ADVANCED DIRECT MANIPULATION

OF FEATURE MODELS

Rafael Bidarra, Alex Noort

Faculty of Electrical Engineering, Mathematics and Computer Science, Delft University of Technology, The Netherlands

Daniel Lourenço, Pedro Oliveira

Instituto Superior Técnico, Technical University of Lisbon, Portugal

Keywords:

Feature modelling, direct manipulation, user interaction, handles, constraints.

Abstract:

In current commercial feature modelling systems, support for direct manipulation of features is not commonly

available. As a result, re-designing is time-consuming due to the inefficient feedback, the insight given is

rather poor, and user interaction often lacks intuitiveness. This is partly due to the lack of speed of current

constraint solvers, but also to deficient interactive facilities. In this paper, we argue that providing advanced

direct manipulation facilities for feature models is possible and can significantly speed up the product design

process, by giving designers a much more intuitive interface, with immediate feedback and deeper insight into

the consequences of each modelling action. An approach to such a direct manipulation interface is presented

that brings together the advantages of direct manipulation of feature models with the necessary emphasis on

fundamental feature modelling paradigms like feature parametrisation and feature validity maintenance. In

particular, it offers a powerful combination of various 3D handles for real-valued feature parameters, with a

preview overlay facility for all modelling operations. Details are provided on how this approach was success-

fully implemented in a prototype feature modelling system.

1 INTRODUCTION

Feature modelling is a design paradigm that comes

as an alternative to the traditional geometry-based de-

sign systems. The founding idea of feature modelling

is to focus the modelling tasks of the designer on a

higher level, facilitating the specification of many dif-

ferent aspects in a product model, and gaining insight

into their inter-relations (Shah and Mäntylä, 1995).

This is achieved by enabling the designer to associate

functional information to the shape information in the

product model.

Although one cannot find a consensual definition

of the concept of feature, one that nicely fits to this re-

search defines a feature as "a representation of shape

aspects of a product that are mappable to a generic

shape and are functionally significant for some prod-

uct life-cycle phase" (Bidarra and Bronsvoort, 2000).

In contrast to conventional CAD systems, in which

the design focus mainly lies on geometry, in a fea-

ture modelling system the designer builds a model

out of features, each of which has a well-defined se-

mantics. As an example, for manufacturing planning

purposes it would be appropriate to provide the de-

signer with features that correspond to the manufac-

turing processes available to manufacture the product

being designed (e.g. slots and holes).

Feature model semantics is mostly represented by

a variety of constraints. Constraints can be used in

feature modelling systems to express characteristics

of the model (e.g. to specify some feature faces to

be co-planar, or restrict a given dimension to a cer-

tain range). But, above all, constraints are used as the

internal constituents of features that express their se-

mantics (e.g. a hole feature could have constraints to

position and orient it, or constraints that express the

physical limits of the drilling machinery available).

Because of this central role of constraints, feature

modelling systems have to make an intensive use of

constraint solving techniques. In particular, geomet-

ric constraints and geometric constraint solving tech-

niques are very common.

To ensure that feature model semantics is main-

tained, the validity of the feature model has to be

130

Bidarra R., Noort A., Lourenço D. and Oliveira P. (2007).

ADVANCED DIRECT MANIPULATION OF FEATURE MODELS.

In Proceedings of the Second International Conference on Computer Graphics Theory and Applications - GM/R, pages 130-136

DOI: 10.5220/0002080301300136

Copyright

c

SciTePress

checked after each model modification. Feature

model validity is usually checked by solving the con-

straints in the model: a valid feature model is a fea-

ture model that satisfies all its constraints. Modelling

systems which guarantee feature model semantics to

be maintained throughout the modelling process are

called semantic feature modelling systems (Bidarra

and Bronsvoort, 2000). So constraints play an im-

portant role during model creation and modification.

