TASK PLANNER FOR HUMAN-ROBOT INTERACTION INSIDE

A COOPERATIVE DISASSEMBLY ROBOTIC SYSTEM

Carolina Díaz, Santiago Puente and Fernando Torres

University of Alicante

Crta San Vicente del Raspeig s/n

PO Box 03080, San Vicente del Raspeig- Spain

Keywords: Human-robot interaction, cooperative, disassembly, task planner.

Abstract: This paper develops a task planner that allows including a human operator which works cooperatively with

robots inside an automatic disassembling cell. This method gives the necessary information to the system

and the steps to be followed by the manipulator and the human, in order to obtain an optimal disassembly

and a free-shock task assignation that guarantees the safety of the human operator.

1 INTRODUCTION

Disassembly is defined as the process of separating

pieces that compose an object (Torres and Puente,

2006). In this process it is very useful to consider

the advantages of cooperative tasks, in which two or

more robots take part, or tasks in which the

intervention of a human being is required (Adams

and Skubic, 2005). Some of those advantages are:

making tasks that a single robot can not do; sharing

information and resources; greater tolerance to

failures; and attending between manipulators and

humans for different tasks. Working in a coordinated

way also provides the system a faster and an

effective disassembly, which allows a consequent

saving of money to the industries that apply it.

The value of a group of entities collaborating

among them, working in group as a team has been

proven many times in many domains. For example,

in nature a group of animals working cooperatively

as a team, can manage to hunt a stronger and bigger

animal. Also in the military service a group of men

with limited resources and specific abilities are

united to create groups with an incredible capacity.

These examples illustrate that a group of entities

with similar or different abilities joined to work in a

team, can produces a work unit with abilities and

capacities greater than the sum of its parts (Navarro-

Serment, et al., 2002). Including two or more agents

working in a cooperative way increases the

performance of the disassembly system, because of

the synergy produces a group of units working

together as a team.

Two groups can be distinguished in cooperative

robots work field:

• Two or more robots working cooperatively to

solve different tasks. This group is called robot-

robot application for forward examples (Tinós and

Terra, 2002; Fonseca and Tenreiro, 2003).

• Cooperative tasks in which robots manipulators

and humans interact, named in this paper robot-

human application (Kumar et al., 2000; Hägele et

al., 2002).

The remarkable issue that differences these two

groups is that when humans and robots interact, the

system must consider more external and internal

sensors in order to avoid humans suffering any

physical damage.

It is important to highlight that this work tries to

use the intervention of a human in task in which the

person has more abilities and general comprehension

than a robot. Robot manipulators transform in

intelligent agents that assist humans in all kind of

task and activities, taking advantages of the

resources and characteristic of each agent and

minimizing the negative properties collaborating

between them.

In the present paper it is observed the advantages

that bring to include a person working in a

cooperative way inside a disassembling cell. Until

recently in most of industrial environments the robot

manipulator was isolated through securities fences,

19

Díaz C., Puente S. and Torres F. (2007).

TASK PLANNER FOR HUMAN-ROBOT INTERACTION INSIDE A COOPERATIVE DISASSEMBLY ROBOTIC SYSTEM.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 19-24

DOI: 10.5220/0001645100190024

Copyright

c

SciTePress

avoiding any possible contact or interaction with

human operators. These were the methods for

guaranteeing the safety of operators inside these

environments (Corke, 1999; Kulic and Croft, 2005;

Ikuta and Nokata, 2003). The present paper set up a

task planner that allows human-robot interaction

taking into account safety aspect.

This article is organized as follows: after the

introduction in Section 2 the process’ architecture is

described. Then, in Section 3, the cooperative task

planner is developed. In Section 4 an application

example is explained. And finally conclusions and

future works are presented.

