A Driving Assistance System for a Manual Wheelchair

using Servo Brakes

Daisuke Chugo

1

, Tatsuya Higuchi

1

, Yuki Sakaida

2

, Sho Yokota

3

and Hiroshi Hashimoto

4

1

School of Science and Technology, Kwansei Gakuin University, Sanda, Hyogo, Japan

2

RIKEN-TRI Collaboration Center for Human-Interactive Robot Research, Nagoya, Aichi, Japan

3

School of Science and Engineering, Setsunan University, Neyagawa, Osaka, Japan

4

Advanced Institute of Industrial Technology, Shinagawa, Tokyo, Japan

Keywords: Manual Wheelchair, Assistive Wheelchair, Servo Brakes.

Abstract: We propose a novel intelligent wheelchair based on the passive robotics. Our proposed assistive wheelchair

consists of a frame, casters, wheels and servo brakes. Our wheelchair system estimates the trajectory its user

wants using the characteristic of the row motion and realizes the estimated tracks by controlling a torque of

its servo brake. Our system requires no actuators, and its mechanism is simple and low cost. There is no risk

by malfunction of servomotors and patients can use it intuitively because they use our wheelchair passively

with their own intentional force. Our key ideas are two topics. One is the development of a passive-type

assistive wheelchair which is suitable for practical use. The other key topic is a novel driving assistance

algorithm with estimation of its user’s intention. For realizing this estimation, we use a minimum jerk

trajectory model, which expresses a typical human movement. Our proposed system compares a beginning

part of row motion by the user and this trajectory model, and estimates a whole row motion which will be

operated. Using our proposed system, the user can drive our wheelchair with a natural feeling. We test our

proposed assistance system by the experiments with our prototype and verify its effectiveness.

1 INTRODUCTION

Wheelchairs are widely used by many people who

are mobility impaired in daily activities. However,

many accidents often occur to wheelchair users and

its risk is serious. More than 80% of wheelchair

accidents are caused by environmental problems

(National Consumer Affairs Center of Japan, 2002).

Especially, an inclination of sidewalk has high risk

for a wheelchair user. In Japan, it is permitted to

incline a sidewalk up to 5deg (Fig.1) (Japan Institute

of Construction Engineering, 2008). This inclination

leads a wheelchair user to run out from the sideway

to the roadway and it causes the accident between a

wheelchair user and a car. Therefore, a driving

assistance system for a wheelchair is important.

In previous works, a lot of assistive technologies

for wheelchairs are developed. In general, many

handicapped people traditionally use power

wheelchairs (Yamaha Motor Co., Ltd., 2012) and

previous researchers have tried to realizing

assistance functions by adding wheels with actuators

and controlling them based on the robot technology

such as motion control technology (Miller and

Slack, 1995), sensing technology and computational

intelligence (Katevas et al., 1997) (Murakami et al.,

2001). These intelligent wheelchairs provide many

functions, such as a suitable motion, an obstacle

avoidance and a navigation; thus, they provide a

maneuverable system. However, many wheelchair

users have an upper body strength and dexterity to

operate a manual wheelchair. For these wheelchair

users, its cost is too expensive and is not acceptable.

On the other hand, a manual wheelchair without

servomotors, which consists of a frame, wheels,

casters and hand brakes, is commercially available

and widely used. Its mechanism is simple and low

cost. There is no risk by malfunction of servomotors

and patients can use it intuitively because they use

these wheelchairs passively with their own

intentional force. Of course, these wheelchairs

cannot assist to drive dynamically as powered

wheelchairs and there is still a risk on a slope such

as Fig.1. Thus, there is no well-adapted wheelchair

assistance system for healthy users who have an

259

Chugo D., Higuchi T., Sakaida Y., Yokota S. and Hashimoto H..

A Driving Assistance System for a Manual Wheelchair using Servo Brakes.

DOI: 10.5220/0004477802590267

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 259-267

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

upper body strength.