Quite some research work has been done on tech-

niques to enable constraint solvers to be used in in-

teractive applications, such as user interface onstruc-

tion (Borning and Duisberg, 1986; Freeman-Benson,

1993; Hosobe, 2001), and geometric modelling sys-

tems (Hsu et al., 1997; van Emmerik, 1991). How-

ever, in current modelling systems, the specification

and the modification of feature parameters that de-

termine its position/orientation and its dimensions,

is still mostly done through the input of values in

dialog boxes, after which the model is updated ac-

cordingly (Parametric Technology Corporation, 2006;

SolidWorks Corporation, 2006; UGS Corporation,

2006). The main disadvantages of this approach are:

inefficient feedback, making the design task much

slower. Each time the designer changes the pa-

rameters of a feature he has to wait for the whole

system of constraints to be solved and only then

can he see the effect of his changes and check the

validity of the model.

lack of insight on the consequences of the modelling

operation. When changing a parameter the user

can only see the original and resulting model of

the operation. In other words, there is no ex-

plicit feedback on which features were affected

and how.

non-intuitiveness due to the fact that the user is sim-

ply editing values in dialog boxes that do not ex-

press how the feature is affected by the parameter.

As a result of these drawbacks, all too often designers

are forced into using a trial-and-error approach to find

the right feature parameter to be changed or to find the

right value for the parameter.

Good interactive facilities for direct manipulation

of features should always deal with the three draw-

backs mentioned above. In this research, we devel-

oped a new approach that allows the designer to se-

lect a parameter of a feature in the model, and sub-

sequently modify its value interactively, while be-

ing provided with real-time feedback on the conse-

quences of the operation. When the designer is sat-

isfied with the model, he can choose to provision-

ally accept the changes and, eventually, let the system

check the model validity.

The most crucial aspect of this approach consists

of being able to provide real-time feedback on the

changes effected to the feature model. Since this vi-

sual feedback has to be generated several times per

second to support interactive modification of a fea-

ture parameter value, all geometric constraints have to

be solved at that same pace. To achieve this, we de-

veloped a technique that (i) reduces the time needed

to solve a geometric model, (ii) can be applied with

a variety of constraint solvers, and (iii) can be eas-

ily implemented. This technique has been recently

presented in (Lourenço et al., 2006), which contains

a detailed description of our model compilation and

constraint solving approach, together with a perfor-

mance analysis of its prototype implementation.

In this paper we focus on how our approach solves

the other two drawbacks mentioned above. Through-

out the paper, we deal with the situation in which

a real-valued feature parameter that determines a di-

mension, or the position or orientation of a feature in

a feature model, is interactively manipulated by a de-

signer. All aspects of our approach described in the

paper were implemented in SPIFF, a prototype fea-

ture modeling system developed at Delft University

of Technology.

We first introduce various aspects involved in our

approach to direct manipulation of features (Section

2). Next we propose several types of feature han-

dles (Section 3), and describe how they are utilised to

yield advanced interactive facilities (Section 4). Fi-

nally, some conclusions are drawn (Section 5).

2 DIRECT MANIPULATION OF

FEATURES

Features can be modified by manipulating their para-

meters. Although a parameter of a feature can also

be a face of another feature to which it is attached,

or with respect to which it is positioned, this paper

only deals with manipulation of real-valued feature

parameters, such as the dimension of a feature, the

distance of a feature with respect to a face of another

feature, etc. An example of a through hole feature

with its parameters is given in Figure 1, showing the

typical entry fields for the various parameter values.

2.1 Feature Manipulation Phases

Direct manipulation of a real-valued feature parame-

ter consists of two phases. In the selection phase, the

parameter to be manipulated has to be selected. In

the interaction phase, the value of the parameter is

ADVANCED DIRECT MANIPULATION OF FEATURE MODELS

131

(a)

(b)

Figure 1: A through hole feature (a), and its parameters (b).

interactively changed by the designer, and the feature

model is updated accordingly by the system.

In the interaction phase, the designer changes the

value of a feature parameter, by using the mouse to

drag an icon that represents the feature parameter on

the displayed feature model. During the dragging, the

model and its visualization are updated continuously

to reflect the modifications.

