Remote Laboratory for Industrial Automation

Rui Delgado

1

, Gustavo Santos

1

, Carlos Cardeira

1

, J. R. C. Pinto

1

, Rui Loureiro

2

,

Otto Leichsenring

3

1

Lisbon Technical University, Instituto Superior Técnico, GCAR – DEM, 1049-001 Lisboa

2

GOM, 1500-371 Lisboa

3

Infocontrol - Electrónica e Automatismos, 2745-740 Massamá

Abstract.

In this paper we present a remotely accessed experiment on

industrial automation. Using this remote access, students may verify the

correctness of their previous work and increase the productivity of laboratory

classes. The experiment provides a web page for interfacing with a

Programmable Logic Controller (PLC) which controls an electro-pneumatic

process. Students may remotely download the program to the PLC and access

to the PLC states and variables remotely, allowing the detection of semantic

errors. Moreover a Webcam shows the image of the process which, not being

essential, provides a more realistic view of the program correctness. The user

has access to the system inputs through a web based Human-Machine Interface

(HMI). This paper results from collaboration between a PLC solution provider

and the university.

1 Introduction

In engineering, good practice is the key to an efficient learning. However in academic

environments sometimes the physical resources and the time available for access to

equipment are not enough. Students usually have a few hours of weekly access to

their laboratory equipments to perform their experiments. Even if they correctly do

their home work something can go wrong during the laboratory access time and ruin

the process.

The worldwide spread of the I

n

ternet and its general acceptance has brought new

opportunities in distance learning as well in traditional learning [2]. Consequently the

concepts of virtual and remote laboratories appear. The first ones use software

simulation of physical devices. The second ones provide remote access to real

laboratory equipment and instruments [1].

As in [1] the common principle of remote laboratory experimentations is that learners

can cha

n

ge system parameters through Internet. Then a special interface converts

those parameters to comprehensible and acceptable data for the local equipments.

These have many advantages as:

Delgado R., Santos G., Cardeira C., R. C. Pinto J., Loureiro R. and Leichsenring O. (2004).

Remote Laboratory for Industrial Automation.

In Proceedings of the First International Workshop on e-Learning and Virtual and Remote Laboratories, pages 28-37

DOI: 10.5220/0001150800280037

Copyright

c

SciTePress

Resource sharing becomes a reality, improving the utilization of costly equipment [2].

Increase of test time in academic environments.

Reduction of class excessive congestion.

We focus that previous simulation is an excellent tool for increasing the productivity

during automation lab sessions. In the automation field, tools like Automation Studio

provide an effective way for students simulate their circuits (pneumatic, electrical or

hydraulic) and to test if the PLC program (Ladder Diagrams or Sequential Flow

Charts) do behave like expected. This previous work of simulation highly increases

the productivity of laboratory sessions. Even without access to such tools, students

may use simple programs made on standard languages to test the correctness of their

logical expressions.

But even using simulation software tools, they are not able to generate code to all the

PLC brands. Some brands are already covered, but in many cases it is still mandatory

to make use of the software tools provided by the PLC manufacturer.

Hence, even if the PLC manufacturer provides free programming software for all the

students, students are only able to detect syntax errors. Existing semantic may only be

detected with a connection to a PLC. It becomes very useful to provide a remote

accessed PLC letting students download their code to the remote PLC, allowing the

detection and correction of semantic errors. Moreover, a web interface for the remote

lab provides the student the ability to simulate inputs activation of the PLC as well as

other useful information for the system state variables. This remote laboratory was

idealized to be used by students of classes of automation and control for their

laboratory class works elaboration.

2 State of the Art

The use of virtual laboratories or remote laboratories are current practices for

increasing the productivity of laboratory courses.

Remote laboratories for automation provide students a full day long access to the

laboratory equipment (24 hours a day and 7 days a week), letting them have time to

correct almost all sorts of errors on their programs.

In our days Internet can easily be a remote gateway to the physical laboratory. It can

be used to remotely provide the realism of local environments [1], where users can

plan and conduct experiments, collect experimental data, and analyse the results as if

they were physically present in the laboratory [2].

