MODELLING

MODIFIED ATMOSPHERE PACKAGING FOR

FRUITS AND VEGETABLES USING MEMBRANE SYSTEMS

Gabi Escuela

1

, Thomas Hinze

2

, Peter Dittrich

1

, Stefan Schuster

2

Friedrich Schiller University Jena,

1

Bio Systems Analysis Group and

2

Department of Bioinformatics, Jena, Germany

Mario Moreno-

´

Alvarez

U.N.E. Sim

´

on Rodr

´

ıguez, Laboratorio de Biomol

´

eculas, Canoabo, Venezuela

Keywords:

P systems, Modified Atmosphere Packaging, fruit modelling, membrane systems, respiration, temperature.

Abstract:

As living materials, post-harvested fruits and vegetables continue their metabolic activity, exhibiting progres-

sive biochemical changes. Optimisation of environmental conditions during storage of these fresh commodi-

ties is required in order to increase their shelf life. In this work we use P systems to abstract molecular inter-

actions that occur between plant organ, film and surrounding atmosphere factors involved in fresh fruit and

vegetable package designs. The proposed model constitutes a general framework to simulate the dynamical

behaviour of these systems, specially due to gas exchanges and temperature fluctuations. Moreover, the model

can be extended introducing other variables and processes that affect quality of such produces. This can be

considered, to the best of our knowledge, the first contribution of Membrane Computing in Food Engineering.

1 INTRODUCTION

Membrane systems (P

˘

aun and Rozenberg, 2002), also

called P systems, had emerged to assist in the mod-

elling of systems of concurrent reactions taking place

in compartments, so as occur in biological systems. In

this paper we use P systems as membrane structures

delimiting compartments that contain multisets of ob-

jects representing molecules. Compartments configu-

ration changes over time (evolve) according to given

rules that represent biochemical reactions and diffu-

sions. In contrast to ODE-based approaches, each

single molecule within the entire system is repre-

sented explicitly as individual entity. Capturing as-

pects of structural dynamics (changes in the mem-

brane structure as well as in the composition of com-

plex molecules) is seen as an advantageous feature of

P systems. Inclusion of reaction kinetics into this for-

malism can be done by discretised kinetic laws (Hinze

et al., 2006). We applied this mathematical formalism

to a real known problem in fruits and vegetables post-

harvest processing.

Fresh fruits and vegetables are living materials

that continue to respire after harvesting exhibiting

progressive biochemical changes. Food Engineer-

ing methods to preserve freshness of post-harvest

produces include low temperature storage and spe-

cial packaging technologies, mainly Modified Atmo-

sphere Packaging (MAP). MAP of fresh fruits and

vegetables refers to the technique of enveloping the

produce in a sealed container of polymeric film in or-

der to modify the O

2

and CO

2

concentrations inside

the package, reducing metabolic activity and increas-

ing shelf life (Paul and Clarke, 2002).

Designing MAP systems is a complex task that

involves considerations about many interrelated envi-

ronmental (as temperature and atmosphere composi-

tion), biological and package technology factors. Ba-

sic biological processes are respiration, transpiration,

ethylene production and compositional changes due

to metabolism. The variability of responses to internal

and external signals depends on the characteristic of

each plant organ type, developmental stage and physi-

ological condition. In addition, much of the behaviour

of a MAP system at cellular level are not fully under-

stood. As examples we can refer to the little knowl-

edge about the effect of CO

2

on the activity of respira-

tory enzymes (Ho et al., 2008). Moreover, the contri-

bution of the biochemical changes that alters physical

properties of cell walls and tissues modifying the tex-

ture of the produce is not known in detail (Gross et al.,

2004). On the other hand, the mechanism of ethylene

306

Escuela G., Hinze T., Dittrich P., Schuster S. and Moreno-Álvarez M. (2010).

MODELLING MODIFIED ATMOSPHERE PACKAGING FOR FRUITS AND VEGETABLES USING MEMBRANE SYSTEMS.

In Proceedings of the Third International Conference on Bio-inspired Systems and Signal Processing, pages 306-311

DOI: 10.5220/0002749103060311

Copyright

c

SciTePress

signal transduction that coordinates fruit ripening pro-

cesses, is another aspect subject to study (Alexander

and Grierson, 2002).

The difficulty to test different combination of

gases and temperatures and the complexity of exper-

imental setup for MAP systems had lead to the de-

velopment of various mathematical models (Exama

et al., 1993; Tijskens et al., 2001; Paul and Clarke,

2002; Ho et al., 2008) and software (Mahajan et al.,

2007). In the literature, many respiration models are

empirical fits of experimental data, based on one par-

ticular type and variety of fruit or vegetable, and most

of them are based on the principles of enzyme ki-

netics and are represented using ODEs (for reviews

see (Fonseca et al., 2002; Rodriguez-Aguilera and

Oliveira, 2009)). However, there exists some lack on

studies about the dynamical behaviour of these sys-

tems in terms of changes in environmental conditions,

so as produce composition and physiology due to de-

velopmental processes (Fonseca et al., 2002). It is

worth mentioning that post-harvested fruits and veg-

etables, unlike other living materials, can be consid-

ered as less robust systems, as their responses on en-

vironmental fluctuations depends mostly on their ac-

tual configuration of biochemical components. In this

context, some authors (G

´

enard et al., 2007; Maha-

jan et al., 2007) have considered the potential ben-

efits of a systematic analysis or process-based mod-

elling approach for fruits and vegetables. Consider-

ing that understanding the reaction network underly-

ing MAP systems can give food experts more knowl-

edge about emergent properties of packaged fruits and

vegetables, we propose a framework based on mem-

brane systems that abstracts basic biochemical reac-

tions that occur in MAP systems. In the future, the

proposed model can serve as a predictive tool to sim-

ulate changes in fresh produce on the molecular level,

due to changes in environmental conditions.

