QUALITATIVE AND QUANTITATIVE PROBABILISTIC

TEMPORAL REASONING

for Industrial Applications

Gustavo Arroyo Figueroa

Electrical Power Research Institute, Reforma # 113, Cuernavaca, Morelos, México.

Keywords: Bayesian networks, temporal r

easoning, uncertainty, diagnosis, thermal power plants.

Abstract: Many real-world domains, such as industrial diagnosis, require an adequate representation that combines

uncertainty and time. Research in this field involves the development of new knowledge representation and

inference mechanisms to deal with uncertainty and time. Current temporal probabilistic models become too

complex when used for real world applications. In this paper, we propose a model, Temporal Events

Bayesian Networks (TEBN), based on a natural extension of a simple Bayesian network. TEBN tries to

make a balance between expressiveness and computational efficiency. Based on a temporal node definition,

causal-temporal dependencies are represented by qualitative and quantitative relations, using different time

intervals within each variable (multiple granularity). Qualitative knowledge about temporal relations

between variables is used to facilitate the acquisition of the quantitative parameters. The inference

mechanism combines qualitative and quantitative reasoning. The proposed approach is applied to a thermal

power plant through a detailed case study, with promising results.

1 INTRODUCTION

In the last years the operating conditions of thermal

power plants have changed. Today, the operation of

thermal power plants must be optimal considering

higher productions profits, safer operation and

stringent environment regulation. An additional

factor is the increment of the age of the plants. The

reliability and performance of the plants is affected

by its age. This means and increase in the number of

equipment failures, thus increasing the number of

diagnoses and control decisions which the human

operator must make. Under this conditions the

complexity of the operation of thermal power plants

have been increased significantly.

As a result of these changes, the computer and

i

nformation technology have been extensively used

in thermal plant process operation. Distributed

control systems (DCS) and information management

systems (IMS) have been playing an important role

to show the plant status. However, in nonroutine

operations such as equipment failures and extreme

operation (start up phase, changes in the load, etc.),

human operators have to rely on their own

experience. During disturbances, the operator must

determine the best recovery action according to the

type and sequence of the signals received. In a major

upset, the operator may be confronted with a large

number of signals and alarms, but very limited help

from the system, concerning the underlying plant

condition. Faced with vast amount of raw process

data, human operators find it hard to contribute a

timely and effective solutions.

The process industry demands new computer

integrate

d technologies the reduce operator´s

working burden by providing operation support

systems. Process operations are knowledge-intensive

work task because thermal plants are large, complex

and influenced by unexpected disturbances and

event over the time. Artificial Intelligent applications

and expert systems in particular, are recognized as

providing efficient solutions to wide range of

industrial problems.

Artificial intelligence applications are showing a

trend

toward to real world domains, such as medicine,

real-time diagnosis, communications, planning,

financial forecasting and scheduling. These

applications have revealed a great need for powerful

methods for knowledge representation. In particular,

the evolutionary nature of these domains requires a

representation that takes into account temporal

information. The exact timing information for things

like lab-test results, occurrence of symptoms,

151

Figueroa G. (2004).

QUALITATIVE AND QUANTITATIVE PROBABILISTIC TEMPORAL REASONING - for Industrial Applications.

In Proceedings of the First International Conference on Informatics in Control, Automation and Robotics, pages 151-156

DOI: 10.5220/0001133701510156

Copyright

c

SciTePress

observations, measures, as well as faults, can be

crucial in this kind of applications.

Aside from temporal considerations, the world

domain knowledge is imprecise, incomplete and not

deterministic. The temporal model must be able to

deal with uncertainty. Among the many formalism

proposed for dealing with uncertainty, one of the most

used techniques for the development of intelligent

systems are probabilistic networks, also known as

Bayesian Networks, causal networks or probabilistic

influence diagrams. Bayesian networks (BN) are a

robust and sound formalism to represent and handle

uncertainty in intelligent systems in a way that is

consistent with the axioms of probability theory (Pearl,

2000). Although BN were not designed to model

temporal aspects explicitly, recently Bayesian

networks have been applied to temporal reasoning

under uncertainty (Santos 1996; Arroyo and Sucar,

1999, Galan and Diez 2002). Prior temporal modeling

techniques have often made a trade-off in

expressiveness between semantics for time and

semantics for uncertainty. Therefore, to integrate

uncertainty and time, it’s necessary a combined

approach integrating strong probabilistic semantics for

representing uncertainty and expressive temporal

semantics for representing temporal relations.

