The Visual Inspection of Solder Balls in Semiconductor Encapsulation

Conceic¸

˜

ao N. Silva

1

, Neandra P. Ferreira

2

, Sharlene S. Meireles

2

, Mario Otani

2

,

Vandermi J. da Silva

1

, Carlos A. O. de Freitas

1

and Felipe G. Oliveira

1

1

Institute of Exact Sciences and Technology (ICET), Federal University of Amazonas (UFAM),

Itacoatiara, Amazonas, Brazil

2

Cal-Comp, Institute of Research and Technological Innovation (ICCT), Manaus, Amazonas, Brazil

neandra pf@calcomp-icct.org.br, sharlene@calcomp-icct.org.br, mario otani@calcomp-icct.org.br

Keywords:

Ball Bond Inspection, Automatic Visual Inspection, Deep Learning.

Abstract:

The growing demand for increasing memory storage capacity has required a high density of integration within

the semiconductor encapsulation and, consequently, has made this process more complex and susceptible

to failures during the production stage. In the semiconductor encapsulation area, the costs of materials and

equipment are high and the profit margin is narrow, making it necessary to rigorously inspect the process steps

to keep the productive activity viable. This work addresses the problem of quality control in silicon wafers

soldering procedure, allowing error detection before the epoxy resin molding process, generating useful infor-

mation for correcting equipment configurations and predicting failures from the raw materials and inputs used

in the process. We propose an approach to classify solder balls, in the soldering process of silicon wafers on

Ball Grid Array (BGA), contained in the Printed Circuit Board (PCB) substrates. The proposed methodology

is composed of two main steps: i) Solder ball segmentation; and ii) Solder ball classification through deep

learning. The proposed predictive model learns the relation between visual features and the different soldering

conditions. Real and simulated experiments were carried out to validate the proposed approach. Results show

the obtained accuracy of 99.4%, using Convolutional Neural Network (CNN) classification model. Further-

more, the proposed approach presents high accuracy even regarding noisy images, resulting in accuracy of

92.8% and 75.7% for a Salt and Pepper and Gaussian noise, respectively, in the worst scenario. Experiments

demonstrate reliability and robustness, optimizing the manufacturing.

1 INTRODUCTION

Automated inspection of semiconductors has been the

focus of numerous research efforts in Microelectron-

ics and Industrial communities in the past few years

(Zhang et al., 2022). The semiconductors inspection

has the role of feeding back the methods with infor-

mation on specific errors, which can be correlated

with production problems. The semiconductors anal-

ysis includes the assessment on occurrence of failures

due to the materials involved in the process or inad-

equate definitions of the machine parameters (Zhang

et al., 2021).

In the semiconductors context, the production of

memory devices represents a great manufacturing

challenge, especially due to the small component’s di-

mensions and the required precision in its operation.

Additionally, the market demand for memory devices

has increased massively, requiring the expansion of

memory production volume, making the manual in-

spection process critical (Chang et al., 2018).

The use of the conventional visual inspection pro-

cess, regarding a trained human operator, presents ef-

fectiveness between 80% and 90% of cases. However,

after the first half working hour, the human operator

visual acuity decreases significantly, for the analysis

of a single type of defect [1]. In Figure 1, is pre-

sented an example of a human visual inspection of

silicon wafers, where the human operator should visu-

ally run through all the components on the PCB sub-

strate looking for different types of defects.

In this paper, we present an approach to clas-

sify solder balls, in the soldering process of a sili-

con wafer, called die, on BGAs, contained in the PCB

substrates. The solder ball is classified into three cat-

egories: i) correct; ii) absence; or iii) failure. We also

introduce a CNN architecture for supervised classifi-

cation of solder balls, which learns the main features

that represent all approached types of soldering condi-

tions. Experiments in real-world scenarios and simu-

750

Silva, C., Ferreira, N., Meireles, S., Otani, M., J. da Silva, V., O. de Freitas, C. and Oliveira, F.

