A Novel Real-Time Wear Detection System for the Secondary Circuit

of Resistance Welding Guns

D. Ibáñez

1a

, E. García

2b

, J. Martos

1c

and J. Soret

1d

1

Dept. of Electrical and Electronic Engineering, University of Valencia, Burjassot, Valencia, Spain

2

Ford Valencia, 46440, Valencia, Spain

Keywords: Resistance Spot Welding, Predictive Maintenance, Secondary Circuit, Welding Gun.

Abstract: Currently, many resources are invested in high-production automotive factories to correct quality defects

caused in the bodywork due to secondary circuit wear. In the same way, energy losses are generated due to

the increase in resistance caused by secondary wear, thus reducing efficiency and increasing the final cost of

the product. This happens because, at present, there is no method that allows the predictive detection of

problems in the secondary and the arms of the welding gun. Consequently, a solution must be developed to

carry out predictive maintenance applicable to the automotive industry to detect this defect. This research

provides an answer by proposing a method to detect variations in the state of the secondary of the welding

gun using existing data in the welding process, specifically, the evolution of the angle of degassing of the

IGBTs of the welding control. To validate the relationship between the control shift angle and the increase in

wear, an electronic simulation software was used to simulate the behaviour of the real welding control.

1 INTRODUCTION

The resistance welding process is one of the most

widely used in the automotive industry for joining the

metal parts of the bodywork, representing around

90% of all welded joints in a bodywork (Koskimäki

et al., 2007; Yu et al., 2014; Hwang et al., 2013). As

the name of the process indicates, it is the resistance

to the current flow of the metals to be welded that

causes the localized increase in heat and the

formation of the nugget welding. For this process, it

is also necessary to exert pressure on the parts to be

welded for a specific welding time. Ultimately,

therefore, welding is generated by a combination of

heat, pressure, and time.

Despite being able to summarize the resistance

welding process as the combination of heat, pressure

and time, this process is highly complex, since it

involves different fields of study such as

electromagnetism, electronics, thermodynamics,

materials and mechanics. (Li et al., 2007)

a

https://orcid.org/0000-0002-3917-9875

b

https://orcid.org/0000-0002-4210-9835

c

https://orcid.org/0000-0002-8455-6369

d

https://orcid.org/0000-0001-8695-6334

Throughout different investigations, it has been

described how the different welding parameters can

influence the quality of the welded joint, such as

pressure (Zhou et al., 2014; Sun et al., 2007; Ibáñez

et at., 2021 ), the current (Aslanlar et al., 2007;

Hwang et al., 2011), the welding time (Aslanlar et al.,

2008) or the misalignment of the welding electrodes

(Ibañez et al., 2020). From all these studies it can be

concluded that either due to external factors or due to

welding parameters, there are many factors that

directly or indirectly affect the final quality of the

welded joint.

To achieve adequate welding quality, it will

therefore be necessary to guarantee that the

parameters influencing welding quality remain stable

over time. One of the defects that can cause variations

in the application of the correct parameters in

welding, especially in the application of current, is

the mechanical state of the electrical circuit of the

welding gun, specifically, of the secondary circuit of

the gun. , that is, the arms of the welding gun.

Ibáñez, D., García, E., Martos, J. and Soret, J.

A Novel Real-Time Wear Detection System for the Secondary Circuit of Resistance Welding Guns.

DOI: 10.5220/0011274300003271

In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2022), pages 185-192

ISBN: 978-989-758-585-2; ISSN: 2184-2809

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

185

Over time, the way of applying the current to the

welding points has been changing to achieve the

highest quality with the best possible efficiency and

power consumption. If the behavior of a single-phase

alternating welding machine is observed, it can be

determined that there are inherent losses in the

alternating voltage supply (Zhou et al. 2001). For this

reason and to guarantee the optimum quality of the

welding, three-phase welding machines are used. The

three-phase voltage is rectified to convert it from

single-phase to direct current. This rectified current

results in lower power losses and higher quality

welding (Munesada et al.2010).

In this type of converter-based welding machines,

the three-phase voltage of the industrial mains line,

typically 440V and 50/60Hz, is converted to single-

phase direct voltage and stored in a capacitor bank to

smooth the voltage.

The capacitor bank is connected to the inverter

circuit formed by an IGBTS bridge that modulates the

wave at a higher frequency than the line. Usually, to

achieve higher welding quality and greater control

over the welding current, the wave is modulated at a

frequency of 1000Hz, this type of machine being

known as mid frequency direct current (MFDC).

