addition of air can also reduce

energy intake to a certain extent and meet modern

people's pursuit of healthy diet (Liu 2009). Because

foam is a typical thermodynamic instability system of

air-liquid two phase, the high specific surface area

and surface free energy of air-liquid interface lead to

unstable foam (Li 2020). Therefore, how to obtain

stable (metastable) foam system in actual food

production and processing is a problem that needs to

be further studied.

a

https://orcid.org/0000-0001-8481-667X

2 FORMATION AND

INSTABILITY OF FOAM

SYSTEM IN FOOD

2.1 Formation of Foam System

The foam in food is a dispersive system composed of

bubbles separated by liquid membrane, where liquid

or semisolid is a continuous phase and gas is

dispersed phase (Diao et al. 2021). The foam

structure is shown in Figure 1. Foam formation

requires four conditions: gas, water, surfactant and

energy. Full contact between gas phase and water

phase is a necessary condition for foaming. Energy

increase the interfacial area between the two phases.

The function of surfactant is to adsorb on the air-

liquid interface to form an elastic liquid film with a

certain thickness, reduce the surface tension and

maintain the stability of the air-liquid interface.

100

Wu, X., Xia, M., Cao, S., Cai, W., Li, L. and Yang, L.

Research Progress of Air-water Interface Stability in Food Foam System.

DOI: 10.5220/0011232900003438

In Proceedings of the 1st International Conference on Health Big Data and Intelligent Healthcare (ICHIH 2022), pages 100-106

ISBN: 978-989-758-596-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Scheme of the foam structures (Li 2020).

2.2 Instability of Foam System

Because of the high surface free energy of the foam

system in the air-water boundary, the foam surface is

unstable. According to the principle of Gibbs free

energy, in order to reduce the interfacial area, the

surface free energy will decrease spontaneously,

resulting in the loss of water film, polymerization and

disproportionation of the bubble film, which will

cause the instability of the foam system (Murray &

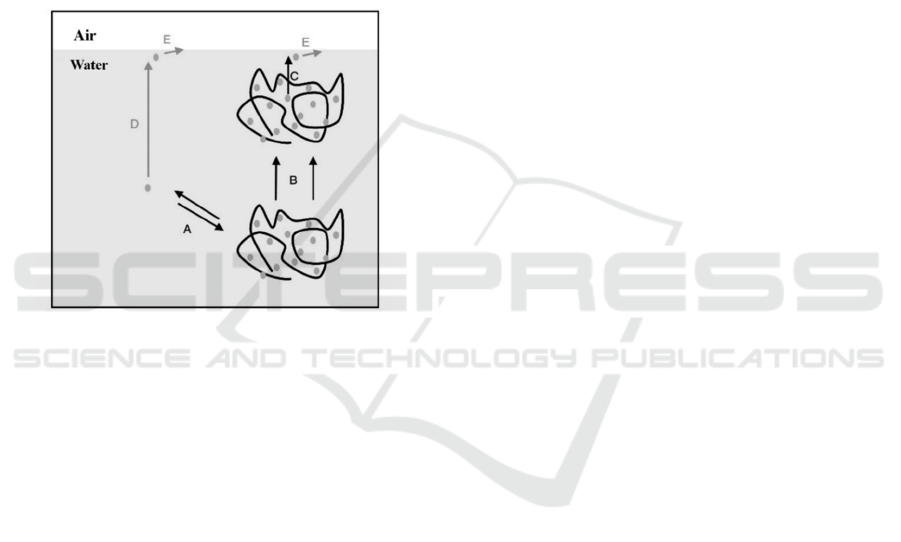

Ettelaie 2004). As shown in Figure 2:

Drainage of water is the process of separation

of air-water two phase in foam system due to

different density (Conroy et al. 2013). Loss of

fluid can result in gradual drying of foam;

Polymerization is the phenomenon that the film

between two adjacent bubbles breaks, resulting

in the merger of two bubbles (Murray et al.

2006).

Disproportionation is the transfer of air in small

bubbles to large bubbles, resulting in the

disappearance of small bubbles (Langevin et al.

2017).

These three phenomena exist simultaneously in

the foam system and contain each other. But no

matter which mechanism is dominant, the final

equilibrium state of the foam system will be separated

into an independent water phase and air phase (Diao

et al. 2021).

Figure 2: This caption has more than one line so it has to be

set to justify.