The Visual Inspection of Solder Balls in Semiconductor Encapsulation.

DOI: 10.5220/0011357400003271

In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2022), pages 750-757

ISBN: 978-989-758-585-2; ISSN: 2184-2809

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Conventional visual inspection of memory devices, in soldering process of silicon wafers. Additionally, are con-

trasted the sizes of a die and solder balls.

lations show that the obtained results are accurate and

applicable in industrial scenarios.

Our main contribution is to provide an approach,

based on deep learning, to detect failures in the die

soldering process. Furthermore, the proposed strat-

egy provides a robust solution for a challenging com-

ponent, in micrometers scale. Also in Figure 1, it is

possible observe the challenging size of solder balls

and the involved features to depict the problem.

The remainder of this paper is structured as fol-

lows. In Section II we present a discussion on re-

lated works regarding Semiconductor Inspection. The

proposed methodology is presented in Section III and

validated by real and simulated experiments discussed

in Section IV. Finally, in Section V we draw the con-

clusions and discuss paths for future investigation.

2 RELATED WORKS

Problems related to automatic visual inspection are of

significant importance and have been the subject of

intensive investigation (Huang et al., 2014) (Vafeiadis

et al., 2018)(Zhang et al., 2022). For fault detection,

the majority of works perform classification of pres-

ence or absence of faults, in manufacturing processes

(Rocha et al., 2016) (Zhang et al., 2021).

Many industrial applications are addressed as a

fault detection approach. In (Rocha et al., 2016), a

visual inspection approach is presented to detect ab-

sence/presence of surface mount components (SMC)

on printed circuit boards (PCB). The authors propose

a methodology based on the combination of Machine

Vision and Machine Learning (using Support Vector

Machine (SVM)) to detect component absence, with

more quality and precision, using noisy digital images

acquired directly from PCB industrial production line.

The obtained results demonstrated the robustness of

the methodology, obtaining 97.25% of accuracy.

(Zhou et al., 2017) has proposed a detection ap-

proach for oil-air and oil-water interfaces, from im-

ages of transparent tubes containing water and oil. A

statistical based approach to detect the mentioned in-

terfaces is used. Through real experiments, results

show that the multi-interface detection method has

high precision and reaches the requirements of indus-

trial applications.

In some industrial applications, semiconductor in-

spection is a paramount task. (Srivastava et al.,

2016) presents an inspection approach for patterned

wafer during the chip fabrication. The authors pro-

posed an unique combination of Broad-Band light

with Dark Field Apertures, to reduce potential defects

in manufacturing process. From the experiments, the

proposed inspection approach demonstrates effective-

ness in real application, achieving approximately 15

wafers per hour.

The authors of (Cao, 2021) proposed a robot vi-

sion inspection system. The industrial robot is used to

detect the surface defects of semiconductor metal tar-

gets online. In this paper, the main goal is to complete

a high purity semiconductor metal target processing

inspection task. As result, the system can completely

replace the traditional manual testing, and improve

the machining quality and efficiency of semiconduc-

tor metal target.

In (Zhou et al., 2021) is presented an approach

to inspect the chips in the wafer backside, during the

manufacturing process. In semiconductor analysis the

scan result is evaluated and compared to the Backside

Database (BDB), to quantify the accuracy achieved.

The experiments demonstrate the effectiveness of the

proposed approach for backside defect Monitoring

strategy.

The Visual Inspection of Solder Balls in Semiconductor Encapsulation

751

Figure 2: Overview of the proposed approach for automatic visual inspection for silicon wafer soldering process, through the

stages: i) Image Segmentation; and ii) Image Classification through deep learning.

