Challenges of Autonomous In-field Fruit Harvesting and Concept of a

Robotic Solution

Tim Tiedemann

1

, Florian Cordes

2

, Matthis Keppner

1

and Heiner Peters

2

1

Department CS, University of Applied Sciences Hamburg, Berliner Tor 7, Hamburg, Germany

2

German Research Center for Artificial Intelligence, Robotics Innovation Center, Bremen, Germany

Keywords:

Agricultural Robotics, Machine Learning, Autonomous Harvesting, Multi-spectral Imaging, Classification.

Abstract:

Since the beginning of humans cultivating plants in fields, agriculture underwent a continuous shift from

purely manual labor over simple machinery to more and more automated processes. Autonomous driving with

navigation and self localization in the field is state of the art. Also, automated machines for fruit processing are

available as well. In cases where the fruit is damageable and varies in size and shape, automated processing is

challenging. One example of such damageable fruits are strawberries. Size, weight, and shape at the optimal

ripeness can vary a lot. Additionally, a change from ripe to overripe occurs relatively quick and is sometimes

hard to recognize. A further challenge when harvesting strawberries is a dense leafage that can cover the fruits

partly or completely. In this paper, a concept of an autonomous in-field strawberry harvesting robot for non-

elevated but ground-raised strawberry plants, with or without a tunnel, is presented. The robot is supposed to

use multi-spectral imaging and machine learning based ripeness classification. Besides the overall concept,

first data of this early-stage project is shown, too.

1 INTRODUCTION

The overall goal of the project presented in this work

is to develop a small scale robotic system for auto-

mated harvesting of strawberries. A small scale robot

can easily scale up to any farm size by being de-

ployed multiple times in parallel, while a lower in-

vestment per unit makes the system also attractive for

smaller farms. The SHIVAA (Strawberry Harvester:

an Innovative Vehicle for Agricultural Applications)

robot will be deployed in open fields alongside human

workers. Initially, we will focus on the picking itself,

however numerous additional use cases have already

been identified and will be elaborated further during

the running project.

1.1 Motivation

Since the beginning of agriculture, mankind sought

for ways to improve the efficiency by increasing the

area of land manageable by one person. Starting

with animal-pulled machinery, over fuel driven multi-

purpose tractors to currently partially self-driving

connected tractors, the complexity and automation in

agriculture increased by time. Generally speaking, a

higher degree of automation in agriculture can lead

to higher efficiency and an improved supply safety.

A combine harvester is a huge machine that allows a

single operator to harvest hundreds of tons of wheat

per day, the current top rate is around 800 t in 8 h.

Yet, there are still fruits and vegetables that are more

labor intensive. Strawberries are a high priced fruit

that up to date needs human labor for harvesting. Ex-

perienced human workers can harvest up to 40 kg per

hour, while the mean value over all workers is more

around 20 kg per hour. With increasing salaries in

countries where workers are classically recruited or

travel restrictions as seen during the COVID-19 pan-

demic crisis, finding human workers for the harvest

gets more and more complicated. Here, a robotic

harvester can fill the gaps from missing human work

force.

1.2 Challenges

Many challenges exist for full automation of agricul-

tural processes in general. Focusing on sensitive fruit

such as strawberries puts further challenges in terms

of careful handling while picking and deploying the

fruit. Furthermore, aiming for a robotic harvesting in

standard outdoor fields without special adaptations to

the harvester leads to more problems that need to be

508

Tiedemann, T., Cordes, F., Keppner, M. and Peters, H.

Challenges of Autonomous In-field Fruit Harvesting and Concept of a Robotic Solution.

DOI: 10.5220/0011321300003271

In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2022), pages 508-515

ISBN: 978-989-758-585-2; ISSN: 2184-2809

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

solved. Figure 1 shows a standard strawberry field

covered with tunnels (with eight ridges each tunnel).

The left photo shows the field in autumn. Strawberry

plants can have leaves effectively hiding the fruit-to-

be-harvested from sensors on a robot. Here, mech-

anisms to exhibit the fruits to a sensor need to be

developed. In Figure 1 (right) the field in spring is

shown. Some fruits are not visible in the camera im-

age, others are partially covered. All the challenges

need to be tackled while guaranteeing a speedy oper-

ation. Clearly, a robot with a worse picking quota than

human workers will stand no chance of being widely

adopted by the market.

