LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH

CULTURES

A Comparison of Adaptive and Robust Strategies

Laurent Dewasme, Alain Vande Wouwer

Service d’Automatique, Universit´e de Mons, 31 Boulevard Dolez, 7000 Mons, Belgium

Daniel Coutinho

Group of Automation and Control Systems, PUCRS, Av. Ipiranga 6681, 90619-900, Porto Alegre, Brazil

Keywords:

Nonlinear robust control, Adaptive control, Fermentation process, Biotechnology.

Abstract:

Linearizing control is a popular approach to control bioprocesses, which has received considerable attention

is the past several years. This control approach is however quite sensitive to modeling uncertainties, thus

requiring some on-line parametric adaptation so as to ensure performance. In this study, this usual adaptive

strategy is compared in terms of implementation and performance to a robust strategy, where the controller

has a fixed parametrization which is determined using a LMI framework so as to ensure robust stability and

performance. Fed-batch cultures of yeast and bacteria are considered as application examples.

1 INTRODUCTION

The culture of host recombinant micro-organisms is

nowadays a very important way of producing bio-

pharmaceuticals. Fed-batch operation is popular in

industrial practice, since it is advantageous from an

operational and control point of view. The off-line

determination of the feeding profile is usually sub-

optimal as some security margin has to be provided

in order to avoid an excess of substrate leading to

the accumulationof inhibitoryby-products(inhibition

of the cell respiratory capacity), namely ethanol for

yeast cultures and acetate for bacteria cultures.

To optimize the culture conditions and to avoid

high concentrations of inhibitory by-products, a

closed-loop solution is required, and a wide diversity

of approaches, e.g., (Pomerleau, 1990; Chen et al.,

1995; Rocha, 2003; Renard and Wouwer, 2008; De-

wasme et al., 2009a; Dewasme et al., 2009b) have

been considered.

In particular, linearizing control (Bastin and

Dochain, 1990) is a very popular approach, which has

been applied successfully in a number of case studies.

However, linearizing control requires the knowledge

of an accurate model, and on-line parametric adap-

tation is usually implemented so as to ensure perfor-

mance. Whereas parametric adaptation is a simple ap-

Substrate

CO

2

Respiro-fermentativeregime

V.P =constant

S= S

crit

Product

Substrate

CO

2

S> S

crit

Respirative regime

S< S

crit

r

o

Substrate

CO

2

Product

CO

2

Product

(r

o

-k

os

r

s

)/k

oa

SubstrateSubstrate

CO

2

Respiro-fermentativeregime

V.P =constant

S= S

crit

Product

Substrate

CO

2

S> S

crit

ProductProduct

Substrate

CO

2

S> S

crit

Respirative regime

S< S

crit

r

o

Substrate

CO

2

Product

CO

2

ProductProduct

(r

o

-k

os

r

s

)/k

oa

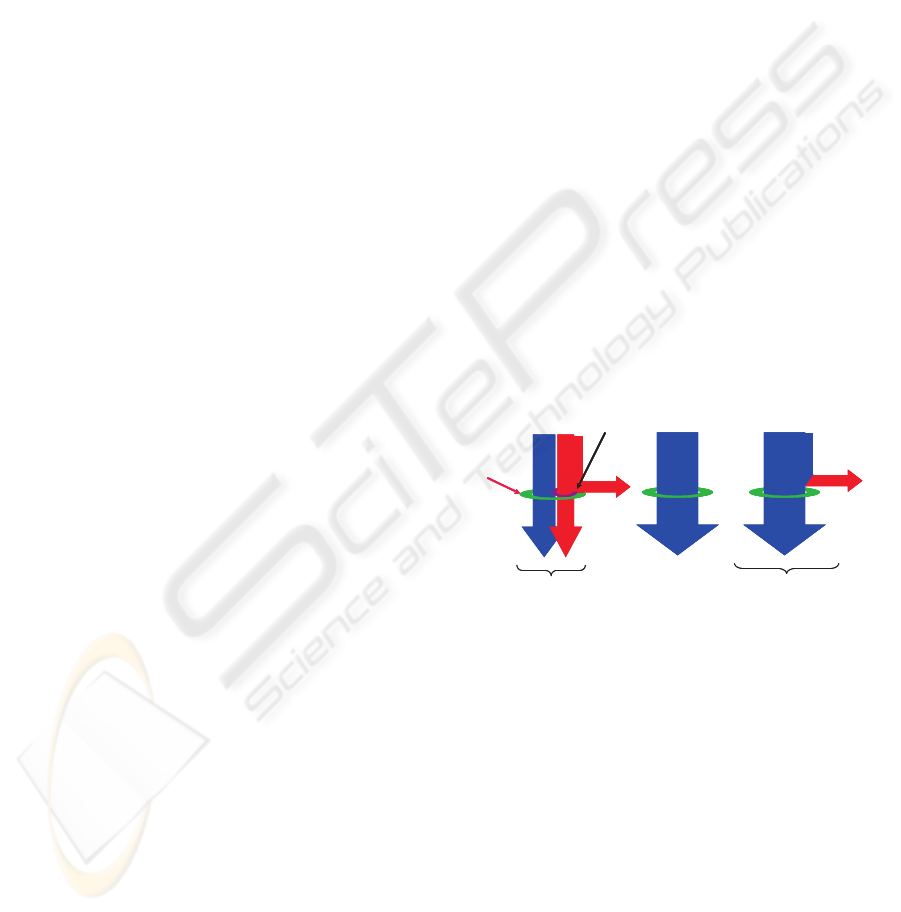

Figure 1: Illustration of Sonnleitner’s bottleneck assump-

tion for cells limited respiratory capacity.

proach, it does not guarantee stability in the presence

of unmodeled dynamics.

In this study, another approach is also considered,

which is based on nonlinear robust control and the

used of Linear Matrix Inequalities (LMIs) to design

the free linear dynamics so as to ensure robust stabil-

ity and performance. A comparison of the adaptive

and robust control approaches is provided in terms

of implementation, and simulation tests shows the re-

spective advantages and limitations of both strategies.

