PRECLINICAL TESTING OF A NEW VENOUS VALVE

Laura-Lee Farrell and David N. Ku

Georgia Institute of Technology, Atlanta, GA 30332-0405, USA

Keywords: Vein, venous valves, thrombosis, patency.

Abstract: Venous valvular incompetency is a debilitating disease affecting millions of patients. Unfortunately, the

current physiologic and surgical treatments are prone to the extreme risk of post-operative thrombosis. A

new design for venous valves has been proposed using biomimicry. The medical device has the shape of a

natural valve with sufficient elasticity to maintain patency and competency in the leg veins. The venous

valve was tested for patency, competency, cyclic fatigue, compressibility, and thrombogenicity. Patency is

maintained with a low opening pressure of less than 3 mmHg. Competency is maintained with

backpressures exceeding 300 mmHg. The valve is fatigue resistant to over ¼ million cycles. The valve can

maintain its integrity when compressed in a stent and deployed without tilting or mal-alignment. Little

thrombus forms on the valve with perfusion of whole blood under pulsatile flow conditions. The pre-

clinical tests demonstrate efficacy as a new venous valve for treatment of chronic venous insufficiency.

1 BACKGROUND

Venous disease will affect 1-3% of the western

world at some point in their lives, yet there are few

effective treatments for the venous system. One such

disease is chronic venous insufficiency (CVI), a

painful and debilitating illness that affects the

superficial and deep vein valves of the legs. When

the valves become incompetent they allow reflux

and subsequent pooling of blood. Symptoms include

swelling, edema, pain, itching, varicose veins, skin

discoloration, ulceration and limb loss. Post-

thrombotic damage within the deep veins is the most

significant cause of CVI, reported as high as 95%.

Current clinical therapies are only moderately

effective; and therefore, the need for a better

solution remains.

Surgical treatment for CVI is avoided due to

lack of accurate surgical technology and the extreme

risk of post-operative thrombosis. Valvuloplasty is

extensively time consuming and reserved for

patients with a congenital absence of functional

valves and severe cases of CVI. This surgical

procedure involves a venotomy, where the valve

cusps are plicated 20-25%. A singular valvuloplasty

is usually sufficient to correct CVI except in systems

that include occlusion of the femoral or popliteal

vein, or absence/incompetence of the

communicating leg veins.

Previous prosthetic vein valves have

experienced complications due to either in vivo

thrombosis, in-growth, foreign body reaction, or

prosthetic disorientation (tilting). The umbilical vein

valves and pellethane valves by Hill et al. failed due

to thrombotic occlusion (Hill et al, 1985). Two-

thirds of the autogenous venous valves by

Rosenbloom et al. failed from complications arising

to thrombosis (Rosenbloom et al, 1988). The

mechanical valves by Taheri et al. failed after three

months due to severe thrombotic occlusion (Taheri

and Schultz, 1995). Partial thrombosis appeared in

the valve cusps of the polyetherurethane valves by

Uflacker (Uflacker, 1993). Thrombosis occurred

immediately after deployment of the gluteraldehyde-

fixed bovine external jugular by Gomez-Jorge et al.

(Gomez-Jorge et al, 2000). Glutaraldehyde-

preserved bovine jugular valve-bearing venous

xenograft show thrombosis by histology (de Borst et

al, 2003).

A second cause of failure is hyperplasia.

Biocompatibility was the primary concern for Taheri

et al. and Gomez-Jorge et al. The two-year non-

patent mechanical valves by Taheri et al. failed due

to dense in-growth of intimal hyperplasia, which

rendered the valves functionless. The

gluteraldehyde-fixed bovine external jugular by

Gomez-Jorge et al. produced a granulomatous

response and foreign body reaction (Gomez-Jorge et

30

Farrell L. and N. Ku D. (2008).

PRECLINICAL TESTING OF A NEW VENOUS VALVE.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 30-35

DOI: 10.5220/0001050000300035

Copyright

c

SciTePress

al, 2000). Between 2000 and 2005 Pavcnik et al

reported on a stent-based porcine small intestine

submucosa prosthesis (Pavcnik et al, 2005); all

failed valves were the result of prosthesis tilting.