The alternating wave produced at the output of the

inverter feeds the single-phase transformer of the

welding gun. (Saleem et al. 2011). This will allow to

have a continuous current in the secondary of the

transformer. This working mode prevents the welding

current from having zero crossings that would cool

the part, allowing faster heating of the welding gun.

In addition, by working with direct current, inductive

power losses or problems with the magnetic material

of the machine are avoided (Wei, 2004; Nagasathya

et al 2013,).

In MFDC machines, the secondary voltage is

determined by the primary voltage, which, as

mentioned, is modified by the inverter controlled by

the IGBTS. If a constant IGTS control shift angle is

maintained, the secondary voltage should remain

constant. Starting from this point, it can be stated that

the welding current, according to Ohm's law, will be

determined by the resistance of the secondary, that is,

the resistance of the welding arms and the resistance

of the metal to be welded. As the total resistance of

the secondary circuit increases, the current flowing

between the electrodes decreases (Arslan et al 2020).

This makes it essential to guarantee the maintenance

of the resistance of the welding arms in such a way

that the way in which the current is applied to the

metal to be welded is not affected.

2 MFDC MACHINE AND

SECONDARY LOAD

The welding current is a fundamental component to

chieve optimal welding quality. In the electronic

diagram of Figure 1, the stages of the power circuit

can be observed differently from the three-phase line

of the electrical network to the continuous single-

phase line of the welding electrodes.

Figure 1: Welding machine electrical schematic.

Modern welding machines have a current control

system, in such a way that it is guaranteed that the

current established by parameters is being applied to

the metal to be welded. The welding machine

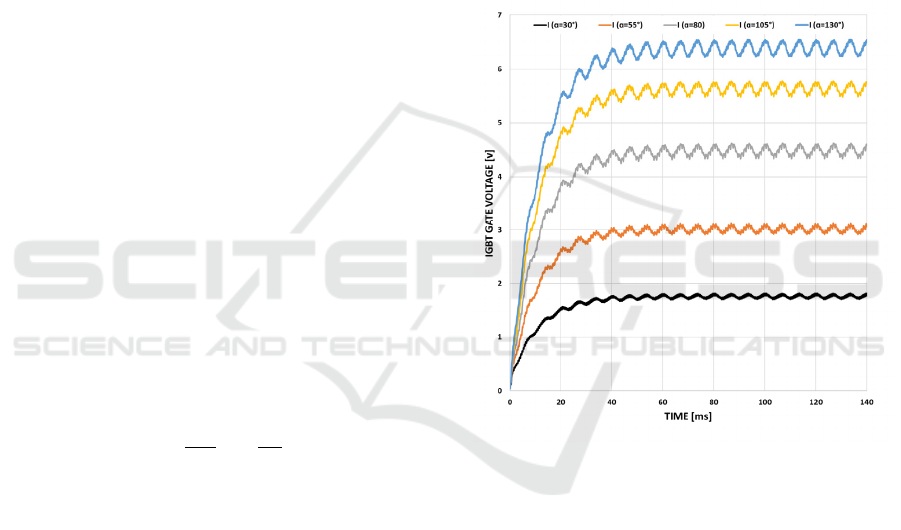

analyzes the secondary current every millisecond and

modifies the control shift angle of the IGBTs firing to

modify the primary voltage, as it can be seen in the

results obtained from the simulation in figure 2 for the

different angle s of shot (α=30°, α=80° and α=105°).

As the control angle between the control signals of

the IGBTs increases, the effective primary voltage

decreases, thus decreasing the secondary voltage and

current (Zhou & Cai,2014).

Figure 2: Response of the primary voltage as a function of

the control shift angle of the IGBTS.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

186

From Figures 1 and 3, the behavior of the IGBT

rectifier can be divided into six segments in one

period. These six segments can be summarized as:

• State 1: In this state, the IBTS Q1 and Q4 are

conductive, therefore it is in active mode

with positive output voltage and output

current i.e., the DC side power is converted

to the load.

• State 2: At this point Q1 and D3 go on,

freewheeling mode with zero and positive

output voltageoutput current.

• State 3: Diodes D2 and D3 then conduct in

feedback mode with negative and positive

output voltage and output current. Power

from the load is sent back to the DC side.

• State 4: returns to active mode with Q2 and

Q3 conducting with negative output voltage

and output current. The DC side power is

converted to the load. State 5: Return to

freewheeling mode with Q2 and D4

conducting with zero and negative output

voltage and output current.