5

Dewasme L., Vande Wouwer A. and Coutinho D. (2010).

LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH CULTURES - A Comparison of Adaptive and Robust Strategies.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 5-13

DOI: 10.5220/0002933300050013

Copyright

c

SciTePress

2 MECHANISTIC MODEL

In this study, we consider a generic model that would,

in principle, allow the representation of the culture of

different strains presenting an overflow metabolism

(yeasts, bacteria, animal cells, etc). This model de-

scribes therefore the cell catabolism through the fol-

lowing three main reactions:

Substrate oxidation :

k

S1

S+ k

O1

O

r

1

X

→ k

X1

X+ k

C1

C (1a)

Overflow reaction (typically fermentation) :

k

S2

S+ k

O2

O

r

2

X

→ k

X2

X+ k

P2

P+ k

C2

C (1b)

Metabolite product oxidation :

k

P3

P+ k

O3

O

r

3

X

→ k

X3

X+ k

C3

C (1c)

where X, S, P, O and C are, respectively, the concen-

tration in the culture medium of biomass, substrate

(typically glucose or glycerol), product (i.e. ethanol

or methanol in yeast cultures, acetate in bacteria cul-

tures or lactate in animal cells cultures), dissolved

oxygen and carbon dioxide. k

ξi

(i=1,2,3) are the yield

coefficients and r

1

, r

2

and r

3

are the nonlinear specific

growth rates given by:

r

1

=

min(r

S

,r

S

crit

)

k

S1

(2)

r

2

=

max(0,r

S

− r

S

crit

)

k

S2

(3)

r

3

=

max

0,min

r

P

,

k

os

(r

S

crit

−r

S

)

k

oa

k

P3

(4)

where the kinetic terms associated with the substrate

consumption r

S

, the critical substrate consumption

r

S

crit

(generally dependent on the cells oxidative or

respiratory capacity r

O

) and the product oxidative rate

r

P

are given by:

r

S

= µ

S

S

S+ K

S

(5a)

r

S

crit

=

r

O

k

os

=

µ

O

k

os

O

O+ K

O

Ki

P

Ki

P

+ P

(5b)

r

P

= µ

P

P

P+ K

P

(5c)

These expressions take the classical form of

Monod laws where µ

S

, µ

O

and µ

P

are the maximal val-

ues of specific growth rates, K

S

, K

O

and K

P

are the sat-

uration constants of the corresponding element, and

Ki

P

is the inhibition constant. k

os

and k

oa

represent

the coefficients characterizing respectively the yield

between the oxygen and substrate consumptions, and

the yield between the acetate and oxygen consump-

tions.

This kinetic model is based on Sonnleitner’s bot-

tleneck assumption (Sonnleitner and K¨appeli, 1986)

which was developed for a yeast strain Saccha-

romyces cerevisiae (Figure 1). During a culture, the

cells are likely to change their metabolism because of

their limited respiratory capacity. When the substrate

is in excess (concentration S > S

crit

), the cells produce

a metabolite product P through fermentation, and the

culture is said in respiro-fermentative (RF) regime.

On the other hand, when the substrate becomes lim-

iting (concentration S < S

crit

), the available substrate

(typically glucose), and possibly the metabolite P (as

a substitute carbon source), if present in the culture

medium, are oxidized. The culture is then said in res-

pirative (R) regime.

Component-wise mass balances give the follow-

ing differential equations :

dX

dt

= (k

X1

r

1

+ k

X2

r

2

+ k

X3

r

3

)X − DX (6a)

dS

dt

= −(k

S1

r

1

+ k

S2

r

2

)X + DS

in

− DS (6b)

dP

dt

= (k

P2

r

2

− k

P3

r

3

)X − DP (6c)

dO

dt

= −(k

O1

r

1

+ k

O2

r

2

+ k

O3

r

3

)X − DO+ OTR

(6d)

dC

dt

= (k

C1

r

1

+ k

C2

r

2

+ k

C3

r

3

)X − DC− CTR (6e)

dV

dt

= F

in

(6f)

where S

in

is the substrate concentration in the feed,

F

in

is the inlet feed rate, V is the culture medium vol-

ume and D is the dilution rate (D = F

in

/V). OTR and

CTR represent respectively the oxygen transfer rate

from the gas phase to the liquid phase and the carbon

transfer rate from the liquid phase to the gas phase.

Classical models of OTR and CTR are given by:

OTR = k

L

a(O

sat

− O) (7a)

CTR = k

L

a(P− P

sat

) (7b)

where k

L

a is the volumetric transfer coefficient and,

O

sat

and P

sat

are respectively the dissolved oxygen

and carbon dioxide concentrations at saturation.

3 A SUBOPTIMAL STRATEGY

The maximum of productivity is obtained at the

edge between the respirative and respiro-fermentative

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

6

regimes, where the quantity of by-product is constant

and equal to zero (VP = 0). Unfortunately, evaluating

accurately the volume is a difficult task as it depends

on the inlet and outlet flows including F

in

but also the

added base quantity for pH control and several gas

flow rates. Moreover, maintaining the quantity of by-

productconstant in a fed-batch process means that the

by-product concentration has to decrease while the

volume increases. So, even if the volume is correctly

measured, VP becomes unmeasurable once P reaches

the sensitivity level of the by-productprobe. For those

practical limitations, a sub-optimal strategy is elabo-

rated through the control of the by-product concentra-

tion around a low value P

∗

depending on the sensitiv-

ity of commercially available probes (for instance, a

general order for ethanol probe is 0.1g/l), and requir-

ing only an estimation of the volume by integration of

the feed rate.

The basic principle of the controller is thus to reg-

ulate the by-product at a constant low setpoint, lead-

ing to a self-optimizing control in the sense of (Sko-

gestad, 2004) and ensuring that the culture operates in

the respiro-fermentative regime, close to the biologi-

cal optimum, i.e., close to the edge with the respira-

tive regime.