The interaction phase needs to be performed real-

time, since the designer needs the feedback of the im-

age of the changed model on the display while drag-

ging the mouse. Real-time here means fast enough

to preserve the illusion of movement, i.e. the illusion

that consecutive images of the same object in a some-

what different position, show a moving object. This

illusion is preserved when the system displays more

than 10 frames (or images) per second (Card et al.,

1983).

2.2 Model Validity Maintenance

Manipulating the parameter of a feature in a model

may turn a valid feature model into an invalid one (see

Section 1), e.g. because an undesirable interaction oc-

curs between two features, or a dimension does not

satisfy its dimension constraint anymore.

An invalid situation should preferably be detected

during the manipulation of the model, and the de-

signer should preferably be immediately informed on

it. In case that it is not feasible to detect the invalid

situation during the manipulation of the model, for

example, because it takes too much time to check the

validity of the model, the validity of the model should

be checked as soon as the manipulation of the model

is ended.

However, in case a model has become invalid

during manipulation of a feature parameter, further

manipulation should not be prohibited, because the

model may turn valid again if the value of the parame-

ter is changed even more. For example, if the model

of Figure 1 would also contain a through slot that

is positioned to the left of the hole, and the through

slot would be moved to the right by manipulating its

position parameter, then, as the through slot and the

hole start to overlap, the model becomes invalid, but

the model turns valid again when the through slot is

moved beyond the hole.

If the model is invalid at the moment that the

manipulation of a feature parameter is ended, then

some validity maintenance mechanism (Bidarra and

Bronsvoort, 2000) should be triggered to assist the de-

signer to make the model valid again.

2.3 Constraint Management

To solve the geometric constraints in the model, a

constraint management scheme is used. The con-

straint management scheme maps a high-level con-

straint model, containing the complex design con-

straints, into a large low-level constraint model, con-

taining primitive constraints, that can be solved by

the constraint solvers used, and updates the high-level

constraint model based on the solved low-level con-

straint model.

Fortunately, in the interaction phase of direct ma-

nipulation, only part of the constraint model needs

to be solved. Since only one feature parameter is

changed during the interaction phase, typically, large

parts of the model do not change, i.e. they are rigid.

Such rigid parts can, therefore, be represented by a

single constraint variable in the low-level constraint

graph, thus avoiding the need to solve all constraints

within the parts.

Constraint managementfor interactive feature ma-

nipulation identifies all rigid parts of the model, and

maps each one to a separate constraint variable in the

low-level constraint model that is solved in the inter-

action phase. The resulting, simple, constraint model

is then used to find the relative position and orien-

tation of the rigid parts during the interaction phase,

given the current value of the feature parameter that

is changed. Again, this model compilation and con-

straint solving approach is described in (Lourenço

et al., 2006), to which the reader is referred for many

details on its fundamentals, implementation and per-

formance.

3 TYPES OF FEATURE HANDLES

Not all parameters of features have a direct geomet-

ric meaning. For such parameters, it is not possible

to assign a feature handle with a natural behaviour.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