Still in semiconductor inspection context, but re-

garding the soldering process, (Zhang et al., 2021)

proposed a strategy to inspect internal circuit boards

in the production of water pumps. In this paper the

authors design a solder joint inspection system based

on machine vision, which can detect the status of sol-

der joints and feed back the current soldering results

to the workers. The method solves the problem of

automatically detecting the welding quality of the cir-

cuit board in the manual welding process, greatly im-

proves the production efficiency of the workshop pro-

duction line, and shortens the product manufacturing

cycle.

(Chang et al., 2018) has proposed an inspection

technique for automated optical inspection (AOI) and

solder paste inspection (SPI), in SMT line. The au-

thors used a machine learning based approach called

automatic mistake reduction (AMR) for Classification

of solder joints in production line. The experimental

results showed that the proposed method is not only

more efficient, but also provides an accurate recogni-

tion rate in the SMT process.

In (Zhang et al., 2022) is proposed an approach

for solder joint defect detection on industrial manu-

facturing process. For this, the authors used a deep

learning based technique to learn features and detect

the failures through a CNN model. Through the ex-

periments the effectiveness of the proposed models is

verified by real-world 3D X-ray images.

The majority of the existing solutions for solder

evaluation are based on the classification of the solder

conditions on positive or negative cases (Chang et al.,

2018). The closest approach, regarding the method-

ological strategy, using CNN models, inspect solder

joints from x-ray images (Zhang et al., 2022). Addi-

tionally, the soldering process assessed by the major-

ity of works tackle milimiters and centimeters scales.

The presented approach is particularly interesting

because it proposes an automatic solder ball classi-

fication for PCB production. Additionally, it is im-

portant to mention that unlike other works whose

tackle solder conditions in millimeters and centime-

ters scale, our work tackle solder balls in micrometers

scale, representing a great challenge for an accurate

automatic visual inspection in semiconductor encap-

sulation process.

3 METHODOLOGY

In this paper, we propose an automatic visual inspec-

tion for silicon wafer soldering process, based on vi-

sual features and deep learning combining. The pro-

posed approach tackles the solder ball classification

problem, during the silicon wafer soldering process,

detecting failures in the semiconductor encapsulation

stage. An overview of the proposed methodology is

shown in Figure 2, whose details will be presented in

the next subsections.

In Figure 2, we present an overview of the

proposed approach, highlighting the main steps to

achieve the solder ball classification, indicating the

correct, absent or failure condition in the ball solder-

ing stage. To reach this goal, images are acquired

continuously and an image segmentation stage is per-

formed. Different features are learnt in a deep learn-

ing procedure, understanding the solder conditions

for an efficient classification.

Our problem can be summarized as follows:

Problem 1 (Automatic Visual Inspection). Let I =

{

i

1

, i

2

, . . . , i

n

}

be a series of silicon wafer images pro-

vided by a camera. For every i

j

∈ I , is extracted a set

of segmented solder ball images S

j

=

{

s

1

, s

2

, . . . , s

m

}

.

Also let B =

{

b

1

, b

2

, . . . , b

k

}

be a series of previously

known solder ball labels. Our main goal is to cor-

rectly associate an unknown segmented solder ball

image (s

w

) to the correspondent solder ball label (b

l

),

representing the solder ball condition during the sol-

dering process.

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

752

3.1 Image Segmentation

In this work the images (I) are initially acquired in

Red, Green and Blue (RGB) model. The first step to

inspect the soldering stage, during the semiconductor

encapsulation process, is to segment the solder balls

(S) contained in the silicon wafer images.

For this solder ball segmentation step, the Haar

cascade method, using boosted cascade of simple fea-

tures, is used (Viola and Jones, 2001). The Haar cas-

cade method works like a machine learning approach,

where the cascade function is trained from a set of

images representing positive and negative cases.

In Haar cascade, for solder ball detection, rectan-

gle features are used to learn patterns. For this, the

sum of the pixels which lie within the white rectan-

gles are subtracted from the sum of pixels in the grey

rectangles. Some rectangle features are shown in Fig-

ure 3.