4 LINEARIZING CONTROL

STRATEGY

The component-wise mass balances of reaction

scheme (1) lead to the following state-space represen-

tation

˙x = Kr(x)X + Ax− ux+ B(u) (8)

where x = [

X S P O C V

]

′

is the state vec-

tor, r(x) = [

r

1

r

2

r

3

]

′

is the vector of reaction

rates, and u = D = F

in

/V is the control input (the di-

lution rate). The matrices K and A, and the vector

function B(·) are given by:

K =

k

X1

k

X2

k

X3

−k

S1

−k

S2

0

0 k

P2

−k

P3

−k

O1

−k

O2

−k

O3

k

C1

k

C2

k

C3

0 0 0

, B(u) =

0

S

in

u

0

k

L

a O

sat

k

L

a P

sat

0

,

(9)

A =

0

3×3

0

3×2

0

3×1

0

2×2

−k

L

a I

2×2

0

2×2

0

1×3

0

1×2

0

,

A feedback linearizing controller is illustrated in

Figure 2. In a first step, this controller is derived as-

suming a perfect process knowledge. The basic idea

Bioreactor

P

X,O

-

+

Controller

u

Process

P*

BioreactorBioreactor

P

X,O

-

+

Controller

u

Process

P*

Figure 2: Linearizing control scheme.

is to derive a nonlinear controller, which allows a lin-

earization of the process behavior ((Chen et al., 1995;

Pomerleau, 1990)).

As the theoretical value of S

crit

is very small (be-

low 0.1 g/l) and assuming a quasi-steady state of S

(i.e. considering that there is no accumulation of glu-

cose when operating the bioreactor in the neighbor-

hood of the optimal operating conditions), the small

quantity of substrate VS is almost instantaneously

consumed by the cells (

d(VS)

dt

≈ 0 and S ≈ 0) and (6b)

becomes:

k

S2

r

2

X = −k

S1

r

1

X + S

in

u (10)

where r

1

and r

2

are nonlinear functions of S, P and O

as given by (2-3).

Replacing r

2

X by (10) in the mass balance equa-

tion for P (6c), we obtain:

˙

P = −

k

P2

k

S1

k

S2

r

1

X − k

P3

r

3

X − u

P−

k

P2

k

S2

S

in

(11)

A first-order linear reference model is imposed:

d(P

∗

− P)

dt

= −λ(P

∗

− P) , λ > 0 (12)

and a constant setpoint is considered so that:

dP

dt

= λ(P

∗

− P) , λ > 0 (13)

Equating (13) and (11), the following control law

is obtained:

F

in

= V

λ(P

∗

− P) + (

k

P2

k

S1

k

S2

r

1

+ k

P3

r

3

)X

k

P2

k

S2

S

in

− P

(14)

where

k

P2

k

S1

k

S2

r

1

and k

P3

r

3

, thekinetic expressions, con-

tain several uncertain parameters.

4.1 A Classical Adaptive Strategy

In (Chen et al., 1995), the parameter uncertainties

are handled using an on-line estimation of the kinetic

term

k

P2

k

S1

k

S2

r

1

+ k

P3

r

3

in the linearizing control law

(14). In this study, the biomass concentration X is

supposed to be measured using a probe (for instance

LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH CULTURES - A Comparison of Adaptive and

Robust Strategies

7

a optical density probe or a conductance probe, which

are nowadays widely available), whereas in (Chen

et al., 1995), an asymptotic observer is used to es-

timate this component concentration. The following

adaptive scheme is therefore a simplified version of

the original algorithm.

F

in

= V

λ(P

∗

− P) +

ˆ

θX

k

P2

k

S2

S

in

− P

(15)

A direct adaptive scheme as described in (Bastin

and Dochain, 1990) is used. Consider the following

Lyapunov function candidate:

V(t) =

1

2

˜

P

2

+

˜

θ

2

γ

(16)

where

˜

P = P

∗

−P,

˜

θ = θ−

ˆ

θ and γ is a strictly positive

scalar. The specific growth rates r

1

and r

3

(and, of

course, the pseudo-stoichiometric coefficient k

4

) are

assumed to be constant so that θ variations are negli-

gible (

dθ

dt

= 0).

Using the Lyapunov stability theory, the time

derivative of the Lyapunov candidate function should

be negative for the closed-loop system to be stable:

dV

dt

=

d

˜

P

dt

˜

P+

˜

θ

d

˜

θ

dt

1

γ

(17)

Considering (13) and a possible parameter mis-

match (

ˆ

θ 6= θ):

d

˜

P

dt

= −λ

˜

P−

˜

θX (18)

so that (17) becomes:

dV

dt

= −λ

˜

P

2

−

˜

P

˜

θX −

˜

θ

d

ˆ

θ

dt

1

γ

(19)

Choosing the following θ adaptive law cancels the

second and the third terms:

d

ˆ

θ

dt

= γX

˜

P (20)

4.2 A Robust Strategy

Structural and parametric uncertainties can be lumped

into a global parametric error:

δ =

¯

θ− θ (21)

where δ is a nonlinear function of (S,P,O) represent-

ing possible inexact cancellations of nonlinear terms

due to model uncertainties and

¯

θ represents the hypo-

thetical exact unknown value. Rewriting the kinetic

term in (15) using the newexpression taken from (21),

we obtain:

u = F

in

= V

λ(P

∗

− P) +

¯

θX − δX

k

P2

k

S2

S

in

− P

(22)

which corresponds to the perturbed reference system:

˙

P = λ(P

∗

− P) − δX (23)

Borrowing the ideas of the Quasi-LPV approach

(Leith and Leithead, 2000), we bound the time-

varying parameter δ which is supposed to belong to

a known set ∆ := {δ : δ ≤ δ ≤ δ} with δ and δ respec-

tively representing the minimal and maximal admis-

sible uncertainties.

The parameter λ is designed to ensure some ro-

bustness and tracking performance to the overall

closed-loop system, which is modeled as follows:

M :

˙

P = −λz− δX

z = P

∗

− P

(24)

where z = P

∗

− P is the performance output.