In this paper, we present the definition and

application of an approach for dealing with

uncertainty and time called Temporal Event

Bayesian Network, based on a natural extension of a

simple Bayesian network. TEBN tries to make a

balance between expressiveness and computational

efficiency. Based on a temporal node definition,

causal-temporal dependencies are represented by

qualitative and quantitative relations, using different

time intervals within each variable (multiple

granularity. The inference mechanism combines

qualitative and quantitative reasoning. The proposed

approach is applied to the diagnosis and prediction

of events and disturbances (events sequence) to

assist the operator in real time assessment of plant

disturbances, and in this way contribute to the safe

and economic operation of thermal power plants.

2 DEFINITION OF A TEBN.

Temporal Event Bayesian Network (TEBN) allows the

representation of temporal and atemporal information

in a probabilistic framework. A TEBN is capable of

representing each variable with its interactions over

multiple points of time. The domain is defined over

time intervals. The state of the domain is represented

by a value at a given time interval. Santos (Santos

1996) use a similar concept, but they used the time

interval only as a temporal constraint. In our approach,

a time interval is an additional component of the

network.

TEBN make a balance between the robust

semantics of Bayesian Networks and the expressive

temporal semantics of the interval algebra. The

temporal expressiveness is defined by the time

intervals. The balance between the exactness and the

complexity of the temporal model is a function of

the numbers of time intervals.

Intuitively, a temporal node consists of a set of

states or values, e.g. {true, false}, {occur, does not

occur}, {high, normal, low}, that the variable or

event can take, and a set of temporal intervals

associated to each state or value of the variable or

event.

Definition 1. A Temporal Node (TN) is an

ordered pair (E, I) in which E is a set of states or

values of a random variable, and I is a set of time

intervals associated to each state or value of the

variable.

Definition 2. A causal-temporal relationship

(CTR) describes a relationship between two

temporal nodes A(Ea, Ia) and B(Eb, Ib), where A is

considered the “cause” and B is considered the

“effect”. Formally, the CTR is written as A(R, P)B

where R is the set of temporal qualitative

relationship between the time intervals, and P is the

causal-temporal quantitative relationship, defined as

a conditional probability matrix. Graphically, a CTR

is represented by a directed edge from the cause

node to the effect node, labeled with R, with a joint

probability distribution P.

A Temporal Event Bayesian Network is a

directed acyclic graph, which consists of finite set of

temporal nodes and a finite set of causal-temporal

relationships.

Definition 3. A TEBN is an ordered pair, (N, T),

where N is a set of temporal nodes and T is set of

causal-temporal relationships given by R and P. Then

EBN=(E, I, R, P) is called a Temporal Event Bayesian

Network.

The TEBN model has two reasoning

mechanisms: qualitative and quantitative temporal-

causal reasoning. Qualitative reasoning is based on

the interval algebra [Allen, 1983]. It is important to

know the qualitative information about the timing

relationships between the events. The qualitative

reasoning has two levels of abstraction. In a superior

level, we use a simplified temporal diagram of the

history of the process using Allen’s representation in

order to define the general relation between the

temporal range of occurrence of the events. In an

inferior level, we apply the transitivity algorithm to

get the temporal relations between each time interval

that defines the temporal node. Qualitative reasoning

permits an early diagnosis of the domain based on

the temporal consistency. This early diagnosis gives

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

152

a preliminary idea about state of domain. The

qualitative mechanism is explained in more detail in

the example of the next section.