1.3 Related Work

Robotic systems which are capable of harvesting

strawberries autonomously have already been pre-

sented by multiple research groups. Some presented

robots were designed for elevated-trough cultures

where the strawberry plants are grown in a trough el-

evated at between 50 cm to 100 cm above ground.

Feng et al. describe a mobile robot platform with a 6-

DOF manipulator and sonar-based navigation (Feng

et al., 2012).

Ge et al. use a similar environment of elevated-

trough cultures and describe very detailed the image

based fruit detection and localization (Ge et al., 2019).

Xiong et al. designed and evaluated different straw-

berry harvesting robots. While some tests of a previ-

ous version were carried out in tunnels and on sandy

ground, they focus on elevated-trough (“table-top”)

cultures in the later publication (Xiong et al., 2020).

However, they show interesting results and insights,

e.g., regarding the gripper, regarding picking in clus-

ters of strawberries, and regarding varying lighting

conditions.

Hayashi et al. present an evaluation of their sys-

tem in a field-test. The environment is an evaluated-

trough setting, too. Interesting is their comparison

of machine and human assessment of the strawber-

ries’ maturity and their solution concept focusing at

night operation and allowing task-sharing with human

workers (Hayashi et al., 2010).

To achieve a similar picking speed as a human

picker, it may be necessary to use dual arm manipula-

tion. (Le Flecher et al., 2019) described a visual pre-

dictive control strategy for two arms sharing a com-

mon work space. An interesting agricultural robot,

which combines several approaches to navigate au-

tonomously in a field was proposed in (Post et al.,

2017), even if it is not explicitly about strawberry har-

vesting. A number of robots have already been pub-

lished that are able to navigate in the open field and

perform manipulation tasks autonomously, e.g. the

robots Artemis (Schwender et al., 2014) and Coyote

(Sonsalla et al., 2015). However, these systems are

not specialized enough for rapid crop manipulation

and consequently too slow for use in the strawberry

field.

Most of the papers listed deal with the cultivation

of strawberries on elevated-trough cultures or cover

only partial aspects of the overall process necessary

for strawberry harvesting. However, the target envi-

ronment of the robot concept described in this work

is non-elevated, ground-based and dam-raised straw-

berry plants, outdoors, with or without tunnels.

Currently, there are several pre-product solutions

of robots for harvesting strawberries. One example

is the Agrobot

1

, which makes use of up to 24 arms

working in parallel. It is stated, that the robot is suit-

able for table cultures as well as free field strawber-

ries. The company Harvest Croo Robotics provides

a comparable system

2

, with 16 arms working in par-

allel. The system can scan a fruit in a 360

◦

view to

assess the ripeness. A visual system is used to locate

the fruit prior to picking it from the plant. Systems

for table cultures are the Rubion

3

developed by the

company Octinion and the Dogtooth

4

robot with two

picking arms.

Finally, work focusing on multi-spectral or hyper-

spectral image classification has been published, too.

Multi-spectral image based classification is used in

several applications. UV, visual, and SWIR 2D im-

ages are used by Tiedemann et al. for the classifica-

tion of a large range of different materials in coarse-

waste recycling (Tiedemann et al., 2021). For applica-

tions in agriculture Pasolli et al. give a good overview

of studies and methods. There, airborne and satel-

lite data collection in the spectral range of 400 nm

to 2,500 nm dominate but terrestrial collections and

the methods (which are good candidates for the straw-

berry classification) are discussed, too (Pasolli et al.,

2018). Devassy and George compare different re-

gression models for the estimation of the firmness

of strawberries using hyperspectral imaging (Devassy

and George, 2021).

Klaoudatos et al. present a non-mobile system

consisting of a standard 6-DOF manipulator, a fin ray

gripper, and a vision system that was tested in labora-

tory only. However, the vision system gives interest-

ing insights by an implementation that uses classical

image processing on red and green channels only plus

depth information from a Kinect sensor (Klaoudatos

1

https://www.agrobot.com/e-series; as of 2022-04

2

https://www.harvestcroorobotics.com/; as of 2022-04

3

https://picking.technology/; as of 2022-04

4

https://dogtooth.tech/; as of 2022-04

Challenges of Autonomous In-field Fruit Harvesting and Concept of a Robotic Solution

509

Figure 1: Left: Photo of an outdoor strawberry field with an 8-row tunnel, taken in autumn (Tiedemann, 2022b, under CC-BY

4.0). Right: Lower view position between the ridges, taken in spring (Tiedemann, 2022a, under CC-BY 4.0).

et al., 2019).