3 FACTORS AFFECTING THE

STABILITY OF FOOD FOAM

SYSTEM

Evenly distributed foam often makes food texture

fine, lubricated, with a certain brightness, but also

enhances the flavor components divergent and

observable (Li et al. 2020). It constitutes the main

sensory attraction of consumers. Stable beer foam can

not only give consumers the sense of enjoyment, but

also reduce the overflow of beer flavor substances. It

prevents the direct contact of oxygen and beer in the

air and oxidize, so as to ensure the quality of beer

(Han 2017). Good foaming and foam stability help to

form the texture of ice cream and extend the storage

period of ice cream (Lian et al. 2020). In inflatable

chocolate, small and stable foam will make the

chocolate more lubricate and delicate, and it will also

be very different in color (Liu2009). Therefore, the

stability of the foam system is critical to the quality

of food. However, foam stability is easily affected by

internal and external factors such as surface tension,

surface viscoelasticity, temperature, pH and

surfactant.

3.1 Formation of Foam System

3.1.1 Surface Tension

With the formation of foam, the surface area of liquid

increases and the surface potential energy increases

(Zhan et al. 2020). The lower surface tension is

favorable for improving the foam stability. The

Laplasse equation shows that the smaller the surface

tension and the smaller the pressure difference, the

more stable the foam is. Xiao Xia (Xiao 2013)

randomly selected 7 kinds of wine samples from the

market to determine the foam retention and surface

tension. The results showed that the surface tension

of the wine with good foam stability was poor. At the

same time, as the storage period lengthened, the foam

retention gradually decreased, and the surface tension

gradually increased.

3.1.2 Surface Viscoelasticity

Surface viscosity refers to the viscosity of the

molecular layer of foaming agent on the liquid

membrane, which is produced by the interaction

between hydrophilic groups and water (Li 2014). The

greater the adsorption force of surfactant molecules

on the air-liquid interface, the higher the surface

viscosity and the better the elasticity of the

Research Progress of Air-water Interface Stability in Food Foam System

101

membrane. The surface viscosity directly determines

the drainage rate of the liquid film, thereby affecting

the stability of the foam to a certain extent. The

greater the surface viscosity, the smaller the drainage

velocity, and the more stable the foam is (Cilurzo et

al. 2019). However, for the production and

processing of ice cream, if the viscosity of the system

is too high, the ice cream material will be too viscous.

During the freezing process, it is difficult for a large

number of air to be evenly distributed in ice cream,

resulting in low expansion rate and poor taste of the

product (Zhan et al. 2020).

Surface elasticity refers to the ratio of the stress

on the surface to its strain. It means the tendency or

ability of the surface to return to the initial state after

deformation under external force (Wu 2017).

Therefore, the surface elasticity of the foam liquid

film can also be considered as ‘self repairing’ ability

to resist external interference. When the liquid film of

the foam is disturbed, this ‘self repair’ capability is

embodied in two aspects:

With the increase of the area of the foam liquid

film and the decrease of the surface density of

the surfactant, the local surface tension

increases, and the surface tension gradient

formed has the tendency to shrink the liquid

film, which is called the Gibbs effect;

Under the action of surface tension gradient,

surfactant molecules migrate from regions with

higher density to regions with lower density,

which is called Marangoni effect (Wang &

Guo 2007).

Generally speaking, Gibbs elasticity is more

suitable for measuring the stability of static foam,

while Marangoni elasticity is often used to measure

the stability of dynamic foam. Zhang (Zhang 2012)

found that the interaction between Tween 20 and

BSA and the formation of gel like interface network

structure enhanced the surface elasticity of the

adsorption film, increased the ability to resist external

interference, reduced the liquid film drainage rate,

and further improved the stability of the foam.

Because there is no adsorbed surfactant on the

surface, the pure aqueous film cannot adjust the

surface tension gradient through the movement of

surfactant or the contraction of the film when

disturbed by the outside world, so it does not have the

ability of ‘self repair’ (Li 2014).

3.2 Influence of External Factors

3.2.1 Temperature

The change of temperature significantly affects the

properties of liquid film. Most of the foam is unstable

at high temperature. As the temperature increases, the

surface viscosity of the liquid film decreases, and the

discharge rate increases, resulting in the decrease of

foam stability (Li 2014). Han (Han 2017) explored

the effect of different pretreatment temperatures on

the stability of beer foam. It was found that the

stability of beer foam decreased with the increase of

temperature, and the higher the temperature, the

worse the foam stability. The reason may be that the

solubility of CO

2

in beer decreases after the

temperature rises, and the dissolution of CO

2

after

ultrasonic oscillation is faster, resulting in larger

volume of individual bubbles formed by beer

foaming, and the decrease of surface viscosity and

foam stability of beer foam.