Roadway Sidewalk

5[deg]

(a) Inclination of the sidewalk (b) The typical sidewalk

Figure 1: Risks of the sidewalk.

Therefore, in this paper, we propose a passive-type

assistive wheelchair with servo brakes. We use a

concept of passive robotics. This system moves

passively based on external force without actuators.

Our system uses servo brakes, which can change

brake torque, and realizes the desired motion using

servo brakes according to the applied force and

reference tracks. For realizing a natural assistance

according to its user’s intention, we develop a novel

driving assistance scheme for a wheelchair with the

estimation of the direction which its user wants to go.

This paper is organized as follows: we introduce

a mechanical design and controller of our system in

section 2; we propose a driving assistance scheme

with the estimation of the user’s intention in section

3; we show experimental results using our prototype

in section 4; section 5 is conclusion of this paper.

2 PASSIVE-TYPE ASSISTIVE

WHEELCHAIR

2.1 Passive System

A passive system realizes a reference motion using

servo brakes with external force applied by its user.

The passive robotics system requires no actuator and

its mechanism is simple, therefore, the system will

be low cost (Goswani et al., 1990) (Rentschler et al.,

2003). In the research area of the assistive robotics,

the passive robotics concept has been used for the

walker and its performance is useful (Hirata et al.,

2007).

This characteristic is especially suitable for a

wheelchair assistance system for healthy users who

have enough upper body strength to operate a

manual wheelchair. Therefore, we adapt this concept

for our wheelchair driving assistance system.