The quantitative reasoning mechanism is based

on probability propagating. The method for

propagating probabilities of a TEBN is an extension

of the polytree and multiconnected algorithms

proposed in the literature (Pearl, 2000). For some

evidence e at the time interval u the posterior

probability of a variable B is as follows:

P(e,u

k ⏐

b

i

,o

j

) P(b

i

,o

j

)

P((b

i

o

j

) | (e,u

k

)) = ------------------------

P(e,u

k

)

where P((b

i

,o

j

) | (e,u

k

)) is the probability associated to

the value b

i

in time interval o

j

given the evidence e in

the time interval u

k

.

The reasoning in TEBN consists in instantiating the

input temporal variables (this can be any variable into

the network) and propagating their effect through the

network to update the probability of the hypothesis

variables (diagnosis and prediction). The reasoning

mechanism starts when a temporal variable is

instantiated, and the probability of all temporal nodes

is update. The quantitative reasoning gives the state of

the domain with some probability value.

The qualitative knowledge about temporal

relations between temporal nodes is relatively easy to

obtain from domain experts. With this knowledge is

possible to know the temporal relations between

events and this is used to facilitate the acquisition of

the quantitative parameters (conditional probabilities).

For instance, given a particular qualitative relation

between nodes A and B, some values in the

conditional probability matrix, P(B/A), are set to zero.

3 AN EXAMPLE OF

APPLICATION

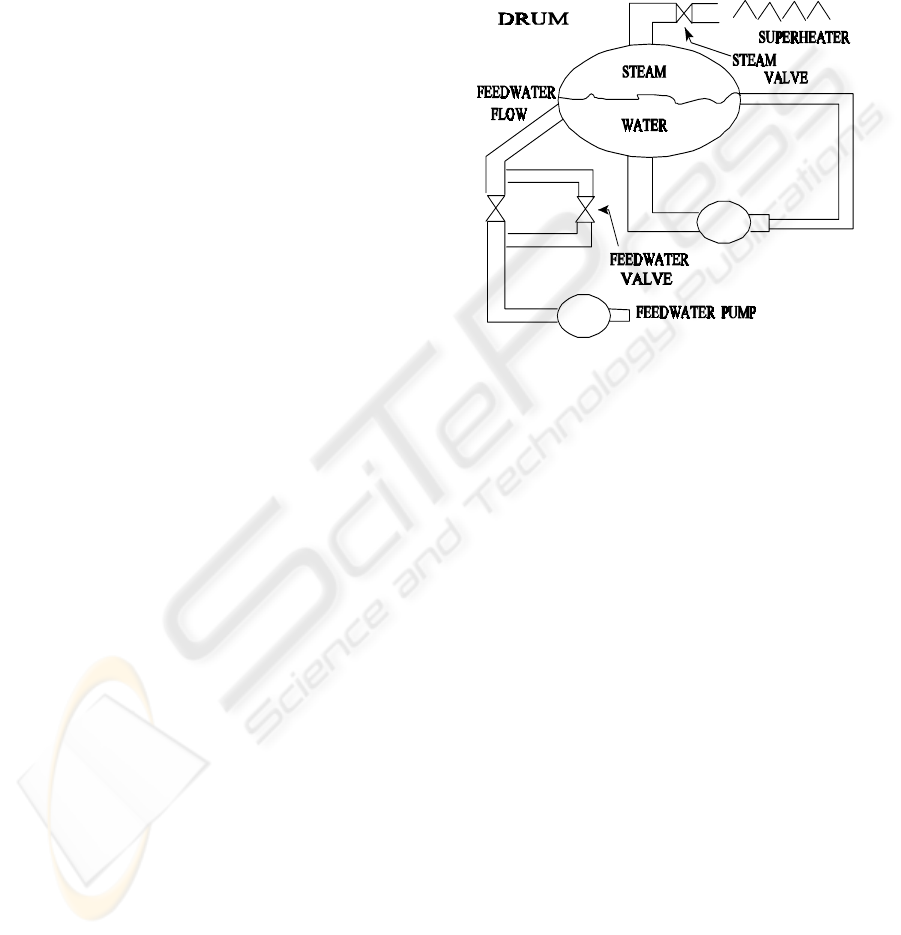

As an illustrative example, we present the drum level

disturbance when a power load increment occurs. The

drum is a subsystem of a thermal power plant. This

subsystem provides steam to the superheater and water

to the water wall of a steam generator. Figure 1 shows

a simplified diagram of a drum system in a thermal

power plant. For the proposes of demonstration,

assume the following hypothetical case.

