BELL SHAPED IMPEDANCE CONTROL TO MINIMIZE JERK

WHILE CAPTURING DELICATE MOVING OBJECTS

Arjun Nagendran, Robert C Richardson

School of Computer Science, University of Manchester, Manchester, United Kingdom

William J. Crowther

School of Mechanical, Aerospace & Civil Engineering, University of Manchester, Manchester, United Kingdom

Keywords: Catching, Impedance Control, Minimum Jerk, Bell Shaped Acceleration.

Abstract: Catching requires the ability to predict the position and intercept a moving object at relatively high speeds.

Because catching is a contact task, it requires an understanding of the interaction between the forces applied

and position of the object being captured. The application of force to a mass results in a change in

acceleration. The rate of change of acceleration is called jerk. Jerk causes wear on the manipulator over time

and can also damage the object being captured. This paper uses a curve that asymptotes to zero gradient at

+/- infinity to develop an impedance controller, to decelerate an object to a halt after it has been coupled

with the end effector. It is found that this impedance control method minimizes the jerk that occurs during

capture, and eliminates the jerk spikes that are existent when using spring dampers, springs or constant force

to decelerate an object.

1 INTRODUCTION

A catch can be defined as the entire process of

intercepting a moving object (by a manipulator),

wherein the object becomes attached to the

manipulator, and decelerating the object to bring it

to a halt. Catching in robotics is an important task

since it is an extension to being able to pick up

stationary objects. Catching has a wide variety of

application areas including manufacturing industries,

sports and space robotics. The ability to consistently

catch objects can be useful in certain sports like

baseball for repeated pitching practice. Catching a

ball using a baseball glove (Riley and Atkeson,

2002) and juggling and catching balls (Sakaguchi

et. al, 1991, Beuhler et. al 1994) have been studied

previously. Burridge et. al (1995), provide an insight

into dynamical pick and place robots. This can be

useful in picking moving objects randomly from

conveyor belts. Most of the literature on catching

describes trajectory planning and interception of the

object before the catch. The catch itself is generally

thought to be an inelastic collision. Minimizing

impact during capture and regulating the forces

thereafter is important to limit damage to the object.

The task of capturing a moving object by robotic

manipulators presents significant difficulties. The

process involves being able to accurately predict the

moving object’s position in time and move the

manipulator to the position where it can intercept the

object (Sakaguchi et. al, 1991). Once the object has

been intercepted, it becomes a part of the

manipulator (Kovecses et. al, 1999) and hence, the

dynamics of the manipulator change. These need to

be taken into consideration during the post-capture

phase. It is required to decelerate the object within

the allowable workspace of the manipulator (Lin et.

al, 1989) to prevent mechanical damage to the

system. At the same time, care must be taken to

decelerate the object within its permissible limits.

During the capture phase, a certain amount of

impact occurs depending on the mismatch in

velocities of the manipulator and the moving object.

Yoshikawa et. al (1994) present a relationship

between the relative velocities between moving

objects and the resulting impulse forces and go on to

calculate the optimum attitude of arms to minimize

mechanical shock. Once the object has been

captured, the kinetic energy of the object must be

dissipated as work done. This is achieved by

decelerating the object over a certain distance. There

504

Nagendran A., C Richardson R. and J. Crowther W. (2007).

BELL SHAPED IMPEDANCE CONTROL TO MINIMIZE JERK WHILE CAPTURING DELICATE MOVING OBJECTS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 504-509

DOI: 10.5220/0001627105040509

Copyright

c

SciTePress

are several methods of decelerating an object after

capture. A well known method is the use of damped

springs. Constant force or springs can also be used

in order to perform the same task. The force profile

used (models of spring dampers, springs or constant

force) is crucial in determining the deceleration and

jerk experienced by the object.

During the process of catching, position control

of the manipulator is an important task. Although

position control can be used to move a manipulator

to intercept the object, this alone is insufficient to

successfully capture the object. While decelerating

the object, it is important to take into account, both

the position of the manipulator with respect to its

workspace and also the force being applied to

decelerate the object. Hogan N (1985) in his three-

part paper presents an approach to control the

dynamic interaction between the manipulator and its

environment. The author states that control of force

or position alone is insufficient and that dynamic

interaction between the two is required. This is

referred to as Impedance Control. Applying force

depending on time is inappropriate since it does not

ensure that the object is stopped over a certain

distance. By applying a force, depending on the

position of the object, the method ensures that the

moving body is brought to a halt by removing it’s

kinetic energy over a certain distance.