This paper is organized as follows: in Section 2

we present a P system framework for MAP, including

the description of components, reaction kinetics and

evolution of the system. Section 3 shows an applica-

tion of the framework considering a package under

modified atmosphere containing two produces. Fi-

nally, in Section 4 we point out some benefits of using

our framework and future extensions of it.

2 A P SYSTEM-BASED MAP

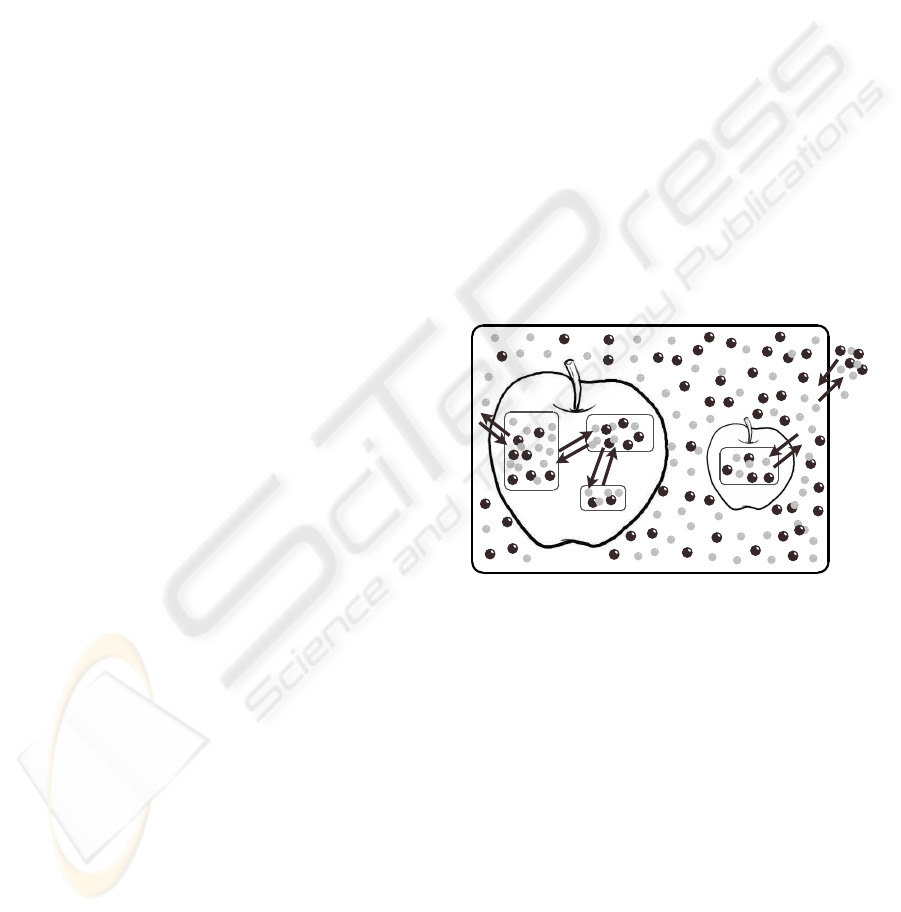

We abstract a fruit or vegetable as a graph of cells

or modules, like tissue P systems (Mart

´

ın-Vide et al.,

2003). Each cell represents a compartment that con-

tains species, and at a specific time, the contents of the

compartment determine the cell configuration. This

serves as a mechanism to differentiate one cell from

other, given the possibility to creating diverse tissue

types, as occurs for example in fruits epicarp, meso-

carp and endocarp tissues (G

´

enard et al., 2007). Addi-

tionally, as gas consumption-production occur inside

the cells, at the mitochondria level, and is stated that

gas diffusion between cells depends on the geometry

of the produce (Ho et al., 2008), differences in gas

content in cells that conform a determinate region can

adequately be represented. This is also in accordance

to the idea that the ripening process usually starts

in one region of a fruit and spreads to neighbour-

ing regions, due to ethylene diffusion starting from

promoter cells (Alexander and Grierson, 2002). Pro-

duces into the package are represented as a population

of membranes, giving the advantage that the model

can deal with distinct fruits and vegetables within the

same film, or the same produce in distinct develop-

mental stages, varieties and/or presentations. Figure

1 shows as example, the schematic representation for

such a system. In the next section we present the for-

mal specification of our model.

package

plant_1

plant_2

cell_1,1

cell_1,2

cell_1,3

cell_2,1

Figure 1: A schematic representation for the MAP system

model. In this case, two produces share a package: plant

1

is

formed by three connected cells, and plant

2

is formed by a

single cell. Arrows represent paths for molecules (spheres)

diffusions.