Figure 3: Examples of rectangle features used in Haar cas-

cade method for solder ball detection in silicon wafer im-

ages.

For the learning process a variant of Ada Boosting

is used both to select a small set of features and train a

classifier (Viola and Jones, 2001). Ada Boosting is an

algorithm used to boost the classification performance

of weak classifiers. Additionally, is designed to select

the single rectangle feature which best separates the

positive and negative examples. For each feature, the

weak learner determines the optimal threshold classi-

fication function, such that the minimum number of

examples are misclassified.

A weak classifier h

j

(x) thus consists of a feature

f

j

, a threshold θ

j

, and a polarity p

j

indicating the di-

rection of the inequality sign:

h

j

(x) =

(

1 if p

j

f

j

(x) < p

j

θ

j

0 otherwise

(1)

Where x is a 24x24 pixel sub-window of an image.

Figure 4 shows the process of solder ball detection

using Haar cascade objetct detection.

(a)

(b)

Figure 4: Example of solder ball detection using Haar cas-

cade method. Figure 4a corresponds to raw silicon wafer

image. Figure 4b corresponds to the solder ball region de-

tection.

3.2 Image Classification

From the segmented solder ball images (S), is per-

formed a classification process to identify different

solder ball conditions (B), like: i) correct; ii) absence;

or iii) failure. For this, in this work, is proposed a

deep learning based approach to understand patterns

and features in different soldering cases.

A CNN is a deep learning architecture strongly

used for computer vision applications. CNN mod-

els can learn and represent effective features to al-

low the classification or regression application in real

problems. In solder ball classification context the pro-

posed CNN model, unlike other classical approaches,

can learns the better features and its representation for

the classification stage, even in different scenarios and

domains.