2 PROCESS’ ARCHITECTURE

The process’ architecture used here is the same

developed in a previous work (Díaz et al., 2006); it

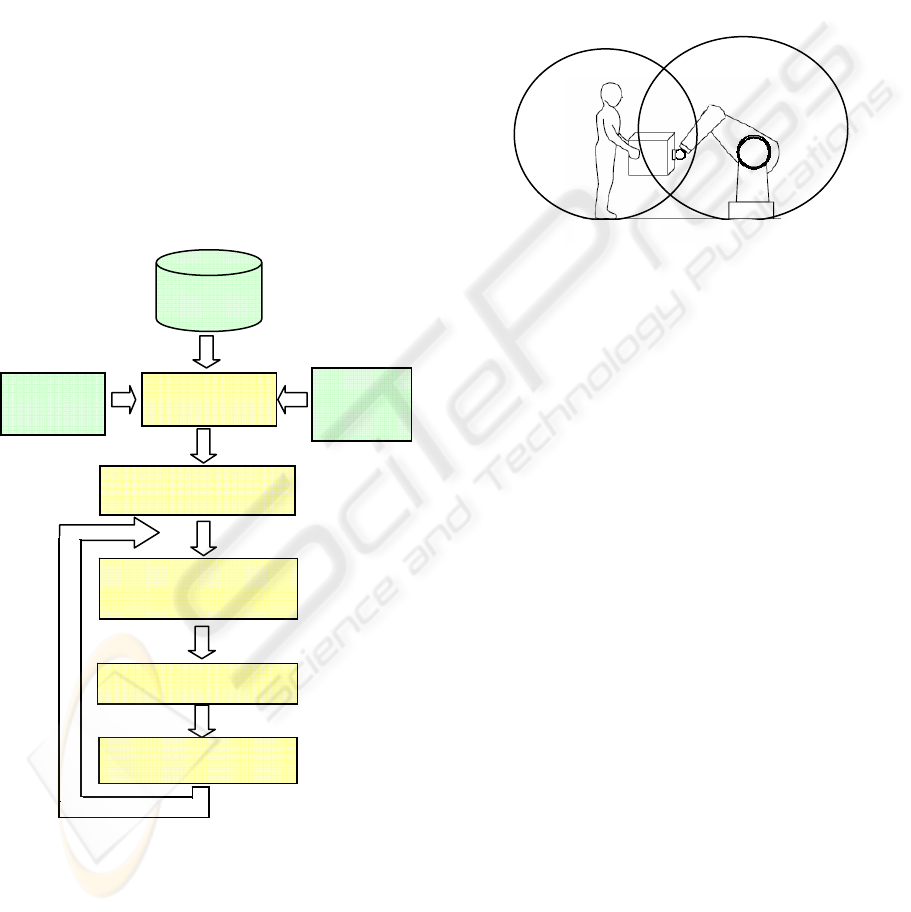

is shown in Figure 1.

Figure 1: Process’ Architecture.

In this scheme the Data Base contains a list of

tasks for disassembling products, through a

relational model graph developed in (Torres et al.,

2003). The Task Planner determines which action

corresponds to each agent. Then a position and a

vision control are applied to avoid collisions in real

time between robots and humans, and also collisions

of these with the environment. This grants the

system the possibility of doing on-line corrections.

This control is not developed in this paper.

The Task Planner has all the information of the

layout of the cell, the storage deposits position, and

the location of each agent work area and their

intersection (Fig. 2). This information is very

important in order to avoid collision, between robot

and human and with the environment.

Figure 2: Scheme human robot working areas.

The Task Planner is the one that determines the

sequence to be followed by the manipulator and the

human who take part in the disassembly task;

looking to obtain the maximum advantage of all the

resources, and reducing the total disassembly time.

Is important to highlight the Vision and Position

Control that is the one on charge to detection and

avoid collision, is not develop in this paper. What is

looking for is obtaining an optimal cooperative task

planning that avoids possible collision in the

intersection area, in normal condition. In case, for

example, when accident takes place the Position and

Vision control is the one that have to take the correct

decision. In this project, it is also working with a

special environment (Corrales et al., 2006) that

allow to monitoring the location of the human

operator in real time.

3 TASK PLANNER

The Task Planner developed in this paper for robot

human interaction is based on (Diaz et al., 2006) for

robot cooperative works; it is important to remark

that only a few modifications have been necessary to

adapt this Task Planner for human-robot interaction.

This brings out the flexibility of the proposed

method. The major modifications have to be done in

another block of the system’s architecture, like in the

Vision and Position Control to allow the system

Data Base

Task Planner

Work

Areas

Deposits

Vision and Position

Control

Robot-Human

Environment

Trajectory Planner

1

E

2

E

12

E

Human Robot

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

20

monitoring the human and robot movement inside

the cell.