132

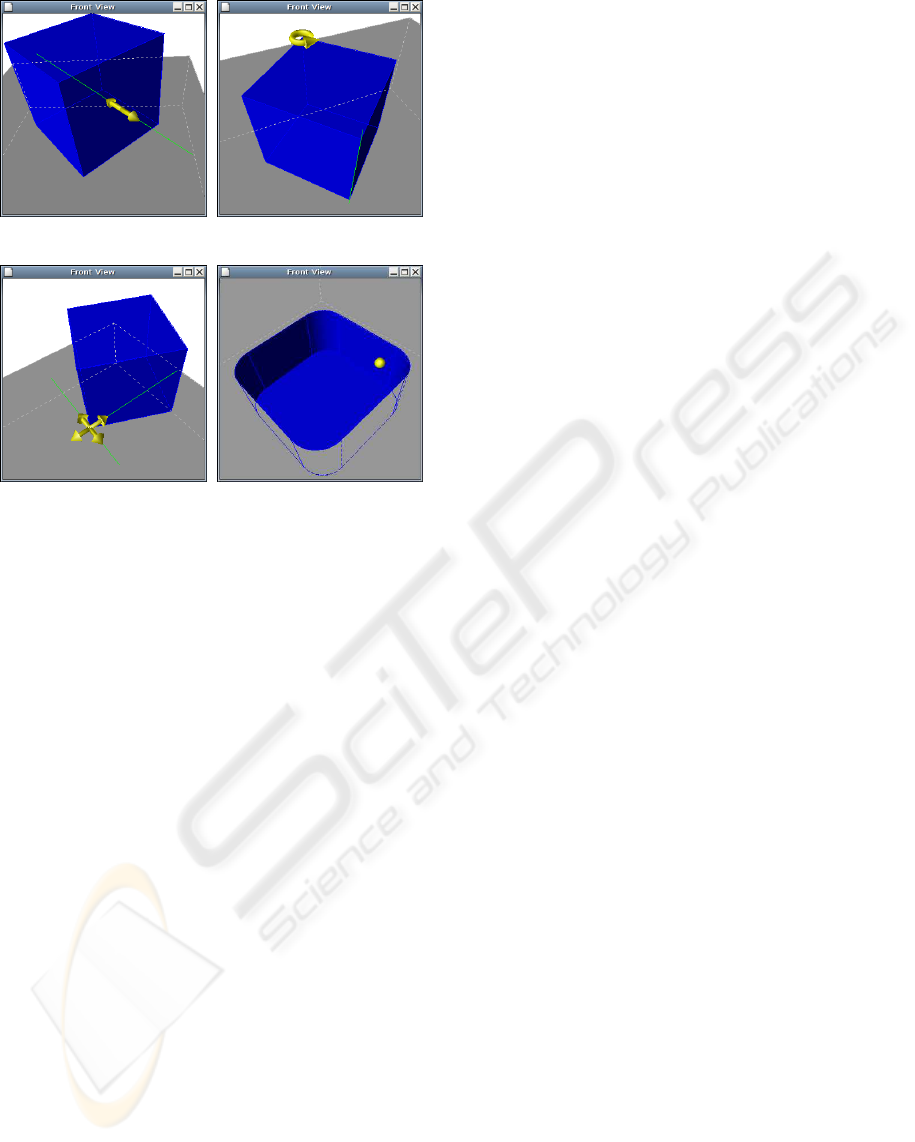

(a) Linear (b) Angular

(c) Planar (d) Slider

Figure 2: Types of handles.

A good example of this situation is a feature that has

a volume parameter. On the other hand, most para-

meters do have a simple geometric meaning, e.g. the

width of a protrusion or the rotation angle of the same

protrusion. As stated before, in this paper we deal

only with such real-valued parameters. For these, four

types of handles were identified that cover most direct

manipulation needs:

• Linear handles

• Angular handles

• Planar handles

• Slider handles

In this approach all handles of a feature are speci-

fied by their relation with reference elements (e.g. ref-

erence points and reference lines) of the feature. With

these references the system will be able to know the

placement of the handles as well as their behaviour

as they are being manipulated. One reference that is

needed for the specification of any type of handle is

the point that specifies its position in the model. These

references are specified at the feature definition like

any other references - using constraints. One very im-

portant consequence of the definition using references

is that the position and orientation of the handles will

be solely determined by the constraint solver.

We will now look with more detail into each of the

proposed handles:

• A linear handle is a handle that moves along a

straight line and reacts linearly with the mouse

movement. Besides the reference point represent-

ing the position, it also contains a reference line

representing the line on which the handle moves.

When the handle is dragged, the new mouse po-

sition is projected against the reference line, and

the parameter variation is given by the difference

between the computed position and the previous

position of the handle. See Figure 2(a).