"The drum is a tank with a steam valve at the

top, a feedwater valve at the bottom, a feedwater

pump which provides water to the drum and a level

control system. The drum level (DRL) can increase

by the increase of the feedwater flow (FWF). The

feedwater flow can increase by two main causes: the

augmentation in the current of feedwater pump

(FWP) and the increase of the opening of the

feedwater valve (FWV). This will lead to an increase

in drum level to a dangerous level. The operator

must open the steam valve in order to increase the

steam flow. This will lead to a reduction of the water

drum level in the drum tank so that the level will

decrease to safe levels. Both disturbance can lead to

down thermal power plant”.

Figure 1: Steam Generator Drum system.

In the process, a signal exceeding its specified limit

of normal functioning is called as an event, and a

sequence of events that have the same underlying

cause are considered as a disturbance. In the

example, the feedwater flow (FWF) can be caused

by two different disturbances: a power load

increment or a control system failure. These

disturbances are characterized respectively by the

feedwater current augmentation (+FWP) and

feedwater opening increase (+FWV).

To determine which of both disturbances are

present is a complicated task. We need additional

information to determine which it is the real cause.

One of these is the temporal information. We can

select the hypothesis of failure according to the time

interval in which the disturbance occurs. The

dynamic of the FWP is faster than the dynamic of

the FWV. In order to reason about the sequence of

facts and disturbances that occur, we require a

temporal representation.