Overall, eight out of ten of the reported valve

designs experienced complications due to

thrombosis.

A new design for venous valves has been

proposed using biomimicry. The medical device

has the shape of a natural valve with sufficient

elasticity to maintain patency and competency in the

leg veins. This paper describes the pre-clinical

verification and validation testing of this new venous

valve.

2 METHODS

The venous devices were subjected to a battery of

tests to demonstrate sufficient function as a one-way

valve, propensity for thrombosis, and suitability for

minimally invasive delivery. The new “GT” vein

valve prosthetic is presented in Figure 1.

2.1 Pulsatile Flow System

This pulsatile system was designed to mimic the

physiologic flow conditions present in the lower

extremity venous system. During normal walking,

compression occurs about 40 times a minute (0.67

Hz). Fresh, whole, porcine blood with heparin (6.0 ±

0.2 U/mL) was transferred into a blood donor

collection bag. The collection bag was raised 30 cm

above the test section, rotated on an orbital mixer,

and attached to 90 cm of vinyl tubing, followed by a

3-way valve, a pressure tap and the test section.

Downstream of the test section, a 50 cm segment of

tubing (3.5 mm inner diameter) was passed through

a pulsatile pump rotating at a frequency of 0.75 Hz.

Pressure upstream of the vein valve was recorded

with a pressure transducer (Harvard Apparatus,

South Natick, MA) and the flow rate was calculated

from measurements with a graduated cylinder and a

stopwatch. The experiment proceeded until flow

cessation by occlusion or the contents of the fluid

reservoir were emptied.

Figure 1: GT vein valve. Upper left, isometric view. Upper

right, cross sectional view. Lower, downstream view.

2.2 Test Section

The test section included a vein valve, a flexible

venous-like tube, and suture material. The valves

were manufactured according to the procedure

outlined in reference (Sathe, 2007). The valve

material was made from a PVA hydrogel

biomaterial. The valve was inserted into the flexible

tube and tightly tied in place to prevent blood from

passing between the valve and the vessel wall. The

flexible tube was further attached to the vinyl tubing

by securing it with suture.

2.3 Dacron Lined Valve

A Dacron-lined valve acted as the positive control.

The lining was constructed from a commercially

available cardiovascular Dacron patch often used

clinically of approximately 14 mm ± 1 mm by 9 mm

± 0.5 mm, which was then sutured to the GT valve.

One stitch was placed on each Dacron piece on the

upstream side, these sutures held the Dacron against

the GT valve.

2.4 Pressure Tests

A syringe was attached to a three-way valve with the

test section and the pressure transducer (Harvard

Apparatus, South Natick, MA); downstream the test

section was open to atmosphere. Pressure was

applied with the syringe and read upstream of the

test section. For opening pressure, the prosthetic

vein valve was orientated with the distal end closest

PRECLINICAL TESTING OF A NEW VENOUS VALVE

31

to the syringe, and the proximal end facing ambient

atmosphere. For backpressure, the prosthetic valve

was reversed in orientation.

2.5 Thrombosis of Whole Blood

Whole blood samples were harvested from pigs and

quickly anti-coagulated with porcine heparin to a

final concentration of 6.0 ± 0.2 U/mL. The samples

were mixed with a nutating rocker at approximately

42 rpm for 15 minutes prior to the experiment.

Experiments were completed within eight hours of

harvesting the blood and conducted at room

temperature.

2.6 Histology

Samples were fixed in 10% formalin (VWR

International, West Chester, PA) for at least 72

hours. Samples were processed and embedded in

paraffin. Deformation of the samples during

processing was expected to be between 30 to 50%.

Samples were cut into 5-micron thin circular cross-

sections, oriented perpendicular to flow. Eight

sections from orifice areas were collected from each

sample. Alternating samples were stained with

Haematoxylin and Eosin stain (H&E), and Carstair’s

stain (specific for platelets). Sections were analyzed

microscopically using a Nikon E600 microscope, a

digital camera and Q-capture software.

2.7 Flat Compression

The valves were evaluated for plastic deformation

with respect to compression time. Initially, they

were evaluated for opening pressure and

backpressure conditions. At periodic time points the

valves were allowed to expand and were re-

evaluated for opening pressure and backpressure

conditions.