• An angular handle is a handle that moves along

an arc in a way that the user is able to specify

an angle parameter. This handle has a reference

line besides the position reference that represents

the axis of rotation around which the angular han-

dle revolves. When the handle is dragged, the

new mouse position is projected onto the plane

perpendicular to the axis of rotation which passes

through the current position of the handle thereby

computing point1. To determine the change in the

parameter affected by this handle an angle is com-

puted. This angle is the angle between two lines in

the plane just mentioned which pass each through

the axis of rotation and through the original po-

sition of the handle and point1 respectively. See

Figure 2(b).

• A planar handle behaves somewhat like a linear

handle with the difference that, instead of having

its movement restricted to a line, its movement is

restricted to a plane (having two linear degrees

of freedom). For this type of handle two refer-

ence lines will be needed to determine the plane

on which it can move. One thing that differs from

this handle to all the others is the fact that by ma-

nipulating it the user is affecting two parameters

of the feature at the same time instead of one. To

determine the change in the parameter values a

computation similar to the one used for the lin-

ear handle will happen with the difference that the

mouse position will now be projected onto each

of the reference lines corresponding to each of the

parameters affected. The motivation for the exis-

tence of this handle is to enable the user to change

the position of features that have it specified by

two distances to external faces. See Figure 2(c).

• A slider handle is also similar to a linear handle

but, in this case, the line will simply be a vertical

line on the viewport with no connection to the ac-

tual feature geometry being changed by such pa-

rameter manipulation. Therefore this handle, un-

like any of the other handles, will contain solely

a reference point for its position and no reference

lines. The slider handle suits nicely to provide di-

rect manipulation to parameters that have no sim-

ADVANCED DIRECT MANIPULATION OF FEATURE MODELS

133

ple nor easy-to-localize geometric meaning, as the

corner radius in the pocket of Figure 2(d).

By combining these four kinds of handles in fea-

ture class definitions, the parameterization of a large

variety of feature classes is easily made ready for the

advanced direct manipulation facilities described in

the next section. Figure 3 shows a few examples of

such feature classes.

4 ADVANCED INTERACTIVE

FACILITIES

The direct manipulation approach developed should

overcome the three disadvantages of traditional fea-

ture manipulation mentioned in Section 1. In other

words, it is required that (i) feedback is efficient,

(ii) that insight into the modelling operation conse-

quences is provided, and (iii) that the relation between

what’s manipulated and the way it affects the feature

becomes intuitive. In this section we describe how

this was achieved.

For efficient feedback every modelling operation

leads to an immediate preview of the result of the op-

eration to the user. This preview is provided through

a transparent overlay display of the resulting model.

The user has insight on the consequences of the oper-

ation, which become clear through the comparison of

the original model with the simultaneously displayed

preview. The manipulation is intuitive because of the

feature handles’ characteristics. The deployed feature

handles (see Section 3) take into account that each

feature parameter has a specific semantics. This se-

mantics will be expressed through the handle’s behav-

iour, positioning and iconic representation.