Multiset Prerequisites. Let A be an arbitrary set and

N the set of natural numbers including zero. A multi-

set over A is a mapping F : A −→ N ∪{∞}. F(a), also

denoted as [a]

F

, specifies the multiplicity of a ∈ A in

F. Multisets can be written as an elementwise enu-

meration of the form {(a

1

,F(a

1

)),(a

2

,F(a

2

)),. ..}

since ∀(a,b

1

),(a, b

2

) ∈ F : b

1

= b

2

. The

support supp(F) ⊆ A of F is defined by

supp(F) = {a ∈ A | F(a) > 0}. A multiset F

over A is said to be empty iff ∀a ∈ A : F(a) = 0. The

cardinality |F| of F over A is |F| =

∑

a∈A

F(a). Let

F

1

and F

2

be multisets over A. F

1

is a subset of F

2

,

denoted as F

1

⊆ F

2

, iff ∀a ∈ A : (F

1

(a) ≤ F

2

(a)).

MODELLING MODIFIED ATMOSPHERE PACKAGING FOR FRUITS AND VEGETABLES USING MEMBRANE

SYSTEMS

307

Multisets F

1

and F

2

are equal iff F

1

⊆ F

2

∧ F

2

⊆ F

1

.

The intersection F

1

∩ F

2

= {(a,F(a)) | a ∈

A ∧ F(a) = min(F

1

(a),F

2

(a))}, the multiset sum

F

1

] F

2

= {(a,F(a)) | a ∈ A ∧ F(a) = F

1

(a) + F

2

(a)},

and the multiset difference F

1

ª F

2

= {(a,F(a)) | a ∈

A ∧ F(a) = max(F

1

(a) − F

2

(a),0)} form mul-

tiset operations. Multiplication of a multiset

F = {(a, F(a)) | a ∈ A} with a scalar c, denoted c · F,

is defined by {(a,c · F(a)) | a ∈ A}.

P System Components. Let N

+

= N \ {0} be the set

of natural numbers without zero, and m,n ∈ N

+

. We

define a P system for a MAP system as a construct:

Π

MAP

= (µ,S, plant

1

,. .., plant

m

,G, L

0

,

D

1

,. .., D

d

, f

1

,. .., f

d

,∆τ)

where:

• µ = [[[]

cell

1,1

...[]

cell

1,n

1

]

plant

1

...[[]

cell

m,1

...[]

cell

m,n

m

]

plant

m

]

package

is

the spatial system structure composed of three inner levels: package,

plants, and cells,

• S is a set of chemical species,

• plant

1

,.. . , plant

m

represent the produces into the package,

• G is a set of global parameters,

• L

0

: S → N is a multiset of axioms representing the initial molecular

configuration,

• D

ν

is a diffusion (communication) rule among package and external

environment (ν = 1,.. . ,d),

• f

ν

: (S → N) → N is a kinetic function attached to diffusion rule D

ν

,

• ∆τ ∈ R

+

is the time discretisation interval.

A diffusion rule D

ν

can be of the form [s] → []s for

molecules s ∈ S leaving the package and released to

the external environment, and []s → [s] for molecules

entering the package, respectively.

Furthermore, each plant

i

is defined as a tuple:

plant

i

= (N

i

,E

i

,G

i

,D

i,1

,. .., D

i,d

i

, f

i,1

,. .., f

i,d

i

)

where:

• N

i

= {cell

i,1

,.. . ,cell

i,n

i

} defines a set of cells within plant i,

• E

i

⊆ N

i

× N

i

specifies a set of directed edges (diffusion channels be-

tween cells),

• G

i

is a set of plant (organ) specific parameters,

• D

i,κ

represents a diffusion rule inside plant i and between plant i and

package (κ = 1,... , d

i

),

• f

i,κ

is a kinetic function attached to diffusion rule D

i,κ

.

Here, a diffusion rule can be of the form

[s]

cell

p,q

→ []

cell

p,q

s for molecules s ∈ S leaving cell

p,q

and spread out into the package. A rule of the

form []

cell

p,q

s → [s]

cell

p,q

describes molecules entering

cell

p,q

from the package. Finally, a rule of the form

[s]

cell

p,q

→ [s]

cell

x,y

formulates the directed transport of

molecule s along the edge (cell

p,q

,cell

x,y

) ∈ E

i

.

Each cell

i, j

is defined as a tuple

cell

i, j

= (L

i, j,0

,R

i, j,1

,. .., R

i, j,r

i, j

, f

i, j,1

,. .., f

i, j,r

i, j

)

where:

• L

i, j,0

: S → N is a multiset of axioms representing its initial molecular

configuration,

• R

i, j,k

= (A

i, j,k

,B

i, j,k

) with A

i, j,k

: S → N (multiset of reactants) and

B

i, j,k

: S → N (multiset of products) specifies a reaction rule including

its stoichiometric factors,

• f

i, j,k

: (S → N) → N is a function corresponding to kinetics of reaction

R

i, j,k

.