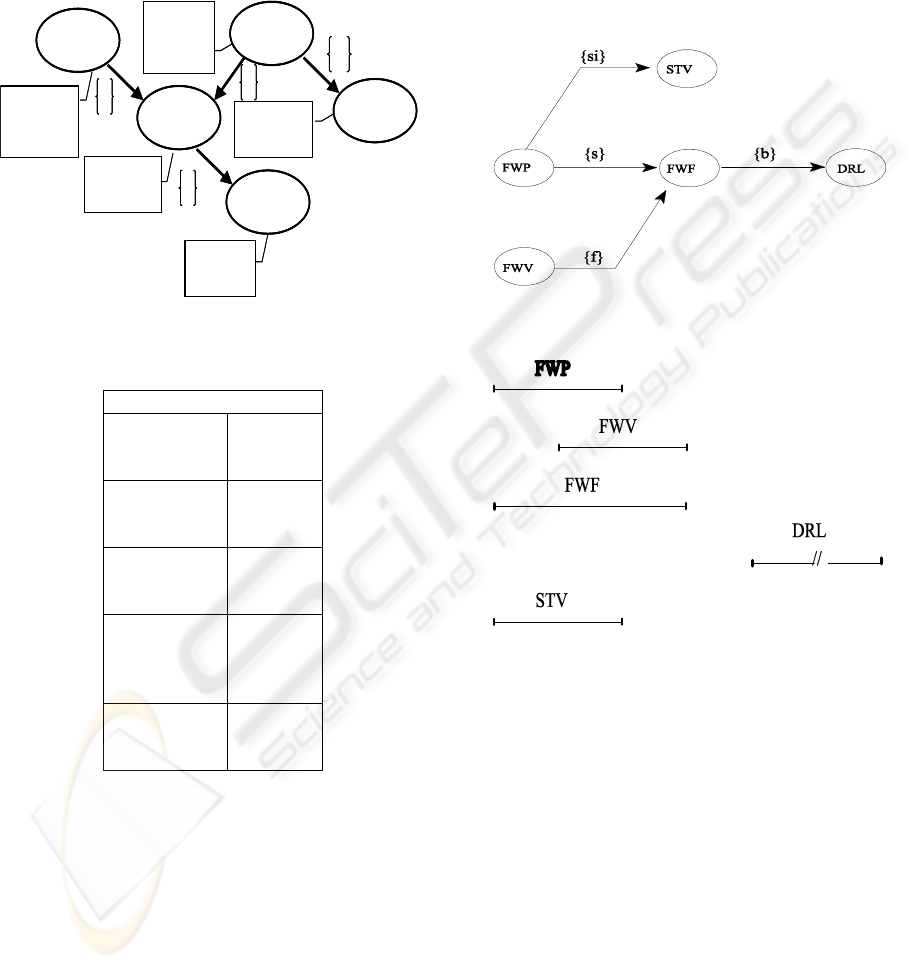

The knowledge representation uses the Allen’s

interval algebra (Allen, 1983) and its thirteen

relations as temporal basis definition and a

probabilistic framework for dealing with quantitative

uncertainty. Figure 2 and table 1, depict a small

TEBN with five temporal nodes, four edges,

temporal relations between nodes and a priori

probabilities. Each temporal node is associated to its

time intervals., all nodes except the node steam

valve have two time intervals. The formalism is

QUALITATIVE AND QUANTITATIVE PROBABILISTIC TEMPORAL REASONING - for Industrial Applications

153

based on the probability of the event occurrence at a

time interval. In this case, the TEBN is an event

network (occurs or does not occur): the event occurs

at the time interval one (for example FWP, O1); the

event occurs at the time interval two (FWP, O2); and

the event does not occur (FWP). The events might

occur only in single time interval.

Figure 2: TEBN for Drum system example.

Table 1: Event probabilities for TEBN

Event Probabilities

FWV, I1

FWV, I2

¬FVW

0.30

0.60

0.10

FWP, O1

FWP, O3

¬FWP

0.60

0.30

0.10

FWF, U1

FWF, U2

¬FWF

0.51

0.48

0.01

STV, Q1

STV, Q2

STV, Q3

¬STV

0.47

0.29

0.12

0.12

DRL,R1,

DRL, R2

¬DRL

0.51

0.48

0.01

4 PROCESS DIAGNOSIS

EXAMPLE

In this section we present the application of the

TEBN model for diagnosis of disturbances in the

drum system depicted in section three. According to

the example, there are two possible causes of an

increase in the feedwater flow (FWF): an

augmentation in feedwater pump current and an

increase in the opening of the feedwater valve.

