Comparing Adaptive and Non-adaptive Models of Cargo

Transportation in Multi-agent System for Real Time Truck

Scheduling

Oleg Granichin

1

, Petr Skobelev

2

, Alexander Lada

2

, Igor Mayorov

2

and Alexander Tsarev

2

1

Saint Petersburg State University, Saint Petersburg, Russia

2

Software Engineering Company «Smart Solutions», Ltd., Samara, Russia

Keywords: Multi-agent Systems, Adaptive Scheduling, Trucks, Cargo Transportation, Simulation, Real-time, Mobile

Resources.

Abstract: The application of multi-agent platform for real-time adaptive scheduling of trucks is considered. In case of

unpredictable events the system works adaptively and doesn’t stop to restart the plan from the beginning.

Different models of cargo transportation for truck companies having own fleet are analysed. The results

show that using adaptive scheduling in real time it is possible to create significantly more profitable

schedules (up to 40-60% compared with rigid models) and save a number of trucks (up to 20%) for the same

amount of orders.

1 INTRODUCTION

The problem of resource optimize allocation are

usually solved, when all the orders and resources are

given in advance and don’t change in the process of

scheduling. In these cases classical batch planning

methods can be used characterized by the time-

consuming full combinatorial search or different

types of heuristics requiring a lot of computational

power (Leung, 2004); (Bonabeau, 2000).

Any change is considered as a need for full

change of schedule, which have to be processed

from scratch. But for solving real-life problems of

resource allocation, existing approaches do not work

at all or produce unfeasible schedules which require

exhausting manual re-work for dispatchers.

For solving such problems we apply multi-agent

technology (Wooldridge, 2002). The approach we

are working on is based on Demand-and-Resource

Networks (DRN) of agents representing orders and

resources (Skobelev, 2011). That allows us to find a

‘well-balanced’ solution acceptable for all the agents

as well as for company as a whole.

As a result of such interactions of agents a near-

to-optimal (acceptable) solution of the problem is

achieved in the form of ‘not-stable equilibrium’,

which can be adaptively corrected in real time after

each new incoming event representing new order or

order cancellation, truck breakdown, delay of work

execution, etc. The developed multi-agent

technology allows us to solve complex resource

allocation, when the number of orders and resources

is not given in advance and there is a high dynamics

of occurring events (Ivashenko, 2011).

The results of the research are important for the

future developments of intelligent freight

management systems and dispatching of any other

mobile resources that are able to operate in real time.

2 THE MODELS OF

TRANSPORTATION PROCESS

ORGANIZATION

Let’s assume that we have a fleet of M trucks based

in certain cities in a transportation network. The

operation cost of each truck is given. Orders come

into the system with the specified points of loading

and unloading, loading start time, unloading finish

time, price and penalties for delays when a loading

or unloading is done later than they should.

Distances between points are also given and

described by a matrix of distances.

The objective is to schedule the trucks in real

time and determine transportation company profit

282

Granichin O., Skobelev P., Lada A., Mayorov I. and Tsarev A..

Comparing Adaptive and Non-adaptive Models of Cargo Transportation in Multi-agent System for Real Time Truck Scheduling.

DOI: 10.5220/0004148602820285

In Proceedings of the 4th International Joint Conference on Computational Intelligence (ECTA-2012), pages 282-285

ISBN: 978-989-8565-33-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

depending on the scheduling strategy (model) and

the number of trucks.

The optimization criterion of the task is the

maximal total profit of all the trucks in company

fleet. The research is done for four different models

of organization of transportation process including

not-adaptive and adaptive models described below.

The total profit of the fleet of trucks is calculated

as a sum of profits of each truck:

i

i

p

P .

(1)

The profit of one truck is:

,

'

j

ij

i

ij

i

j

i

t

q

t

q

c

p

t

(2)

where sum includes all orders j executed by the

truck i, c

j

– price of order j per time unit, q

i

– cost of

the truck per time unit, t

ij

– time of execution order j

by truck i, t’

ij

– empty run time for order j.

Let’s consider 4 models of transportation process

organization.

Model #1 – the ‘Returning to base after an order

execution’ model. After each order execution the

truck should return to the base point. Order is

assigned to a truck that has a ‘window’ in its

schedule during the order time period. If the loading

point of the order is a different city, then the truck

should arrive there at the loading time. No

reassignments of the trucks already assigned to the

orders are allowed.

Model #2 – the ‘No return to base after an order

execution’ model. After each order execution truck

stays at the order destination point, without returning

to base, and waits for a next order.