Although many of the pre-product solutions pro-

vide promising approaches, two major drawbacks

stand out in our opinion. Solutions that already work

in the field are mostly very large and complex ma-

chines that, although performance still needs to be

improved, require a large investment volume. Smaller

systems, with lower barriers to investment, have so far

been limited to specific types of cultivation such as

table crops and their performance is far too slow for

widespread use, yet. And a general solution for stan-

dard non-elevated/non-table-top fields is still missing.

2 PROPOSED ROBOTIC

CONCEPT/SOLUTION

2.1 Requirements

A detailed list of all the requirements we found in

workshops and discussions with farm owners is be-

yond the scope of this paper. However, the most im-

portant requirements are summarized as follows

• operation in open field, all weather conditions

possible: rain, heat, frost, mud, dust,... an IP rat-

ing of IP65 shall be reached.

• row width is different on different farms. Cur-

rent setpoint is 1 m row width, needs to be easily

adaptable

• experienced human pickers can pick 40 kg of

strawberries per hour, the mean is around 20 kg.

Given the mean weight of a strawberry, the rover

shall reach around 25 harvested strawberries per

minute.

• a payload capacity of 90 kg for the final system

shall be reached. 90 kg of ripe fruits are to be ex-

pected per row in high season.

2.2 Overall Concept

2.2.1 General Platform Concept

The general robotic concept forsees a four wheeled

rover system, roughly the size of a table. Four legs

will be used to reach a platform height well above the

strawberry plants. Two manipulation arms with spe-

cific gripper elements are mounted to the robot such

that they can operate below the main platform. All

four wheels will be actively driven, while only the

two hind wheels are steerable in order to reduce the

number of actively actuated joins as far as possible.

A detailed description of the current system design is

provided in Section 2.3.

2.2.2 Concept of Operation

For start of operations, the robot is deployed by a hu-

man at the strawberry field. Once enabled, the hu-

man operator navigates the robot to the first row to be

harvested using a remote control unit. After manual

placement, the robot is standing with its body over

the first strawberry plants. By enabling the harvesting

mode, the robot starts its operational loop:

1. detect strawberries

2. extract gripping poses for

(a) ripe strawberries

(b) foul/overripe fruits

3. harvest all strawberries below robot using linear

drivable manipulation arms

4. put ripe fruit into selling boxes / overripe fruit into

waste bin

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

510

5. if end of row is not reached move platform for-

ward one body length begin at 1., else

6. execute row change and start at 1.

2.2.3 Scenarios

The overall objective of the project is to enable the

SHIVAA system to move mostly autonomously in the

strawberry field and harvest strawberries. The robot

should be deployed in an outdoor field, possibly with

humans working in close vicinity of the robot.

The system includes a base platform which can

move around the field on wheels. The current con-

cept forsees 4 driven wheels, two of which are also

steerable, see also Section 2.3. The base platform

is equipped with one or more manipulators, each of

which can in turn hold a gripper as an end-effector.

For detecting ripe strawberries, the platform and/or

the manipulators are equipped with suitable imaging

sensor technology. Additional sensor technology on

the platform enables self-localization in the field and

reliable tracking of the strawberry rows. The platform

is also equipped with a receptacle for empty straw-

berry crates, which are ready loaded with hulls.

The demonstration scenario intended for SHIVAA

follows the concept of operations as described in Sec-

tion 2.2.2. After manual deployment at the first row,

the rover autonomy is initiated and the robot starts

picking strawberries. The rover drives forward a full

body length and initiates a detection cycle. The poses

of the ripe fruits to be harvested and the foul fruits

to be sorted out are extracted and sent as two indi-

vidual lists to the manipulation planner. After plan-

ning the manipulator trajectory, harvesting of a fruit is

conducted, before a new manipulation plan is issued.

Once all fruit are harvested or sorted out beneath the

current robot position, the rover drives forward a body

length and the cycle starts over again.

Further scenarios investigated are (i) leave pick-

ing: The leaves of the plants are to be reduced be-

fore the harvesting season. This might help the plants

to build better fruits, reduce humidity and hence fun-

gal attack and consequently the use of fungicide. (ii)

Mowing between the rows: On farms where there is

grass in between the rows of strawberries, the robot

can be used to keep the grass short. (iii) keeping track

of ripeness: while driving through the rows (during

harvest or other tasks) the robot can take the ripeness

of the fruits to project an expected harvest for the next

time frame. A forecast of the harvested amount of the

next week can help setting efforts and prices.