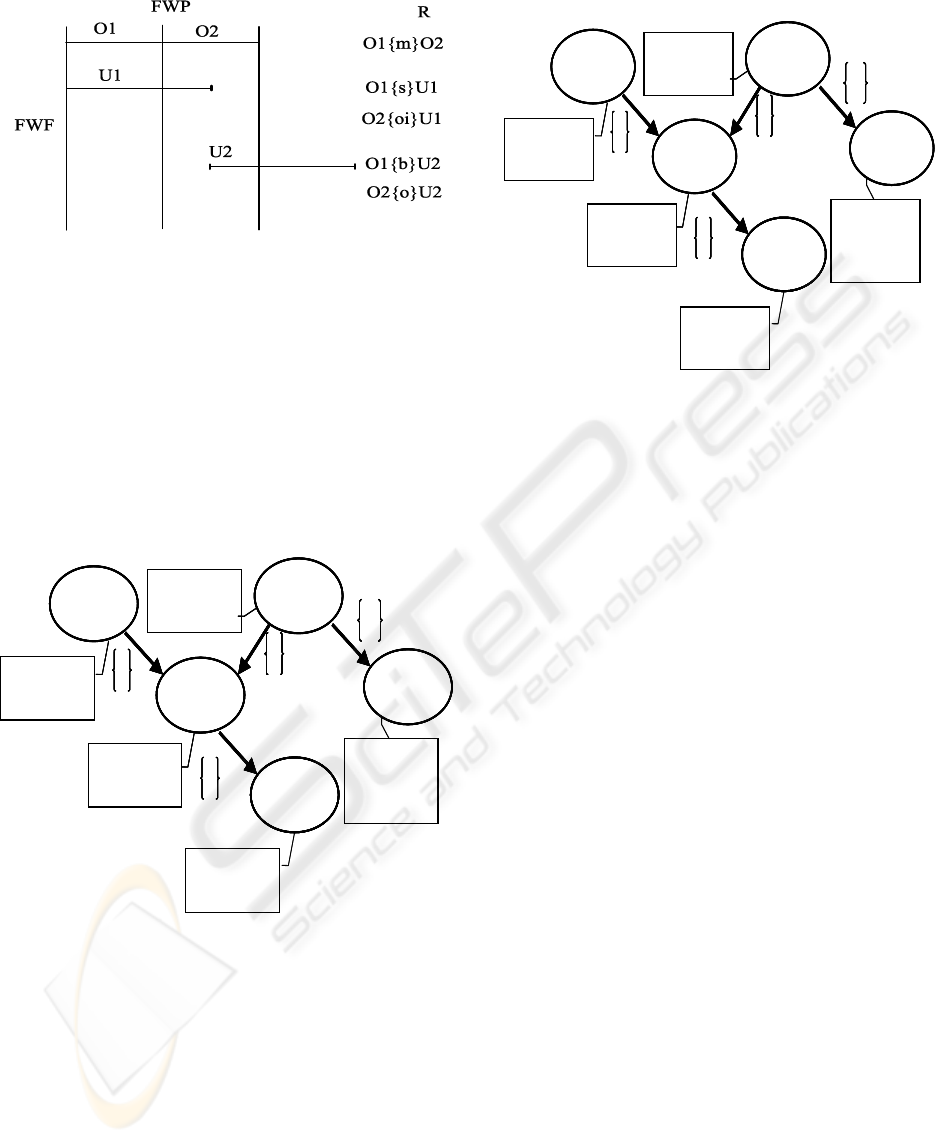

Figure 3 and figure 4 show the simplified

temporal diagram and the consistent scenario of the

drum level disturbance. Theses diagrams define the

qualitative temporal relation between the time range

of event occurrence. For instance the temporal

relation between the temporal range of FWP and

FWF is start and the temporal relation between the

temporal range of FWV and FWF is finishes.

FWV

Feedwater

valve

opening

increase

FWF

STV

DRL

FWP

Feedwater

pump

current

increase

Feedwater

flow

increase

Drum

Level

High

Steam

valve

increase

f

b

si

s

FWV

FWV

Feedwater

valve

opening

increase

FWF

FWF

STV

STV

DRL

DRL

FWPFWP

Feedwater

pump

current

increase

Feedwater

flow

increase

Drum

Level

High

Steam

valve

increase

f

f

b

b

si

si

s

s

Figure 3: Simplified temporal diagram of the drum

system.

Figure 4: Temporal consistent scenario of the drum

system.

Figure 5, shows the temporal relations between the

time intervals of node FWP and node FWF. The

intervals at the top, O1 and O2 represent the time

intervals of FWP and the intervals U1 and U2

represent the time interval of the FWF. The relations

between the four intervals are shown in the right.

These relations can be obtained for each pair of

nodes. Both diagrams, permits to made a preliminary

selection of hypotheses and give an initial idea about

the disturbance (faulty) that occurs. For this the time

relations are considered, which produce a set of

temporal constraints that permit to select some

hypotheses using a consistency algorithm.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

154

Figure 5: Temporal relations between the FWP and FWF

time intervals

Quantitative reasoning in the TEBN gives the most

probable hypotheses. The causal-temporal

relationships between events are used for

determining the most probable cause (disturbance).

For instance, the figure 6 depicts the case when the

event drum level high (DRL) occurs in the time

interval R1. In this case the most probable cause is a

feedwater pump current augmentation (+FWP). This

disturbance may be characterized by a power load

increase.

Figure 6: The drum level high occurs at the time interval

R1

Figure 7 depicts the case when the drum level high

(DRL) occurs in the time interval R2. In this case the

most probable cause is an increase in the opening of

the feedwater valve. This disturbance may be

characterized by a failure in the level control system.

To confirm which is the most probable disturbance

is needed the time of occurrence of the increase of

feedwater flow. This reasoning makes it possible to

answer questions such as: “The event drum level

high occurred 1:30 minutes after that the feedwater

flow increase occurred. What is the most probable

disturbance (cause)?”.