3.2.2 pH

The change of pH affects the ionization of the foam

system. Ionization is closely related to the interaction

in the whole solution, the adsorption of molecules at

the air-water interface and the interaction at the

interface. Li et al. (Li, et al. 2017) found that the egg

white protein produced excessive negative charges in

alkaline solution, which increased the static repulsion

between protein molecules and weakened the stability

of the foam system. However, for egg yolk protein,

the increase of pH is helpful to the dissociation of

insoluble yolk protein particle aggregates, improve its

adsorption capacity at the air-water interface, reduce

the surface tension, and help to enhance the stability

of the foam system. The results are quite different

from those of the egg white foam system in alkaline

solution. Kuropatwa et al. (Kuropatwa et al. 2009)

found that whey protein and egg white protein

complex at pH 9.0 had higher foaming and foam

stability. This is because the electrostatic interaction

of proteins has occurred before foaming, and the

protein of the composite system is adsorbed at the air-

water interface. Under alkaline conditions, expanded

β-Lactoglobulin monomer can increase the

interaction of egg white protein whey protein

complex. Compared with neutral conditions, the

foaming property and foam stability of the composite

system increased. However, Li et al. (Li 2009) tested

the foam stability of benzyl phosphate under different

pH. Compared with the results of pH=5.5 and

ICHIH 2022 - International Conference on Health Big Data and Intelligent Healthcare

102

pH=7.2, it was found that the stability of pH=5.5

foam was good.

3.2.3 Surface Active Agent

In order to make foam easily generated and stable, it

is necessary to add stabilizer to the system, usually

surfactants. Its existence not only makes foaming

easy, but also makes foaming speed faster than bubble

breaking speed, thus obtaining stable foam (Li 2020).

As shown in Fig. 3, the foam generated by pure water

will burst quickly after reaching the interface.

However, the foam formed by surfactant solution can

be stabilized. This is because a large number of

surfactants can adsorb to the air water interface,

reduce the surface tension, and form a viscoelastic

interfacial film around the bubble through non

covalent molecular interactions and covalent two

sulphide crosslinking, thus forming and stabilizing

the foam (Perez et al. 2006). Gao (Gao 2020)

compared the pure rice flour bread with the rice flour

bread added with pullulan polysaccharide, and found

that the addition of pullulan polysaccharide improves

the characteristics of rice flour bread, such as high

hardness, poor elasticity and difficult to chew. The

reason may be that pullulan as a surfactant, combined

with water, form a more compact viscoelastic colloid

in the continuous phase, increase foam stability, and

better preserve the gas generated during fermentation.

Schmidt et al. (Schmidt et al. 2010) studies found that

the interfacial activity of the compound formed by

rapeseed protein and pectin was higher than that of

pure rapeseed protein, and the thicker interfacial film

could be formed at the air water interface, resulting in

the decrease of water permeability and the rise of the

stability of the foam.

Figure 3: Rise of bubbles in pure aqueous phase and

surfactant solution (Cilurzo et al. 2019).

3.2.4 Ion

The effect of inorganic salts on foam stability is

mainly through interaction with surfactant (Yu et al.

2010). The addition of inorganic salts will introduce

ions which with charge opposite to surfactant

headgroup. When the amount of inorganic salt is

small, the charged ions will be adsorbed on the

surface of the surfactant base, reducing the

electrostatic repulsion between the adjacent

surfactants, making them close to each other, thus

reducing the interfacial tension. This will help to

enhance the stability of the foam (Teng et al. 2005).

However, when the content of inorganic salt is too

high, the combination of excess inorganic salt ions

and surfactants may lead to the failure of surfactant or

destroy the electric double layer structure, which is

not conducive to the stability of foam (Liu 2011). Wu

Gang (Wu 2017) studied the mechanism of the effect

of inorganic salts on the foam stability of surfactant

and its composite system. It was found that the

addition of sodium salt had a negative effect on the

stability of surfactant foam, and the higher the

concentration of sodium salt, the more unfavorable to

foam stability. Low concentration of calcium salts

and magnesium salts had a favorable effect on foam

stability, and magnesium salt had greater impact than

calcium salts. When high concentration, the stability

of surfactant foam would also be adversely affected.

The higher the concentration, the worse the foam

stability.