This is an area being explored in actual scientific researches, and some solution are

presented using software simulation as Mathworks/Matlab+Simulink [5] or National

Instruments Labview [4] . Other approaches exist [1] [6] using JAVA technologies.

This work regards a remote laboratory for automation. It introduces an approach for a

remote laboratory using SAIA software and hardware, which also allows, easily, the

conception of HMI (Human-Machine Interface) using HTML and Javascript, visible

at any web browser, with a certain level of security in the remote access of these

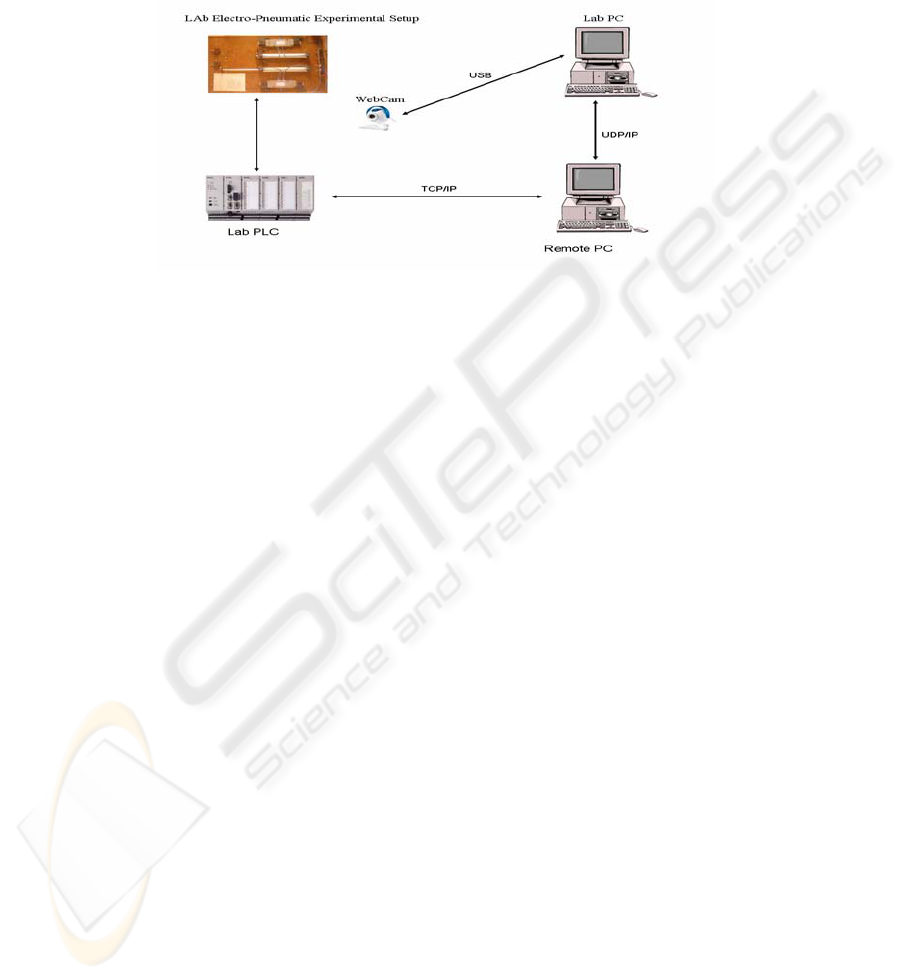

interfaces (Fig.1).

27

3 Proposed Solution

A remote laboratory has two distinct elements: the physical laboratory equipment, and

the remote PC that controls and supervisions it.

Fig. 1. System architecture.

In our system the laboratory equipment consists of SAIA-BURGESS PCD4.M170

PLC, where previously programmed routines, should be downloaded and tested. This

PLC can have connected other equipments as electro-pneumatic experimental setups,

energetic analysers, access control readers, etc.

This PLC has integrated a Web Server, which supports the allocation of HTML files

and communicates with remote PCs, via a TCP/IP protocol. For this effect the PLC

has incorporated an Ethernet RJ45 Connector.