• State 6. Finally, Q1 and D4 conduct in

feedback mode with positive voltage and

negative output current. Power from the load

is sent back to the DC side.

According to this description, the output voltage

will depend on the period that it is in each of the

states, that is, on the control shift (. Therefore, by

adjusting the control shift, the output voltage can be

adjusted.

The Fourier series of the output voltage can be

obtained as follows:

𝑉

=

4𝑉

𝑛𝜋

sin

𝑛𝛼

2

cos(𝑛𝜔𝑡)

,,…

(1)

Where V

d

represents the output voltage at the

rectifier and α is the control shift.

In this way, the secondary voltage can also be

related to the control shift angle of the IGBTs, as the

welding control increases the control shift angle

between the signals, the secondary voltage is reduced.

In a similar way and due to the power conservation

law, the secondary current will also be influenced by

the primary power, therefore, as the control shift

angle between the control signals increases, the

welding current decreases, considering constant

resistance, can be obtained from the simulation figure

3, in which the relationship between the control shift

angle and the final welding current is observed.

Following Ohm's law, the welding current is

determined not only by the secondary voltage but will

also be influenced by the resistance of the secondary

circuit. This resistance of the circuit can be divided

into two blocks: The first load can be defined as those

elements that do not directly participate in welding,

that is, joints between the copper elements of the gun,

cooled braids, welding arms, etc. If the welding gun

is in an optimal state of maintenance, this resistance

should remain constant. In the second load block are

those elements that have an active role in welding,

that is, this resistance is made up of the electrode

holders, the electrodes, the connection between the

electrode and the metal, the resistance of the metal

and the resistance of the union between the metals to

be welded. This resistance will depend on the type of

material, the type of electrodes and the wear of the

electrodes.

Figure 3. Response of the secondary current as a function

of the control shift angle of the IGBTs.

Due to this variability of the welding points and

to guarantee the energy supplied to the joint and

therefore the quality of the joints, the welding

machines regulate the control shift angle of the

IGBTs in such a way that the current supplied does

not depend on resistance, but this will depend solely

on the control of the welding machine.

3 SECONDARY CIRCUIT WEAR

Eventually, mainly due to the erosion caused by the

fatigue of the work cycles of the welding guns, the

secondary circuit begins to show wear. Specifically,

these wears appear in the first block of the load

defined in the previous section.

A Novel Real-Time Wear Detection System for the Secondary Circuit of Resistance Welding Guns

187

The wear that can appear in the secondary is very

diverse, since, based on the definition of this load

block, it is made up of different components and

joints, as shown in figure 4. The main worn elements

that can occur in a secondary are:

• Corrosion on welding arms caused by water

leaks at welding gun joints or caused by

changing electrodes.

• Transformer pins worn or fired due to poor

cooling or lime scale.

• Cracked arms caused by metal fatigue over

time.

• Clogged refrigerated braids.

• Cracked or missing weld strips.

All these wears contribute notably to the increase

in the resistance of the first load-bearing block. This

first block does not initially have a direct influence on

the weld if the welding machine control can reach the

optimum welding current. However, as these wears

become more noticeable, typical welding problems

begin to appear, such as sparks, inconsistent weld

joints, or even missing welds.

On the other hand, an increase in secondary

resistance means an increase in the power consumed

during welding. If this increase in resistance is caused

by wear, the power supplied to the welding point will

be the same, however, the power consumed during

the process will increase, causing greater energy

consumption.

Figure 4: Real cases of wear in the secondary circuit.

Figure 5 shows the control shift angle necessary

to reach each of the currents. Each of the curves

represents a parasitic resistance value of the

secondary corresponding to the simulated resistance

value of the first block, keeping the second block with

a constant load. In this way, it can be verified that as

the resistance of the secondary caused by wear

increases, the angle necessary to achieve the desired

current also increases, that is, the voltage of the

primary increases and therefore the energy consumed

during welding.

Figure 5: Evolution of the control shift angle depending on

the resistance of the secondary.

4 SECONDARY WEAR

DETECTION

Due to the implications of this defect in both welding

quality and energy consumption, its early detection is

essential.

Specifically, a method is presented for the

predictive detection of secondary circuit wear by

monitoring the control shift angle of the IGBTs. The

method bases its operation on the collection of

welding data in real time from the welding guns

during their normal work cycle.