Model #3 – the ‘Delays with penalties’ model.

Orders can be scheduled with delays of time of

arrival at the loading point. In this case profit with

penalty calculation is:

,

'''

'

k

ik

k

ik

i

ik

k

k

j

ij

i

ij

i

j

i

t

p

t

q

t

q

c

t

q

t

q

c

p

t

(3)

where the sum by index j includes all orders that

were executed just in time by the truck i, the sum by

index k includes all orders that were executed with

delays t

’’

ik

, p

j

– penalty of each delay per time unit.

Model #4 – the ‘Adaptive scheduling with penalties’

model. It is equal to the previous model, but it

allows the truck reassignment when a profit from a

new order is higher than a profit from the previous

one.

3 THE MULTI-AGENT

SIMULATOR

A special multi-agent simulator (MAS) has been

created for modelling of adaptive real time

scheduling. It works as follows. Every truck is

associated with a truck agent, every order – with an

order agent. The agents are able to send and receive

messages and take decisions according to their logic

and current situation. The unified spatio-temporal

scale is defined to achieve visibility of results and

unified logic: time is counted from the moment of

the first order entry. The upper border of planning is

determined by the planning horizon, calculated in

days. The distances are brought to time scale by

division of the distances by the average speed.

When a new order comes, a request for its

allocation is sent to all the truck agents. ‘Candidates’

for re-scheduling (in case of increasing profit) are

ordered of the prospective profit. Then the order

agent chooses the truck that gives the maximal

profit. The profit is calculated as a difference

between the order revenue (price) and the order full

cost. When order implies an empty run to loading

point, its cost is also deducted from the revenue. In

case of strategy (model), where penalties are

applied, their influence on profit is analyzed. For

penalty is proportional to time of delay, the orders

with big delays will not be scheduled.

Let’s consider world of simulations for one

truck. There are 4 cities (points) given, among which

the distances are determined by the matrix (see

Table 1) in days of trip. Time of trip doesn’t

necessarily correspond to the distance, because of

roads quality.

At the beginning of the trip the truck is located in

the point 1. At different times cargo transportation

orders #1-5 to different points come into the system.

Duration of execution of an order is 1-2 days.

Scheduling horizon equals t = 10 days. The costs of

orders are calculated equally using company tariff as

c = 3 standard units (SU) / day, i.e. 2-days trip would

have cost of 6 SU. Idle time of a truck leads to daily

loss of q=0.3 SU.

Table 1: Matrix of distances among cities.

Point 1 Point 2 Point 3 Point 4

Point 1

0 1 1 2

Point 2

1 0 2 1

Point 3

1 2 0 1

Point 4

2 1 1 0

Daily running cost in case of empty run of truck

or order execution is q=1. Drivers are allowed to

ComparingAdaptiveandNon-adaptiveModelsofCargoTransportationinMulti-agentSystemforRealTimeTruck

Scheduling

283

execute orders with delays, but every day of delay

costs pp = 0.6 SU. Some orders are shifted to the

right on the time axis because of this. The aim is to

be able to schedule trips, as orders come in (the

orders are not known in advance) and calculate

profit. Orders are marked with a number according

to the place in the sequence of entry into the system

and characterized by time of their entry (moment of

entry t), moments of start and finish of order

execution, duration (in days), point of loading and

point of unloading (Table 2).

Table2: Parameters of orders.