To reduce risk factors inside an industrial cell in

which robots and humans works Burke et al., 2003

proposed three criteria:

• Redesigning the working cell looking for

the way that the danger is eliminated.

• Control the danger thought sensor or physical

limits.

• Warn and train the human operator which

work in the cell.

In this paper the last two items of these criteria

are considered; controlling the danger through a

vision and position control and educating the person

about the dangers of working cooperatively with

robot manipulators in a disassembly system.

The

dangers are reduced considerably making a suitable

task plan. The planner is the system that determines

to which agent correspond each action execution and

the precise moment to be executed, to obtain a

successful disassembly free of collisions.

Given the relational model graph described on

(Torres et al., 2003), a hierarchical graph that

represent the structure that sets up the product to be

disassembled is obtained. This graph also contains

all the actions to disassemble a product and gives

much useful information, like the precedence and the

parallelism between tasks. Crossing this graph the

rules that specify the sequence to disassemble a

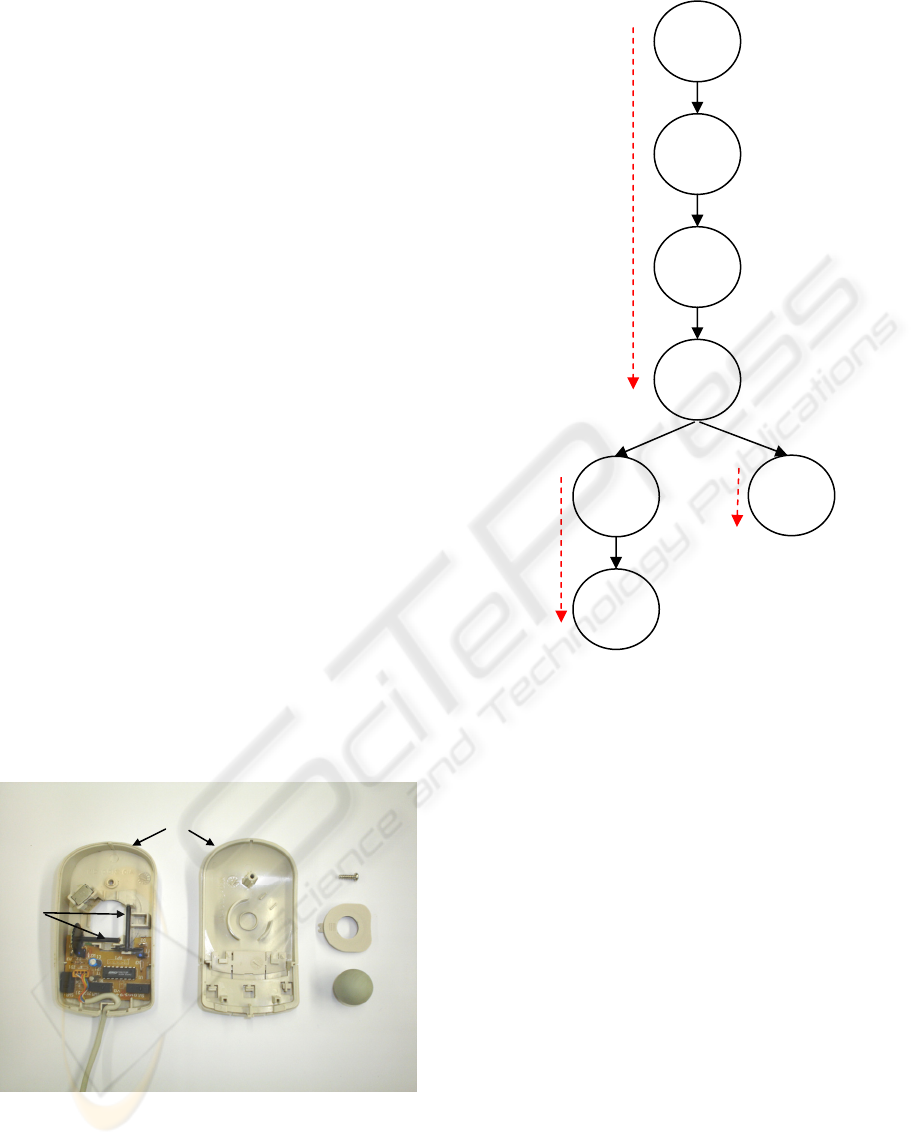

product are obtained. In Figure 3 the component of a

PC’s mouse are shown and in Figure 4 the relational

model graph for disassembly this products is

observed.