The first derivative of acceleration is called jerk.

Jerk is undesirable as it increases the rate of wear on

the manipulator and can also cause damage to the

object being captured. It is known to cause vibration

and is a measure of impact levels that can excite

unmodelled dynamics. This effect is more evident in

delicate or flexible structures (Muenchhof and

Singh, 2002, Barre et. al, 2005). It has been stated

(Kyriakopoulos and Saridis, 1991) that jerk

adversely affects the efficiency of the control

algorithms and joint position errors increase with

jerk. P Huang et. al (2006) in their work state that

jerk affects the overall stability of the system and

also causes vibrations of the manipulator and hence

must be minimized. Macfarlane and Croft (2001)

state that jerk limitation results in improved path

tracking, reduced wear on the robot and also results

in smoothed actuator loads.

In this paper, we assume that the process of

tracking and intercepting an object has been

completed. We then analyze the use of springs,

spring dampers and constant force in decelerating

the object during post-capture (once capture has

occurred). It is found that these methods result in a

high jerk. Hence a method to decelerate an object

over a certain distance keeping the jerk to a

minimum is proposed. The method establishes a bell

shaped impedance relationship between force and

position. The results of this method are then

compared to the other methods.

2 CAPTURE METHODS

A moving object has a certain amount of kinetic

energy associated with it. This is dependant on the

mass of the object and its velocity. For a body of

mass ‘m’ kg, travelling with a velocity ‘v’ m/s, the

kinetic energy is given by:

Kinetic Energy = ½ m v

2

(1)

In order to bring the object to rest, a certain

amount of force must be applied in a direction,

opposite to that of the motion of the object. For the

object to completely come to rest, it is required that

the amount of work done be equal to the kinetic

energy of the object. The work done is given by:

Work Done = Force * Displacement (2)

Equating (1) and (2),

Force * Displacement = ½ m v

2

(3)

Using equation (3), the force required to

decelerate an object over a certain distance can be

worked out. This however is a constant force. As the

distance over which the object must be decelerated

to a halt becomes small, the amount of force to be

applied becomes large and vice versa. Since force is

directly proportional to acceleration (from Newton’s

equation F = m * a), it follows that the deceleration

experienced by an object is greater when the object

is brought to a halt over a shorter distance than over

a longer distance. Hence, if the maximum

deceleration tolerable by a body is known, the

distance over which it can be brought to a halt by

applying a certain amount of force can be worked

out using equation (3). To decelerate the body, force

can be applied in different ways. Although force

control alone is sufficient to decelerate the object, it

is important to take into account, both the position of

the object and the force being applied to it (Hogan,

1985). An impedance controller can be used wherein

the output force is dependant on the position of the

object. This ensures that the amount of deceleration

experienced by the object at any position can be kept

within predefined limits. Impedance control requires

measuring the position of the object, and applying a

force depending on the desired impedance. The

desired impedance determines the amount of force to

be applied depending on the object’s position. The

BELL SHAPED IMPEDANCE CONTROL TO MINIMIZE JERK WHILE CAPTURING DELICATE MOVING

OBJECTS

505

amount of force applied controls the position of the

object, thus establishing a dynamic relationship

between force and position. Although the term

impedance control is usually associated with spring

damper response, in a broader sense, the desired

impedance can be a constant force, a spring or a

spring damper.

3 SIMULATION

The dimensional parameters used in the simulation

are mass, velocity and distance. We define the

following dimensionless variables in order to

perform non dimensional analysis of the results:

s

x

x =

ˆ

;

s

mv

F

F

2

ˆ

=

;

s

v

a

a

2

ˆ

=

;

2

3

ˆ

s

v

j

j =

(4)

where x is displacement, s is total distance over

which body decelerates, m is mass, v is velocity, F is

force, a is acceleration and j is jerk.