FWV

FWF

STV

FWP

f

b

si

s

FWV

FWV

FWF

FWF

STV

STV

DRL

DRL

DRL

FWPFWP

f

f

b

b

si

si

s

s

DRL, R1 = 0.00

DRL, R2 = 1.00

¬DRL = 0.00

STV, Q1 = 0.36

STV, Q2 = 0.32

STV, Q3 = 0.15

¬STV = 0.17

FWP, O1 = 0.43

FWP, O2 = 0.39

¬FWP = 0.18

FWV, I1 = 0.29

FWV,I2 = 0.70

¬FWV = 0.01

FWF U1 = 0.05

FWF,U2 = 0.95

¬FWF = 0.00

FWV

FWV

FWF

FWF

STV

STV

FWPFWP

f

f

b

b

si

si

s

s

FWV

FWV

FWF

FWF

STV

STV

DRL

DRL

DRL

DRL

DRL

DRL

DRL

FWPFWP

f

f

b

b

si

si

s

s

s

s

DRL, R1 = 0.00

DRL, R2 = 1.00

¬DRL = 0.00

STV, Q1 = 0.36

STV, Q2 = 0.32

STV, Q3 = 0.15

¬STV = 0.17

FWP, O1 = 0.43

FWP, O2 = 0.39

¬FWP = 0.18

FWV, I1 = 0.29

FWV,I2 = 0.70

¬FWV = 0.01

FWF U1 = 0.05

FWF,U2 = 0.95

¬FWF = 0.00

Figure 7: The drum level high occurs at the time interval

R2

In this model, the time range definition of the

intervals is independent of the hour of the day. In

many real-domains the events do not occur as a

function of the day hour. Under this situation, the

TEBN is a model relative, not absolute. The

reasoning mechanism starts when any event in the

network is detected. The time interval definition is

only dependent of the causal-temporal relationships

between the events.

FWV

FWF

STV

FWP

f

b

si

s

FWV

FWV

FWF

FWF

STV

STV

DRL

DRL

DRL

FWPFWP

f

f

b

b

si

si

s

s

DRL, R1 = 1.00

DRL, R2 = 0.00

¬DRL = 0.00

STV, Q1 = 0.59

STV, Q2 = 0.26

STV, Q3 = 0.10

¬STV = 0.05

FWP, O1 = 0.77

FWP, O2 = 0.22

¬FWP = 0.01

FWV, I1 = 0.32

FWV,I2 = 0.52

¬FWV = 0.16

FWF U1 = 0.95

FWF,U2 = 0.04

¬FWF = 0.01

FWV

FWV

FWF

FWF

STV

STV

FWPFWP

f

f

b

b

si

si

s

s

FWV

FWV

FWF

FWF

STV

STV

DRL

DRL

DRL

DRL

DRL

DRL

DRL

FWPFWP

f

f

b

b

si

si

s

s

s

s

DRL, R1 = 1.00

DRL, R2 = 0.00

¬DRL = 0.00

STV, Q1 = 0.59

STV, Q2 = 0.26

STV, Q3 = 0.10

¬STV = 0.05

FWP, O1 = 0.77

FWP, O2 = 0.22

¬FWP = 0.01

FWV, I1 = 0.32

FWV,I2 = 0.52

¬FWV = 0.16

FWF U1 = 0.95

FWF,U2 = 0.04

¬FWF = 0.01

The use of qualitative reasoning mechanism

permits an early diagnosis. The early diagnosis gives

a preliminary idea of the events and disturbance that

occurred. The quantitative reasoning gives the

occurrence of events and disturbances with some

probability values. The TEBN has been applied into

two systems of a steam generator: drum level system

and condenser system. The result obtained in this

two subsystems indicate that it can be useful for

many uncertainty temporal reasoning tasks that

involve prediction and diagnosis in real complex

environments (Arroyo et al., 2000).