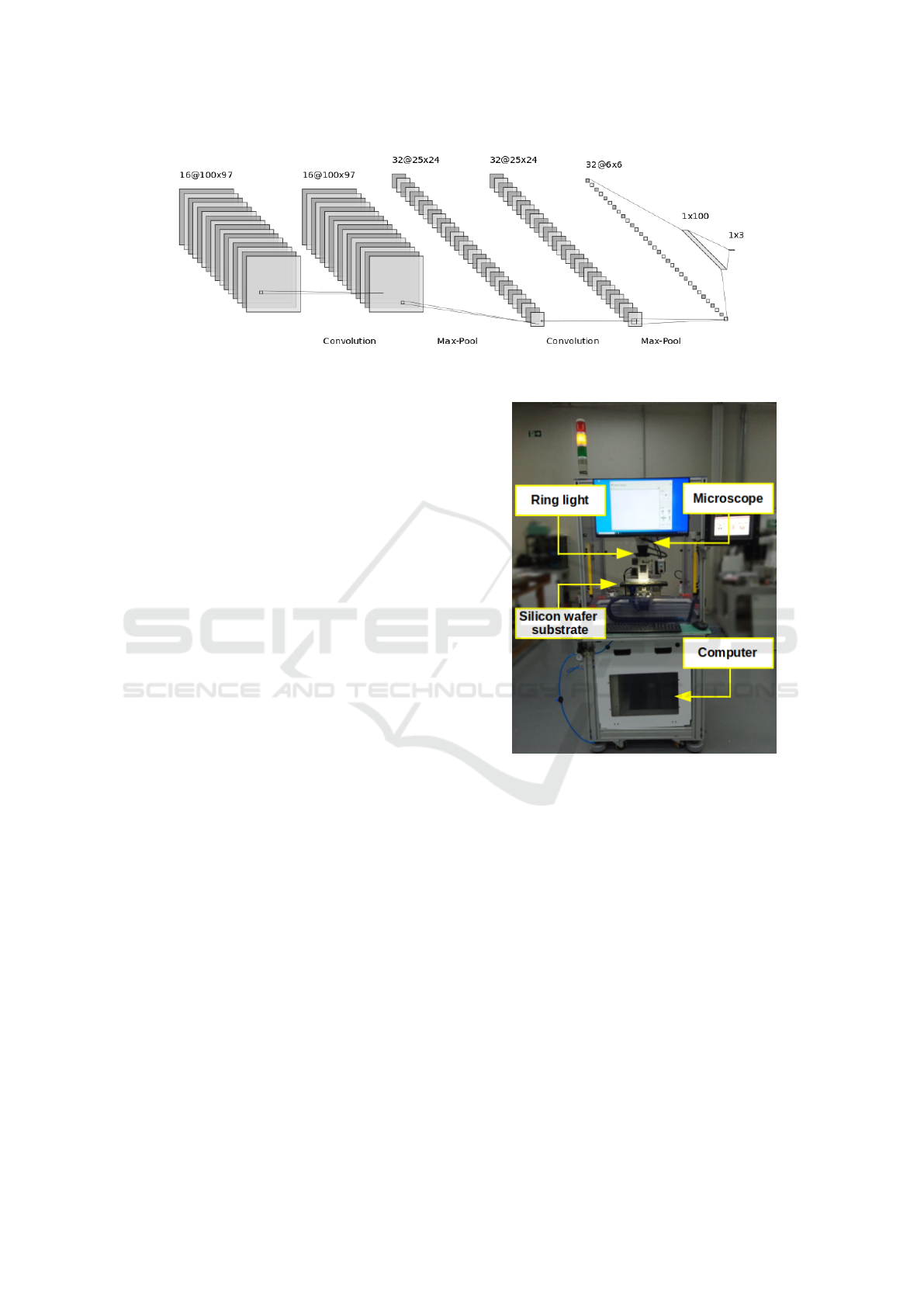

The proposed CNN model is composed by two

convolutional layers, with 16 filters in first layer and

32 filters in second layer. The filters size in first

layer were (5, 5), while in second layer were (9, 9).

The size of the fully-connected layer were 100. The

ReLU activation function is used in convolutional lay-

ers, with Max Pooling of size window (2, 2). In the

training stage, are used: the SGD optimization algo-

rithm, learning rate equals to 0.001, with momentum

0.9; for 40 epochs and using a batch size of 32.

A CNN model is used for solder ball classifica-

tion due to good results achieved in semiconductor

automation scenarios (Zhang et al., 2022). The pro-

posed CNN model is also used due to good feature

representation learning, depicting distinct and com-

The Visual Inspection of Solder Balls in Semiconductor Encapsulation

753

Figure 5: Proposed CNN architecture.

plementary features for modeling of different solder

ball conditions, unlike classical approaches. The pro-

posed CNN architecture for the soldering stage, dur-

ing the semiconductor encapsulation process, can be

observed in Figure 5.

4 EXPERIMENTS

In this section we present experimental results and

compare the obtained performance against existing

approaches.

4.1 Experimental Setup

The proposed experimental setup is composed by an

Olympus stereomicroscope SZ61-TR, coupled with a

camera SC180, mounted on a XYZ cartesian robot

with precise movements. Additionally, a ring light

is coupled with the stereomicroscope, providing con-

trolled illumination conditions. A Dell computer with

an Intel

®

Core

T M

i7-8550U CPU and 32 GiB DDR3-

2133 main memory is used to execute the proposed

approach (Figure 6).

4.2 Solder Ball Classification

Assessment

This experiment evaluates the accuracy of the pro-

posed approach for solder ball classification. Dif-

ferent approaches to tackle the solder ball classifica-

tion problem are implemented and evaluated. The

comparison approaches are: i) Local Binary Pattern

(LBP) and SVM classifier, with third degree polyno-

mial kernel; ii) LBP and Ada Boosting (AB) clas-

sifier; iii) LBP and Random Forest (RF) classifier;

iv) Histogram of Oriented Gradient (HOG) and SVM

classifier, with third degree polynomial kernel; v)

HOG and AB classifier; and vi) HOG and RF clas-

sifier. The comparison techniques were used due

Figure 6: Experimental setup used for automatic visual in-

spection for solder balls in PCB manufacturing process.

to good results obtained in automatic semiconductor

analysis (Iglesias. et al., 2021) and overall automatic

visual inspection context (Rahman et al., 2019)(Thie-

len et al., 2020).