2.2 System Configuration

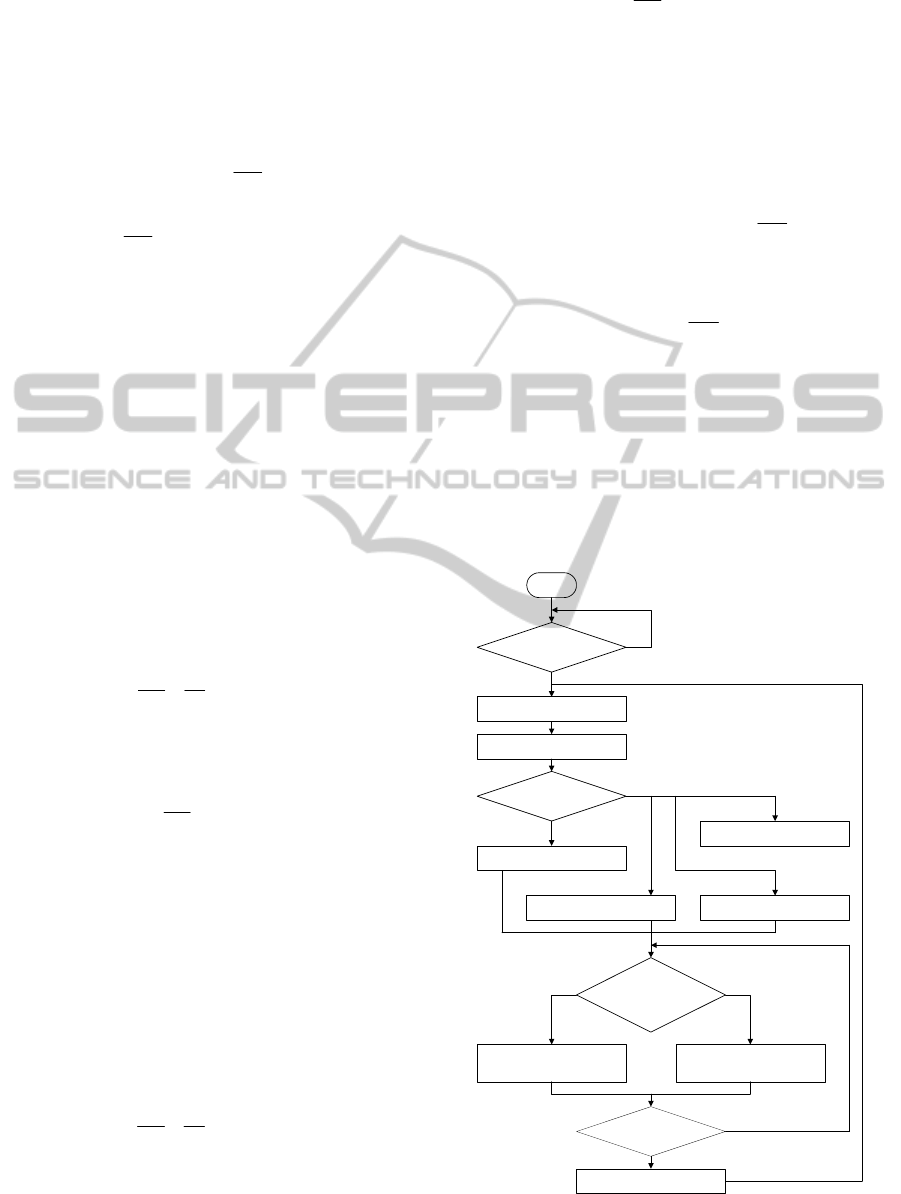

Fig. 2(a) shows our prototype. Our proposed

wheelchair utilizes a powder brake, which is one of

a servo brake. A powder brake is widely used in

industrial purposes and its cost is low comparing

with the other servo brakes. We choose the powder

brake as Fig.2(b) (ZKG-YN50, Mitsubishi Electric

Corp.), which can generate enough brake torque for

stopping 4km/h moving wheelchair with a 100kgf

user by 1sec.

Our prototype is based on a normal wheelchair

(BM22-42SB, Kawamura Cycle Co. Ltd.) and our

system has compatibility with a general wheelchair,

which fulfills these standards (ISO7193, 7176/5).

This means the user can built our system into their

wheelchair without a special construction.

Fig.3 shows its controller. Our wheelchair has

two powder brakes with the tension controller on

each wheel. Our system can measure the rotational

velocity using encoders on each wheel. All devices

including the batteries are equipped in its body and

can continue to work more than 24 hours without an

external power supply.

(a) Overview (b) Installed brake

Figure 2: Our Prototype.

Control PC

Human Interface

DA Converter

(Contec AIO-

160802AY-USB)

Tension Controller

(Mitsubishi LD-

10PAU-A)

Conuter

(Contec CNT24-

2(USB)GY)

Powder Brake

(Mitsubishi ZKG-

50YN)

Encoder

Right Wheel

Left Wheel

Same

System

Figure 3: Our Control System.

2.3 Kinematics

Fig.4 shows a kinematic relationship of our

wheelchair. The rotational radius of its trajectory R

is derived as (1).

LR

LR

vv

vvT

R

2

(1)

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

260

where the velocity of a right wheel is

R

v

and one of

a left wheel is

L

v

. The distance between the wheels

is T. If R is negative, the wheelchair turns to right

direction and if R is positive, it turns to left direction.

From (1), the ratio between

R

v

and

L

v

sets its

turning radius and in next section, we will discuss

this ratio for derivation the trajectory path.

T

Wheelchair

x

y

R

Human

v

L

v

R

v

Figure 4: Kinematic model of the wheelchair.

3 DRIVING ASSISTANCE

CONTROLLER

3.1 Concept of Our proposed

Controller

Many previous researches on the wheelchair driving

assistance control are designed for powered

wheelchairs (Katsura and Ohnishi, 2004); (Sakai et

al., 2010); (Takahashi et al., 2000) and they are

based on traction control. However, a passive system

does not generate a traction force and cannot use

these methods. Thus, we develop a driving

assistance control scheme which is based on a

velocity control.

Usually, a movement of a wheelchair consists of

two phases. In first phase, its user rows a wheelchair

and accelerates it. In this phase, a movement of the

wheelchair is based on its user’s intention. In second

phase, the wheelchair runs with inertia. In this phase,

a shape of a ground such as slopes influences

movement of the wheelchair easily.