5 EMPIRICAL EVALUATION

Table 2 summarizes the results of simulating failures

for the four disturbances of the feedwater and

superheater systems. The process data was generated

by a full scale simulator of a thermal power plant. We

selected 80% of this data-base (800 registers) for

parameter learning and 20% (200 registers) for

evaluation. The model was evaluated empirically

using two scores: accuracy and a measure based on the

Brier score (total square error). The Brier score is

defined as: BS = Σ

n

i=1

(1 – P

i

)

2

. P

i

is the marginal

posterior probability of the correct value of each node

QUALITATIVE AND QUANTITATIVE PROBABILISTIC TEMPORAL REASONING - for Industrial Applications

155

given the evidence. The maximum Brier score is:

BS

MAX

= Σ

n

(1)

2

. A relative Brier score is defined as:

RBS (in %) = {1 – (BS

/ BS

MAX

) } x 100.

The results of the evaluation are shown in terms of

the mean and the standard deviation for both scores.

These results show the prediction and diagnosis

capacity of the temporal model in a real process. Both

scores are between 80 and 97% for all the set of tests,

with better results when intermediate nodes are

observed, and slightly better results for prediction

compared to diagnosis. We consider that these

differences have to do with the “distance” between

assigned and unknown nodes and with the way that the

temporal intervals were defined. We are encouraged

by the fact that the model can produce a reasonable

accuracy in times that are compatible with real time

decision making.

Table 2: Empirical evaluation results

Parameter µ σ

Prediction

% of RBS

% of accuracy

87

84

9.19

14.98

Diagnosis

% of RBS

% of accuracy

84

80

8.09

11.85

Diagnosis and

prediction

% of RBS

% of accuracy

96

95

4.71

8.59

6 CONCLUSIONS

The TEBN generates a formal and systematic

structure used to model the temporal evolution of

dynamics domains. TEBN is a hybrid model that

combines a qualitative representation based on

interval algebra with a quantitative representation

based on a natural extension of Bayesian networks.

Each event or variable occurrence is associated with

a time interval. The definition of the numbers of

time intervals for each variable is free (multiple

granularity) and can be see as a trade off between

the complexity and the accuracy needed for

depicting the knowledge of the temporal domain.

The model combines qualitative and quantitative

causal-temporal reasoning mechanisms. The

qualitative reasoning mechanism is based on the

interval algebra and permits an early diagnosis. The

early diagnosis gives a preliminary idea about of

process state. The quantitative reasoning mechanism

is based on the propagation of probabilities and

gives the occurrence of events and disturbances with

some probability values.

The formalism satisfies the requirements of

temporal knowledge acquisition, low computational

cost and temporal expressiveness. The qualitative

knowledge about temporal relations between

temporal nodes is relatively easy to obtain from

domain experts and is used to facilitate the

acquisition of the quantitative parameters

(conditional probabilities).

Our future work will be focused on developing and

integrating an intelligent support system (ISS) to aid

the operation of human operators of thermal power

plants. The ISS will be integrate by four modules:

signal validation, supervisory system, diagnostic

system, and planning systems. The ISS will be used to

assist an operator in real-time assessment of plant

disturbances and in this way contribute to the safe and

economic operation of power plants.

REFERENCES

J. F. Allen, 1983. Maintaining Knowledge about Temporal

Intervals. Communications of the ACM, 26(11):832-

843.

G. Arroyo-Figueroa and L.E. Sucar, 1999. A temporal

Bayesian Network for diagnosis and prediction, In Proc.

15

th

UAI Conference, 13-20.

G. Arroyo-Figueroa, Y. Alvarez and L.E. Sucar, 2000,

SEDRET-an intelligent system for the diagnosis and

prediction of events in power plants, Expert Systems with

Applications, 18:75-86.

S. F. Galan and F. J. Diez, 2002. Networks of probabilistic

events in discrete time, Int. J. of Approximate Reasoning,

30 : 181-202.

Peter Haddawy, 1996. A Logic of Time, chance, and

action for representing plans. Artificial Intelligence,

80(2), 243-308, 1996.

K. Murphy, 2002, Dynamic Bayesian Networks:

Representation, Inference and Learning, PhD Thesis,

UC Berkeley, Computer Science Division.

Judea Pearl, 2000, Causality, models, reasoning and

inference, Cambridge University Press: London.

E. Santos Jr. and J. D. Young, 1996, Probabilistic Temporal

Networks. Report AFIT/EN/TR96-006 AFIT.

ICINCO 2004 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

156