4 POLYSACCHARIDE

HYDROCOLLOID REGULATES

THE STABILITY OF FOAM

SYSTEM

Because of its excellent foaming properties,

solubility, emulsification and gelation, the protein has

been widely used as a surfactant in the production and

processing of foam food (Narsimhan & Nin 2018).

However, individual protein molecules are not ideal

candidates for stable foaming systems because they

cannot fully adjust the high Laplace pressure

difference at the air-water interface (Shankaran &

Chinnaswamy 2019). Since most high molecular

weight polysaccharides are hydrophilic, they do not

have much adsorption tendency at the air-water

interface. However, they greatly enhance the stability

of the dispersion system through their thickening or

gelling properties. Therefore, in the food industry,

polysaccharides are used to synergistic protein

maintain the stability of the foam system and

emulsion system (Dickinson 2003). A classic

example is the use of pectin to stabilize casein

micelles in yogurt. Due to electrostatic interaction,

negatively charged pectin molecules are adsorbed on

Research Progress of Air-water Interface Stability in Food Foam System

103

casein micelles and prevent casein from acid-induced

aggregation due to electrostatic and spatial repulsion

(see Fig. 4) (Renate et al. 2005). Among them,

polysaccharides act as two roles. One is to control the

rheological properties of the continuous phase. The

other is to increase the thickness of the adsorption

film, which reduces the rate of thinning of the bubble

film and increases the stability of the foam (Sadahira,

et al. 2018). The addition of polysaccharide water

colloid significantly improves the viscosity of gluten

free dough and hinders the escape of gas during

fermentation, so as to improve the quality of bread

and prolong the shelf life of bread, which solves the

dietary problems faced by celiac patients to a certain

extent (Niño-Medina et al. 2019).

Figure 4: Model for polysaccharide controlled protein

adsorption at the air/water interface (Renate et al. 2005) (A

: partition free protein and protein bound to

polysaccharide, B : diffusion of protein/polysaccharide

complexes in bulk, C:availability of complexed protein

for interface, D:diffusion of free protein in bulk, E:

kinetic barrier for protein adsorption)

From the existing research, the application of

polysaccharide hydrocolloid in the stabilization of

food foam system is based not only on its electrostatic

interaction with protein, but also by the covalent

grafting products formed by Maillard reaction with

proteins, which play an important role in modifying

the functional properties of proteins (Diao et al.

2021). The amino group on the protein and the

carboxyl group of reducing sugar bind to each other

can significantly improve the solubility and oxidation

resistance of protein, and further improve the stability

of foam system (Yu 2016). In the process , the

amino group on the protein and the carboxyl group of

reducing sugar bind to each other can significantly

improve the solubility and oxidation resistance of

protein, and further improve the stability of foam

system (Yu 2016). At present, many studies have

reported that proteins are modified by various food

grade substrates to obtain a stable foaming system.

Ovalbumin pullulan cement shows better foaming

performance and surface activity than natural protein

(Sheng et al. 2020). A large number of studies have

shown that the increase of protein foaming ability by

glycosylation reaction is mainly due to the covalent

connection between sugars and proteins, which

increases the hydrophilic groups in proteins, which

may lead to the increase of protein solubility, or the

formation of protein melting spherical structure

caused by mild heat treatment, which improves the

hydrophobicity of protein surface (An et al. 2014,

Murray 2007).

Because proteins usually have high surface

activity, most protein microgel particles also have

surface activity, and their Pickering particles can

adsorb efficiently at the air-water interface and

require very high desorption energy. Therefore, it has

higher viscoelasticity compared with the interfacial

film formed by single protein adsorption. Microgel

particles can also be composed of polysaccharides

with gel characteristics. Although most

polysaccharides are non surface active substances,

they can be combined with other components, such as

proteins or lipids, so as to achieve good adsorption

effect (Li 2020). From the perspective of food,

protein and polysaccharides have great advantages as

microgel particles, which can control the size of

surface active particles reasonably by controlling the

size of complex biopolymers or their mixtures (Chen

et al. 2017). In the presence of protein /

polysaccharide complexes, the foam stability

increases due to the formation of viscoelastic colloids

in continuous phases (Zhan et al. 2019). The protein

/ polyphenol complex which whey protein with gallic

acid (GA) and epigallocatechin gallate (EGCG) have

a similar strengthening effect (Cao & Xiong 2017).

Despite the above findings, the foam formation

properties of the composites are not always consistent

with their foam stability. For example, tannic acid

improves foam stability, but it inhibited the foam

formation of sodium caseinate (Zhan et al. 2018).