We now give a brief description of how the user

interacts with the feature model under this approach,

in a way that materializes the requirements presented

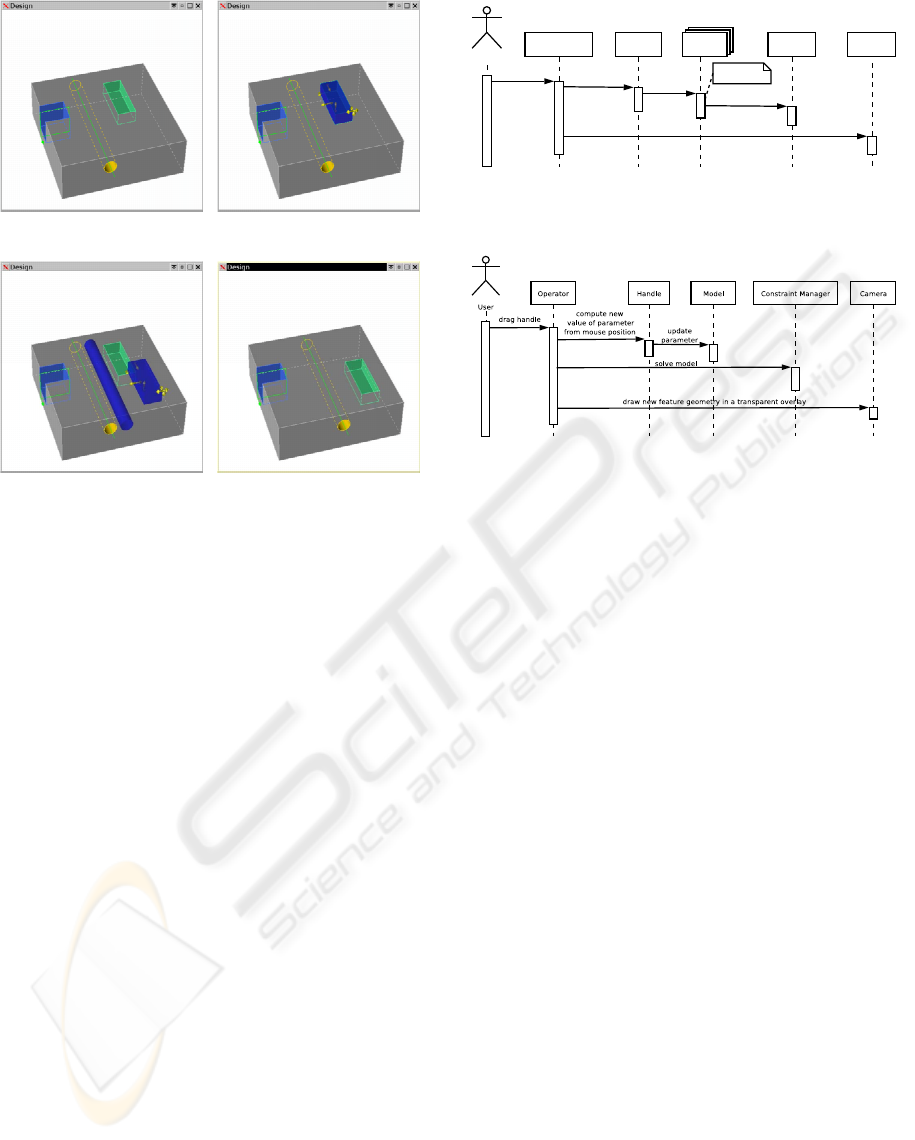

previously. For this, the example given in Figure 4

will be used.

• When a user selects a feature to be edited it is

highlighted with a transparent overlay with a dis-

tinguishing color and its available handles are dis-

played on the screen; see Figure 4.(b).

• The user may then edit the handles by dragging

them. When the user does so the display is up-

dated according to the change in the parameter.

When this happens, all the features which were

affected by the variation of the parameter also ap-

pear as a transparent overlay; ; see Figure 4.(c).

These changes are not final and can be undone.