To compare the above impedance control

methods a simulation model was built using Visual

Nastran 4D software. This was interfaced to a

simulink model of the impedance controller. It

involves an object of mass 5 kg, moving with a

velocity of 5m/s. It is assumed that the object has

been successfully intercepted and coupled to the end

effector. A linear actuator is used to decelerate the

object. The impedance controller varies the amount

of force exerted by the linear actuator depending on

the position of the moving object (and the force

model – spring. etc). In order to make a fair

comparison of the different impedance controllers, it

was decided to decelerate the object to a halt over a

fixed distance of 2m. The results for each of the

methods are discussed below.

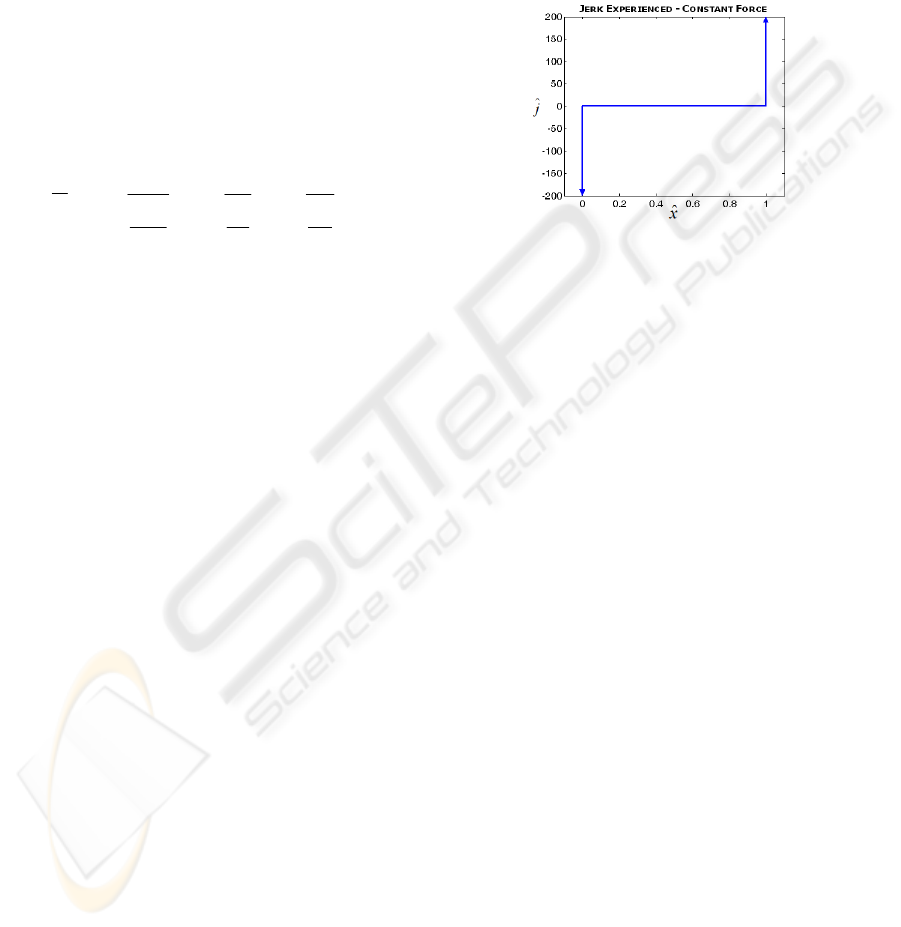

3.1 Jerk Analysis - Constant Force

The first model of the impedance controller was

designed to exert a constant force to decelerate the

object. Because the desired impedance is a constant

force irrespective of the position, the requirement for

a feedback loop is eliminated. The constant force

required was worked out using equation (3). For the

chosen values of mass (5kg) and velocity (5m/s), the

kinetic energy of the object is 62.5Nm. The distance

over which the object must decelerate is given to be

2m. Hence using (3), the force required is 31.25N.

This constant force was applied to the moving object

in the simulation. When constant force is used to

decelerate the vehicle, the sudden application of

force at the point of contact and also the sudden

removal of force at the end, result in a jerk. A graph

of

x

ˆ

against j

ˆ

is shown in Figure 1. The spikes at

the beginning and the end indicate a high jerk at the

points of application and removal of the force, and

in theory are infinite.

Figure 1: Jerk experienced when constant force is used.