Therefore, high performance food hydrocolloids

exhibiting excellent foaming and foam stability are

still being constantly excavated.

5 CONCLUSIONS

In the food industry, the stability of the foam system

will directly affect the quality of the interface leading

foods. Therefore, controlling the stability of foam

system, regulating protein aggregation behavior and

ICHIH 2022 - International Conference on Health Big Data and Intelligent Healthcare

104

understanding the relevance between surfactant and

foam system play an important role in guiding the

development of foam food industry. Future research

on food foam system can focus on establishing a

relationship model of protein (polysaccharide)

molecular polymer foam system, and clarify the

mechanism between the three. It aims at precisely

regulating protein nano polymer in order to obtain an

ideal foam system, and provide a theoretical basis for

the application of foam food in the food industry.

ACKNOWLEDGEMENTS

This study was supported by National Natural

Science Foundation of China (Grant No. 31901680).

REFERENCES

An, Y. Cui, B. Wang, Y. (2014). Functional properties of

ovalbumin glycosylated with carboxymethyl cellulose

of different substitution degree. J. Food Hydrocoll. 40,

1-8.

Briceno-Ahumada, Z. & Langevin, D. (2017). On the

influence of surfactant on the coarsening of aqueous

foams. J. Adv Colloid Interfac. 244, 124-131.

Cao, Y.Y. & Xiong, Y.L.L. (2017). Binding of Gallic Acid

and Epigallocatechin Gallate to Heat-Unfolded Whey

Proteins at Neutral pH Alters Radical Scavenging

Activity of in Vitro Protein Digests. J. J Agr Food

Chem. 65(38), 8443-8450.

Chen, X.W. Yang, D.X. Zou, Y. (2017). Stabilization and

functionalization of aqueous foams by Quillaja

saponin-coated nanodroplets. J. Food Res Int. 99, 679-

687.

Cilurzo, F. Critello, C.D. Paolino, D. (2019). Polydocanol

foam stabilized by liposomes: Supramolecular

nanoconstructs for sclerotherapy.J. Colloid Surface B.

175, 469-476.

Conroy, M.W. Taylor, J.C. Farley, J.P.(2013). Liquid

drainage from high-expansion (HiEx) aqueous foams

during and after filling of a container. J. Colloid Surface

A. 426, 70-97.

Diao, Y.C. Zhang, Y.P. Zhang, W. N.(2021). Research

progress of protein nanomaterials foam system .J. Food

Science: 1-11,

http://kns.cnki.net/kcms/detail/11.2206.TS.20201211.

1647.026.html.

Dickinson, E. (2003). Hydrocolloids at interfaces and the

influence on the properties of dispersed systems. J.

Food Hydrocoll. 17(1),25-39.

Gao, Y.Q. (2020). Effects of different processing methods

on the quality of rice dough and bread. D. Shenyang

Normal University.

Han, Y.P. (2017). Study on the mechanism of malt protein

Z stabilizing beer foam. D. Jiangnan University.

Kuropatwa, M. Tolkach, A. Kulozik, U. (2009). Impact of

pH on the interactions between whey and egg white

proteins as assessed by the foamability of their

mixtures.J. Food Hydrocoll. 23(8), 2174-2181.

Lian, J.W. Zhang, J.J. Han, D.(2020) Effect of the dual

protein on the quality of ice cream. J. Sci. Technol.

Food Ind. 41(17), 8-12.

Li, Y.Y. (2014). Study on influencing factors and plugging

ability of foam stability .D. China University of

Petroleum (East China)

Li, J. Wang, C. Li, X. (2017). Effects of pH and NaCl on

the physicochemical and interfacial properties of egg

white/yolk. J. Food Biosci. 23, 115-120.

Li, M.S. Zhao, G.H. Ye, F.Y. (2020). Progress in nano-and

micro-particle-stabilized foams and their implications

in food technology. J. Food and Fermentation

Industries. 46( 13) , 270-279.

Liu, L.N. (2009). Research on the technology of aerated

chocolate. D. Jiangnan University.

Liu, L.Y. (2011). Sodium caseinate-polysaccharide

interactions at the oil-water interface: Effect on

emulsion stability. D. South China University of

Technology.

Li, W. (2009). Effect of pH and NaCl Concentration on the

Stability of Surfactant-Free foam films. J.

Langmuir.25(1), 294-297.

Li, X. (2020). Engineered interface for explaining foaming

characteristics of egg white protein systems and

regulation mechanisms. D. Jiangnan University.