Using the specific SAIA PG5 application in the remote Personal Computer (PC), any

user can connect, download, test and debug remotely his programmed routines as if he

was on site. The remote PC can also run a specific Web Server (SAIA Web-Connect)

which allows the access of the HTML pages allocated in the PLC at any Web browser

to anyone with permission. In this way HMI can easily be conceived and accessed to

remotely control and monitor the PLC using the widely spread acknowledgement of

HTML and Javascript languages. In order to provide a live view of what is happening

in the laboratory a Webcam is used connected via USB to a local PC.

For the video communication between the Lab PC and the remote PC a typical

internet live video conference application can be used. Any user simply connects

remotely to the Lab PC and watches what’s happening in the laboratory.

3.1 Communication PLC-Remote PC

The communication between the PLC and the PC running the Web Server can be

made using TCP/IP, S-BUS or PGU. The last two modes are specific for SAIA PLCs.

They use a RS232 connection and the communication and respective configuration is

made with the Web Server provided by SAIA-BURGESS (SAIA Web-Connect)

which is installed in the PC [11]. Since the PC is located remotely the implemented

28

solution was made through TCP/IP. SAIA-Burgess Web Server functions are split:

The PLC has the responsibility to do the file administration while the PC running the

Web Server handles the requests from TCP/IP communications used to call control

and monitoring functions. It is then possible to communicate between the PC and

PLC using a simple, efficient protocol that uses fewer resources than TCP/IP.

Reduced to the transfer function, this protocol does not affect the real-time behaviour

of the PLC. Standard browsers, like Microsoft Internet Explorer or Mozilla, make file

requests to the Web Server using the TCP/IP protocol. To enable communication with

the Web Server in the PLC, the Web-Connect software must be installed on a PC,

which works as the communication part of the Web Server. Web-Connect receives

those requests from the browser using the TCP/IP protocol and forwards them with an

efficient protocol from the PC to the PLC. This is made using one of the possible

communication modes previously configured. PLC answers are converted back into

TCP/IP and sent to the browser. Some advantages of this Web Server are: Simple and

low-cost creation of control and monitoring interfaces (HMI) with familiar HTML

editors, such as Frontpage or Dreamweaver; Control and Monitoring of the system

accessing the interface with commonly used web browsers, like Microsoft Internet

Explorer or Mozilla.

The configuration is made using a setup page pre-built in the Web Server accessed

with a common web browser at a location http://<pc-ip-address>/setup. After the

station configuration the web interface can be accessed at a location http://<pc-ip-

address>/<station-name>.

3.2.1 HTML Server

The HTML Server is the core of the Web Server. Its function is sending HTML pages

requested by the web browser (as well as images) across the S-BUS Driver to the PC.

HTML pages or images are stored in the user files memory of the PLC, which were

previously downloaded to it, along with the remaining program.

The HTML server also checks HTML pages for possible existing Process Data Point

(PDP) identification key.

When the HTML Server finds a PDP key in a HTML page, sends it to the Data Server

which transfers them in the requested PLC data from the PLC’s memory back to the

HTML Server.

PDP keys are embedded in the HTML code, being used for addressing PLC data.

Below are some examples of these keys application:

%%PDP,,I16,B% addressing one input “I16” and format is binary.

%%PDP,,R300,F% addressing the register 300, format is in floating point.

%%PDP,,DB10.20,d% addressing Data Block 10, element 20, format is decimal.

More detailed information about the Web Server and its individual elements can be

seen in [7].

3.3 Examples

The system described in this article can be used by students to develop possible

solutions to problems presented to them in lessons such as the ones below:

29

3.3.1 First problem: Secure Turn-On

“When machines operation may wound operators, a safety measure consists in

requiring that the machine only starts when two switches are pressed, to force the

operator to use both hands, improving his security conditions. A commonly used trick

used by irresponsible operators consists in using something to keep one the buttons

pressed (like a matchstick), and using only the other button, keeping the other hand

free. To prevent this, develop a program that only activates the cylinder when the two

buttons are pressed within a three seconds maximum delay.”

3.3.2 Second problem: E-commerce orders dispatching

“In an online store, after a client selects the product he wants to buy, he selects the

amount of the product to dispatch. That store has a dispatch warehouse which

receives that amount and immediately processes it through a packaging circuit that

packs the order to the client.”

To simulate this environments an electro-pneumatic setup was used in the laboratory.