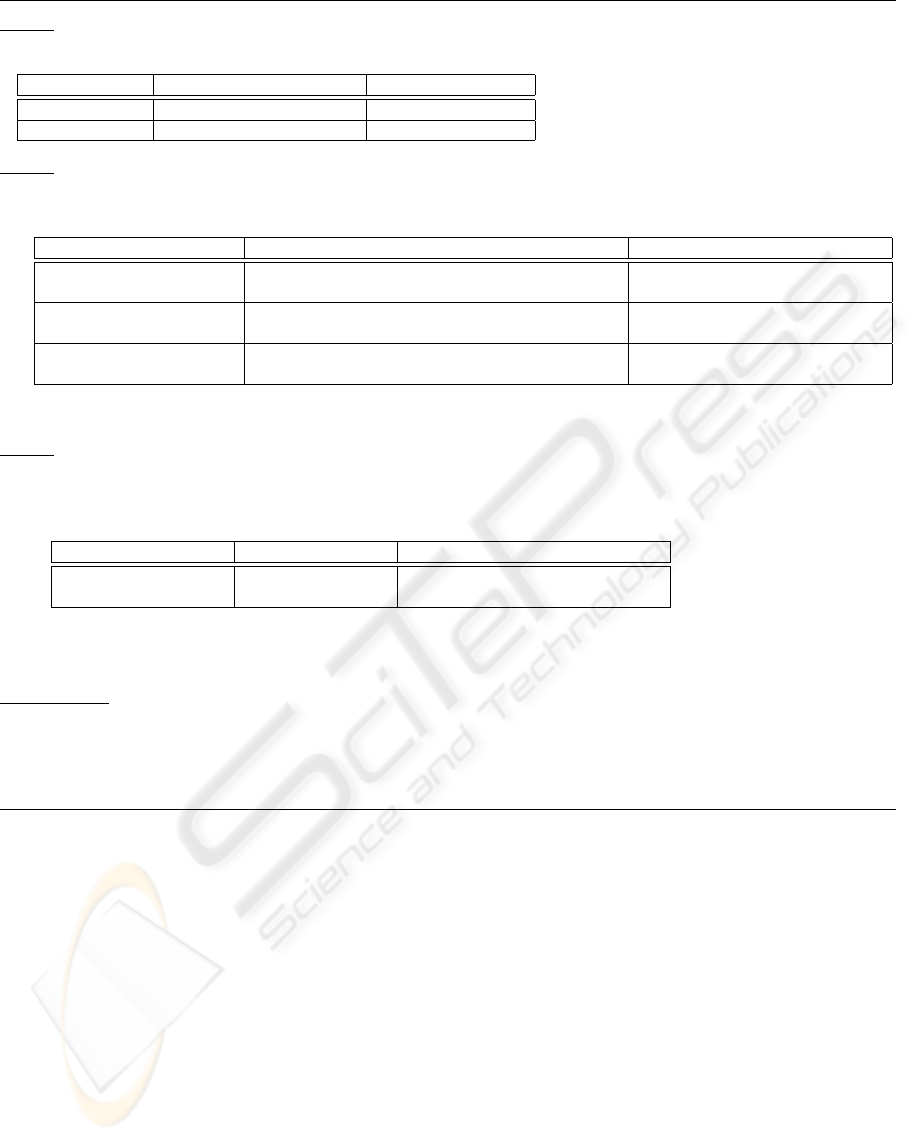

System Evolution. A P system of the form Π

MAP

evolves by successive progression of its configuration

at discrete points in time t ∈ N for what we assume a

global clock. Two consecutive dates t and t + 1 spec-

ify a time span ∆τ. A system step at time t consists

of three modification stages carried out from outer

to inner spatial components of the system. Firstly,

the diffusion between package and its environment is

considered. To this end, the rules D

1

up to D

d

are

employed. Afterwards, the diffusion between pack-

age and cells as well as the intracellular diffusion is

utilised by employing the rules D

i,κ

for each plant

i = 1,.. .,m. The last modification stage concerns ap-

plication of the reaction rules specified in each cell.

To cope with conflicts that can occur if the available

amount of substrate cannot satisfy all matching dif-

fusion and reaction rules, we prioritise all rules by

their index: D

1

> D

2

> ... > D

d

. Moreover, for each

plant i: D

i,1

> D

i,2

> ... > D

i,d

i

and for each cell i, j:

R

i, j,1

> R

i, j,2

> .. . > R

i, j,r

i, j

. Thus, we keep determin-

ism of the system evolution and enable mass conser-

vation. An alternative method for coping with con-

flicts is randomisation in selection and sequentialisa-

tion of diffusion and reaction rules.

The application of an arbitrary rule is organised

into two consecutive steps. The first step identifies

all molecules from the rule’s left hand side acting as

sources for diffusion or reactants. These molecules

are removed from the current configurations. Corre-

sponding molecules from the right hand side (desti-

nations in case of diffusion and products in case of

reactions) are then added. We formulate discretised

reaction-diffusion kinetics by specification of scalar

functions f : M → N based on a multiset M : S → N.

Each function f converts the current configuration (L

t

or L

i, j,t

), a multiset of objects, into the number of

turns for application of the corresponding diffusion or

reaction rule. Here, kinetic laws

ˆ

f(s) for each species

s ∈ S employ the multiplicity of its occurrences to for-

mulate the corresponding reaction rate. For updating

the entire system configuration, we define an iteration

scheme as shown in Figure 2.