Characteristics

Order number

1 2 3 4 5

Time of entry

1 3 5 6 7

Start time of execution

3 4 7 8 9

Finish time of execution

5 5 9 9 10

Where from

4 3 1 4 3

Where to

1 1 4 3 1

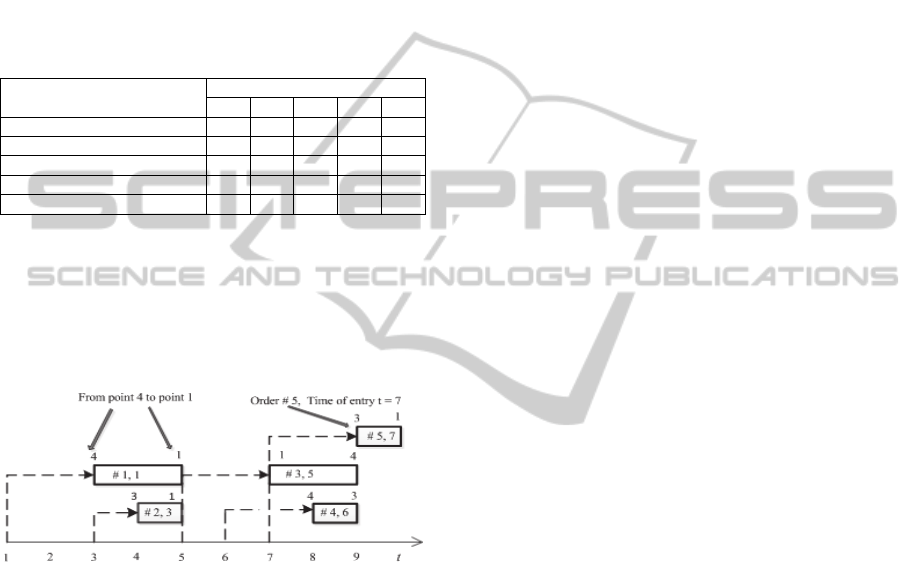

Figure 1 shows orders as rectangles, with the

order number and the time of entry. Above each

rectangle ‘where from – where to’ locations are

described. The start and the finish of each rectangle

correspond to the start and the finish of the order

execution.

Figure 1: Diagram of orders entry and scheduling.

Let’s calculate the profit of truck #1 in the Model

#3, where penalties are applied. We will calculate

the profit P at the moments of transition of the truck

from one state to another step by step.

Step 1. Execution of order #1 will require to start at

the moment t=1 from point #1 to point # 4 and will

take 2 days till the moment t=3. At the moment t=3

the profit is P=-q*2=-2.

Step 2. The transportation of cargo from point 4 to

the point 1 will take 2 days, and at t=5 the truck will

arrive at the point 1 with the profit P=-2+(c-q)*2=-

2+2*2=2. Assume that the truck agent assesses

options of further schedule and execution upon

arrival to point 1 at time t=5. Its profit at point 4 is

P=2. By this time order # 3 has been entered at the

moment of time #3. There are two options to execute

it:

Order #2 is to be executed with delay;

Order #2 is rejected, idle time cost is accepted,

order #3 from the same point 1 is to be taken; for

order # 2 can be executed with delay before

execution of order #3, no further options will be

taken into consideration. Let’s take a more precise

look at 2 options.

Step 3. Truck needs to reach point 3, moving from

point 1 (1 day trip), pick up the order and execute it,

going from point 3 to point 1 (1 day). The increase

of profit is dp=-1*q+(c-q)*1=-1+2=1.

Penalty applied because of delay is -pp*2=-2*0.6=-

1.2. As a result the truck will be at the moment t=7

at the point 1 with the profit P=2+1-1.2=1.8.

Execution of the order would seem to be

unprofitable, but one should take into consideration

that in case of cancellation of the order the truck

would stay idle for 2 days, and the profit at the

moment t=7 would be P=2-2*0.3=1.4.

Step 4. That’s why the truck agent is interested in

the execution of order #2 with delay, order #3, t=

7…9 (from point 1 to point 4) - 2 days, profit is

P=1.8+2*(c-q)=1.8+2*2=5.8, and the truck moves to

point 4.

Step 5. At the moment t=9 new order# 5 comes in

at the point 3 with start time of execution t=9; empty

run to its loading point is 1 day, what puts the order

beyond the 10-days scheduling horizon limit. That’s

why the truck agent rejects the order. There is an

outdated order #4 from point 4 to point 3, its

execution start time should be t=8. The truck agent

assesses profit from possible shift of order by a day.

Step 6. Execution of the order #4, empty run is not

required, dp=(3-1)*1=2-penalty 0.6=1.4. If this

order were rejected, the truck would stay idle for 1

day till the end of the scheduling horizon and then

dp=-1*0.3=-0.3. That’s why the truck agent accepts

the order #4.

Outcome: orders #1 and 3 are executed without

delay, order #2 – with allowed delay of 2 days and

order #4 – with allowed delay of 1 day. Order #5 is

rejected. Total profit in 10 days is P=5.8+1.4=7.2.