2.8 Radial Compression

The GT valves were inserted into balloon

expandable Palmaz stents, 10mm diameter and 20-

25mm in length, (Cordis Endovascular, Miami, FL;

and IntraTherapeutics, St. Paul, MN), and sutured

into place. The valves were evaluated for opening

pressure and backpressure.

2.9 In Vivo Placement

Placement inside an actual vein has been

problematic for some previous designs. The valves

might tilt or dislodge in the vein. Thus, our valves

were surgically placed in the correct anatomic

position in animals. The external jugular veins

(EJV) were exposed on four previously deceased,

2.5 year old, 50-60 Kg Dorset ewe sheep. A vertical

incision was performed on the EJV and the

prosthetic was placed inside the vein. The vessel

diameter was measured and the prosthetic valve was

manipulated to evaluate potential misplacement.

This procedure was repeated on the iliac veins.

3 RESULTS

The GT vein valve was evaluated for patency,

competency and cyclic life (Sathe, 2006). The valve

withstood 300 mm Hg of backpressure with less

than 0.3 mL leakage per minute, demonstrated a

burst pressure of 530 ± 10 mm Hg , opened with a

pressure gradient as low as 2.0 ± 0.5 mm Hg. The

patency and competency endpoints were statistically

unchanged after 500,000 cycles of cyclic testing.

3.1 Thrombosis from Pulsatile Blood

Flow

Blood was perfused through five GT vein valves; a

graphical representation is shown in Figure 2. All

five valves remained patent after 20 minutes of

blood flow without significant flow rate

deterioration. The average blood flow rate was 11.8

± 0.4 mL/min. The upstream pressure fluctuated

between 15 – 21 mmHg. Once the system was

exhausted of blood, the pressure dropped off to just

above 10 mmHg. When the flow system depleted

the blood reservoir the roller pump tried to pull

blood through the valve, the upstream and

downstream sections of the valve would collapse

due to the negative pressure. There was no gross

thrombus visible on any of the valve leaflets. The

leaflets remained functional and the valves remained

competent against backpressure.

The Dacron-lined valves initially produced the

same velocity profiles as the GT valves; though,

they did not remain patent for the experiment, but

rather occluded completely. The flow rate reduced

after two to eight minutes into the perfusion. On

average, the Dacron lined valves occluded after 6 ±

3.6 min of perfusion. The upstream pressure

fluctuation prior to occlusion was between 15 – 21

mmHg, and after occlusion, the pressure was

constant at 24 ± 1mmHg. The frequency of

occlusion for the Dacron lined valves in this assay

was significant to p<0.02. With occlusion, the

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

32

flexible tube collapsed violently instead of the valve

reopening. Thus, the system was a severe

demonstration of the adherent nature of the

occluding thrombus. The Dacron valves were

visually inspected at the end of the experiment. The

polyester fibers were covered with red blood and

were visibly matted down. After occlusion, some

red clot remained in the lumen of the tubes. The GT

valves and Dacron lined valves were preserved for

histological analysis.

0

50

100

150

200

250

0 5 10 15 20 25

Time (min)

Volume (mL)

PVA Valve 1

PVA Valve 2

PVA Valve 3

PVA Valve 4

PVA Valve 5

Dacron Valve 1

Dacron Valve 2

Dacron Valve 3

Figure 2: Perfused blood volume over time in the GT and

Dacron-lined valves. The GT valves produced a constant

flow rate; whereas, the Dacron lined valves produced a

gradual cessation of flow.

Histology was performed on both the GT and

Dacron lined valves to identify cell accumulation

and the cause for cessation of flow. The histology

stains used were Haematoxylin and Eosin stain

(H&E), and Carstair’s stain (specific for platelets).

The PVA material is represented as pink in the H&E

stain and a faint blue-grey in the Carstair’s stain.

With regard to the Dacron lined valve slides, the

gray circular structures represented the Dacron

fibers. The red debris located between the Dacron

leaflets represented the cellular material that was

preventing blood from passing through the leaflets in

the in vitro model. Further analysis with Carstair’s

stain revealed that platelet aggregation with fibrin

strands was a key component in the red debris. The

presence of platelets on the Dacron leaflets, and the

complete absence of platelets on the GT valves

confirmed that the in vitro blood flow assay had the

potential to thrombose, yet the GT valves do not

exhibit any thrombosis or clot in this system.