Let w = [

P

∗

X

]

′

⊂ L

2,[0,T]

be the disturbance

input to the system M , a(λ, δ) =

λ −δ

and

c =

1 0

. The closed-loop system (24) can be

rewritten:

M :

˙

P = −λP+ a(λ, δ)w

z = − P + c w , δ ∈ ∆

(25)

Consider the finite horizon (for instance, between

the instant 0 and the time T) L

2

-gain of system M

(M. Green and D.J.N. Limebeer, 1994), representing

the worst-case of the ratio of kzk

2,[0,T]

(i.e., the finite

horizon 2-norm of the tracking error) and kwk

2,[0,T]

(i.e., the finite horizon 2-norm of the disturbance in-

put), which is defined as:

kM

wz

k

∞,[0,T]

= sup

δ∈∆,06=w⊂L

2,[0,T]

kzk

2,[0,T]

kwk

2,[0,T]

(26)

Thus, the parameter λ is designed based on the H

∞

control theory (M. Green and D.J.N. Limebeer, 1994;

Skogestad and Postlethwaite, 2001). Let α > 0 be an

upper limiting of kM

wz

k

∞,[0,T]

. Thus, the problem is

to find α such that:

min

λ,δ∈∆

α : kM

wz

k

∞,[0,T]

≤ α (27)

while ensuring the robust stability of system (25).

This optimization problem can be written in terms

of linear matrix inequalities (LMIs) and solved us-

ing readily available toolboxes, e.g., SeDuMi (Sturm

et al., 2006) can be applied to solve the prob-

lem. These constraints can be easily obtained via a

quadratic Lyapunov function (S.Boyd, L.El-Ghaoui,

E.Feron and V.Balakrishnan, 1994)

V(P) = P

′

QP = QP

2

(28)

where Q is a strictly positive symmetric matrix (i.e.,

Q = Q

′

≻ 0) and ”

′

” corresponds to the transposition

matrix operation.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

8

The minimization in (27) is then equivalent to:

min α : V(P) ≻ 0 ,

˙

V(P) +

1

α

z

′

z− αw

′

w ≺ 0 (29)

where, using (25) and (28), the time derivative of

V(P) is given by:

˙

V(P) =

˙

P

′

QP+ P

′

Q

˙

P

= (−λP+ aw)

′

QP+ P

′

Q(−λP+ aw)

= −λP

′

QP+ (aw)

′

QP− λP

′

QP+ P

′

Qaw

= −2λP

′

QP+ a

′

w

′

QP+ P

′

Qaw (30)

Using (30) in (29), the following expression is ob-

tained:

P

w

′

−2m Qa

a

′

Q −αI

n

w

P

w

−

1

α

zz

′

≺ 0 (31)

where m = λQ and I

n

w

is the unity matrix of dimen-

sion n

w

× n

w

and n

w

is the dimension of w.

Now, consider the following lemma (Schur Com-

plement):

Lemma 1. The following matrix inequalities are

equivalent

(i) T > 0,R − ST

−1

S

′

≻ 0

(ii) R > 0, T − S

′

R

−1

S ≻ 0

(iii)

R S

S

′

T

≻ 0

Hence, using the expression of z,a and c in (25)

and Lemma 1, the optimization problem in (27) can

be written as follows:

min

Q,m

α : α > 0 , Q = Q

′

> 0 and

−2m m −δQ −1

m −α 0 1

−δQ 0 −α 0

−1 1 0 −α

≺ 0 (32)

If there exists a feasible solution to the above op-

timization problem for all δ evaluated at the vertices

of ∆, then (27) is satisfied and λ = mQ

−1

.

Remark 1. Quadratic Lyapunov functions may be

conservative for assessing the stability of parameter-

dependent systems (G. Chesi and Vicino, 2004).

However, a parameter-independent Lyapunov func-

tion is considered in this study for two main reasons:

1. λ is parametrized with the Lyapunov matrix Q

so as to obtain a convex design condition. A

parameter-independent matrix Q therefore results

in a parameter-independent control law;

2. the variation of δ is a priori unknown.

Remark 2. This method is likely to be conservative,

as the parameter δ has to bound the nonlinearities

of the inexactly cancelled terms. Less conservative

results can be obtained by considering the approach

of (D.F. Coutinho, M. Fu, A. Trofino and P. Dan`es,

2008) to deal with the nonlinearities at the cost of a

larger computational effort.

5 NUMERICAL RESULTS

In this section, for comparing the adaptive and ro-

bust linearizing control strategies, several numeri-

cal simulations considering small-scale bacteria and

yeast cultures (respectively in 5 and 20 [l] bioreac-

tors) are performed. The first simulation set is dedi-

cated to yeast cultures with initial and operating con-

ditions: X

0

= 0.4g/l, S

0

= 0.5g/l, E

0

= 0.8g/l, O

0

=

O

sat

= 0.035g/l, C

0

= C

sat

= 1.286g/l, V

0

= 6.8l,

S

in

= 350g/l. The second simulation set is dedicated

to bacteria cultures with initial and operating condi-

tions: X

0

= 0.4g/l, S

0

= 0.05g/l, A

0

= 0.8g/l, O

0

=

O

sat

= 0.035g/l, C

0

= C

sat

= 1.286g/l, V

0

= 3.5l,

S

in

= 250g/l

The values of all model parameters are listed in

Tables 1, 2, 3 and 4. Note that, for yeast cultures,

coefficients k

os

and k

oa

are simply replaced by k

O1

and k

03

while k

O2

= 0, in accordance with the model

of (Sonnleitner and K¨appeli, 1986). For the bacte-

ria model, parameters values are taken from (Rocha,

2003) and slightly modified to adapt the yield coeffi-

cient normalization to the proposed reaction scheme

(1) and kinetic model (with a slight difference in the

formulation of r

3

).

The state variables are assumed available (i.e.,

measured) online for feedback. The adaptive and ro-

bust linearizing feedback controllers proposed in sec-

tion 4 aim at tracking the byproduct set-point (E

∗

and

A

∗

= 1 g/l) which is chosen sufficiently low so as to

stay in the neighborhood of the optimal trajectory but

also sufficiently high to avoid probe sensitivity limi-

tations. In this setup, a noisy byproduct measurement

is considered.