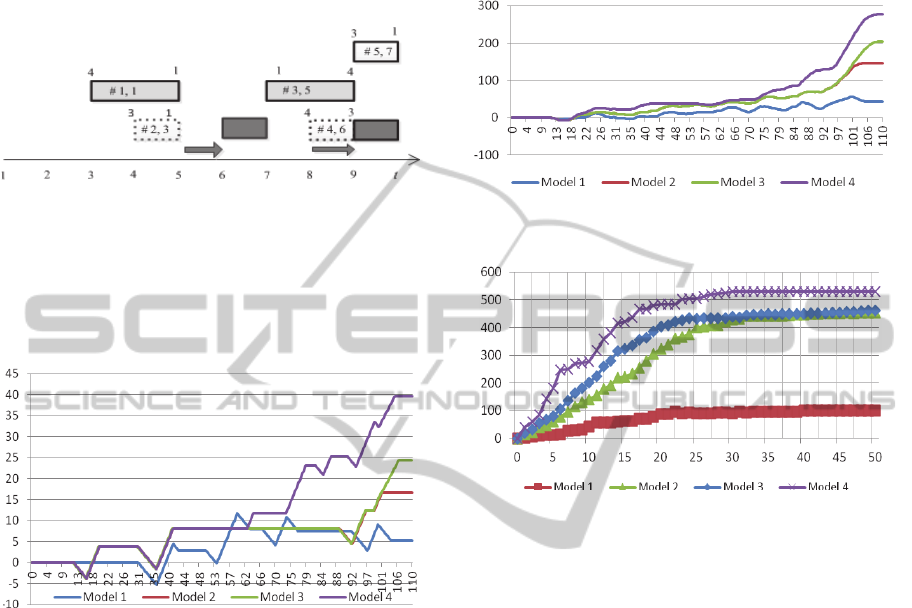

Final track of the truck is shown on the Figure 2.

The truck starts from the point 1 to the point 4. Then

it executes the order #1 from the point 4 to the point

1 without delay. Then it goes to the point #3 to

execute the order #2. Then it executes the order #2

with delay. After this the truck executes the order #3

from the point 1 to the point 4 without delay. Then it

executes the order #4 with delay. The order #5

remains unfulfilled, because it goes beyond the

scheduling horizon (t=10). The delayed orders on

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

284

Figure 2 are shown with dark grey, when penalties

are applied; light grey marks orders without delay;

shifts in schedule are shown with wide arrows;

shifted orders are shown with dotted borders;

rejected order is white (not visible).

Figure 2: Diagram of execution of adaptive schedule by

one truck.

4 THE RESULTS OF THE

EXPERIMENTS

Figure 3: Dynamics of a profit for the truck depending on

model of transportation.

Trucks schedules were created for orders based on

the 4 used models of transportation. Graphs of

dynamic profit per each truck and dynamics of sum

of trucks profit depending on time was found

(Figure 3 – Figure 4). The designed MAS allows

also to study the profit depending on trucks number

for each flow of orders. For simplicity we don’t

consider standing costs of trucks. The trucks amount

was varied from 0 to 50 (Figure 5). Satiation modes

differ for the different models. The lowest profit

value is in the Model #1 because less amount of

orders are scheduled and additional expenses occur

after returning to the base. The Model #3 far exceeds

the Model #2 because it uses the same amount of

trucks as in Model #2 but more orders are scheduled.

But in a satiation mode it gives almost no benefits

vs. the Model #2, because when the trucks number is

high enough there are very few orders that are

executed with delays so Model #2 and Model #3 will

be almost equal. The Model #4 is the best one. It

gives approximate 20% more profit then Model #2

and Model #3. It allows using less trucks during the

plan execution. The reason is the adaptive re-

scheduling of orders in real time.

Figure 4: Dynamics of sum of trucks profit depending on

transportation models.

Figure 5: The dependence of the profit to the used trucks

number in the different transportation models.

REFERENCES

Leung , Y-T., 2004. Handbook of Scheduling: Algorithms,

Models and Performance Analysis. Chapman & Hall.

London.

Bonabeau, E., Theraulaz, G., 2000. Swarm Smarts. What

computers are learning from them? Scientific

American, vol. 282, no. 3, pp. 54-61.

Wooldridge, M., 2002. An Introduction to Multi-Agent

Systems. JohnWiley & Sons. London, 2

nd

edition.

Skobelev, P.: Multi-agent technology for real time

resource allocation, scheduling, optimization and

controlling in industrial applications, 2011. In

HoloMAS 2011, 5th International Confrence on

Industrial Applications of Holonic and Multi-Agent

Systems. Springer. Berlin. pp. 1-14.

Ivaschenko, A., Skobelev, P., Tsarev, A., 2011. ‘Smart

solutions’ multi-agent platform for dynamic

transportation scheduling. In ICAART 2011, 3rd

International Conference on Agents and Artificial

Intelligence, vol. 2, pp. 372-375.

ComparingAdaptiveandNon-adaptiveModelsofCargoTransportationinMulti-agentSystemforRealTimeTruck

Scheduling

285