The setting parameters for SVM classifier, with

polynomial kernel, were gamma equals to 0.001, C

equals to 1.0 and kernel degree equals to 3. For AB

classifier the setting parameters were, number of esti-

mators equals to 100. For RF classifier the setting pa-

rameters were, number of estimators equals to 30 and

max depth equals to 30. The parameters tuning for

the proposed approach was performed varying a set

of parameters to maximize accuracy, during the train-

ing and testing stages. Different scenarios changing

the number of convolutional layers, the number of fil-

ters, the size of filters, the number of fully-connected

layers, the size of the fully-connected layers and the

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

754

learning rate were experimented.

The classification model training is performed

from a set of input images and the testing stage re-

gards another set of input images, since is applied the

cross validation 5-fold protocol. The dataset used for

the training process, is composed by 1003 images of

solder balls, acquired during the semiconductor en-

capsulation process

The achieved results show that the proposed CNN

model outperforms the other classic techniques, as we

can observe in Table 1. The better classic perfor-

mances were obtained using LBP descriptor, depict-

ing texture features, and HOG descriptor, depicting

shape features. In addition, were used the RF classi-

fier to detect failures during the soldering stage.

Table 1: Results for solder ball classification. This experi-

ment presents the accuracy for CNN (proposed), HOG and

LBP descriptors. Additionally, were used the Random For-

est (RF), Support Vector Machine (SVM-Poly3) and Ada

Boosting (AB) for classification problem.

Method Accuracy

LBP + SVM Poly 3 26.208 ± 3.345

LBP + AB 84.345 ± 2.937

LBP + RF 90.627 ± 0.975

HOG + SVM Poly 3 19.342 ± 3.076

HOG + AB 87.241 ± 2.088

HOG + RF 95.114 ± 0.736

Our method 99.400 ± 0.583

The proposed approach achieved accurate results,

in the solder ball classification process, due to the

learning of different filters during soldering process.

The CNN process allows the learning of patterns in

different contexts and regarding different features.

Thereby, some solder ball conditions can be bet-

ter represented and classified using the convolutional

learning process.

4.3 Robustness Evaluation of Solder

Ball Classification in Presence of

Noise

This experiment evaluates the robustness of the pro-

posed approach for solder ball classification in pres-

ence of noise. Two different types of noise are added

in solder ball images, Salt and Pepper and Gaussian

noises. All the classic techniques, used in experiment

4.2 and the proposed CNN model, are evaluated. In

this experiment the added noise simulates the image

acquisition process regarding the presence of noise.

For this assessment, the classification model train-

ing is performed from a set of images without noise

and the testing stage regards another set of images

Table 2: Results for robustness evaluation of solder ball

classification, in presence of noise. In this experiment all

the considered methods are evaluated for Salt and Pepper

noise.

Salt and Pepper

Noise density 0.005 0.01 0.02

LBP+SVM

19.342

± 3.076

19.342

± 3.076

19.342

± 3.076

LBP+AB

83.944

± 2.579

82.450

± 2.361

75.664

± 6.442

LBP+RF

90.127

± 1.214

90.025

± 2.094

87.134

± 2.060

HOG+SVM

19.342

± 3.076

19.342

± 3.076

19.342

± 3.076

HOG+AB

76.663

± 3.336

60.505

± 7.125

27.508

± 5.172

HOG+RF

83.452

± 2.376

74.076

± 2.700

37.082

± 4.371

Our method

97.163

± 0.707

95.275

± 1.030

92.846

± 3.836

Table 3: Results for robustness evaluation of solder ball

classification, in presence of noise. In this experiment all

the considered methods are evaluated for Gaussian noise.