To design the parameter λ in (23) via the optimiza-

tion problem (27), the parameters K

S

, K

P

, K

O

, K

i

P

and µ

S

, µ

O

are assumed to be respectively varying of

±100% and ±15% from their nominal values. Simu-

lating the operating conditions of the control strategy

in (22), we may infer that δ = −δ = 0.5/3600 s

−1

for

yeast cultures and δ = −δ = 0.1/3600 s

−1

for bac-

teria cultures. In light of (25) and (27), these con-

straints yield for yeasts and bacteria, respectively to

λ = 0.0056 and λ = 0.0046.

Concerning the adaptive control law, λ = 1 and

LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH CULTURES - A Comparison of Adaptive and

Robust Strategies

9

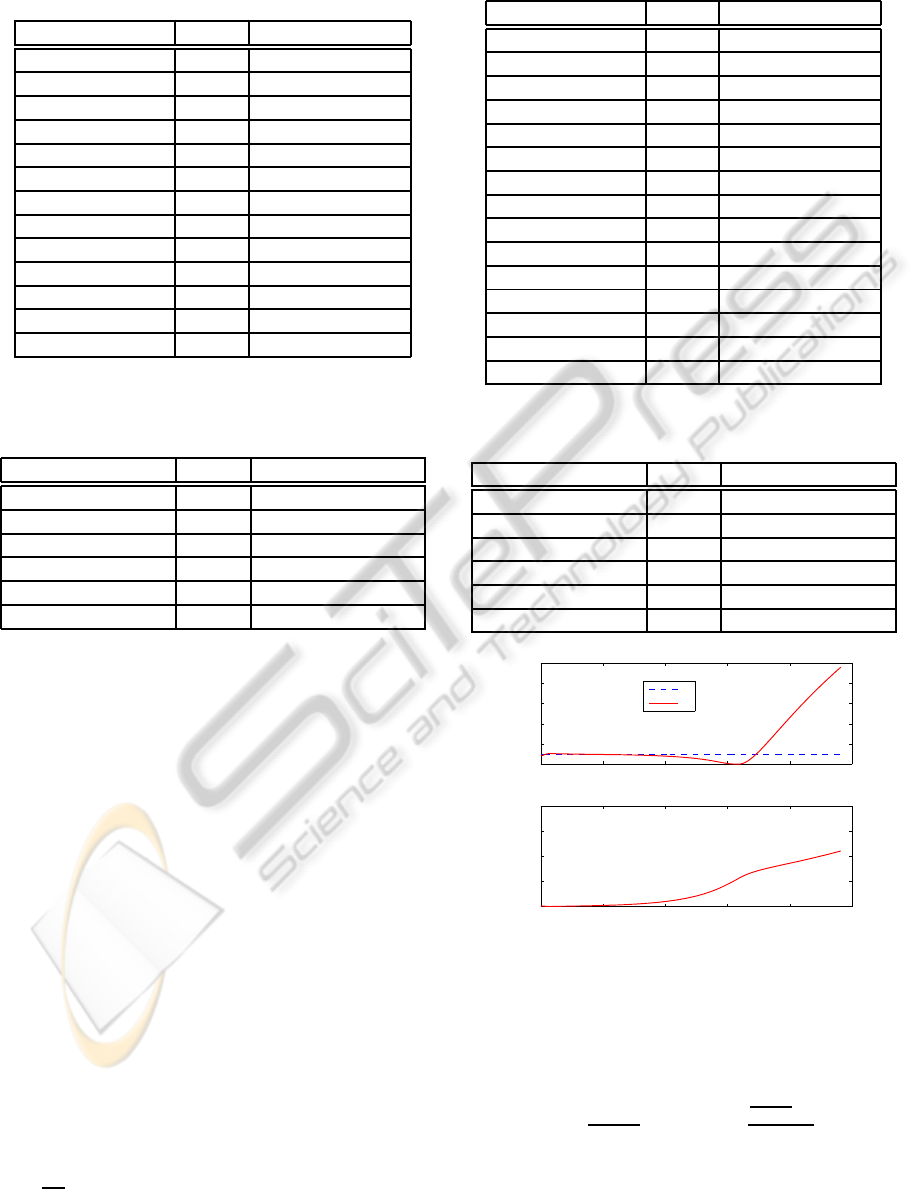

Table 1: Yield coefficients values of Sonnleitner and

K¨appeli for S. cerevisiae model (Sonnleitner and K¨appeli,

1986)

Yield coefficients Values Units

k

X1

0,49 g of X/g of S

k

X2

0,05 g of X/g of S

k

X3

0,72 g of X/g of E

k

S1

1

k

S2

1

k

P2

0,48 g of E/g of S

k

P3

1

k

O1

0,3968 g o f O

2

/g of S

k

O2

0 g of O

2

/g of S

k

O3

1,104 g of O

2

/g of E

k

C1

0,5897 g of CO

2

/g of S

k

C2

0,4621 g of CO

2

/g of S

k

C3

0,6249 g of CO

2

/g of E

Table 2: Kinetic coefficients values of Sonnleitner and

K¨appeli for the S. cerevisiae model (Sonnleitner and

K¨appeli, 1986)

Kinetic coefficients Values Units

µ

O

0,256 g of O

2

/g of X /h

µ

S

3,5 g of S/g of X /h

K

O

0,0001 g of O

2

/l

K

S

0,1 g of S/l

K

E

0,1 g of E/l

Ki

E

10 g of E/l

γ = 0.05 for yeast cultures while λ = 2 and γ = 0.25

for bacteria cultures. Note also that the sampling pe-

riod is chosen equal to 0.1 h.