2.3 Robotic Platform

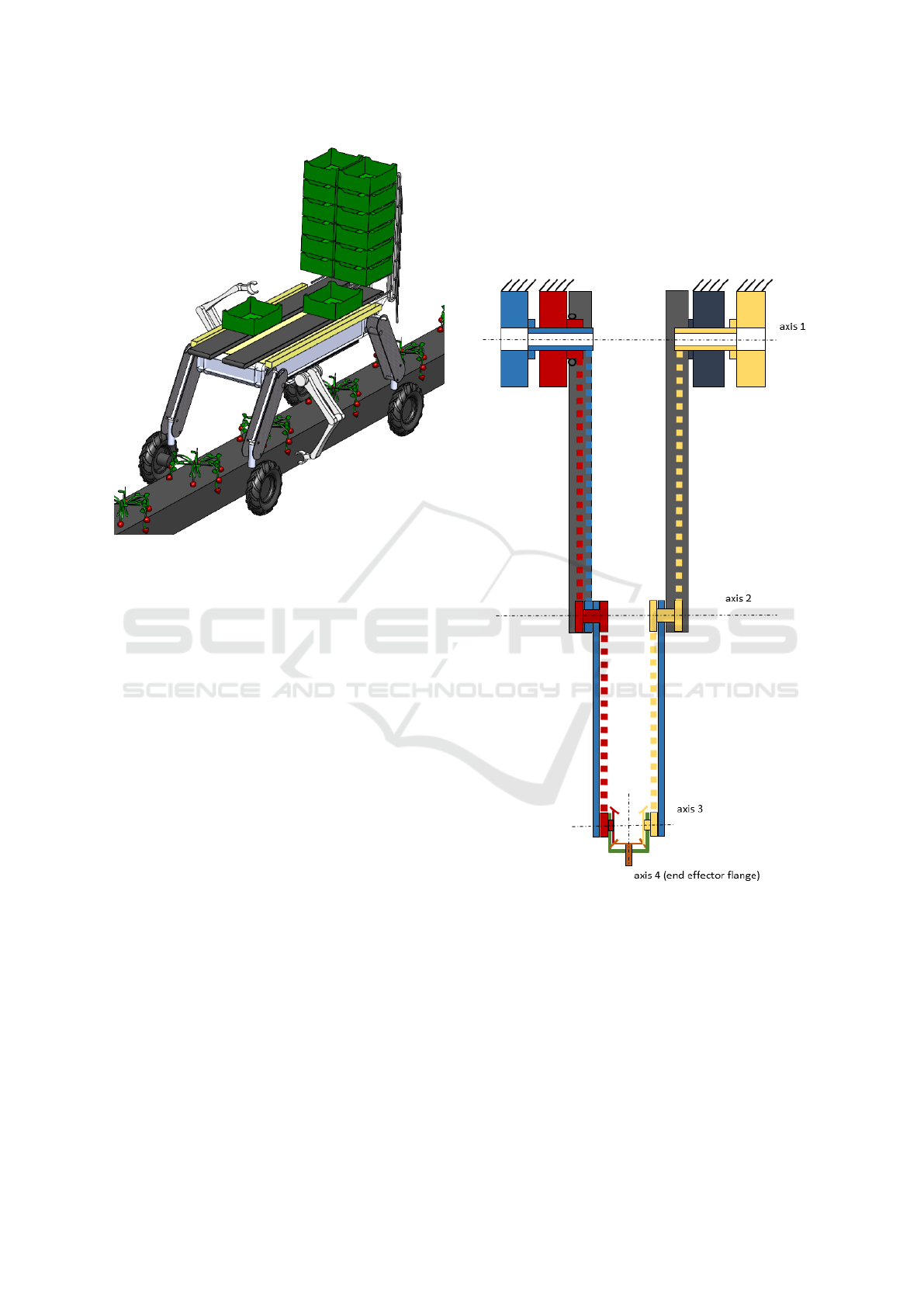

The SHIVAA system is intended to be a small, cost-

effective system for harvesting strawberries on dam

cultures in the open field (see Figure 2). The unloaded

weight of the system is limited to max. 120 kg, so

that it can be carried by four persons if necessary. To

allow autonomous operation of the system for at least

3 hours, the robot is equipped with a 1.5 kWh Li-Ion

battery.