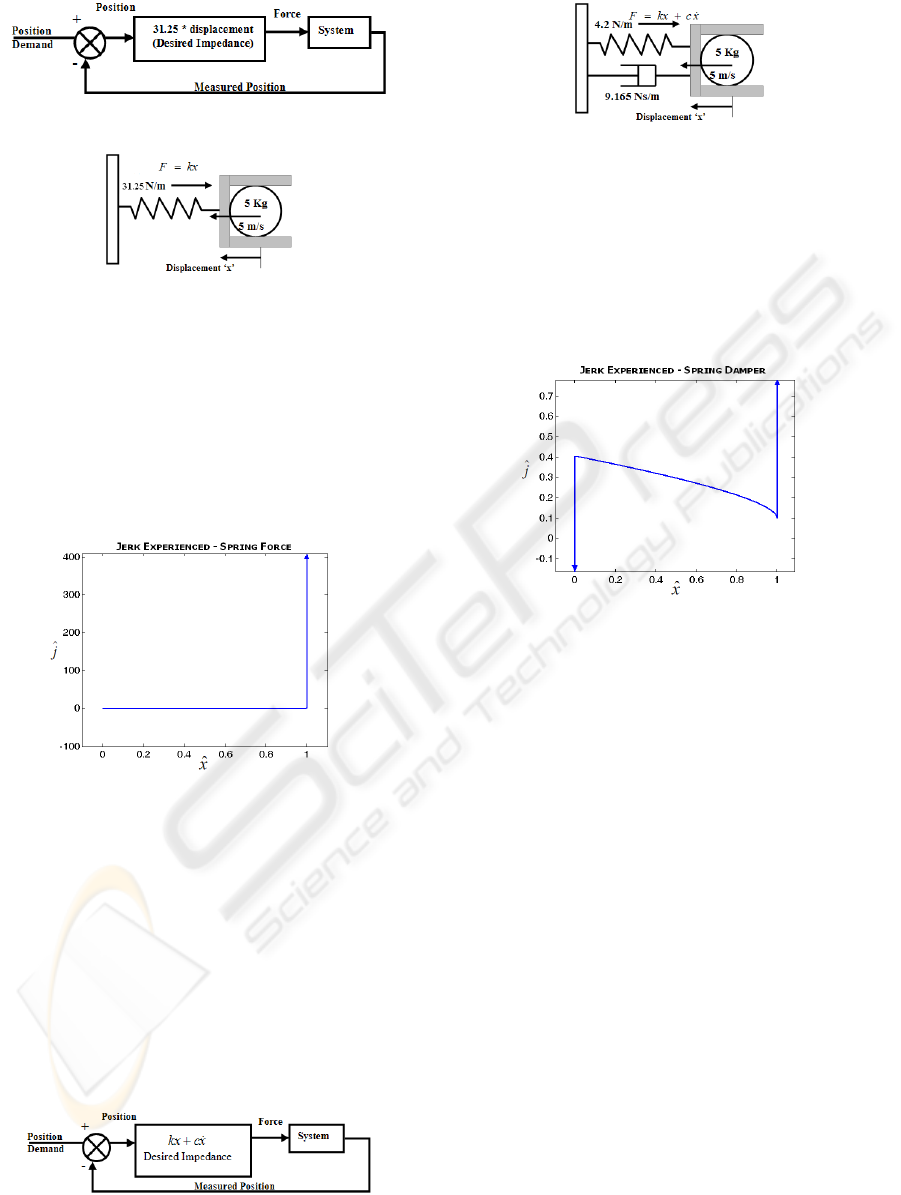

3.2 Jerk Analysis - Spring

In order to minimize the jerk that occurs at the

beginning of the capture, it is important that the

force being applied gradually increases from zero to

a maximum value, with time. This kind of behaviour

is characteristic of a spring, since the amount of

force applied by the spring is proportional to the

displacement of the object. As the spring is

compressed, the force being applied increases. This

behaviour was simulated using the impedance

controller shown in Figure 2. The relation between

the force and position (or desired impedance) is

given as Force = Spring Constant * displacement.