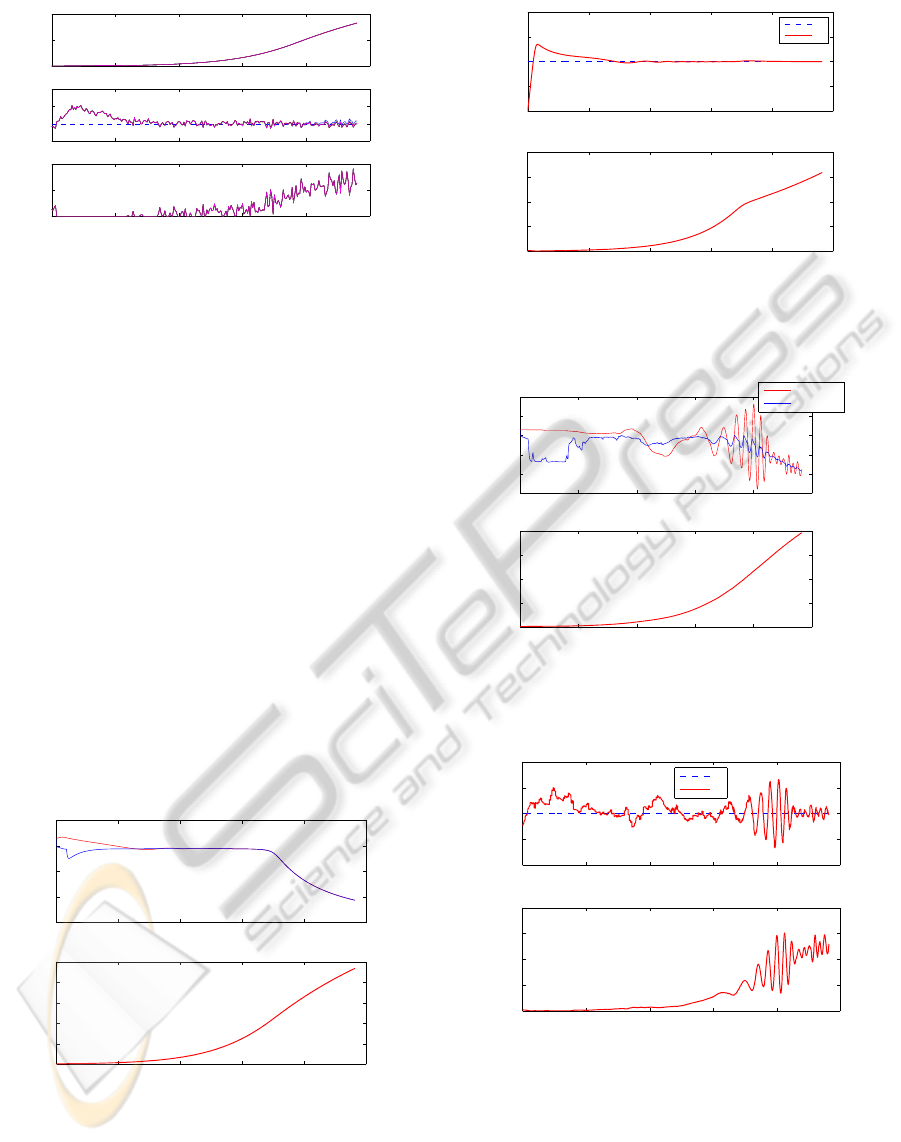

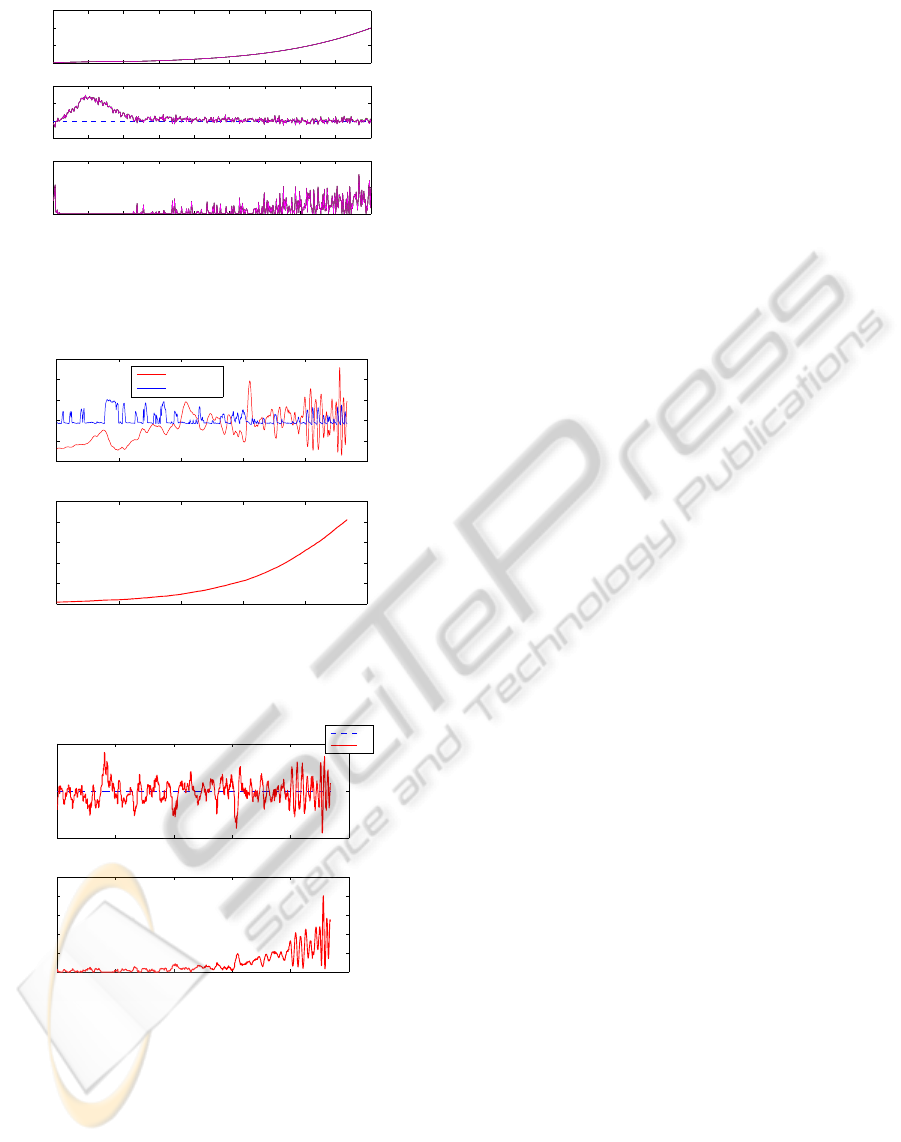

Before discussing the results of the proposed

methods, it is interesting to observe the performance

of a plain linearizing controller, i.e. without adapta-

tion or robustification, applied to the yeast process in

the presence of modeling errors. For instance, con-

sider the situation where the user selects a relatively

high gain λ = 1, and

ˆ

θ is fixed to k

P2

/2. Figure 3 illus-

trates the consequences of such choices. Even if the

controller behaves correctly during the first hours, the

divergence of the ethanol signal during the last hours

will impact the quality of the culture.

Figure 4 shows now the closed-loop response of

biomass X, ethanol E concentrations, and the inlet

feed rate F

in

, for five different values of the kinetic

parameters (which were randomly chosen) in yeast

cultures under a robust control strategy. In all sim-

ulation runs, a white noise is added to the ethanol

concentration measurement with a standard deviation

of ±0.1 [g/l] and the culture is considered as always

evolving in the optimal operating conditions in which

r

1

=

r

O

k

O1

and r

3

= 0 so that the hypothetical parameter

Table 3: Yield coefficients values of Rocha’s E.coli model

(Rocha, 2003)

Yield coefficients Values Units

k

X1

1

k

X2

1

k

X3

1

k

S1

0,316 g of S/g of X

k

S2

0,04 g of S/g of X

k

P2

0,157 g of A/g of X

k

P3

0,432 g of A/g of X

k

O1

0,339 g of O

2

/g of X

k

O2

0,471 g of O

2

/g of X

k

O3

0,955 g of O

2

/g of X

k

C1

0,405 g of CO

2

/g of X

k

C2

0,754 g of CO

2

/g of X

k

C3

1,03 g of CO

2

/g of X

k

os

2,02 g of O

2

/g of X

k

oa

1,996 g of O

2

/g of X

Table 4: Kinetic coefficients values of Rocha’s E.coli

model (Rocha, 2003)

Kinetic coefficients Values Units

µ

O

0,7218 g of O

2

/g of X /h

µ

S

1,832 g of S/g of X /h

K

O

0,0001 g of O

2

/l

K

S

0,1428 g of S/l

K

A

0,5236 g of A/l

Ki

A

6,952 g of A/l

0 5 10 15 20 25

0

2

4

6

8

10

E [g/l]

E*

E

0 5 10 15 20 25

0

1

2

3

4

x 10

−4

F

in

[l/s]

Time [h]

Figure 3: Yeast cultures – ethanol concentration and feed

rate when the controller is designed using a plain linearizing

control approach (no adaptation and no robustification) in

the presence of modeling errors.

¯

θ in (22) is taken as

¯

θ =

˜

k

P2

k

S1

k

S2

r

1

+

˜

k

P3

r

3

≈

k

P2

k

S1

k

S2

r

O