Using its characteristic, we propose a novel

driving assistance controller for a passive-type

assistive wheelchair. Our proposed scheme estimates

a trajectory its user wants to go at a beginning of the

first phase and controls its wheels based on the

estimated result by the end of the second phase.

When the user rows the wheel again, our system

finishes this wheel control and restarts from the

estimation process.

Our estimation scheme measures a beginning

part of a row motion by the user and compares a

measuring trajectory and a minimum jerk trajectory

model which expresses a typical human motion

(Flash and Hogan, 1985); (Seki and Tadakura,

2004). After estimation the user’s intention, our

system sets the reference trajectory based on this

result and controls the servo brake for realizing it.

Our idea does not require additional force sensors.

Thus, its implementation for a general wheelchair is

easy and its cost is low.

3.2 Minimum Jerk Trajectory Model

In the field of neurophysiology, previous researchers

have analyzed voluntary human arm movements and

demonstrated that they can be closely approximated

by a minimum jerk trajectory model with

characteristic velocity profile (Flash and Hogan,

1985). This model is useful for various fields of

human robot interaction technologies (Seki and

Tadakura, 2004) and in this study, we use this model

for the estimation of a row motion by the wheelchair

user.

In the minimum jerk trajectory model, the human

arm movements, supporting one-dimensional

movement, is expressed as the trajectories which

minimize (2).

f

t

j

dt

dt

txd

C

0

2

3

3

(2)

where

f

t

is the final time of the movement and

33

dttxd

is the differential of acceleration, called

jerk.

j

C

is an extremum when

tx

is the solution

of Euler-Poisson equation. The resulting equation is

represented by (3).

0

6

6

d

t

txd

(3)

This condition shows that

tx

is the fifth order

polynomial as (4).

01

2

2

3

3

4

4

5

5

atatatatatatx

(4)

We assume the start position is

0

x

and end position

is

f

x

. Furthermore, we assume the velocity and

acceleration are zeros at the start position and the

end position, then the boundary conditions are

derived as (5).

0,0,

00,00,0

0

ffff

txtxxtx

xxxx

(5)

Appling (5) to (4),

tx

is expressed as (6) and (7).

345

00

10156

xxxx

f

(6)

ADrivingAssistanceSystemforaManualWheelchairusingServoBrakes

261

f

t

t

(7)

Using the minimum jerk trajectory model, we define

the human arm behavior characteristic on the row

movement on the wheelchair.