The robot can move forward on four actively

driven wheels with a top speed of min. 6 km/h and

a preliminary estimated nominal torque of each drive

of 35 Nm. To allow various steering modes the rear

wheels are equipped with individually controllable

steering actuators. Because of the layout of the dam

crops the track width is fixed to exactly one meter

with a wheelbase of approximately two meters. To

compensate ground unevenness up to at least 100 mm

by the undercarriage the rear legs are coupled via a

differential.

Strawberry picking is performed on both sides and

below the robot, so that the lower face of the central

body must be at least 0.8 m above ground level to en-

sure a wide enough manipulation area.

Two manipulator arms, each equipped with a grip-

per, are used for picking and manipulating fruit. Since

a manipulation space of at least one meter along the

strawberry row is to be covered on both sides of the

dam in order to be able to statistically compensate for

non-uniform growth, the manipulators can be moved

on linear guides along the sides of the robot.

The further kinematic chain of each manipulator

consists of three DOF arranged in a plane orthogonal

to the longitudinal axis of the robot, and an additional

rotation around the central axis of the end effector.

The reach of one manipulator is approximately 0.8 m,

with the length of the upper and lower arm segments

being 0.4 m each. The manipulator arms follow a low

inertia design principle to allow fast movements with

high accelerations between picking and placement lo-

cations. To achieve this, all four drives are shifted

to the base of the robot so that their mass does not

need to be accelerated except along the linear guide.

The drives are kinematically coupled to the arm base.

The torque is transmitted to the respective joints via

belt drives, with the more distant joints being coupled

from joint to joint. Because the axis of rotation of the

fourth DOF is not in the same plane as the other joint

axes, the third and fourth DOF are coupled differen-

tially. The movement of these two DOF is therefore

dependent on the interaction of the same two drives.

A plastic bevel gear is used for the differential cou-

pling. Figure 3 shows a schematic view of the arm

Challenges of Autonomous In-field Fruit Harvesting and Concept of a Robotic Solution

511

Figure 2: Mechanical concept of the proposed strawberry

picking robot.

actuation concept.

The actuation of the arm DOF is done by BLDC di-

rect drives. External rotor motors are used for this

purpose. The transmission to the respective joint axis

is performed by up to two belt gear stages with a

total reduction ratio of up to 1:6. The transmission

ratio is selected according to the respective nominal

torque requirements, whereby the same motor is used

for each degree of freedom.

The picking process takes place independently on

both sides of the robot, with the fruit being picked be-

low the robot and placed directly into provided boxes

above the robot. Each fruit thus only needs to be

touched once, minimizing the risk of damage to the

fruit. Due to the limited linear travel speed of the

manipulators along the longitudinal axis of the robot,

the deposit boxes are moved along on conveyor belts

to follow the manipulator position. Full boxes can

be transported to the back of the robot while empty

boxes are supplied from a storage system on the robot.

Fruits that have been classified as overripe or bad

fruits during image recognition are not placed in the

boxes but in depositories along the robots flanks.

In order to keep the inertia of the entire manip-

ulator as low as possible, especially the end effector

should apply minimal weight. In this case the end ef-

fector will probably be a gripper with a maximum of

two DOF, whereby the fruit is first sucked in and held

in the center of the gripper by a vacuum system so

that, in a second step, the fruit can be easily enclosed

by the gripper. Separating the fruits from the plant oc-

curs by a combined pulling and twisting motion with

the help of the manipulator arm. The required un-

der pressure system can be placed in the central robot

body, so that only a pneumatic tube and the electric

wiring has to be transferred through the arm.

Figure 3: Schematic representation of the arm actuation,

where the black motor actuates axis 1, the blue motor actu-

ates axis 2, and the red and green motor are coupled differ-

entially to axes 3 and 4. If they rotate in the same direction,

the end effector rotates around axis 3. If they rotate in the

contrary direction, the end effector rotates around axis 4.

2.4 Sensor Setup for Fruit Detection

and First Data

The tasks the sensory system of the robot has to fulfill

are (1) the detection of strawberries within the robot’s

workspace, (2) the classification of the strawberries in

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

512

ripe, not yet ripe, and overripe, and (3) the localiza-

tion of the ripe and the foul strawberries (both have

to be harvested and will be put into different boxes).

Optionally, a detection of leaves could be a task for

the robot in case leaves have to be removed or pushed

aside by the robot. And finally, one additional de-

mand might be that the system needs to be run ei-

ther at night (compare (Hayashi et al., 2010)) with

controlled but fully artificial lighting or at day time –

with brighter environmental lighting but varying with

dawn, dusk, and weather conditions.