k

O1

(33)

Figure 4 shows that during the start-up phase, F

in

saturates to 0, leading to an ethanol overshoot (see

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

10

0 5 10 15 20 25

0

50

100

X [g/l]

0 5 10 15 20 25

0

1

2

3

E [g/l]

0 5 10 15 20 25

0

2

4

x 10

−4

Time [h]

F

in

[l/s]

Figure 4: Yeast cultures – biomass and ethanol concentra-

tions, and feed rate – robust control strategy – results of 5

runs with random parameter variations and a noise standard

deviation of ±0.1 [g/l].

Figure 4). The different curves are more or less indis-

tinguishable (the same noise signal is applied during

the 5 runs) except in the last hours where the conse-

quences of model errors appear. Nevertheless, these

results are very satisfactory as model errors have a

negligible influence.

Figures 5 and 6 show the results of a simulation

performed with the same initial and operating con-

ditions with the adaptive strategy, in the ideal case

where there is no measurement noise, whereas Fig-

ures 7 and 8 correspond to a noise standard devia-

tion of ±0.05 [g/l] added to the ethanol concentra-

tion measurements. Due to sensitivity problems of

the adaptive law, higher noise levels usually lead to

computational failures. When the parameter adapta-

tion performs well, the productivity of the adaptive

and robust strategies is more or less the same, i.e., a

biomass concentration of approximately 80 g/l is ob-

tained within 24 hours.

0 5 10 15 20 25

2

4

6

8

10

x 10

−5

θ adaptation

θ [s

−1

]

0 5 10 15 20 25

0

20

40

60

80

100

X [g/l]

Time [h]

Figure 5: Yeast cultures – θ adaptation and biomass concen-

tration – adaptive control strategy – no measurement noise.

Figure 9 shows the closed-loop response of

biomass X, acetate A concentrations, and inlet feed

rate F

in

, for five different values of the kinetic pa-

rameters which are randomly chosen, in the bacteria

0 5 10 15 20 25

0.8

0.9

1

1.1

1.2

E [g/l]

E*

E

0 5 10 15 20 25

0

1

2

3

4

x 10

−4

F

in

[l/s]

Time [h]

Figure 6: Yeast cultures – ethanol concentration and feed

flow rate – adaptive control strategy – no measurement

noise.

0 5 10 15 20 25

2

4

6

8

10

12

x 10

−5

θ adaptation

θ [s

−1

]

0 5 10 15 20 25

0

20

40

60

80

X [g/l]

Time [h]

Estimated θ

Real θ

Figure 7: Yeast cultures – θ adaptation and biomass concen-

tration – adaptive control strategy – noise standard deviation

of ±0.05 [g/l].