The welding cycle of a welding gun in a real

welding line can be described as: the new electrodes

are placed on the electrode holder and welding points

begin to be made on the metal to be welded, in the

specific case of the manufacture of the car body, the

characteristics of the metals to be welded vary

depending on the piece, so each specific welding joint

needs its own parameterization to achieve the

required welding quality. After making a series of

welding points, usually between 150-200 joints, the

electrodes are milled to return them to their initial

geometry and remove any dirt that might remain

attached.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

188

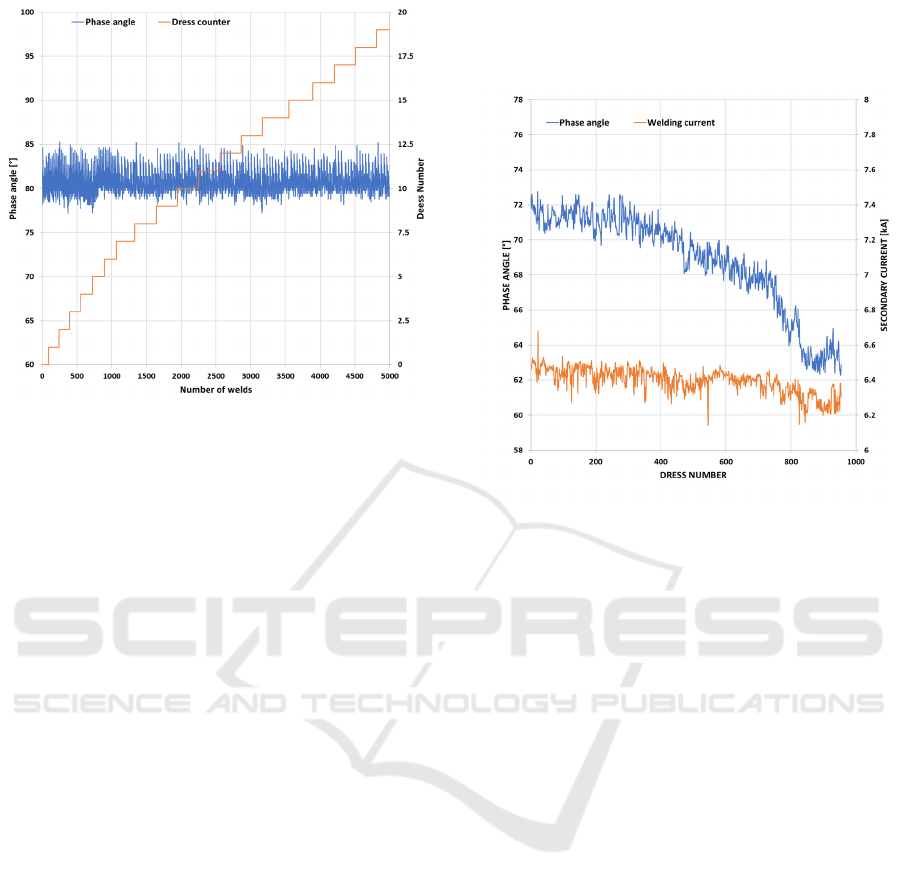

Figure 6: Control shift angle along the electrode life.

Within this work cycle, there is a variation of the

welding current and the control shift angle of the

IGBTs. This variation is given both by the differences

in the metal to be welded and by the degradation of

the electrode. It can be considered that this variation

remains constant when passing from one duty cycle

to another, so if the entire cycle is reduced to a single

value, it could be stated that the average current and

the control shift angle should remain constant.

Figure 5 shows the control shift degrees for a

welding gun together with the evolution of the

number of joints made. It can be seen how despite the

variation between each of the points represented, the

trend remains stable.

After observing that the usual behaviour of the

work cycle between milling is stable, the hypothesis

can be raised since when the secondary circuit begins

to show wear, a distortion will be observed in the

wear data due to the correction of the welding

machine to guarantee the desired current.

Figure 6 shows the actual data of a welding gun

that shows a beginning of degradation. In this case, it

is observed how it goes from a stable behaviour to a

behaviour with a downward trend. This means that for

the same welding current, the welding machine needs

a higher electrical consumption and therefore the

parasitic resistance of the secondary circuit has

increased.

From the comparison of figures 6 and 7, it can be

determined that by carrying out continuous

monitoring of the control shift angle of the IGBTs, it

is possible to detect changes in the parasitic resistance

of the secondary circuit. In other words, the

hypothesis of the analysis of the evolution of the

control shift angle for the determination of the

increase in wear in the secondary circuit of the

welding machine is confirmed.

Figure 7: Evolution of the control shift angle with the wear

of the secondary circuit.