For the solution of several classification tasks in

agriculture and other applications a combination of

visual images (sometimes with a separate “red-edge”

channel) and near-infrared (NIR) images are used –

sometimes extended by UV and/or short-wave in-

frared (SWIR) images (Tiedemann et al., 2021). In a

first phase, sample data of ripe, not ripe, damaged and

overripe strawberries is collected in 17 spectra from

250 nm to 1,550 nm. Based on the first data collec-

tion a subset of the 17 spectra is selected for the final

prototype and is evaluated in a second phase. The up

to 17 2D-images are used together for the detection

and classification task. If a strawberry is detected and

needs to be harvested, its position relative to the robot

is determined using a further sensor. For this task a

time-of-flight (TOF-) camera, a stereo camera, or a li-

dar will be used. The selection of the sensor to be used

in this task is done based on tests in the first project

phase.

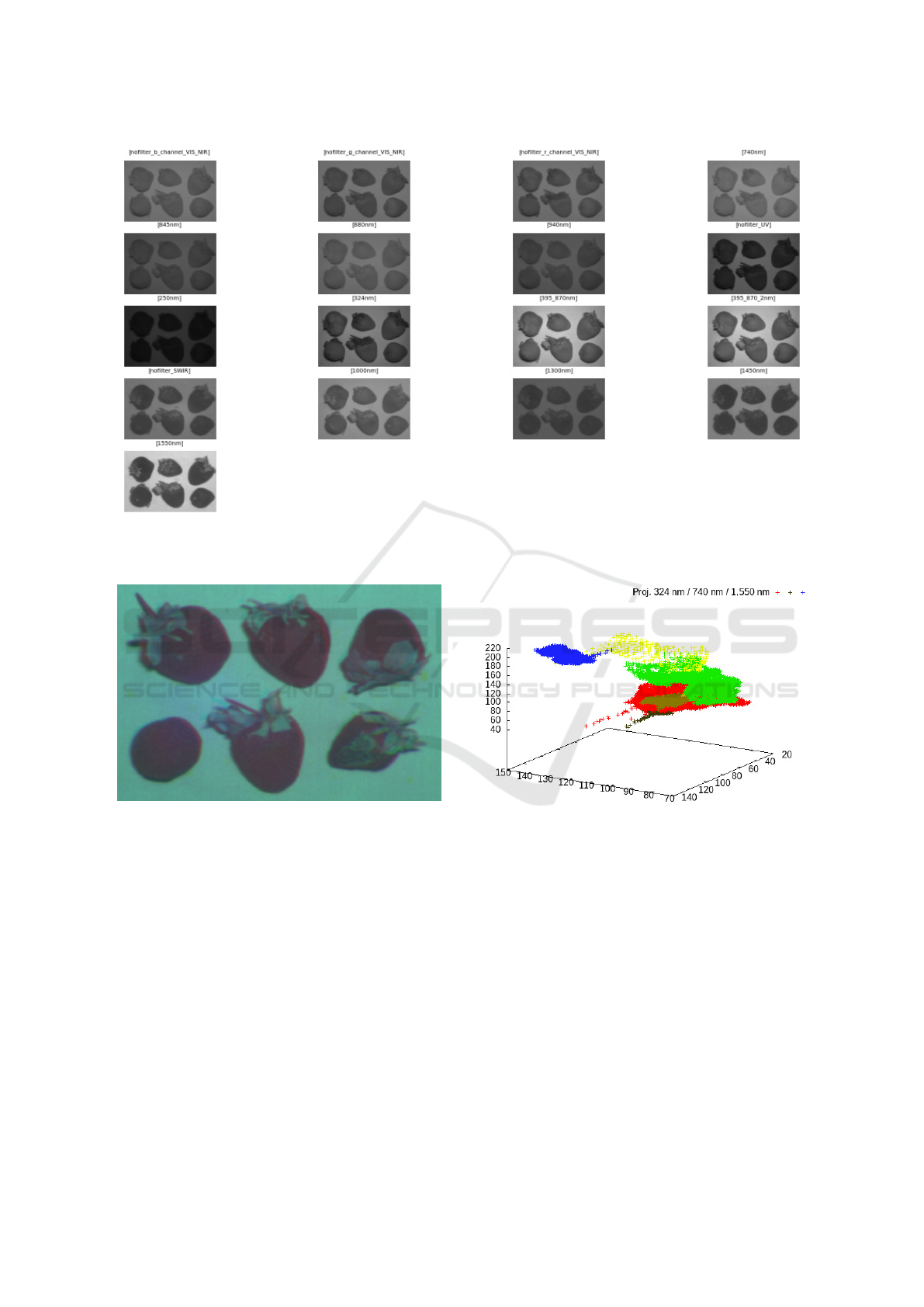

The multi-spectral imaging (MSI) data sets are

collected with three different cameras (UV camera,

visual camera, SWIR camera) and with different spec-

tral filters. Figure 4 shows an exemplary overview of

one MSI data set.