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

308

Stage 1 (diffusion between package and external environment):

∀α = 1,..., d

diffusion rule conditions action

D

α

= [σ] → []σ (σ ∈ S) ∧ ({(σ, f

α

)} ⊆ L

t

) L

t

:= L

t

ª {(σ, f

α

)}

D

α

= []σ → [σ] (σ ∈ S) L

t

:= L

t

] {(σ, f

α

)}

with f

α

(L

t

) =

¥

k

α

(G) · ∆τ ·

ˆ

f(|L

t

∩ {(σ,∞)}|)

¦

Stage 2 (diffusion between plant cells and package):

∀i = 1, ... ,m

∀α = 1,. .., d

i

diffusion rule conditions action

D

i,α

= [σ]

cell

i, j

→ []

cell

i, j

σ (σ ∈ S) ∧ (cell

i, j

∈ N

i

) ∧ ({(σ, f

i,α

)} ⊆ L

i, j,t

)

L

i, j,t

:= L

i, j,t

ª {(σ, f

i,α

)}

L

t

:= L

t

] {(σ, f

i,α

)}

D

i,α

= []

cell

i, j

σ → [σ]

cell

i, j

(σ ∈ S)∧ (cell

i, j

∈ N

i

) ∧ ({(σ, f

i,α

)} ⊆ L

t

)

L

t

:= L

t

ª {(σ, f

i,α

)}

L

i, j,t

:= L

i, j,t

] {(σ, f

i,α

)}

D

i,α

= [σ]

cell

i, j

→ [σ]

cell

i,k

(σ ∈ S)∧ (k 6= j) ∧ (cell

i, j

∈ N

i

) ∧ (cell

i,k

∈ N

i

)

∧((cell

i, j

,cell

i,k

) ∈ E

i

) ∧ ({(σ, f

i,α

)} ⊆ L

i, j,t

)

L

i, j,t

:= L

i, j,t

ª {(σ, f

i,α

)}

L

i,k,t

:= L

i,k,t

] {(σ, f

i,α

)}

with f

i,α

(L

t

) =

¥

k

i,α

(G,G

i

) · ∆τ ·

ˆ

f(|L

t

∩ {(σ,∞)}|)

¦

Stage 3 (reactions occurring within each cell):

∀i = 1, ... ,m

∀ j = 1, ... ,n

i

∀α = 1, ... ,r

i, j

reaction rule conditions action

R

i, j,α

= (A

i, j,α

,B

i, j,α

) f

i, j,α

· A

i, j,α

⊆ L

i, j,t

L

i, j,t

:= L

i, j,t

ª f

i, j,α

· A

i, j,α

] f

i, j,α

· B

i, j,α

with f

i, j,α

(L

i, j,t

) =

$

k

i, j,α

(G,G

i

) · ∆τ

∏

∀c∈supp(A

i, j,α

):(R

i, j,α

=(A

i, j,α

,B

i, j,α

))

ˆ

f(|L

i, j,t

∩ {(c,∞)}|)

|A

i, j,α

∩{(c,∞)}|

%

Increment time t:

L

t+1

:= L

t

∀i = 1, ... ,m

∀ j = 1, ... ,n

i

L

i, j,t+1

:= L

i, j,t

Figure 2: Iteration scheme for the temporal evolution of Π

MAP

system.

3 SIMULATION

As a first application, we introduced as rules into the

model only the basic processes involved in a MAP

design: respiration and fermentation, so as gas dif-

fusion between membranes. Respiration rate can be

expressed in terms of O

2

consumed or CO

2

produced.

The respiratory quotient (RQ), the ratio of CO

2

pro-

duced to O

2

consumed, ranges from about 0.7 to 1.4

depending on the substrate and its metabolic state (if

the substrate is a lipid, RQ < 1, and RQ > 1 for or-

ganic acids)(Fonseca et al., 2002). When carbohy-

drates are aerobically respired, the RQ is near 1, and

the reaction is represented by Eq. (1). The influence

of gas composition on respiration rates of produce has

been widely represented by Michaelis Menten-type

equation (Fonseca et al., 2002). In this context, respi-

ration rate is considered as a function of concentration

in terms of enzymatic reaction, with O

2

in the place

of substrate and the product CO

2

acting as inhibitor.

C

6

H

12

O

6

+ 6 O

2

→ 6CO

2

+ 6 H

2

O + energy (1)

Transpiration occurs due to the fact that fruits and

vegetables internal atmosphere is saturated with wa-

ter vapour, while external atmosphere contains lesser.

Therefore, water loss rate depends on the external and

internal water vapour pressure gradient.

Temperature dependence over respiratory rate and

over film permeability was represented using Arrhe-

nius equation (Eq. 2).

k = F × e

−E

a

/R×T

(2)

MODELLING MODIFIED ATMOSPHERE PACKAGING FOR FRUITS AND VEGETABLES USING MEMBRANE

SYSTEMS

309

where E

a

is the activation energy, expressed in joule

per mol, defined as the energy that must be overcome

for a chemical reaction to occur; R is the gas constant

(≈ 8.314 J · K

−1

mol

−1

), T the absolute temperature,

F is the pre-exponential factor that represents the total

number of molecular collisions per second; and k cor-

responds to the number of collisions per second that

result in a reaction. This can be related to the proba-

bilistic approach to P systems introduced by (Arde-

lean and Cavaliere, 2003) in order to obtain more

biological-like models. In this context, the Arrhenius

exponential term can be viewed as the probability per

time unit that the reaction takes place.