• When the user chooses to Apply the modelling

operations, changes which have been made (and

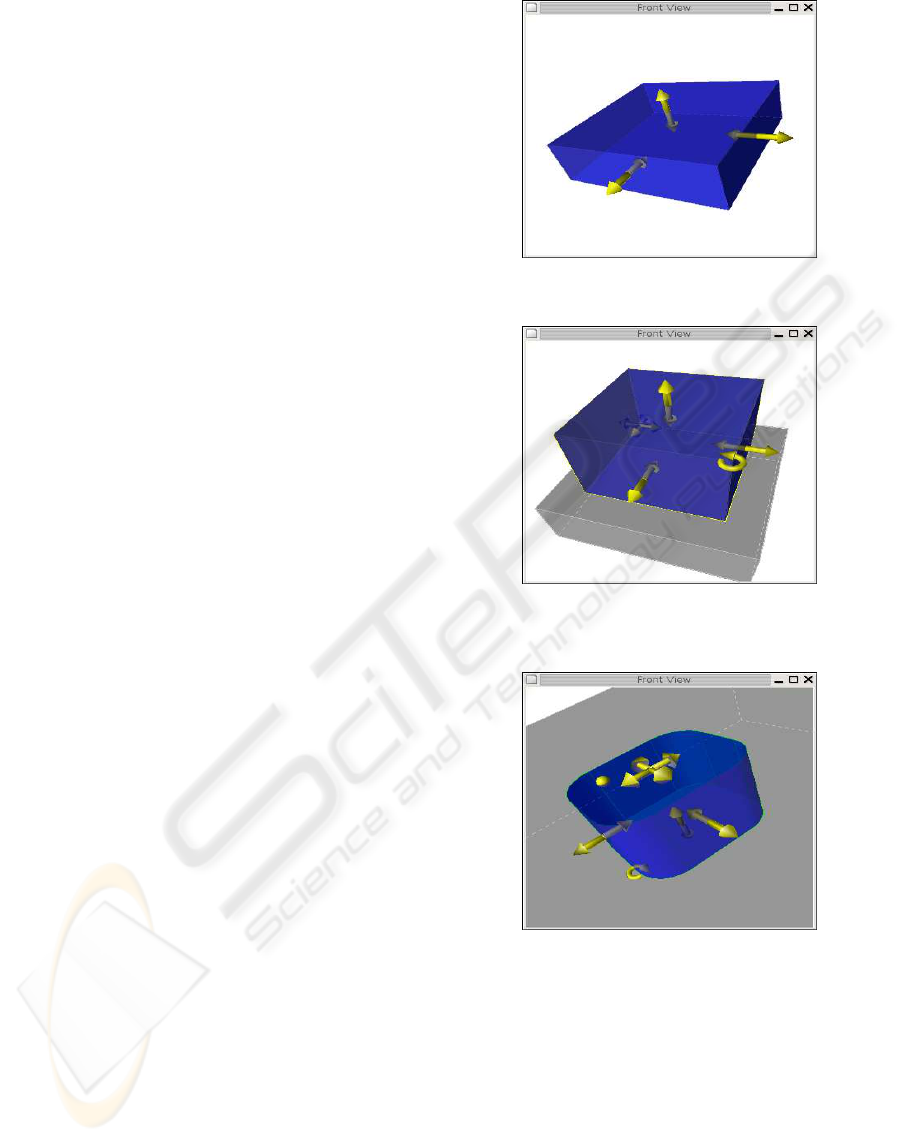

(a) Base Block feature with handles for

width, height and length

(b) Block Protrusion feature with han-

dles for width, height, length, rotation

and position

(c) Rounded Rectangular Pocket feature

with handles for width, height, length,

rotation, position and corner radius

Figure 3: Examples of handle specifications for three dif-

ferent feature classes.

highlighted) previously become final and the full

model display is updated with the new parameter

values; see Figure 4.(d).

• When the user chooses to Dismiss the modelling

operation, the changes which have been made

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

134

(a) Initial model (b) selection of the pocket

(c) dragging of the pocket (d) Final model

Figure 4: Interactively modifying a feature: the through

hole, positioned relatively to the pocket, is highlighted and

dragged together with it.

since the last Apply are undone.

As described in Section 2.1, two important phases

exist in the flow of events for handle manipulation:

the selection phase, when the user selects a parameter

of a feature to be edited, and the interaction phase,

each time the respective handle is dragged.

Figure 5 is a high level diagram of the flow of

events that happens when the user selects a feature

to be edited. Here, the user selection leads to the ac-

tivation of all the handles of the feature – the handle

is displayed and registered in the Operator (a control

entity). The feature is also highlighted with a trans-

parent overlay.

The flow of events that results from a single drag

event of the user is depicted in figure 6. The drag

event is reported to the Operator with the information

of the new mouse position. The operator sends a mes-

sage to the Handle which leads to the computation of

the new value of the parameter and to its update in

the model. This computation is obviously done tak-

ing into account the handle behaviour (see section 3).