Figure 3: Components of a Pc’s mouse.

Figure 4: Hierarchical Graph to disassemble a PC’s mouse.

In Figure 4 the product considered corresponds

with a PC’s mouse. In this case the rules for this

object are:

Rule 1= Remove Top + Separate internal boll +

Remove Screw 1+ Separate external case.

Rule 2 = Cut Cable + Remove CI Board.

Rule 3 = Remove axes.

The Task Planner based on these rules to

constructs the decision trees that allocate the

different tasks between robot and human, to obtain a

cooperative and successful disassembly of a product.

In a working cooperative environment and taking

into account the workspace intersection, two types of

task are defined:

• Common Tasks: are those in which is

required two or more entities working in the

same specific object. For example the

extraction of a CD player.

• Parallel Tasks: those in which each entity

does a specific task. The presence of only one

entity is required. It can be executed in

simultaneous way. For example the extraction

of a Card Slot and simultaneously the extraction of

the Energy Source.

Remove

To

p

Separate

ball

Remove

axes

Cut

Cable

Remove

IC Board

R1

R2

R3

Remove

Screw 1

Separate

Ext. Case

Internal

Ball

Cable

IC Board

Top

Screw

External

Case

Axes

TASK PLANNER FOR HUMAN-ROBOT INTERACTION INSIDE A COOPERATIVE DISASSEMBLY ROBOTIC

SYSTEM

21

11

12

A

Grasp Mouse

A

Deposit Ball

=

=

21

22

A

Extrac Top

A

Deposit Top

=

=

[]

111121

221222

12

, ,...,

, ,...,

, ,...,

p

q

rrr rs

AAA A

A

AA A

AAA A

⎡⎤

=

⎣⎦

⎡⎤

=

⎣⎦

=

[

]

12

, ,...,

n

A

AA

Modelling these rules and according to the type

of task to be executed (Tc o Tp) the decisions trees

are constructed. These determine the assignment of

all the actions to be done; to disassemble the product

in an optimal and cooperative way.

From the relational model graph the different

rules are obtained. These rules are divided into

actions A, for each action corresponds a tool T, and

each action is divided into sub-action if it is possible.

In general, to construct the decision trees and to

model the system, the following sets are defined:

Number of Robots =

12

, ,..., ,...,

ij

RR R R

⎡⎤

⎣⎦

Number of Humans =

12

, ,..., ,...,

ij

H

HHH

⎡⎤

⎣⎦

Task’s Type =

where: Tc: Common Task.

Tp: Parallel Task.

Rules = Task =

each task is divided in actions.

Actions =

and each action is divided into sub-actions

For each action, a respective tool exists. In other

words, it exist the same number of actions as tools:

Tools =

[

]

12

, ,...,

n

TT T

In tasks in where robot and human cooperate.

The actions are assigned to the human due to their

qualities and abilities. It is obvious that the hands are

considered as the tool that the worker used to

execute action.

According to the sets described before and to the

type of task, the trees that determine the optimal

allocations of the actions were constructed like are

developed in (Díaz et al., 2006). In order to

determine the optimal path an information gain is

empirically assigned for each robot or human. In this

work the costs are assigned according to the

characteristics of each action. Time is the most

important characteristic in this application.

There are to highlight that the system does not

handle with synchronizing the task between human

and robot, it only perform the distribution of task

between them. The synchronization between them is

ensured by the vision and position control system.

4 APPLICATION EXAMPLE

Here a disassembled cooperative task is executed

working in a cell compose by only one human

operator and one robot manipulator Mitsubishi® PA-

10. Named

11

and RH respectively

Modeling from Rule 1 obtained from the

relational model graph shown in Fig. 4 it is obtained:

Rule 1= Remove Top + Separate internal boll +

Remove Screw 1+ Separate external case.