It is composed by two pneumatic cylinders, each controlled by double-acted electrical

controlled pneumatic directional valve (5/2). To read each cylinder position there are

two toggle switches, normally open. The first cylinder simulates the filling of the

package with the selected amount of the product, while the second cylinder closes and

pushes the order out of the circuit to be shipped. It is pretended that the students

execute the cycle using the knowledge they acquire in lessons, like programming

routines to read inputs, set outputs and use counters and timers.

4 Developments

To develop the solution to the problem described above, it is necessary to create the

project using PG5, creating the source and Graftec files. Graftec is the name for the

SAIA implementation of IEC 61131-3 Sequential Function Charts which is much

closed to Grafcet). The necessary routines to control the PLC’s inputs and outputs are

developed in these files.

To make the button pressing simulation via web it’s necessary to add a Web-Server

project file, so that web pages can be added, after created.

Web pages are created using standard html editors and embedding PDP keys in them,

to access PLC data, as described previously. In this particular case, sample web pages

supplied with Web-Connect were used, with some minor modifications, to simulate

the pressing of the two buttons required in the problem. These web pages have to be

placed in the “html” subfolder of the created PG5 project so they can be added and

processed by the Web-Builder.

After the creation of the necessary files and their compilation, the project can be

downloaded to the PLC. This is done through the PG5, after configuring the IP

address of the PLC and password, if necessary.

30

4.1 Solution to the first problem

The first step was to create the Graftec routine that perform the realized task in the

SAIA PG5 application.

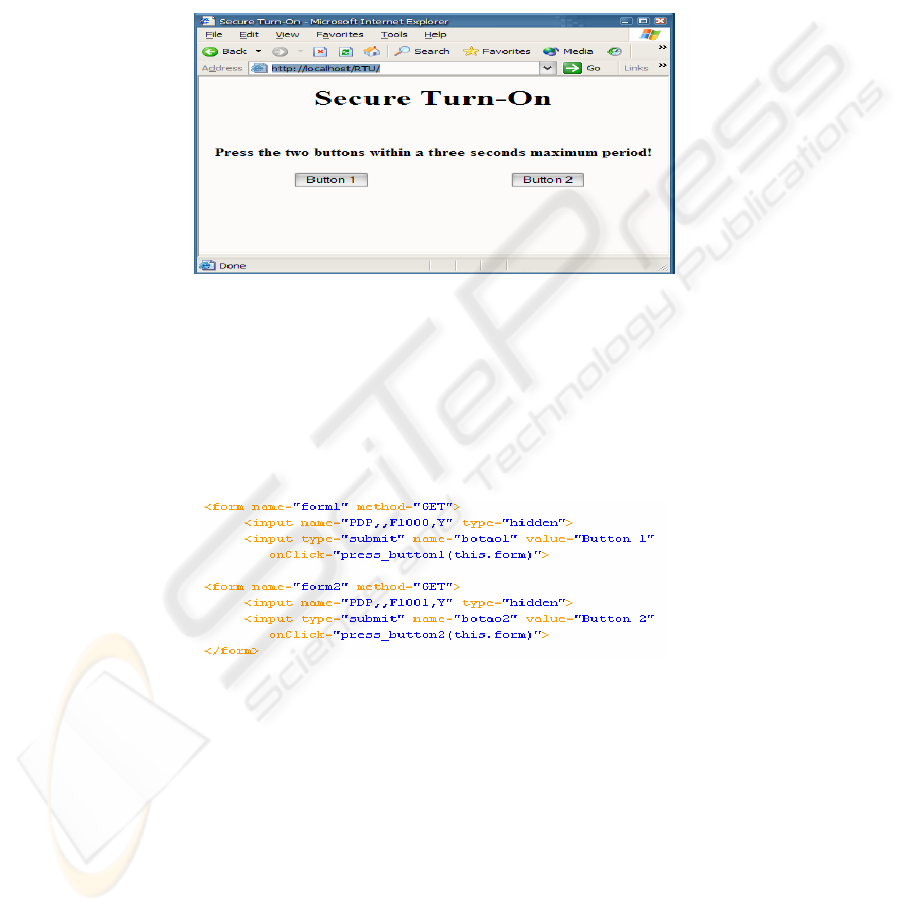

After the SAIA-Graftec conception a simple HTML interface was conceived (Fig. 2)

at any HTML editor.