The distance over which the body comes to rest is

kept the same as before (2m). The spring constant

‘k’ was chosen to achieve this behaviour by equating

the energy of the object to the energy of a spring:

½ m v

2

= ½ k x

2

(5)

where ‘k’ is the spring constant, and ‘x’ is the

displacement. The kinetic energy of the object is

62.5 Nm. The displacement ‘x’ is 2m, which is the

distance over which the body must decelerate. Using

these values in the equation (5), ‘k’ is found to be

31.25 N/m. The free body diagram equivalent to the

resulting system is shown in Figure 3. It must be

noted, that using a spring to stop the object over the

same distance as before (2m) requires the maximum

value of deceleration to be twice as much as when

using constant force.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

506

Figure 2: Impedance controller as spring.

Figure 3: Free Body Diagram: Spring system.

The jerk profile when using a spring to

decelerate the object is shown in Figure 4. It can be

seen that the jerk is zero initially when a spring is

used as compared to when applying a constant force.

However, at the end, when the body comes to rest,

the spring continues to apply a force proportional to

the displacement, and stopping the body at that

position results in a jerk spike as indicated.

Figure 4: Jerk when spring behaviour impedance is used.

3.3 Jerk Analysis – Spring Damper

In order to eliminate the jerk that occurs towards the

end of a spring system, the use of a critically

damped spring damper system is considered. The

impedance controller for this system is shown in

Figure 5. The desired impedance for this system is

given by

xckxForce

+=

, where ‘k’ is the spring

constant, ‘c’ is the damping constant, ‘x’ is the

displacement and ‘

x

’ is the velocity of the object.

The spring constant and damping constant are

chosen so that the body decelerates over 2m.

Figure 5: Spring Damper impedance control.

Figure 6: Free Body Diagram: Spring Damper System.

The values of ‘c’ and ‘k’ to achieve this are

found to be 9.165 Ns/m and 4.2 N/m respectively.

The resulting system would then behave as a spring

and a damper, the free body diagram of which is

shown in Figure 6. The force exerted to stop the

object is high initially and gradually decreases when

a spring damper is used.

Figure 7: Jerk when spring damper impedance is used.

Because the force is less towards the end, the

jerk towards the end is lower (for the chosen

sampling interval) than in the case of the spring.

However, the large amount of force applied at the

beginning results in a high jerk as shown in Figure 7.

4 BELL SHAPED IMPEDANCE

CONTROL

From the above analysis of using constant force,

spring and a spring damper to decelerate a body, it is

immediately clear that jerk is an issue with all the

methods. In theory, all these methods cause an

infinite amount of jerk on the body, and for the

chosen sample interval, a finite but large amount of

jerk as shown in the graphs. This jerk can be

responsible for an unsuccessful catch as the object

may bounce off on impact, or sustain damage. In

order to keep the jerk to a minimum, we propose a

new method of impedance control, where the

relationship between force and position is in the

form of a bell curve. The method uses knowledge of

statistics and probability distributions to establish

the required relationship. The graph of the

probability density of a raised cosine distribution is

BELL SHAPED IMPEDANCE CONTROL TO MINIMIZE JERK WHILE CAPTURING DELICATE MOVING

OBJECTS

507

in the shape of a bell curve. This knowledge can be

used to establish a relationship between the force

and position. The probability density function of this

distribution is given as:

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−

+=

π

s

ux

s

suxf cos1

2

1

),;(

(6)