3.3 Estimation of the User’s Intention

Using the minimum jerk trajectory model, we

estimate the direction its user wants to go. For

realizing the estimation, we propose a following

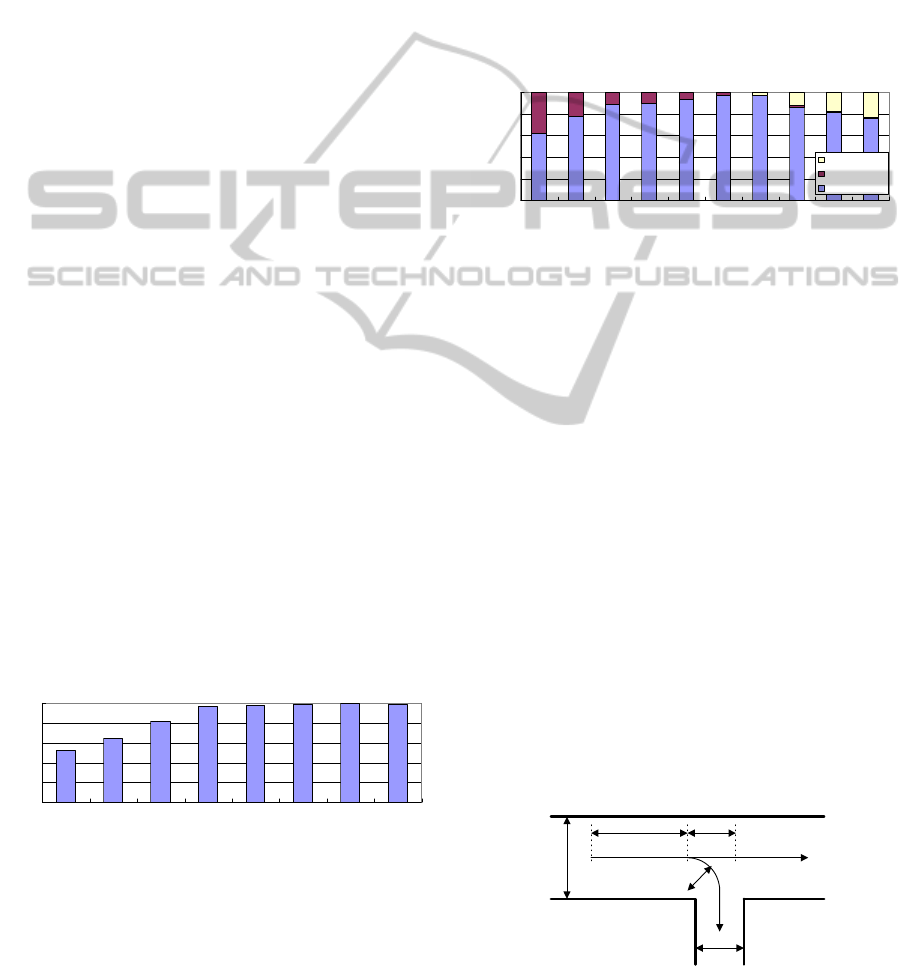

method as show in Fig.5.

Our system measures a rotation velocity of each

wheel. If the rotation velocity of a right or left wheel

increases

t

continuously, our system judges the

user rows the wheelchair and starts to estimate the

user’s motion using the minimum jerk trajectory

model. Our system sets

2.0t

sec experimentally

and this value is derived in section 4.1.

Furthermore, our system sets the time

0

tt

at

the moment when the rotation velocity increases. At

the same time, our system measures the position

(

0

x

), velocity (

0

x

) and acceleration (

0

x

). We

assume that the boundary condition of the minimum

jerk trajectory model is as (8) (Seki and Tadakura,

2004). The velocity and the acceleration at

0

tt

are not necessarily zeros as (5) because the user may

row the hand rim and accelerate the wheelchair

when the wheelchair moves.

0,0,

,,

000

000000

ffff

ttxttxxttx

xtxxtxxtx

(8)

Using this assumption, the minimum jerk trajectory

model is derived as (9) and (10).

133

2

1683

10156

23

2

0

0

234

00

345

00

tt

x

ttx

xxxtx

f

(9)

f

t

tt

0

(10)

In (9) and (10), unknown values are end position

f

x

and the final time

f

t

. Therefore, our system uses a

pattern matching method as (11) and derives

f

x

and

f

t

which minimize

ff

txc ,

. We define the

f

x

and

f

t

which leads the minimum value of

ff

txc ,

as

0f

x

and

0f

t

.

tt

t

realffff

dttxttxxtxc

0

0

,,

(11)

where

ff

txx ,

is the trajectory model with the end

position

f

x

and the final time

f

t

.

tx

real

is

measurable value. Thus,

00

,

ff

txx

approximates

the user’s motion with the sufficient accuracy for

estimating its trajectory. In this study, we set the

candidate of these values (

f

x

and

f

t

) as (12) based

on our preliminary experiment results for reducing a

calculation load of our controller.

0.5,,2.1,1.1,0.1

50.1,,15.0,10.0,05.0

f

f

t

x

(12)

Our system excuses this matching process on each

wheel. Therefore, our system estimates

0f

x

in right

wheel (

R

f

x

0

) and in left wheel (

L

f

x

0

), and estimates

0f

t

in right wheel (

R

f

t

0

) and in left wheel (

L

f

t

0

). Our

system uses these values for the direction estimation

its user wants to go.