The press of a button is represented in the PLC by a flag set. The HTML code

consists in a form for each button (Fig. 3).

Fig. 2. HTML interface.

Each form has two inputs: one that corresponds to the physical button that appears in

the web browser and other which is a hidden field with the PDP key to the

correspondent flag in it. When a button is clicked in the web page a Javascript

function is called that sets the element of the hidden field, corresponding to the PLC

flag, by the process described in section 3.1.1.

Fig. 3. HTML interface code.

If the two buttons are pressed within 3 seconds, each corresponding flag is set in this

period and the Grafcet routine running in the PLC sets the cylinder output.

After all the programming realized the HTML file was added to the Web Server

project file, the Graftec and source files were build and the resulting program was

downloaded to the PLC memory. All these can be done in the PG5.

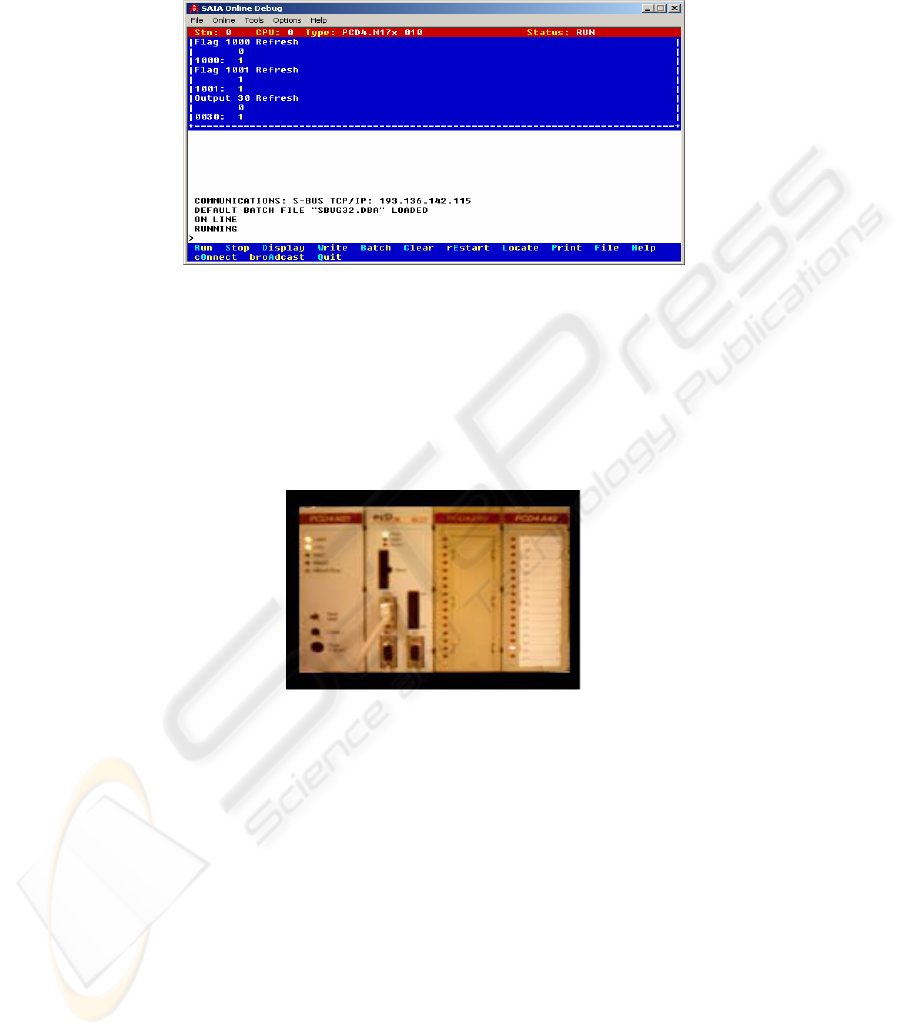

Next the user can go online with the PLC via the SAIA Online Debug (Fig. 4), to

remotely test and debug the conceived routines. If these are working correctly the user

31

can access the HTML interface conceived at any web browser, after the Web-Connect

being launched.

Fig. 4. Online Debug.