and is supported in the interval u – s to u + s. The

amplitude of this distribution is 1/s and occurs at u

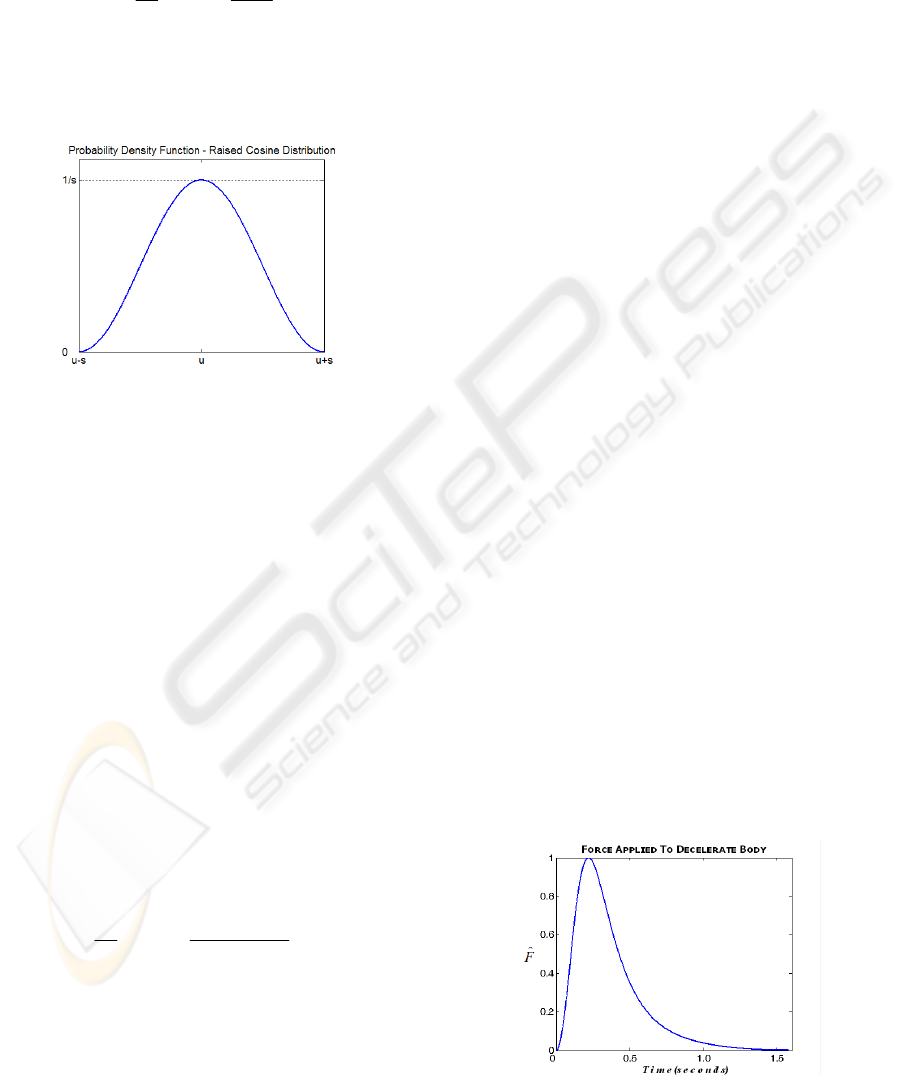

(Figure 8).

Figure 8: Raised Cosine Distribution - Bell Shaped.

It will be advantageous to establish a relationship

between force and position such that the body being

captured decelerates over a known distance and

experiences a certain maximum deceleration. From

the above equation (6), the distance over which the

object must decelerate is between u – s and u + s.

Hence, u and s are chosen as half the maximum

distance. Because the maximum amplitude is

dependant on s, a scaling factor is required to

achieve the required maximum deceleration for a

given distance. Hence, equation (6) is modified to

include a scaling factor A chosen such that A/s is the

maximum force tolerable. If the maximum

deceleration is known, the maximum force tolerable

by the object, using Newton’s equation is Force =

mass * deceleration. In order to establish an

impedance relationship, a force must be applied

depending on the position of the object and hence,

equation (6) can be written in terms of force and

position as

⎥

⎦

⎤

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−

+=

π

s

uPosition

s

A

Force cos1

2

(7)

Equation (7) results in a force being output

depending on the position of the object and ensures

that the deceleration of the object is kept within the

tolerable limit. It is important to note that the area

under this bell curve determines the total work done,

and in order to decelerate the body to a complete

halt, this must be equal to the total kinetic energy of

the object. The area under this bell curve is 50% of

the total area under the rectangle with sides equal to

the maximum deceleration and maximum distance

over which the body decelerates. This is illustrated

in the example that follows. We compare this

method to the example used with the spring-damper,

spring and constant force methods. The distance

over which the body decelerates is 2m. Hence, u and

s are chosen to be 1 and the relative position of the

object is from 0m to 2m during which the force is

applied to decelerate the object. The maximum

amplitude of this curve is however 1/s which is

equal to 1, for the chosen s. The area under the

curve must be equal to the kinetic energy of the

object. For the 5kg mass travelling at 5m/s, the

kinetic energy is 62.5kgm

2

/s

2

(or Nm), as established

previously. The area under the bell curve is given as

Area = ½ * Force * displacement where Force is

worked out using Newton’s equation and

displacement is the distance over which the body

decelerates (50% area as mentioned earlier).