After the new value is set, the Operator orders the

Constraint Manager to solve the model. This solving

process is done with the incremental constraint man-

agement solution specially optimized for direct ma-

nipulation described in (Lourenço et al., 2006). The

simple idea of this process is to add a preprocessing

User

User Interface Handle

select feature

for editing

Feature

prepare to edit

activate

draw handle

Operator Camera

register handle

draw selected feature overlay

Figure 5: Interaction diagram of what happens when the

user selects a feature for editing.

Figure 6: Interaction diagram of what happens when the

user drags a handle.

step when a parameter is first manipulated that boosts

the constraint solving performance to further changes

in that same parameter. With the new model values re-

sulting from the constraint solving process a transpar-

ent preview of the result of the operation is rendered

and displayed.

5 CONCLUSIONS

In this paper a new approach to the direct manipula-

tion of feature models was presented. Several types

of handles for parameters with a simple and intuitive

geometric meaning were introduced. In addition, a

slider handle was developed, for situations in which

the feature class designer wants to add direct ma-

nipulation to a generic parameter lacking an easy-to-

localize geometric meaning. The main aspects of the

new approach were discussed, together with its pro-

totype implementation within the SPIFF feature mod-

elling system, demonstrating its value and feasibility.

The definition of handles at the feature class level

is such that handles only depend on reference ele-

ments that are specified as any others in the system.

This solution has the advantage of having the posi-

tion and orientation of handle references automati-

cally computed in the constraint solving process.

For an effective and insightful feedback on the

modelling operations, a transparent preview of the

model is overlaid as the user directly manipulates a

feature through its handles. In this way the user can

ADVANCED DIRECT MANIPULATION OF FEATURE MODELS

135

clearly see the effects of the modelling operations and

compare the result with the original situation.

The prototype implementation has been success-

ful in making the manipulation of feature models a

very intuitive process, effectively improving the user

experience and, therefore, confirming the high poten-

tial of the approach.

REFERENCES

Bidarra, R. and Bronsvoort, W. F. (2000). Semantic feature

modelling. Computer-Aided Design, 32(3):201–225.

Borning, A. and Duisberg, R. (1986). Constraint-based

tools for building user interfaces. ACM Transactions

on Graphics, 5(4):345–374.

Card, S., Moran, T., and Newell, A. (1983). The Psychology

of Human-Computer Interaction. Lawrance Erlbaum

Associates, Hillsdale, N.J.

Freeman-Benson, B. N. (1993). Converting an existing

user interface to use constraints. In Proceedings of

the ACM Symposium on User Interface Software and

Technology, pages 207–215. ACM Press.

Hosobe, H. (2001). A modular geometic constraint solver

for user interface applications. In Proceedings of the

14th annual ACM symposium on User interface soft-

ware and technology, pages 91–100. ACM.

Hsu, C., Huang, Z., Beier, E., and Brüderlin, B. (1997).

A constraint-based manipulator toolset for editing 3d

objects. In Proceedings of the fourth ACM symposium

on Solid modeling and applications, pages 168–180.

ACM.

Lourenço, D., Oliveira, P., Noort, A., and Bidarra, R.

(2006). Constraint solving for direct manipulation

of features. Journal of Artificial Intelligence for

Engineering Design, Analysis and Manufacturing,

20(4):369–382.

Parametric Technology Corporation (2006).

Pro/ENGINEER product information.

http://www.ptc.com.

Shah, J. J. and Mäntylä, M. (1995). Parametric and

Feature-based CAD/CAM. John Wiley & Sons, Inc.,

New York.

SolidWorks Corporation (2006). Solidworks 2006 product

information. http://www.solidworks.com.

UGS Corporation (2006). Unigraphics NX product infor-

mation. http://www.ugs.com.

van Emmerik, M. J. G. M. (1991). Interactive design of 3D

models with geometric constraints. The Visual Com-

puter, 7(5/6):309–325.

GRAPP 2007 - International Conference on Computer Graphics Theory and Applications

136