In order to have a more realistic experience an internet live video conference

application can be launched and after established the connection with the Lab PC,

with the Webcam connected, the user can have a real-time view of what’s happening

in the laboratory (Fig. 5). If the two buttons are pressed within the right period in the

remote web browser the results in the laboratory can be remotely seen.

Fig. 5. Remote live view of the Lab PLC.

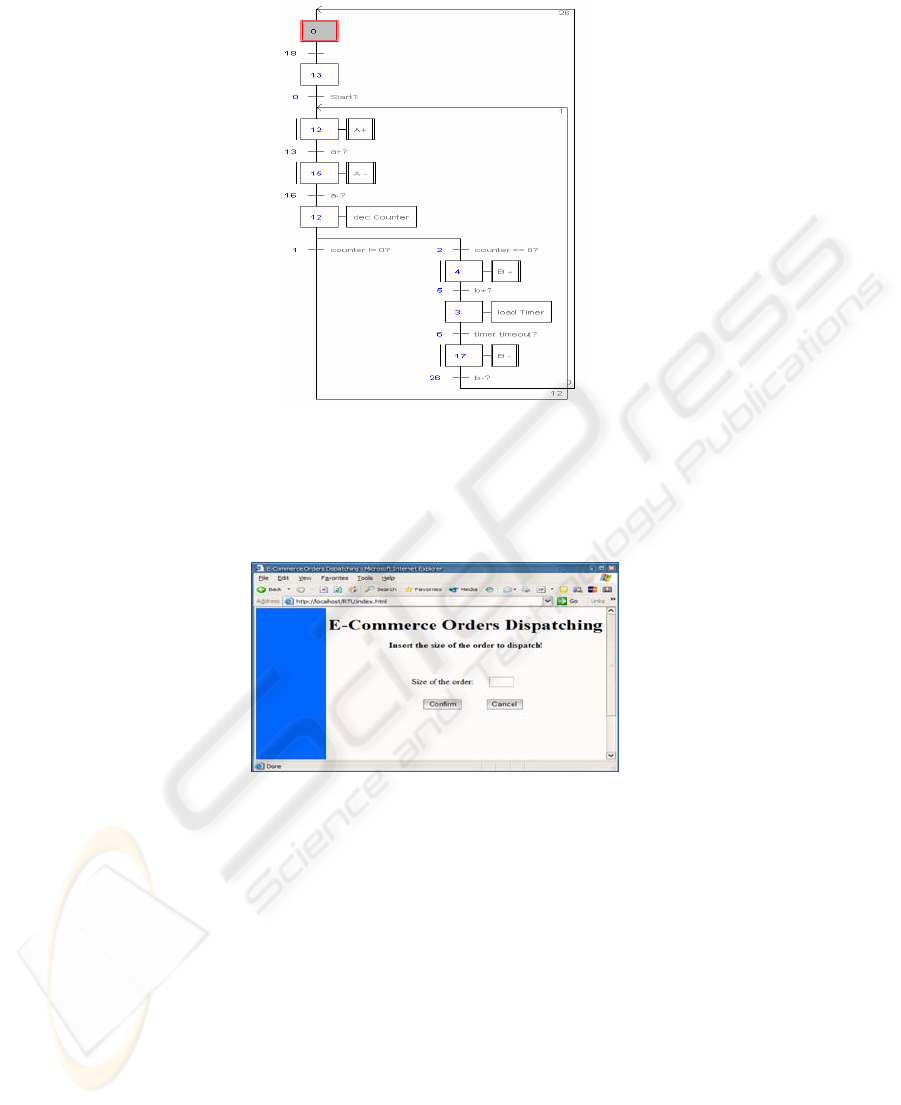

4.2 Solution to the second problem

In the first place the SAIA-Graftec routine was created (Fig. 6). A start flag launches

the routine. Then an output is set that actuates the first cylinder (via the respective

electro-pneumatic valve). After its position detected by the actuated toggle switch the

cylinder retracts. This cycle is repeated as many times as the value of a counter (with

the size of the order to dispatch). Next a second cylinder is actuated and stays in this

position for 3 seconds (using a timer), after which it retracts.

32

Fig. 6. Second problem implementation.