To analyze and to visualize the relation between

single spectral components and the classification of

ripeness, false color images can be used. In Figure 5

an example is depicted with the spectral images of

845 nm, 1,450 nm, and with an image taken by the

SWIR camera with no filter as components red, green,

and blue, respectively. At the bottom right strawberry

a defective/foul area can be recognized quite easily.

The actual advantages of MSI can be utilized fully

when all available spectral images (dimensions) are

used. However, this data is hard to study and to

understand for humans. E.g., the false color image

uses only 3 of the 17 dimensions. However, to clas-

sify ripe from non-ripe from overripe strawberries and

from other parts of the plants, machine learning (ML)

based methods will be applied and studied. These

methods use all 17 dimensions and are supposed to

be able to classify correctly between the classes men-

tioned above. First tests will be carried out with sup-

port vector machines (SVM) which were dominating

classification tasks until deep methods as the convo-

lutional neural networks (CNN) showed better perfor-

mance in several applications. However, these were

high-dimensional classification task like image clas-

sification with hundreds or thousands dimensions and

with local relations between input dimensions. It is

expected that such properties need not to be used in

the classification task in this project, thus, no object

classification / no classification of a whole strawberry.

Rather, a classification on single pixel basis is planned

as a first step, using only the 17 gray values of the dif-

ferent spectra. In a second step pixel classifications

can be grouped by size and class leading to an ordered

list of strawberries of different classes and sizes.

To get a first impression of the task the classifier

has to solve, again a visualization with only up to

four dimensions is helpful. Besides more elaborated

and complex methods as principle component analy-

sis (PCA) or t-SNE visualization, a simple projection

from the 17-dimensional to a three-dimensional space

can give interesting insights. Figure 6 shows a projec-

tion on the dimensions 324 nm, 740 nm, and 1,550 nm

with the color as fourth dimension encoding the class

of the pixel as labeled ground truth. There, the back-

ground (blue) can be separated clearly from the rest,

stem and leaves (yellow and green) are harder to sep-

arate (but could be possible), the brown non-ripe area

and the black (defective part) area are close to the red

(healthy and ripe) area but seems to be separable.

These first results of the data analysis give a good

reason to start with simple classification methods as

SVM or a simple multi-layer perceptron (MLP). Fur-

thermore, clustering, followed by a feature selection

and dimensionality reduction study will be next steps.

As a preparation for the next following step, a

first data collection in the field has been carried out.

Figure 7 shows the camera setup placed between the

ridges (dams). Four cameras have been used there

to collect multi-spectral data: (1) a UV camera, (2)

a SWIR camera, (3) a visual camera without an in-

ternal IR filter, and (4) a standard visual camera with

IR filter. The first three cameras were consecutively

equipped with different filter configurations to take

separate images per spectral band. The fourth cam-

era was used to take a visual reference image.

Next steps in this early project state are the pre-

processing of the collected data, a manual analysis of

the data and running first classification tests.

Challenges of Autonomous In-field Fruit Harvesting and Concept of a Robotic Solution

513

Figure 4: Overview of all images taken of a single scene. The images were taken with one of three cameras (UV, SWIR,

visual) and with one of multiple filters (or with no filter) in the range of 250 nm to 1,550 nm. The set of all images is used as

a single multi-spectral imaging (MSI) data set.

Figure 5: Example of a false color image.

3 SUMMARY AND OUTLOOK

This work presents a concept for an in-field ground-

based dam-raised strawberry harvesting robot, its me-

chanical setup, its sensor equipment, and planned

classification methods. Furthermore, first collected

data is shown and very first results of a data analy-

sis are discussed.

The next steps cover (1) the system specification,

(2) the mechanical design process in different steps

and (3) further in-field data collections. A set of

potentially applicable machine learning classification

methods will be evaluated using the data collection

sets.