In (13), we estimate the average velocity in the

first phase of the wheelchair movement and we

assume this velocity shows the user’s intention.

L

f

L

f

est

L

R

f

R

f

est

R

t

x

v

t

x

v

0

0

0

0

,

(13)

where

est

R

v

is estimated velocity of right wheel and

est

L

v

is one of left wheel.

From (13), the rotational radius

est

R

of the

estimated trajectory is derived as (14). If

est

R

is

negative, the wheelchair turns to right direction and

if

est

R

is positive, the wheelchair turns to left

direction. Furthermore, when (15) is fulfilled, our

system judges that its user wants to go at straight

and sets

est

L

est

R

vv

.

straight

threshold

v

is the threshold which

is derived experimentally.

er

hand, when (22)

i

s

??f(14)

(14)

straight

threshold

est

L

est

R

vvv

(15)

If the

000

, ctxc

ff

, our system judges the user

does not row the wheelchair. In this study, we set

this threshold (

0.3

0

c

) experimentally. This value

is derived in section 4.1.

When both wheels have fulfilled this condition,

our system judges the wheelchair accelerates

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

262

without the user’s will and stops the wheelchair with

maximum brake traction for safety reason. When

only one of the wheels has fulfilled this condition,

our system judges the user turns with small radius.

In this case, our system sets the estimated value as

(16) in case of the right wheel or (17) in case of the

left wheel.

L

f

L

f

est

LR

est

R

t

x

vtvv

0

0

0

,

(16)

0

0

0

, tvv

t

x

v

L

est

L

R

f

R

f

est

R

(17)

3.4 Wheel Control Algorithm

Based on the estimated result, our system controls its

wheels with a PID controller. The control algorithm

is as follows.

For fitting the wheelchair to the estimated

trajectory, the ratio between the velocity of the right

wheel and the left wheel is same to the estimated

results. Therefore, our system defines the control

reference of both wheels (

ref

R

v

and

ref

L

v

) as (18).

ref

L

ref

R

est

L

est

R

vvvv ::

(18)

Our system uses only servo brakes for controlling

the wheelchair. Thus, when (19) is fulfilled, our

system sets the control reference as (20) and (21).

L

R

est

L

est

R

v

v

v

v

(19)

maxmax

max

vvifvv

vvifvv

R

ref

R

RR

ref

R

(20)

ref

R

est

R

est

L

ref

L

v

v

v

v

(21)

In this case, our proposed system sets

R

ref

R

vv

and

controls the left wheel. At the left wheel,

ref

LL

vv

and our system can control the velocity with its

servo brake. For safety reason, if the velocity

exceeds the limitation value

max

v

, our system

reduces its moving speed to this limitation.

On the other hand, when (22) is fulfilled, our

system sets the control reference as (23) and (24),

and controls right wheel with its servo brake.

L

R

est

L

est

R

v

v

v

v

(22)

maxmax

max

vvifvv

vvifvv

L

ref

L

LL

ref

L

(23)

ref

L

est

L

est

R

ref

R

v

v

v

v

(24)

After setting the control references, our system uses

PID controller as (25) in the left wheel or (26) in the

right wheel when its velocity does not exceed the

limitation. The control error integrates from

0

t

and

our assistance system tries to maintain the direction

at the beginning of the row motion.

dt

de

kdtekek

L

d

t

LiLpLR

0

,0

(25)

L

ref

LL

vve

(if (19) is fulfilled.)

0,

0

L

R

d

t

RiRpR

d

t

de

kdtekek

(26)

R

ref

RR

vve

(if (22) is fulfilled.)

According to (25) and (26), our system maintains the

ratio between the velocity of the right wheel and the

left wheel as (18). Therefore, our system with the

proposed algorithm, controls the wheels only for

fitting the trajectory its user wants and its velocity

depends on the user’s motion. Our system reduces

the moving speed of the wheelchair only in case of

Start

Is acceleration more than a

threshold value for

Δ

t?