It is sub-divide into two tasks:

1

2

= Remove Top + Separate Ball

= Remove Screw 1 + Separate Case.

s

s

T Remove internal ball

T Separate external case

=

=

Executing

s1

T for this application is divided into

two actions according to the corresponding tool used

to execute each action. To execute

s1

T , first one of

the entities has to hold the mouse while the other

removes the top, then:

1

= Grasp mouse + Remove Top + Separate Ball

s

T Remove internal ball =

where:

11112

A

AA

=

+ it is sub-divided in two actions:

where:

22122

A

AA

=

+ it is sub-divide into two actions::

where:

In this application the task is a Common Type

Task Tc. The human and the robot work

simultaneously on the same object, and the work

area must be the intersection

12

E as shown in Figure

2. The decisions trees where the actions are assigned

1

2

(Parrallel Jaw)

(Handing Extraction)

A

Grasp mouse and Separate ball

ARemove top

=

=

[

]

,Tc Tp

[

]

12

, ,...,

m

Ts Ts Ts

⇒

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

22

11

12

the first action is asigned to the robot PA-10.

the second action is asigned to the human.

RA

HA

→

→

result obviously, given the simplicity of the working

cell, then result:

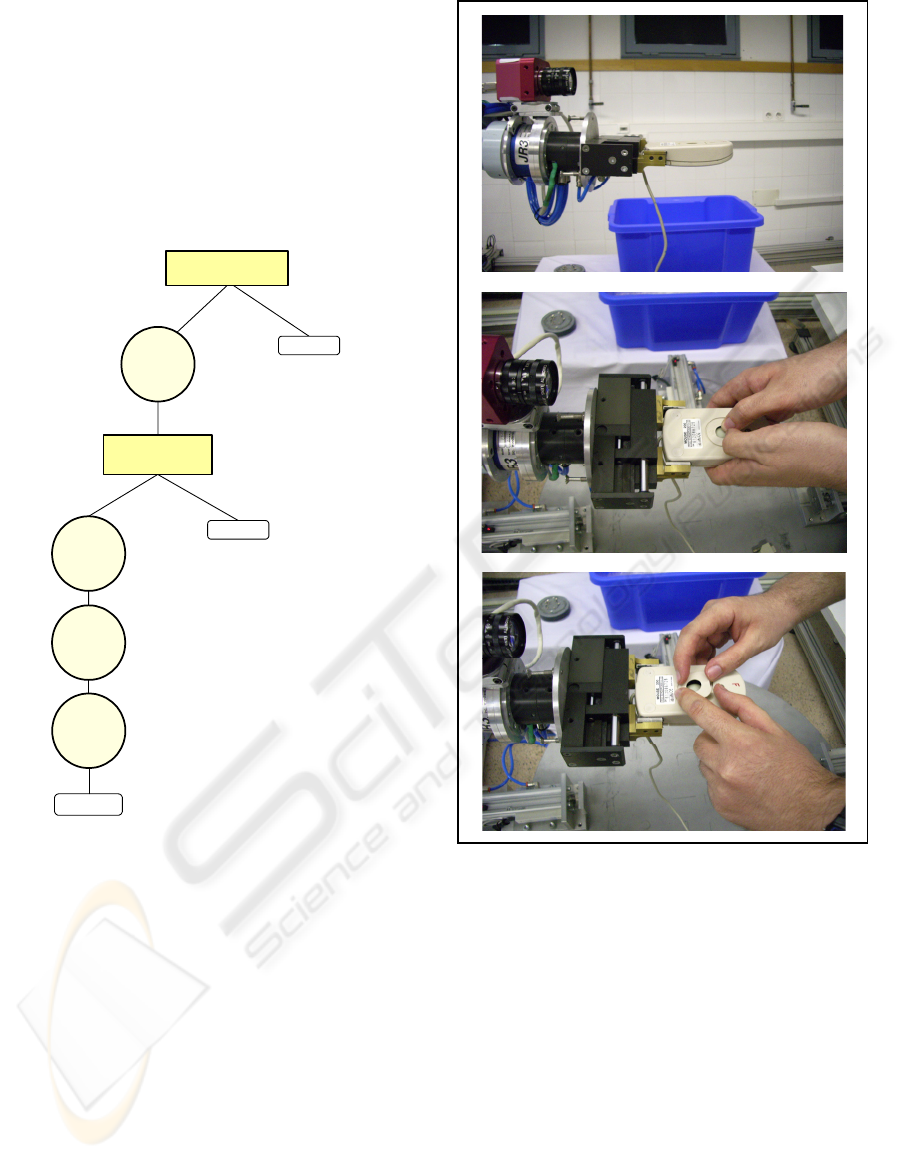

The decision tree shown in Figure 5 is

constructed for planning

s1

T .