3.2 Plastic Deformation – Flat

Compression.

Valves were subjected to flat compression. Prior to

compression the valves demonstrated an opening

pressure of 3 mm Hg ± 1 mm Hg, and a

backpressure of at least 100 mm Hg. Subsequently at

2 hrs, 4 hrs and 6 hrs after compression the valves

exhibited an opening pressure of 3 mm Hg and

maintained competency with a backpressure of 100

mm Hg.

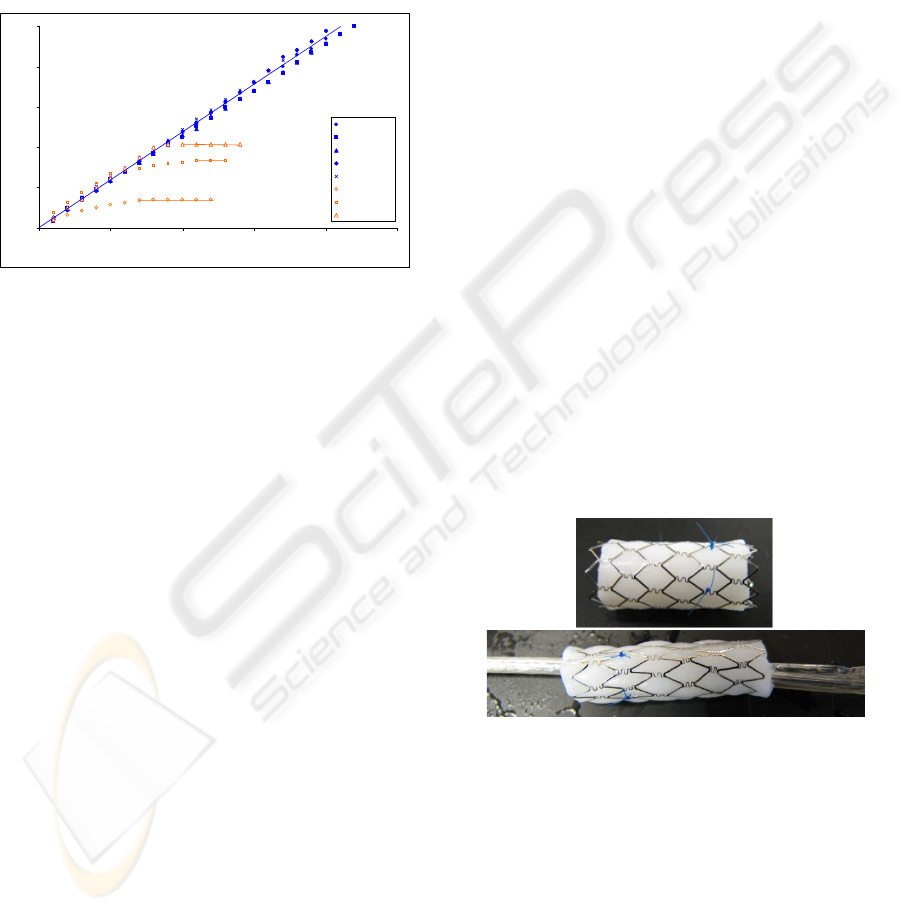

3.3 Radial Compression

The average initial outside diameter of the valve-

stent system was 8.8 mm ± 0.1 mm. Prior to

compression exposure the valves demonstrated an

opening pressure of 3 mm Hg ± 1 mm Hg, and a

minimum backpressure of 100 mm Hg. The average

compressed outside diameter of the valve-stent

system was 6.5 mm ± 0.1 mm. They were

compressed for 1hr and subsequently expanded,

shown in Figure 3. Visually the expanded valves

retained their original configuration. The valves

exhibited an opening pressure of 4 mm Hg ± 1 mm

Hg and withstood a backpressure of 100 mm Hg.

The average expanded outside diameter of the valve-

stent system was 9.5 mm ± 0.5 mm. All valves met

the original design criteria of opening pressure

below 5 mm Hg and a backpressure up to 100 mm

Hg.