System calucurates on

the both wheels.

00

,

ff

txc

Is more than

in both wheels?

00

,

ff

txc

0

c

System detects motion model and sets

the control reference.

Is acceleration more than a

threshold value for

Δ

t?

Which of the wheels rotates

the faster comparing with their

reference values?

System sets and human motion

estimation process starts.

0

tt

Emergency stop

System uses PID control for the right

wheel for realizing the estimated path

at .

0

tt

System uses PID control for the left

wheel for realizing the estimated path

at .

0

tt

All wheels

No wheel

Only left wheel

System detects motion model at right

wheel and sets the reference.

System detects motion model at left

wheel and sets the reference.

Only right wheel

Right wheel Left wheel

Yes

No

Yes

No

System ends the wheel control process

based on estimated trajectory at .

0

tt

Figure 5: Estimation and control flow of our system.

ADrivingAssistanceSystemforaManualWheelchairusingServoBrakes

263

the exceeding the limitation value

max

v

for safety

reason.

Our system applies this control algorithm during

one row motion based on its estimated trajectory,

and in next row motion, our system re-estimates the

user’s trajectory and applies this algorithm again as

Fig.5.

4 EXPERIMENTS

4.1 Parameter Derivation

Our assistance system uses two parameters,

t

is

the estimation time parameter and

0

c

is the pattern

matching parameter which judges the row motion is

done by the user or not. In this experiment, we

derive the suitable values for two parameters.

4.1.1 Estimation Time Parameter

Our system estimates the row motion of the user by

the measured wheel rotation velocity data during

t

seconds. Therefore, if our system sets

t

is large

value, our system can use the large measuring data

for estimation and the estimation accuracy will

increase. However,

t

causes the time delay and

t

should be small for increasing usability.

This experiment uses 810 row motions by six

subjects who use a wheelchair daily. Our proposed

system estimates the whole operation from its

t

motion at the begging. Comparing between the

estimated motion and the motion which extracted

manually, we derive the success rate as Fig.6. From

the experimental results in Fig.6, if the

t

is larger

than 0.2[sec], the estimation performance is suitable.

Therefore, we choose the smallest value from them

and set

2.0t

.

53

65

82

97 98 99 100 99

0

20

40

60

80

100

0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

Estimation time [sec]

Success rate [%]

Figure 6: Success rate of each estimation time.

4.1.2 Pattern Matching Parameter

Our system judges the user has not performed any

motion if the pattern matching error (11) exceeds the

pattern matching parameter

0

c

. Therefore, this

parameter is important for the safety of the user.

In this experiment, we adapt this evaluation

method to the measuring data of our previous

preliminary experiment in section 4.1.1. In these

measuring data, the wheelchair accelerates 1100

times and 810 times are performed by the user’s row

motion. The experimental results are shown in Fig.7.

The positive failure is the misjudgment the human

motion as the acceleration by other reason and the

negative error is the misjudgment the acceleration by

other reason as the human motion. The negative

error is more serious problem for safety reason and

we choose

0.3

0

c

.

0%

20%

40%

60%

80%

100%

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Threshold (C

0

)

Rate [%]

N ega tive F ailure

Positive Failure

Success

Figure 7: Success rate of each pattern matching parameter.

4.2 Field Test using our Prototype

For verifying the effectiveness of our system, we

make two experiments using our prototype. In first

experiment, we test the trajectory estimation

performance. The other experiment, we test the

performance of our wheelchair assistive system on

the slope environment.

4.2.1 Estimation of the User’s Trajectory

In this experiment, we test the proposed trajectory

estimation scheme. The subject moves on the

trajectory as Fig.8 and our system estimates it. We

test 6 cases. In each case, six subjects who are

healthy young people test our prototype ten times.

Two subjects are left-handed and four subjects are

right-handed. Fig.8 shows the experimental

environment. We show the trajectory by drawing on

the linoleum flat floor as Fig.8 and the subject

moves on it using the wheelchair according to this

trajectory.