After this the main cycle of the order dispatch is completed. The next step was the

conception of the HTML interface (Fig. 7).

Fig. 7. Second problem HTML interface.

In this interface the user remotely inserts, in a Web browser, the size of the order to

dispatch and confirms it clicking in the “Confirm” button. Like in the first exercise,

previously described, HTML forms, with PDP keys embedded, were used to access

the PLC memory, with the help of Javascript functions. The “Confirm” button calls a

Javascript function that sets the PLC start flag and loads the counter. Next the finished

built program can be downloaded to the PLC, and remotely tested and debugged with

the SAIA Online Debugger.

The user can also see what’s happening in the laboratory with the previously referred

live video conference application (Fig. 8).

33

Fig. 8. Second problem remote live view of the Lab.

5 Conclusions

We presented a remote access automation lab allowing students to test both syntax

and semantic errors on their home work. The use of this tool increases the

productivity of laboratory sessions. Previous simulation of the logical functions of the

circuits has already provided good results as it was remarked by the student’s reports.

In this paper we present another step to let students, not only simulate, but have “real”

remote access to the equipment and test the correctness of their work.

Further work will implement a portal for controlling the access to the site. By now

only a password control is implemented in the PLC but a portal to control the access

to the experiment has to be implemented to control which user has exclusive access to

the equipment and to limit its use for a given time. Moreover we seek that the PLC

manufacturer might stand up a similar site allowing people to test a higher variety of

their equipments, allowing students to remotely work with equipments that may even

not exist in the laboratory.

This work was developed in a research laboratory supported by POCTI, FCT,

Ministério da Ciência e do Ensino Superior and by FEDER program. The

collaboration of the SAIA-BURGESS Local Representative “Infocontrol” was also

highly appreciated.

References

1. A. Leleve, H. Benmohamed, P. Prevot, C. Meyer, “Remote Laboratory Towards an

integrated training system”, ITHET03 Marrakech, MOROCCO, July 7-9, 2003

2. G. Guimaraes, T. Maffeis, L. Pereira, G. Russo, M. Bergerman, E. Cardozo, and F.

Magalhaes, "REAL: A Virtual Laboratory for Mobile Robot Experiments," 1st IFAC

Conference on Telematics Applications in Automation and Robotics, TA 2001, pp.209-214,

Weingarten, Germany, 2001.

34

3. D. Gillet, H. A. Latchman, Ch. Salzmann, and O. D. Crisalle, “Hands-on Laboratory

Experiments in Flexible and Distance Learning” in Journal of Engineering Education as an

Educational Brief (00-033), 2000

4. S. H. Chen, R. Chen, V. Ramakrishnan, S. Y. Hu, Y. Zhuang, C. C. Ko and B. M. Chen,

"Development of remote laboratory experimentation through Internet," in IEEE Hong Kong

Symposium on Robotics and Control, pp. 756-760, July 1999

5. C. Bonivento, L. Gentili, L. Marconi and L. Rappini, "A Web-Based Laboratory For Control

Engineering Education," in 2nd International workshop on tele-education using Virtual

Laboratories, August 8-9, Sherbrooke, Canada, 2002

6. C. Röhrig and A. Jochheim R, "The Virtual Lab for controlling real experiments via

Internet" in IEEE International Symposium on Computer-Aided Control System Design,

Hawaii, USA, 1999.

7. R. Delgado, G. Santos, C. Cardeira, R. Loureiro, O. Leichsenring, “Web-Based Supervision

of Remote Units”, accepted to Controlo’2004: the 6th Portuguese Conference on Automatic

Control, Faro, June 7-9, 2004

8. D. Bailey, E. Wright, SCADA for Industry, Newnes, 2003.

9. S. Boyer, SCADA: Supervisory Control and Data Acquisition, ISA - The Instrumentation,

Systems, and Automation Society, 1999

10. R. Neto, João Alves, Jorge Alves, A. Carvalho, I. Fonseca, N. Miguel, E. Emílio, H.

Fachada, "Remote Control of Industrial Processes", in Controlo’2000, Guimarães, October

4-6, 2000

11. Saia - Burguess, "Manual Web-Server Classic", document n. 26/790, Edition E2,

18.05.2003.

35