3.4 In Vivo Placement

The prosthetic was positioned inside the external

jugular veins and iliac veins of four sheep as

depicted in Figure 4. The 10 mm prosthetic vein

valve was of appropriate size for the EJV of sheep.

Figure 3: Above, Genesis Palmaz Stent (Cordis) with GT

vein valve. Below, radially compressed valve and stent on

a balloon catheter.

The 10 mm prosthetic vein valve was too small

for the iliac vein. Vigorous manipulation of the

prosthetic in situ did not cause any misplacement,

tilting, or orientation problems. Tilting was of no

concern due to the long profile of the prosthetic. A

suite of valve sizes ranging from 10mm to 4 mm in 2

mm increments were created to account for varying

vessel sizes, as seen in the iliac of sheep.

PRECLINICAL TESTING OF A NEW VENOUS VALVE

33

4 DISCUSSION

Evaluating the thrombotic potential of a prosthetic

vein valve in an in vitro set-up is a novel process, as

the thrombotic potential is typically evaluated in an

animal model. Animal studies require the long

process of approval from animal care and use

committees, the trials are costly, the study itself is

time consuming, and animal lives are sacrificed. In

vivo models are necessary to determine the

biocompatibility of the prosthetic device, and an

important step towards clinical trials; yet using an in

vitro thrombosis model provides an appropriate

intermediate step between valve development and

expensive in vivo studies.

The GT venous valve demonstrates low

thrombus formation in the whole blood perfusion

system, as it remained patent after 20 minutes of

perfusion with no adherent platelets. In contrast,

the Dacron valves occluded after 6 ± 3.6 min of

perfusion. Histology revealed adherent fibrin, RBCs

and platelet thrombus under histological analysis.

The time of occlusion for the Dacron lined valves in

this assay was significantly shorter than the GT

valves (p<0.02).

When designing an in vitro model it is most

relevant for the model to be as close to physiologic

conditions as possible. The in vitro model perfuses

whole porcine blood through a prosthetic vein valve.

The pulsatile frequency of the system, 0.75Hz,

approximates the normal walking cadence of an

adult. A potential limitation to this in vitro set-up is

that the flow through the prosthetic valves was 11.8

± 0.4 mL/min, yet the blood flow through the

femoral vein is around 70 mL/min. The flow was

lower than physiologically observed valves because

the frequency and collection time were selected, but

the tubing diameter was restricted. The tubing

diameter could not be increased to reduce flow as it

was limited to the pulsatile pump tubing

specifications. Even though platelet adhesion in a

stenosis happens at high velocities, vein thrombosis

typically is thought to occur at low velocities.

Therefore modeling a low flow rate may be more

appropriate, since it is a worse-case scenario.

For instance, when one sits for a long period of

time on a transatlantic flight and the calf pump is not

actively engaged, the blood is traveling at a lower

velocity back to the heart.

Figure 4: Above, GT valve positioned beside right

external jugular vein. Below, GT valve implanted into

right external jugular vein.

The future of medical implants lies in

percutaneous devices; therefore, to create a

marketable and less invasive implant, a percutaneous

delivery system has been designed for the GT vein

valve. An appropriate delivery route may be from

the external jugular vein down through the heart to

the femoral or iliac vein. Reduction of the crimped

valve profile may be achieved by decreasing the

thickness of the cylindrical supporting material.

Future improvements could include incorporation of

antithrombotics or other eluting drugs into the valve

to limit thrombosis, inflammation or foreign body

response mechanisms. Due to the low in vitro

thrombotic potential and the successful previous

clinical use of the material as a medical implant

material, clinical trials may be considered.

Given the successful implementation of pre-

procedure crimping of percutaneous heart valves

(Edwards Life Sciences), a similar technique was

pursued for the GT vein valve to allow it to be

compressed within 6 hours of implantation. The

portable stent crimper makes this possible.