5 REAL-TIME MONITORING

SYSTEM

This method is designed to be applied in real welding

lines, specifically, for this study, ARO type C and X

welding guns controlled by means of the BOS6000

welding timer have been analysed.

First, a protocol is established for the acquisition

of welding data in real time. This first step notably

reduces the amount of data that is handled, since, as

shown in the previous sections, each of the control

shifts of each welding point is not analysed, but rather

it is analysed based on the average control shift of all

weld joints made throughout a milling cycle.

Therefore, this first step collects the data from the

welding database, performs the average by cycles and

indexes the data in the database on which the alarms

are generated.

𝑊=𝑄

1.5𝐼𝑄𝑅 (2)

For the generation of alarms, a simple method of

detecting changes in behaviour is established. As

shown in equation 1, the warning limit is established

by calculating the sum of the third quartile plus 1.5

times the interquartile of the data series. Similarly, the

alarm level is established as the sum of the third

A Novel Real-Time Wear Detection System for the Secondary Circuit of Resistance Welding Guns

189

quartile plus 3 times the interquartile as describe in

equation 3.

𝐴

=𝑄

3𝐼𝑄𝑅 (3)

Figure 8: Alarm system.

Therefore, initially, an initial amount of data is

needed to calculate the quartiles and thus establishing

the warning and alarm limits, that is, an amount of

data is needed to make an initial calibration.

In this way, when new data arrives from a specific

welding gun, the data is labelled according to whether

it is within the established warning and alarm

thresholds. When a welding gun begins to show wear,

the data will go from being in the good working group

to the warning or alarm group, thus being able to carry

out the necessary actions to reduce and minimize the

quality problems associated with this defect.

In short, this entire system can be described

according to the flow chart in Figure 8.

This programming has been carried out for validation

on 450 welding guns installed on a real welding line.

Usually, a welding gun installed on a high production

line can do around 10,000 welding points per day,

which would mean working with around 450,000 data

per day. With the simplification of the average

between milling cycles, this amount of data can be

reduced to about 2500 daily data, which significantly

reduces the number of resources needed for their

management and analysis.

Figures 9 and 10 show two real graphs of

behaviour for two different welding guns in a period

of two months.

Figure 9, corresponding to what has been called

gun A, shows the behaviour for a welding gun in good

condition. The offset angle data oscillates within a

range of two degrees but rarely reaches the warning

threshold, so it is not necessary to carry out any

maintenance on the welding gun.

Figure 9: Evolution of the control shift angle gun A.

However, looking at Figure 10, the data shown

presents three behaviour zones. In the first zone, or

initial zone, the data is above the warning threshold

but shows a variable behaviour. In the second zone,

the data exceeds the warning threshold, and the value

remains stable over a certain time, finally, and as no

maintenance action is performed, the offset angle data

increases significantly, which means that the

resistance of the secondary is increasing

exponentially.

Figure 10: Evolution of the control shift angle gun B.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

190

Similarly, comparing both figures it can be seen

how the energy consumption, as described in the

previous sections, remains constant over time for gun

A, however, to perform the same welding cycle gun

B needs each time a greater contribution of energy,

which is lost in the parasitic resistance of the

secondary.

In short, from the comparison of figures 9 and 10

it can be determined that the method chosen for

setting the warning and alarm thresholds seems to be

the right one to carry out predictive maintenance.

6 CONCLUSION

Throughout this paper, an effective method for

detecting wear in the secondary circuit of resistance

welding guns has been shown. This defect causes a

decrease in welding quality and also an increase in

energy consumption in resistance welding processes.

Electronic simulation has shown how the relationship

between current and control shift angle is easily

demonstrable. From this relationship it has been

assumed that if an analysis of the history of the data

is carried out, an increase in the wear of the secondary

welding circuit can be determined.

This method has been applied in a real factory,

adapting the study for data reduction, and simplifying

the analysis and sending of alarms to those

responsible for maintenance.

From the real data acquired in the production

lines, it has been possible to validate that this method

is viable and reliable for the detection of wear

problems in the welding lines through the analysis of

the shift angle control.

ACKNOWLEDGEMENTS

This study was supported by the Universidat de

València, Ford Spain S.L. and Fundación para el

Desarrollo y la Innovación (FDI), Spain, which the

authors gratefully acknowledge.

REFERENCES

Koskimäki, P. Laurinen, E. Haapalainen, L. Tuovinen, and

M. Juha Röning, “Application of the extended knn

method to resistance spot welding process

identification and the benefits of process information,”

IEEE Trans. Indus. Electron. 54(5), 2823–2830 (2007).