Figure 5: Decision Tree

s1

T .

In Figure 5 it is observed that the tool availability

is checked in each moment to make the system more

reliable. There, actions cannot be executed in a

parallel way because of the precedence between

them or to avoid the human may suffer any physical

damage. For example, action

12

A

which corresponds

to deposit the ball, cannot be started until the action

22

A

(human extracting the top) has finished.

In Figure 6 the real sequence to execute

s1

T is

shown.

Figure 6: Sequence

s1

T .

5 CONCLUSIONS

A cooperative Task Planner is set out. It allows

developing cooperative task between manipulator

and task in which robot and human interaction is

needed inside a disassembly system. The main goal

is to provide a safe and flexible cooperative system.

This system could achieve greater productivity in the

industry.

Robots are use to assist the human operators in

some specific industrial tasks, reduce the fatigue,

and increase the accuracy in areas in which only a

YES

NO

11

?RT⇔

111

RA

NO

ERROR

12

?HT⇔

END

121

HA

122

HA

112

RA

ERROR

YES

TASK PLANNER FOR HUMAN-ROBOT INTERACTION INSIDE A COOPERATIVE DISASSEMBLY ROBOTIC

SYSTEM

23

human can bring global knowledge, experience, and

comprehension in the executing of the task

It is observed, that the modifications made in the

task planning block to adapt it to cooperative tasks

between man-robot, are minimum. Therefore a

future project work might consider extending the use

of the Task Planner to other types of applications

like services robots, where work between robots and

humans has a great potential.

ACKNOWLEDGEMENTS

This work was funded by the Spanish MEC project

“Diseño, implementación y experimentación de

escenarios de manipulación inteligentes para

aplicaciones de ensamblado y desensamblado

automático” (DPI2005-06222), and by the Spanish

G.V. project “Desensamblado automático

cooperativo para el reciclado de productos”

(GV05/003).

REFERENCES

Adams, J., Skubic, M., 2005. Introduction to the Special

issue on Human-Robot Interaction. IEEE Transaction

on System, Man, and Cybernetics. Part A. Vol. 35, No.

4, pp. 433-437

Burke, J., Murphy, R., Rogers E., Scholtz J., Lumelsky V.,

2003. Final Report for the DARPA/NSF

Interdisiplinary study on Human-Robot Interaction.

Transaction IEEE Systems, Man, and Cybernetics.

Part A, Vol. 34, No. 2

Corrales, J.A., Torres, F., Candelas, F., 2006. Tecnologías

en la Inteligencia Ambiental. XXVII Jornadas de

Automática. Almería. Spain.

Corke, P. I. 1999. Safety of advance robots in human

enviroments. Proceeding of the IARP 1999.

Diaz, C., Puente, S.T., Torres, F. 2006. Task Planner for

a Cooperative Disassembly Robotic System.

Proceeding of the 12th IFAC Symposium on

Information Control Problems in

Manufacturing. Lyon. France. Vol. 1, pp. 163-168.

Ikuta, K., Nokata, M., 2003. Safety evaluation method of

desing and control for human care robots. The

International Journal of Robotics Research. Vol. 22,

pp. 281-297.

Kulic, D., Croft, E., 2005. Safe Planning for Human-Robot

Interaction. Journal of Robotics System. pp. 433-436

Navarro-Serment, L., Grabowski, R., Paredis, C., Khosla,

P., 2002. Millibotspag. IEEE Robotics & Automation

Magazine. Vol 9, No. 4, pp 31-40.

Torres, F., Puente, S.T., Aracil ,R. 2003. Disassembly

planning based on precedence relations among

assemblies. The International Journal of Advanced

Manufacturing Technology.Vol. 21. No. 5. pp. 317-

327.

Torres, F., Puente, S.T., 2006. Editorial: Intelligent

disassembly in the demanufacturing process. The

International Journal of Advanced Manufacturing

Technology.Vol. 30. pp. 479-480.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

24