Evaluating the thrombotic potential of a prosthetic

1 mm

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

34

vein valve in an in vitro blood set-up is a novel

process. The most common practice to test the

thrombotic potential is in an animal model, where

eight out of ten studies reviewed failed due to in vivo

thrombosis. The two most successful vein valve

studies use acellular tissues: the SG-BVV was

constructed from porcine small intestine submucosa

(SIS), and the PVVB used gluteraldehyde-preserved

bovine jugular valves (Moll, 2003), (Gale et al,

2004). The GT vein valve provides several

advantages over SIS and gluteraldehyde-preserved

bovine jugular valves. Zoonosis from animal tissue

prosthetics is possible and the use of animal derived

prosthetics may be culturally or religiously

controversial, therefore a synthetic material would

alleviate these concerns. The PVVBs are fixed with

gluteraldehyde, which is a toxic substance that will

prevent cells from integrating into the material in

vivo. This gluteraldehyde preservation process will

cause a limited cyclic life due to the cross-linking of

the collagen fibers, and ongoing biocompatibility

issues due to the gluteraldehyde toxicity. The SIS

tissue appears to be an appropriate material for vein

valve prosthetics with regards to its

biocompatibility. However, despite revisions to the

SIS vein valve, the SG-BVV continues to experience

in vivo tilting. Tilting is not an issue with the GT

vein valve because of the long axial dimension. In

addition, GT vein valve can be mass-produced and

the design is easily modified. This is unlike acellular

tissues which require extensive tissue preparation

and processing times and modification of the tissue

valve design could create concerns regarding

suturing locations and tissue-to-stent attachment

sites.

Another feature of the new GT Valves is that

they may be processed to include embedded drugs,

which could promote cell growth and/or reduce

thrombus formation. It has superior biocompatibility

and structural integrity, may be mass-produced, and

has the potential to utilize new drug delivery

technologies.

Providing relief to chronic venous insufficiency

is a worthwhile pursuit as patients experience

swelling, edema, pain, itching, varicose veins, skin

discoloration, ulceration and limb loss. Current

clinical therapies are only modestly effective; and

therefore, a prosthetic vein valve may provide a cure

for this debilitating disease. With successful animal

and human trials this valve could provide a useful

therapy the 7 million people suffering from chronic

venous insufficiency. The GT valve exhibits

excellent flow, full competency, fatigue-resistance,

low-thrombogenicity, material flexibility, and in situ

placement consistency.

REFERENCES

de Borst, G.J., et al., A percutaneous approach to deep

venous valve insufficiency with a new self-expanding

venous frame valve. Journal Of Endovascular Therapy,

2003. 10(2): p. 341-349.

Gale, S.S., et al., Percutaneous venous valve

bioprosthesis: initial observations. Vascular And

Endovascular Surgery, 2004. 38(3): p. 221-224.

Gomez-Jorge, J., A.C. Venbrux, and C. Magee,

Percutaneous deployment of a valved bovine jugular

vein in the swine venous system: a potential treatment

for venous insufficiency. Journal Of Vascular And

Interventional Radiology: JVIR, 2000. 11(7): p. 931-

936.

Hill, R., et al., Development of a prosthetic venous valve.

Journal of biomedical materials research., 1985. 19(7):

p. 827.

Moll, F. Venous Valves for Chronic Venous Insufficiency.

in Vascular and Endovascular Controversies. 2003.

London, UK.

Pavcnik, D., et al., Significance of spatial orientation of

percutaneously placed bioprosthetic venous valves in

an ovine model. Journal Of Vascular And

Interventional Radiology, 2005. 16(11): p. 1511-1516.

Rosenbloom, M.S., et al., Early experimental experience

with a surgically created, totally autogenous venous

valve: a preliminary report. Journal of vascular

surgery, 1988. 7(5): p. 642.

Sathe, R.D. and D.N. Ku, Design and Development of a

Novel Implantable Prosthetic Vein Valve. J Med

Devices, 2007. 1: p. 105-112.

Taheri, S.A. and R.O. Schultz, Experimental prosthetic

vein valve. Long-term results. Angiology., 1995.

46(4): p. 299.

Uflacker, R. Percutaneously introduced artificial venous

valve: Experimental use in pigs. in The 1993 Annual

Meeting of the Western Angiographic & Interventional

Society. 1993. Portland, OR.

PRECLINICAL TESTING OF A NEW VENOUS VALVE

35