J. Yu, D. Choi, and S. Rhee, “Improvement of weldability

of 1 GPa grade twin-induced plasticity steel,” Welding

J. 93(3), 78s–84s (2014).

G. Hwang, P. Podrzaj, and H. Hashimoto, “Note:

Resistance spot welding using a microgripper,” Rev.

Sci. Instrum. 84(10), 106105-1–3 (2013).

Y. B. Li, Z. Q. Lin, S. J. Hu, and G. L. Chen, “Numerical

analysis of magnetic fluid dynamics behaviors during

resistance spot welding,” J. Appl. Phys. 101(05),

053506 (2007)

Zhou, Kang, and Lilong Cai. "Study on effect of electrode

force on resistance spot welding process." Journal of

applied physics 116.8 (2014): 084902.

Sun, H. T., et al. "Effect of variable electrode force on weld

quality in resistance spot welding." Science and

Technology of Welding and Joining 12.8 (2007): 718-

724.

Ibáñez, D.; García, E.; Martos, J. and Soret, J. (2021). A

Novel Method for the Real-time Force Losses

Detection in Servo Welding Guns. In Proceedings of

the 18th International Conference on Informatics in

Control, Automation and Robotics - ICINCO, ISBN

978-989-758-522-7; ISSN 2184-2809, pages 669-676.

DOI: 10.5220/0010549006690676 (2021)

Saleem, Jawad & Majid, Abdul & Haller, Stefan &

Bertilsson, Kent. (2011). A study of IGBT rupture

phenomenon in medium frequency resistance welding

machine. 236-239. 10.1109/ACEMP.2011.6490602.

Aslanlar, Salim, et al. "Effect of welding current on

mechanical properties of galvanized chromided steel

sheets in electrical resistance spot welding." Materials

& Design 28.1 (2007): 2-7

Hwang, In Sung, Mun Jin Kang, and Dong Cheol Kim.

"Expulsion reduction in resistance spot welding by

controlling of welding current waveform." Procedia

Engineering 10 (2011): 2775-2781.

Aslanlar, S., et al. "Welding time effect on mechanical

properties of automotive sheets in electrical resistance

spot welding." Materials & Design 29.7 (2008): 1427-

1431.

Ibáñez, D.; García, E.; Martos, J. and Soret, J. (2020). Real-

time Electrode Misalignment Detection Device for

RSW Basing on Magnetic Fields. In Proceedings of the

17th International Conference on Informatics in

Control, Automation and Robotics - ICINCO, ISBN

978-989-758-442-8; ISSN 2184-2809, pages 142-149.

DOI: 10.5220/0009820801420149

Y. Zhou,S.J. Dong And K.J. Ely, “Weldability of Thin

Sheet Metals by Small-Scale Resistance Spot Welding

using High-Frequency Inverter and Capacitor-

Discharge Power Supplies,” in Journal of Electronic

Materials, Vol. 30, No. 8, 2001.

T.Munesada, Y.Takasaki, T.Sonada “Spot Welding current

control with a frequency controlled inverter power

supply.” 16th International Conference on Electrical

Engineering” July 11-14, 2010 Busan Korea

Li, Wei .Energy consumption in AC and MFDC resistance

spot welding, XI the Sheet Metal Welding Conference,

Heights, Michigan. p. 1-12. 2004.

A Novel Real-Time Wear Detection System for the Secondary Circuit of Resistance Welding Guns

191

Nagasathya N., Boopathy S. R., Santhakumari A. MFDC-

An energy efficient adaptive technology for welding of

thin sheets, IEEE Energy Efficient Technologies for

Sustainability Conference (ICEETS),2013, Nagercoil,

India, p. 901-906.

Arslan, Serdal & Tarimer, İlhan & Güven, Mehmet & Oy,

Sibel. (2020). A medium frequency transformer design

for spot welding machine using sizing equation and

finite element analysis. Engineering review. 40. 42-51.

10.30765/er.40.3.05.

Zhou, K. and Cai, L. (2014), Study of safety operation of

AC resistance spot welding system. IET Power

Electronics, 7: 141-147. https://doi.org/10.1049/iet-

pel.2013.0094

Gao, David (Zhiwei) (2016). Electric Renewable Energy

Systems || DC–AC inverters, (), 354–381.

doi:10.1016/B978-0-12-804448-3.00016-5

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

192