Gaussian

Noise density 0.005 0.01 0.02

LBP+SVM

19.342

± 3.076

19.342

± 3.076

19.342

± 3.076

LBP+AB

17.948

± 2.031

17.748

± 3.463

18.147

± 2.459

LBP+RF

19.342

± 3.076

19.242

± 3.029

19.142

± 2.994

HOG+SVM

19.342

± 3.076

19.342

± 3.076

19.342

± 3.076

HOG+AB

15.548

± 2.271

15.655

± 1.455

15.951

± 2.014

HOG+RF

24.025

± 5.277

20.240

± 4.440

16.155

± 1.634

Our method

81.602

± 1.748

79.430

± 2.916

75.703

± 3.175

with added noise. Figure 7 represents solder ball im-

age examples. Figure 7a represents a solder ball with-

out noise. Figure 7b represents a solder ball with Salt

and Pepper noise, with 0.02 noise density. Figure 7c

represents a solder ball with Gaussian noise, with 0.02

noise density.

The achieved results in this experiment show that

the proposed CNN model presents better performance

even in the presence of noise, as we can observe in

Table 2 and Table 3. Table 2, through the accuracy

and variance measures, shows the solder ball classi-

fication results for Salt and Pepper noise, for the dif-

ferent used techniques. Table 3, through the accuracy

The Visual Inspection of Solder Balls in Semiconductor Encapsulation

755

(a) (b) (c)

Figure 7: Example of solder ball images in presence of noise. Figure 7a corresponds to raw solder ball image. Figures 7b and

7c correspond to raw image added with Salt and Pepper noise and Gaussian noise, respectively.

and variance measures, shows the solder ball classi-

fication results for Gaussian noise, for the different

used techniques. Results show that the proposed CNN

model outperforms the other classification approaches

even in presence of noise, demonstrating the robust-

ness of the proposed approach.

5 CONCLUSION

In this paper, we addressed the problem of solder-

ing visual inspection in semiconductor encapsulation.

Unlike other state-of-the-art approaches, our method

achieve high accuracy and present the great capacity

of inspect very tiny solder ball conditions, providing

improvement to the semiconductor encapsulation and

production process.

Real-world and simulated experiments involving

different classification techniques and simulated noise

types have shown that the obtained solder ball clas-

sifications are reliable and accurate, considering the

obtained results. Additionally, the proposed approach

demonstrates robustness, even in presence of noise

during image acquisition, and feasibility to real indus-

trial application, once the experiments were carried

out in real scenario.

As future work, we intend to combine different

classification methods to improve the solder ball clas-

sification accuracy. We also intend to concentrate

efforts to extend the automatic visual inspection ap-

proach to tackle other types of problems related to

semiconductor encapsulation. The wire bond analysis

and inspection is also a relevant problem we intend to

investigate and incorporate in production lines.

ACKNOWLEDGMENT

This work was developed with support from Cal-

Comp Eletronic through R&D project in Institute of

Exact Sciences and Technology of Federal University

of Amazonas, Itacoatiara, Amazonas.

REFERENCES

Cao, Y. (2021). Design and application of robot vision in-

spection system for semiconductor metal target. In

2021 3rd International Symposium on Robotics In-

telligent Manufacturing Technology (ISRIMT), pages

464–467.

Chang, Y.-M., Wei, C.-C., Chen, J., and Hsieh, P. (2018).

Classification of solder joints via automatic mistake

reduction system for improvement of aoi inspection.

In 2018 13th International Microsystems, Packaging,

Assembly and Circuits Technology Conference (IM-

PACT), pages 150–153.