In order to apply our model, we simulate the dy-

namical behaviour of an instance of a Π

MAP

with two

hypothetical fruits as it is shown in Fig. 1, using

continuous film and passive MAP as package tech-

niques. Rules that use symbol between reactants

and products must been interpreted as reversible reac-

tions. Into the formalism described in Fig. 2, a rule of

the form D

α

= [σ] []σ, for example, consists in the

following two rules, in order of application: [σ] → []σ

and []σ → [σ].

S = {CO2,Ethanol,Glucose,H2O,O2}

G = {M, T, R,A,E,CO2ex,H2Oex,O2ex,EaCO2, E aO2, pCO2, pO2, pH2O}

N

1

= {cell

1,1

,cell

1,2

,cell

1,3

}

N

2

= {cell

2,1

}

G

i

: {ErO2, rO2,ErCO2 f ,rCO2 f } ∀i ∈ {1,2}

D

1

: []

package

O2 [O2]

package

f

1

(L

t

) =

$

A

E

· (O2ex − L

t

(O2)) · pO2 · e

−EaO2

R · T

%

D

2

: [CO2]

package

[]

package

CO2

f

2

(L

t

) =

$

A

E

· (L

t

(CO2) − CO2ex) · pCO2 · e

−EaCO2

R · T

%

D

3

: [H2O]

package

[]

package

H2O

f

3

(L

t

) =

¹

A

E

· (L

t

(H2O) − H2Oex) · pH 2O

º

D

1,1

: []

cell

1,1

O2 [O2]

cell

1,1

f

1,1

(L

t

) = k

1,1

· L

t

(O2)

D

1,2

: [CO2]

cell

1,1

[]

cell

1,1

CO2 f

1,2

(L

t

) = k

1,2

· L

t

(CO2)

D

1,3

: [H2O]

cell

1,1

[]

cell

1,1

H2O f

1,3

(L

t

) = k

1,3

· L

t

(H2O)

D

1,4

: [O2]

cell

1,1

[O2]

cell

1,2

f

1,4

(L

t

) = k

1,4

· L

t

(O2)

D

1,5

: [CO2]

cell

1,2

[CO2]

cell

1,1

f

1,5

(L

t

) = k

1,5

· L

t

(CO2)

D

1,6

: [H2O]

cell

1,2

[H 2O]

cell

1,1

f

1,6

(L

t

) = k

1,6

· L

t

(H2O)

D

1,7

: [O2]

cell

1,2

[O2]

cell

1,3

f

1,7

(L

t

) = k

1,7

· L

t

(O2)

D

1,8

: [CO2]

cell

1,3

[CO2]

cell

1,2

f

1,8

(L

t

) = k

1,8

· L

t

(CO2)

D

1,9

: [H2O]

cell

1,3

[H 2O]

cell

1,2

f

1,9

(L

t

) = k

1,9

· L

t

(H2O)

D

2,1

: []

cell

2,1

O2 [O2]

cell

2,1

f

2,1

(L

t

) = k

2,1

· L

t

(O2)

D

2,2

: [CO2]

cell

2,1

[]

cell

2,1

CO2 f

2,2

(L

t

) = k

2,2

· L

t

(CO2)

D

2,3

: [H2O]

cell

2,1

[]

cell

2,1

H2O f

2,3

(L

t

) = k

2,3

· L

t

(H2O)

R

i, j,1

: Glucose+ 6 O2 → 6 CO2 + 6 H2O ∀i ∈ {1, 2}∧ j ∈ {1,2,3}

f

i, j,1

(L

i, j,t

) =

L

i, j,t

(Glucose)

Θ

i, j,1,1

+ L

i, j,t

(Glucose)

·

L

i, j,t

(O2)

6

Θ

i, j,1,2

+ L

i, j,t

(O2)

6

·

M

i

3

· rO2 · e

−ErO2

R · T

R

i, j,2

: Glucose → 2 Ethanol + 2 CO2 ∀i ∈ {1, 2}∧ j ∈ {1,2,3}

f

i, j,2

(L

i, j,t

) =

$

L

i, j,t

(Glucose)

Θ

i, j,2,1

+ L

i, j,t

(Glucose)

· M

i

· rCO2 f · e

−ErCO2 f

R · T

%

Temperature is represented by T and expressed

in Kelvin (K). O

2

, CO

2

and H

2

O abundances in the

outside are represented by O2ex, CO2ex and H2Oex

respectively. A and E symbolise the surface area in

cm

2

and the thickness of the packaging film in mil

(1mil = 0.00254cm). pO2 and pCO2 represent the

reference film permeability in mL · mil · cm

2

· hr

−1

·

atm

−1

for O

2

, CO

2

and H

2

O, respectively. EaO2 and

EaCO2 symbolise the permeability activation energy

expressed in J · mol

−1

for O

2

and CO

2

, respectively.

M

i

symbolises mass of the produce i in kg. For sim-

plicity, we assume that each cell in a produce has the

same mass. rO2 and rCO2 f corresponds to the preex-

ponential factor for produce respiration and fermen-

tation in mL · kg

−1

· hr

−1

. ErO2 and ErCO2 f rep-

resent the respiration and fermentation activation en-

ergy for the produce expressed in J · mol

−1

. Most of

the values for these symbols were taken from the liter-

ature (Exama et al., 1993). Symbols O2, CO2, H2O,

Ethanol and Glucose represent amounts of species

O

2

, CO

2

, H

2

O, Ethanol and Glucose. Initial values

for these symbols in each compartment and the rest

of the parameters were assigned empirically.