Murray, B.S. DickinsonI, E. Gransard, C. et al. (2006).

Effect of thickeners on the coalescence of protein-

stabilized air bubbles undergoing a pressure drop. J.

Food Hydrocoll. 20,114-123.

Murray, B.S & Ettelaie, R. (2004). Foam stability: proteins

and nanoparticles. J. Curr Opin Colloid In. 9(5), 314-

320.

Murray. B.S. (2007). Stabilization of bubbles and foams. J.

Curr Opin Colloid In. 12(5), 232-241.

Narsimhan, G. & Nin, X. (2018). Role of Proteins on

Formation, Drainage, and Stability of Liquid Food

Foams. J. Annu Rev Food Sci T. 9, 45-63.

Niño-Medina, G. Muy-Rangel, D. (2019). Dietary Fiber

from Chickpea (Cicer arietinum) and Soybean (Glycine

max) Husk Byproducts as Baking Additives:

Functional and Nutritional Properties. J. Molecules.

24(5), 991-1000.

Perez, O.E. Sanchez, C.C. Pilosof, A. M. (2006). Dynamics

of adsorption of hydroxypropyl methylcellulose at the

air–water interface. J. Food Hydrocoll. 22(3), 872-878.

Renate, A. Martien, A, et al.(2005). Use of polysaccharides

to control protein adsorption to the air–water interface.

J. Food Hydrocoll. 20(6), 872-878.

Sadahira, M.S. Rodrigues, M.I. Akhtar, M.(2018).

Influence of pH on foaming and rheological properties

of aerated high sugar system with egg white protein and

hydroxypropyllmethylcellulose. J. LWT-Food Sci

Technol. 89, 350-357.

Schmidt, I. Novales, B. Boue, F.(2010). Foaming properties

of protein/pectin electrostatic complexes and foam

Research Progress of Air-water Interface Stability in Food Foam System

105

structure at nanoscale.J. J Colloid Interf Sci. 2010,

345(2), 316-324.

Shankaran, P.I.& Chinnaswamy, A. (2019). Instant coffee

foam: An investigation on factors controlling

foamability, foam drainage, coalescence, and

disproportionation. J. J Food Process Eng. 42(6), 1-12.

Sheng, L. Tang, G.Y. Wang, Q. (2020). Molecular

characteristics and foaming properties of ovalbumin-

pullulan conjugates through the Maillard reaction. J.

Food Hydrocoll. 100, 105384-105392.

Teng, H.N. Wang, F. Sun, M.J. (2005). Influence of Salts

on Aqueous Two-phase System of Cationic and

Anionic Surfactant Aqueous Mixture. J. Acta Chim

Sinica. (17), 1570-1574+1548.

Wang, M.M. Guo, D.H. (2007). Foamability of foaming

agent and effecting factors. Advances. J. In Fine

Petrochemicals. (12), 40-44+47.

Wu, G. (2017). Effect of inorganic salts on foam stability

of surfactant and its composite systems. D. China

University of Petroleum (East China).

Xiao, X. (2013). Study on the relationship between beer

surface tension and foam durability. D. Gansu

Agricultural University.

Yu, D. Huang, X. Deng, M. (2010). Effects of Inorganic

and Organic Salts on Aggregation Behavior of Cationic

Gemini Surfactants. J. J Phys Chem B. 114(46), 14955-

64.

Yu, J. (2016). Research on citrus pectin-soy protein isolate

electrostatic interaction, characteristic of interfacial

adsorption and emulsifying stability. D. Huazhong

Agricultural University.

Zhan, F.C. Hu, J.G. He, C. (2020).Complexation between

sodium caseinate and gallic acid: Effects on foam

properties and interfacial properties of foam. J. Food

Hydrocoll. 99, 105365.

Zhan, F.C. Li, J. Shi, M.Q. (2019). Foaming properties,

linear and nonlinear surface dilatational rheology of

sodium caseinate, tannin acid and octenyl succinate

starch ternary complex. J. J Agr Food Chem. 67(8),

2340–2349.

Zhan, F.C. Li, J. Wang, Y.T. (2018). Bulk, foam and

interfacial properties of tannic acid/sodium caseinate

nanocomplexes. J. J Agr Food Chem. 6832-6839.

Zhang, H.H. (2012). The effect of bovine serum albumin on

the foam properties of tweens surfactants. D. Shandong

University.

ICHIH 2022 - International Conference on Health Big Data and Intelligent Healthcare

106