Equating this to the kinetic energy of the object, the

force required is found to be 62.5N. Hence, A must

be chosen such that A/s = 62.5. Since s = 1, A = 62.5.

Using the calculated values of A, u and s, the final

equation for force, in terms of position or the desired

impedance to minimize jerk is implemented.

The force applied to decelerate the object was

determined by the impedance relationship

established in equation (7). The maximum

deceleration experienced by the object is the same as

when a spring is used. A graph of force applied

using the impedance relationship to decelerate the

object against time is shown in Figure 9. Because

the position of the object changes faster initially due

to its approach velocity, the force required rises

steeply at the beginning. The force applied based on

the object’s position, slows the object down and

gradually eases off so as to stop the object over the

desired distance of 2m. The jerk profile for this

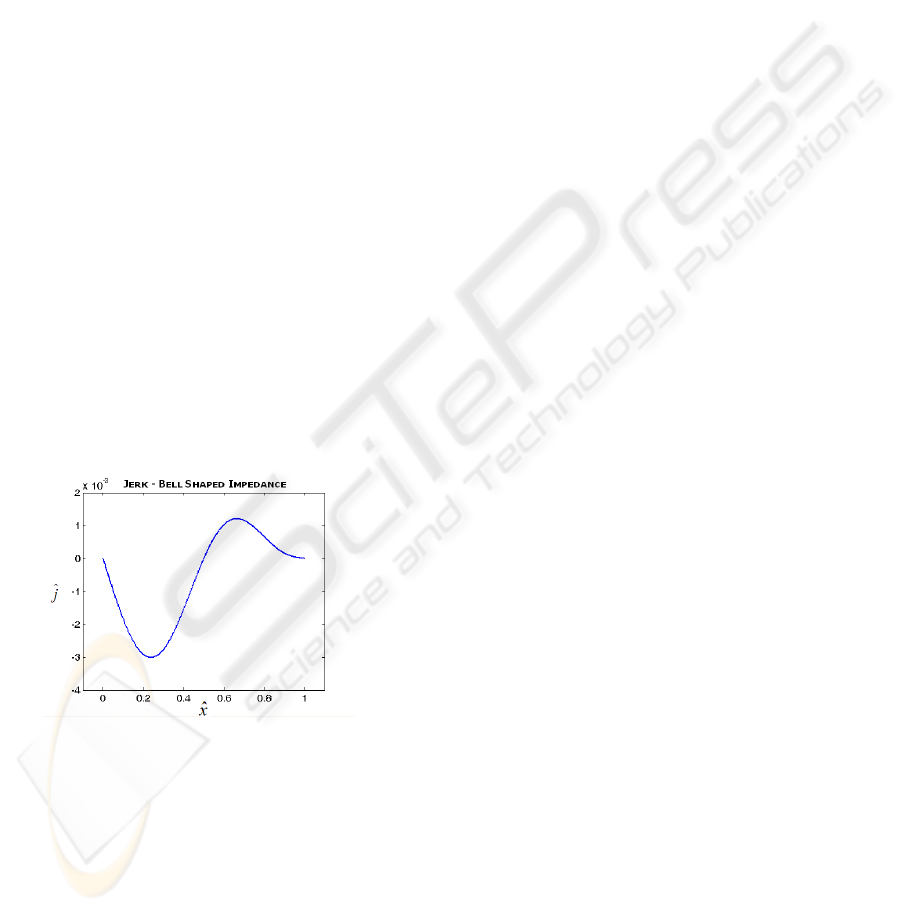

method is shown in Figure 10.

Figure 9: Force applied using Bell Shaped Impedance.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

508

It is a smooth curve, with no spikes and the

amount of maximum jerk is very low as compared to

any of the other methods. In reality, actuators

themselves have inherent dynamics that prevent

them from generating instantaneous changes in

force. The greater the required instantaneous change

in force, the more pronounced the actuator dynamics

will become. Therefore, minimum jerk profiles, that

limit the required rate of change of force, can be

implemented with a greater degree of accuracy.