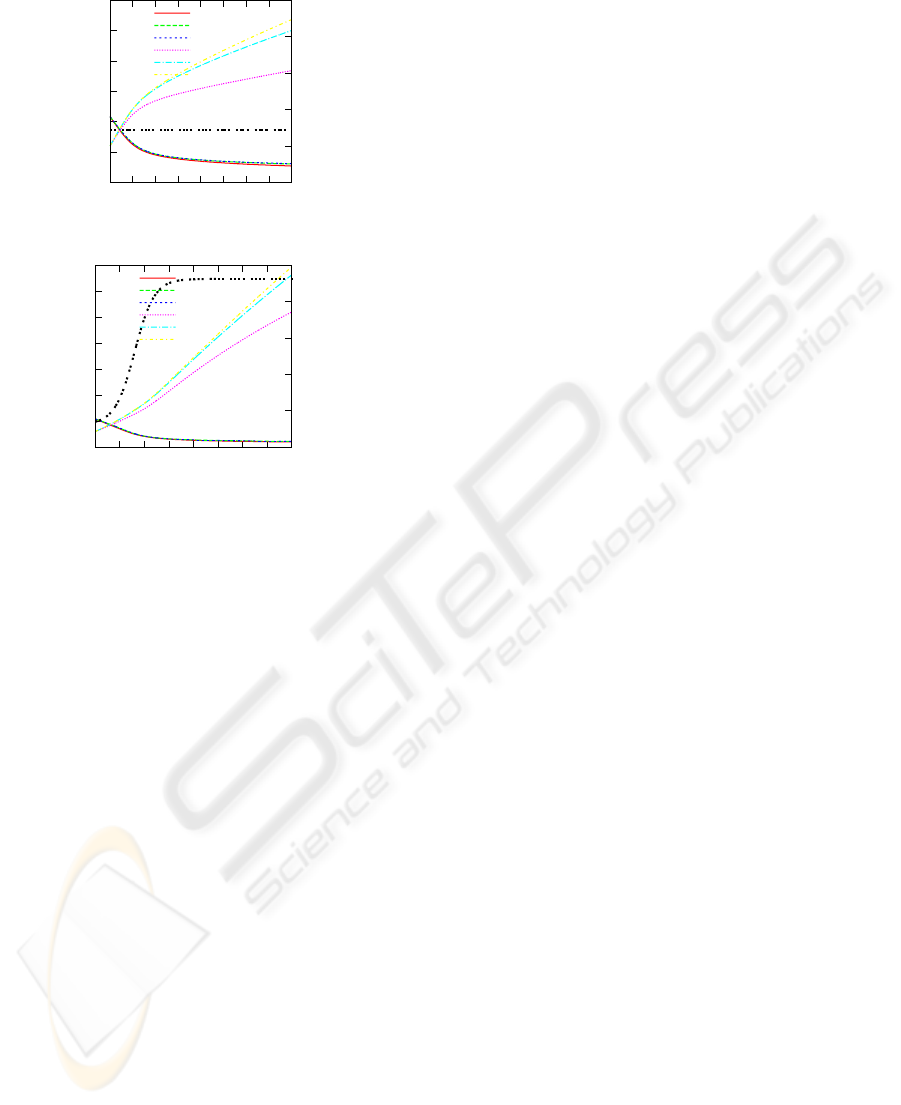

Figure 3 shows the corresponding courses of

plant

1

internal gas composition, resulting from fol-

lowing parameter setting for the discrete iteration

scheme: A = 100, E = 1, M

i

= 0.1, pO2

i

= 1620000,

EaO2

i

= 43100, pCO2

i

= 238000, EaCO2

i

= 34300,

rO2

i

= rCO2 f

i

= 3 × 10

14

, ErO2

i

= ErCO2 f =

70700, pH2O

i

= 1, Θ

i, j,1,k

= 1, for i ∈ {1, 2} and j ∈

{1,2, 3} and k ∈ {1,2}; k

1, j

= 0.2 for j ∈ {1,..., 9},

k

2, j

= 0.2 for j ∈ {1,... ,3}. A fixed value T =

277.15 was considered for a constant temperature sce-

nario, and transient values for 273.15 ≤ T ≤ 293.15

were obtained through a sigmoid function to repre-

sent changes in temperature over time in another sce-

nario. Simulations have been performed using Co-

pasi (Hoops et al., 2006). Differences in internal

gas composition of plant

1

have been observed dur-

ing time due to the interplay between cellular respira-

tion and fermentation processes and intercellular dif-

fusion. Those differences could determine the form

of maturation of the produce, in this case, from the

center to the skin. An equilibrium is reached in the

package gas composition, while respiration rates of

the produces diminished.