0 5 10 15 20 25

0

0.5

1

1.5

2

E [g/l]

E*

E

0 5 10 15 20 25

0

1

2

3

4

x 10

−4

F

in

[l/s]

Time [h]

Figure 8: Yeast cultures – ethanol concentration and feed

flow rate – adaptive control strategy – noise standard devia-

tion of ±0.05 [g/l].

cultures under a robust control strategy. Figures 10

and 11 show similar simulation runs with the adap-

tive strategy. The same comments concerning the

noise sensitivity apply.

Note that the productivity is lower in the bacteria

LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH CULTURES - A Comparison of Adaptive and

Robust Strategies

11

0 5 10 15 20 25 30 35 40 45

0

10

20

30

X [g/l]

0 5 10 15 20 25 30 35 40 45

0

1

2

3

A [g/l]

0 5 10 15 20 25 30 35 40 45

0

0.5

1

x 10

−4

Time [h]

F

in

[l/s]

Figure 9: Bacteria cultures – biomass and acetate concen-

trations, and feed rate – robust control strategy – results of 5

runs with random parameter variations and a noise standard

deviation of ±0.1 [g/l].

0 10 20 30 40 50

0

0.2

0.4

0.6

0.8

1

x 10

−4

θ adaptation

θ [s

−1

]

0 10 20 30 40 50

0

5

10

15

20

25

X [g/l]

Time [h]

Estimated θ

θ

Figure 10: Bacteria cultures – θ adaptation and biomass

concentration – adaptive control strategy – noise standard

deviation of ±0.05 [g/l].

0 10 20 30 40 50

0.5

1

1.5

A [g/l]

A*

A

0 10 20 30 40 50

0

0.2

0.4

0.6

0.8

1

x 10

−4

F

in

[l/s]

Time [h]

Figure 11: Bacteria cultures – acetate concentration and

feed flow rate – adaptive control strategy – noise standard

deviation of ±0.05 [g/l].

cultures (for biological and operating reasons, bacte-

ria strains lead to reaction rates and, therefore, growth

rates that are smaller than yeast reaction rates). How-

ever, from a control point of view, results are satisfac-

tory in both cases.

6 CONCLUSIONS

Linearizing control is a powerful approach to the con-

trol of fed-batch bioprocesses. In most applications

reported in the literature, on-line parameter adapta-

tion is proposed in order to ensure the control per-

formance despite modeling uncertainties. On-line pa-

rameter adaptation is however sensitive to measure-

ment noise, and requires some kind of tuning. On

the other hand, robust control provides an easy design

procedure, based on well established computational

procedures using the LMI formalism. Large paramet-

ric and structural uncertainties, as well as measure-

ment noise levels can be dealt with.

ACKNOWLEDGEMENTS

This paper presents research results of the Belgian

Network DYSCO (Dynamical Systems, Control, and

Optimization), funded by the Interuniversity Attrac-

tion Poles Program, initiated by the Belgian State,

Science Policy Office. The scientific responsibility

rests with its authors.

REFERENCES

Bastin, G. and Dochain, D. (1990). On-Line Estimation and

Adaptive Control of Bioreactors, volume 1 of Process

Measurement and Control. Elsevier, Amsterdam.

Chen, L., Bastin, G., and van V. Breusegem (1995). A case

study of adaptive nonlinear regulation of fed-batch bi-

ological reactors. Automatica, 31(1):55–65.

Dewasme, L., Richelle, A., Dehottay, P., Georges, P., Remy,

M., Bogaerts, P., and Wouwer, A. V. (2009a). Lin-

ear robust control of s. cerevisiae fed-batch cultures

at different scales. In press, Biochemical Engineering

Journal.

Dewasme, L., Wouwer, A. V., Srinivasan, B., and Per-

rier, M. (2009b). Adaptive extremum-seeking con-

trol of fed-batch cultures of micro-organisms exhibit-

ing overflow metabolism. In Inproceedings of the AD-

CHEM conference in Istanbul (Turkey).

D.F. Coutinho, M. Fu, A. Trofino and P. Dan`es (2008). L2-

gain analysis and control of uncertain nonlinear sys-

tems with bounded disturbance inputs. Int’l J. Robust

Nonlinear Contr., 18(1):88–110.

G. Chesi, A. Garulli, A. T. and Vicino, A. (2004). Robust

analysis of LFR systems through homogeneous poly-

nomial Lyapunov functions. 49, (7):1211–1215.

Leith, D. and Leithead, W. (2000). Survey of gain-

scheduling analysis and design. International Journal

of Control, 73:1001–1025.

M. Green and D.J.N. Limebeer (1994). Linear Robust Con-

trol. Prentice Hall.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

12

Pomerleau, Y. (1990). Mod´elisation et commande d’un

proc´ed´e fed-batch de culture des levures pain. PhD

thesis, D´epartement de g´enie chimique. Universit´e de

Montr´eal.

Renard, F. and Wouwer, A. V. (2008). Robust adaptive con-

trol of yeast fed-batch cultures. Comp. and Chem.

Eng., 32:1238–1248.

Rocha, I. (2003). Model-based strategies for computer-

aided operation of recombinant E. coli fermentation.

PhD thesis, Universidade do Minho.

S.Boyd, L.El-Ghaoui, E.Feron and V.Balakrishnan (1994).

Linear Matrix Inequalities in System and Control The-

ory. SIAM.

Skogestad, S. (2004). Control structure design for complete

chemical plants. Computers and Chemical Engineer-

ing, 28(1-2):219–234.

Skogestad, S. and Postlethwaite, I. (2001). Multivariable

Feedback Control - Analysis and Design. John Wiley

& Sons, New York, NJ.

Sonnleitner, B. and K¨appeli, O. (1986). Growth of

Saccharomyces cerevisiae is controlled by its limited

respiratory capacity : Formulation and verification of

a hypothesis. Biotechnol. Bioeng., 28:927–937.

Sturm, J. F., Romanko, O., and Plik, I. (2006). SeDuMi,

version 1.1R3. Online – http://sedumi.mcmaster.ca/.

LINEARIZING CONTROL OF YEAST AND BACTERIA FED-BATCH CULTURES - A Comparison of Adaptive and

Robust Strategies

13