Figure 6: Projection on three axes of a sample data set. Blue

is background, green are leaves, red is the strawberry fruit

in a healthy state, yellow is the stem. Especially interesting

are (1) the brown area within the red area which is a non-

ripe strawberry and the small black part below the red area

which is taken from a defective part.

ACKNOWLEDGEMENTS

The activities described in this paper are part of the

project RoLand with support from the Federal Min-

istry of Food and Agriculture (BMEL) by decision of

the German Bundestag. The Federal Office for Agri-

culture and Food (BLE) provides coordinating sup-

port for artificial intelligence (AI) in agriculture as

funding organisation, grant number 28DK103A20 /

28DK103B20 / 28DK103C20.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

514

Figure 7: Setup used for a first in-field data collection. A

rigid frame carries four cameras used to collect the multi

spectral data. In this setting the frame is placed between the

ridges.

REFERENCES

Devassy, B. M. and George, S. (2021). Estimation of straw-

berry firmness using hyperspectral imaging: a com-

parison of regression models. Journal of Spectral

Imaging, 10.

Feng, Q., Wang, X., Zheng, W., Qiu, Q., and Jiang, K.

(2012). New strawberry harvesting robot for elevated-

trough culture. International Journal of Agricultural

and Biological Engineering, 5(2):1–8.

Ge, Y., Xiong, Y., Tenorio, G. L., and From, P. J.

(2019). Fruit localization and environment percep-

tion for strawberry harvesting robots. IEEE Access,

7:147642–147652.

Hayashi, S., Shigematsu, K., Yamamoto, S., Kobayashi, K.,

Kohno, Y., Kamata, J., and Kurita, M. (2010). Eval-

uation of a strawberry-harvesting robot in a field test.

Biosystems engineering, 105(2):160–171.

Klaoudatos, D. S., Moulianitis, V. C., and Aspragathos,

N. A. (2019). Development of an experimental straw-

berry harvesting robotic system. In ICINCO (2), pages

437–445.

Le Flecher, E., Durand-Petiteville, A., Cadenat, V., and Sen-

tenac, T. (2019). Visual predictive control of robotic

arms with overlapping workspace. In International

Conference on Informatics in Control, Automation

and Robotics (ICINCO).

Pasolli, E., Prasad, S., Crawford, M. M., and Tilton, J. C.

(2018). Advances in hyperspectral image classifica-

tion methods for vegetation and agricultural cropland

studies. In Hyperspectral Indices and Image Classifi-

cations for Agriculture and Vegetation, pages 67–104.

CRC Press.

Post, M. A., Bianco, A., and Yan, X. T. (2017). Au-

tonomous navigation with ros for a mobile robot in

agricultural fields. In 14th International Conference

on Informatics in Control, Automation and Robotics

(ICINCO).

Schwender, J., Roehr, T. M., Haase, S., Wirkus, M., Manz,

M., Arnold, S., and Machowinski, J. (2014). The

artemis rover as an example for model based engi-

neering in space robotics. In ICRA Workshop on Mod-

elling, Estimation, Perception and Control of All Ter-

rain Mobile Robots.

Sonsalla, R. U., Akpo, J. B., and Kirchner, F. (2015). Coy-

ote iii: Development of a modular and highly mo-

bile micro rover. In Proc. of the 13th Symp. on Ad-

vanced Space Technologies in Robotics and Automa-

tion (ASTRA-2015).

Tiedemann, T. (2022a). Outdoor Strawberry Field

in Tunnel, View Between Ridges. figshare. doi

https://doi.org/10.6084/m9.figshare.19929950.v1.

Tiedemann, T. (2022b). Strawberry Field, 8-

Row Tunnel, in Autumn. figshare. doi

10.6084/m9.figshare.19929332.v1.

Tiedemann, T., Keppner, M., Runge, T., V

¨

ogele, T.,

Wittmaier, M., and Wolff, S. (2021). Concept of

a robotic system for autonomous coarse waste re-

cycling. In Proceedings of the 18th International

Conference on Informatics in Control, Automation

and Robotics-ICINCO, pages 493–500. INSTICC,

SciTePress.

Xiong, Y., Ge, Y., Grimstad, L., and From, P. J. (2020). An

autonomous strawberry-harvesting robot: Design, de-

velopment, integration, and field evaluation. Journal

of Field Robotics, 37(2):202–224.

Challenges of Autonomous In-field Fruit Harvesting and Concept of a Robotic Solution

515