4 CONCLUSIONS

Using a membrane based model for MAP, we pre-

sented a framework that is able to abstract packag-

ing for different fruit and vegetable types, varieties

or developmental stages. Respiration of the produce

BIOSIGNALS 2010 - International Conference on Bio-inspired Systems and Signal Processing

310

0

5e+023

1e+024

1.5e+024

2e+024

2.5e+024

3e+024

0 0.5 1 1.5 2 2.5 3 3.5 4

270

275

280

285

290

295

Particle numbers

Temperature (K)

Time

Plant

1

O2

11

O2

12

O2

13

CO2

11

CO2

12

CO2

13

0

1e+024

2e+024

3e+024

4e+024

5e+024

6e+024

7e+024

0 0.5 1 1.5 2 2.5 3 3.5 4

270

275

280

285

290

295

Particle numbers

Temperature (K)

Time

Plant

1

O2

11

O2

12

O2

13

CO2

11

CO2

12

CO2

13

Figure 3: Dynamical behaviour for gas composition for

plant

1

in constant and varying temperature scenarios.

is considered as the basic process when modelling

MAP, and predictions about the dynamical behaviour

of such systems can be improved taking into ac-

count environmental, biological and technical factors.

Our approach allows extensions including other low

level processes, such as ethylene signaling pathway,

cell/tissue rupture due to produce cutting and trans-

port of other molecules, that can been easily modeled

using P systems. When the formalism showed in Fig-

ure 2 is hidden in a software, the specification is in-

tuitive an accessible for an expert focussing on MAP

modelling. Finally, the quality of the packaged pro-

duce (taste, texture, colour and appearance) is based

on some subjective consumer evaluation. These traits

are based on specific product properties, such as sugar

content, volatile production and cell wall structure

(Tijskens et al., 2001), and therefore can be intro-

duced into the model through reactions, as a mech-

anism to obtain more knowledge about the impact of

packaging conditions over product quality.

ACKNOWLEDGEMENTS

GE is supported by Universidad Sim

´

on Bol

´

ıvar (Cara-

cas, Venezuela) and Deutscher Akademischer Aus-

tausch Dienst (DAAD) Grant A/08/94489.

REFERENCES

Alexander, L. and Grierson, D. (2002). Ethylene biosynthe-

sis and action in tomato: a model for climacteric fruit

ripening. J. Exp. Bot., 53(377):2039–2055.

Ardelean, I. and Cavaliere, M. (2003). Modelling biological

processes by using a probabilistic P system software.

Natural Computing, 2(2):173–197.

Exama, A., Arul, J., Lencki, R., Lee, L., and Toupin, C.

(1993). Suitability of plastic films for modified atmo-

sphere packaging of fruits and vegetables. J Food Sci,

58(6):1365–1370.

Fonseca, S., Oliveira, F., and Brecht, J. (2002). Modelling

respiration rate of fresh fruits and vegetables for mod-

ified atmosphere packages: a review. J Food Eng,

52(2):99–119.

G

´

enard, M., Bertin, N., Borel, C., Bussieres, P., Gautier, H.,

Habib, R., Lechaudel, M., Lecomte, A., Lescourret,

F., Lobit, P., and Quilot, B. (2007). Towards a vir-

tual fruit focusing on quality: modelling features and

potential uses. J Exp Bot, 58(5):917–928.

Gross, K., Wang, C., and Saltveit, M. (2004). The com-

mercial storage of fruits, vegetables, and florist and

nursery stocks. Agriculture Handbook, 66.

Hinze, T., Lenser, T., and Dittrich, P. (2006). A protein sub-

structure based P system for description and analysis

of cell signalling networks. Lect Notes Comput Sci,

4361:409–423.

Ho, Q., Verboven, P., Verlinden, B., Lammertyn, J., Vande-

walle, S., and Nicolai, B. (2008). A continuum model

for metabolic gas exchange in pear fruit. PLoS Com-

putational Biology, 4(3):e1000023.

Hoops, S., Sahle, S., Gauges, R., Lee, C., Pahle, J., Simus,

N., Singhal, M., Xu, L., Mendes, P., and Kummer, U.

(2006). Copasi—a complex pathway simulator. Bioin-

formatics, 22(24):3067–3074.

Mahajan, P., Oliveira, F., J., M., and Frias, J. (2007). Devel-

opment of user-friendly software for design of modi-

fied atmosphere packaging for fresh and fresh-cut pro-

duce. Innovative Food Science and Emerging Tech-

nologies, 8(1):84–92.

Mart

´

ın-Vide, C., P

˘

aun, G., Pazos, J., and Rodr

´

ıguez-Pat

´

on,

A. (2003). Tissue P systems. Theor Comput Sci,

296(2):295–326.

Paul, D. and Clarke, R. (2002). Modelling of modified at-

mosphere packaging based on designs with a mem-

brane and perforations. J Membr Sci, 208(1–2):269–

283.

P

˘

aun, G. and Rozenberg, G. (2002). A guide to membrane

computing. Theor Comput Sci, 287(73–100):73–100.

Rodriguez-Aguilera, R. and Oliveira, J. (2009). Review of

design engineering methods and applications of active

and modified atmosphere packaging systems. Food

Engineering Reviews, 1(1):66–83.

Tijskens, L., Hertog, M., and Nicola

¨

ı, B. (2001). Food Pro-

cess Modelling. Woodhead Pub.

MODELLING MODIFIED ATMOSPHERE PACKAGING FOR FRUITS AND VEGETABLES USING MEMBRANE

SYSTEMS

311