5 DISCUSSIONS & CONCLUSION

The jerk graphs reveal that the amount of jerk is

greatly reduced if a bell shaped curve of force

against position is used to capture the object (Figure

10). However, in comparison with the constant force

method, the amount of deceleration experienced by

the object is high. A trade off between the amount of

tolerable jerk and tolerable acceleration is required

to be able to generate the required response. An

important assumption in this method is that the

velocity and mass of the object at the point when

capture occurs is known. This ensures that the body

decelerates within a certain maximum distance and

allows for the force to be specified at every position

along its path. Any error in this estimation can result

in incorrect calculation of kinetic energy and the

object will not stop within the required distance.

Figure 10: Jerk for Bell Shaped Impedance control.

For accurate calculation, the velocity and mass of

the object must be estimated in real time, after which

self tuning can be used to generate the required bell

shaped impedance control. Additionally, capturing

an object requires a high speed of operation and it is

much more difficult to apply quick changing forces

from actuators at high speeds. The smooth bell

shaped acceleration profile also means that forces

can be applied with much more ease, due to the

gradually changing curve.

REFERENCES

P. Huang, Y. Xu, B. Liang (2006) Global Minimum-jerk

trajectory planning of Space Manipulator,

International Journal of Control, Automation, and

Systems, Vol. 4 (4), pp. 405-413.

K. J. Kyriakopoulos, G. N. Saridis (1991) Minimum jerk

trajectory planning for robotic manipulators, Proc.

SPIE, Vol. 1387, pp. 159-164.

A. Piazzi, A. Visioli (1997) An interval algorithm for

minimum-jerk trajectory planning of robot

manipulators, Proc. of the 36th Conference on

Decision and Control, San Diego, California USA, pp.

1924.

M. Muenchhof, T. Singh (2002) Desensitized Jerk

Limited-Time Optimal Control of Multi-Input

Systems, Journal of Guidance, Control, and

Dynamics. Vol. 25(3) pp.474-481.

K. J. Kyriakopoulos, G. N. Saridis (1988) Minimum-jerk

path generation, Proc. of IEEE International

Conference on Robotics and Automation, Philadelphia,

PA, pp. 364-369.

N. Hogan (1985) Impedance control: An approach to

manipulation: Part I- theory. Journal of Dynamic

Systems Measurement and Control, Vol.107(11), pp.1-

7.

P. J. Barre, R. Bearee, P. Borne, E. Dumetz (2005)

Influence of a jerk controlled movement law on the

vibratory behaviour of high-dynamics systems.

Journal of Intelligent and Robotic Systems. Vol. 42,

pp. 275–293.

S. Macfarlane and E. A. Croft (2001) Design of Jerk

Bounded Trajectories for On-line Industrial Robot

Applications. IEEE International Conference on

Robotics and Automation, Seoul, S. Korea.

J. Kovecses, W. L. Cleghorn, R. G. Fenton (1999)

Dynamic modelling and analysis of a robot

manipulator intercepting and capturing a moving

object with the consideration of structural flexibility.

Multibody System Dynamics 3, pp. 137–162.

Z. Lin, V. Zeman , R. V. Patel (1989) On-line robot

trajectory planning for catching a moving object.

Proceedings of the IEEE International Conference on

Robotics and Automation, Scottsdale, AZ, pp. 1726–

1731.

T. Sakaguchi, Y. Masutani, F. Miyazaki (1991) A Study

On Juggling Task, IEEE/RSJ International Conference

on Intelligent Robots and Systems, IROS 91, pp. 1418–

1423.

M. Buehler, D.E. Koditschek, P.J. Kindlmann (1994)

Planning and control of robotic juggling and catching

tasks. International Journal of Robotics Research,

Vol. 13(2), pp. 101-108.

R. R. Burridge, A. A. Rizzi, D.E. Koditschek (1995)

Toward a Dynamical Pick and Place. IEEE/RSJ

International Conference on Intelligent Robots and

Systems, IROS 95, Vol.2, pp. 292–297.

BELL SHAPED IMPEDANCE CONTROL TO MINIMIZE JERK WHILE CAPTURING DELICATE MOVING

OBJECTS

509