Huang, R., Sorini, A., and McNulty, J. (2014). Quantita-

tive solder inspection with computed tomography. In

2014 IEEE Symposium on Product Compliance Engi-

neering (ISPCE), pages 82–85.

Iglesias., B., Otani., M., and Oliveira., F. (2021). Glue

level estimation through automatic visual inspection

in pcb manufacturing. In Proceedings of the 18th

International Conference on Informatics in Control,

Automation and Robotics - ICINCO,, pages 731–738.

INSTICC, SciTePress.

Rahman, N. N. S. A., Saad, N. M., Abdullah, A. R., and

Ahmat, N. (2019). A REVIEW OF VISION BASED

DEFECT DETECTION USING IMAGE PROCESS-

ING TECHNIQUES FOR BEVERAGE MANUFAC-

TURING INDUSTRY. Jurnal Teknologi, 81(3).

Rocha, C. S., Menezes, M. A. G., and Oliveira, F. G.

(2016). Detecc¸

˜

ao autom

´

atica de microcomponentes

smt ausentes em placas de circuito impresso. In

ICINCO 2022 - 19th International Conference on Informatics in Control, Automation and Robotics

756

Menotti, D. and Miranda, P., editors, Workshop on In-

dustry Applications (WIA) in the 29th Conference on

Graphics, Patterns and Images (SIBGRAPI’16), vol-

ume 1, S

˜

ao Jos

´

e dos Campos, SP, Brazil.

Srivastava, A., Tolle, I., Mraz, A., Gupta, S., Huang, R.,

Nguyen, H., Dey, L., Jain, A., Lee, S.-H., and Kini, S.

(2016). Non-traditional inspection strategy for inline

monitoring in excursion scenarios: Defect inspection.

In 2016 27th Annual SEMI Advanced Semiconductor

Manufacturing Conference (ASMC), pages 197–200.

Thielen, N., Werner, D., Schmidt, K., Seidel, R., Reinhardt,

A., and Franke, J. (2020). A machine learning based

approach to detect false calls in smt manufacturing. In

2020 43rd International Spring Seminar on Electron-

ics Technology (ISSE), pages 1–6.

Vafeiadis, T., Dimitriou, N., Ioannidis, D., Wotherspoon, T.,

Tinker, G., and Tzovaras, D. (2018). A framework for

inspection of dies attachment on PCB utilizing ma-

chine learning techniques. Journal of Management

Analytics, 5(2):81–94.

Viola, P. and Jones, M. (2001). Rapid object detection us-

ing a boosted cascade of simple features. In Proceed-

ings of the 2001 IEEE Computer Society Conference

on Computer Vision and Pattern Recognition. CVPR

2001, volume 1, pages I–I.

Zhang, K., Huang, T., Su, Z., and Guan, T. (2021). De-

sign of solder quality inspection system based on ma-

chine vision. In 2021 IEEE 5th Advanced Information

Technology, Electronic and Automation Control Con-

ference (IAEAC), volume 5, pages 2413–2418.

Zhang, Q., Zhang, M., Gamanayake, C., Yuen, C., Geng,

Z., Jayasekara, H., wei Woo, C., Low, J., Liu, X.,

and Guan, Y. L. (2022). Deep learning based sol-

der joint defect detection on industrial printed circuit

board x-ray images. Complex & Intelligent Systems,

8(2):1525–1537.

Zhou, D., Zhang, G., and Guo, Y. (2017). Detecting multi-

interface from oil-water separation image based on

difference statistics method. In 2017 IEEE Inter-

national Conference on Smart Cloud (SmartCloud).

IEEE.

Zhou, J. G., Chen, H., Long, Y., Wang, K., Guo, H., and

Liu, F. (2021). Backside defect monitoring strat-

egy and improvement in the advanced semiconductor

manufacturing. In 2021 China Semiconductor Tech-

nology International Conference (CSTIC), pages 1–5.

The Visual Inspection of Solder Balls in Semiconductor Encapsulation

757