(B) (C)(A)

3m

1.5m

1.5m

R

2.5

m

(D)

R=0.5m or 1m

(E)

Figure 8: Experimental trajectory.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

264

The condition of each case is as follows.

Case1: The subject starts at (B) and goes straight.

Around (C), the subject accelerates the wheelchair

to (E) again. Our system estimates the trajectory at

(B) and (C).

Case2: The subject starts at (A) and goes straight

at 0.6m/s. Around (B), the subject accelerates the

wheelchair to the straight direction. Furthermore,

around (C), the subject accelerates the wheelchair

to the straight direction again. Our system

estimates the trajectory at (B) and (C).

Case3: The subject starts at (B) and turns to (E). A

turning radius is 1m. Our system estimates the

trajectory at (B).

Case4: The subject starts at (A) and goes straight

at 0.6m/s. Around (B), the subject turns to (E). A

turning radius is 1m. Our system estimates the

trajectory at (B).

Case5: The subject starts at (B) and turns to (E). A

turning radius is 0.5m. Our system estimates the

trajectory at (B).

Case6: The subject starts at (A) and goes straight

at 0.6m/s. Around (B), the subject turns to (E). A

turning radius is 0.5m. Our system estimates the

trajectory at (B).

As the results, our system judges the straight

direction in all trials in case (1) and (2). Fig.9 shows

the estimated row motion in case (2). We can verify

that our system succeeds to estimate the user’s row

motion twice in each wheel.

0

0.2

0.4

0.6

0.8

1

1.2

012345

Time [sec]

Velocity [m/sec]

Wheel Velocity

Estimation1

Estimation2

0

0.2

0.4

0.6

0.8

1

1.2

012345

Time [sec]

Velocity [m/sec]

Wheel Velocity

Estimation1

Estimation2

(a) Left wheel (b) Right wheel

Figure 9: Estimated row motion in case (2).

Fig. 10 shows estimated results by our proposed

system in case (3) to (6) and Fig.11 shows the

estimated row motion in case (4). In all cases, our

system can estimates the turning radius with 12%

error maximum and its accuracy is enough for

practical use. The estimated results in case (3) are

more accurate than the result in case (4). Because in

case (4), the subjects turn at (B) with 0.6m/s and it is

difficult for them to trace the trajectory accurately.

Furthermore, the subjects operate the right wheel

with the complex motion. From Fig.11(b), the

subject does not row the right wheel, however, he

coordinates the wheel velocity. Therefore, our

system misjudges the velocity of the right wheel and

in this case, estimated velocity is larger than its

actual velocity.

0

0.5

1

1.5

Case3 (R=1m) Case4 (R=1m) Case5 (R=0.5m) Case6 (R=0.5m)

Estimated Radius [m]

Figure 10: Estimated results in case (3) to (6).

The estimated results in case (5) and (6), there is

same tendency in case (3) and (4). In both cases, the

radius is 0.5m and the estimated results in case (5)

are more accurate than the result in case (6). The

disturbance of the estimated results in case (6) is

large because for realizing the reference radius

(0.5m), the subject should fix the right wheel and it

causes the complex motion at (B) point.

The estimated error by left-handed subjects and

right-handed subjects are almost same. However,

left-handed subjects turn at about 0.57m/s and right-

handed subjects turn about 0.52m/s in case (4). This

may mean right turn motion is easy for left-handed

person and in our future work, we should discuss a

dominant hand of the wheelchair user.

0

0.2

0.4

0.6

0.8

1

1.2

01234

Time [sec]

Velocity [m/sec]

Wheel Velocity

Estimation

0

0.2

0.4

0.6

0.8

1

1.2

01234

Time [sec]

Velocity [m/sec]

(a) Left wheel (b) Right wheel

Figure 11: Estimated row motion at right direction in case

(4). In the right wheel, our system detects there is no row

motion by the subject.

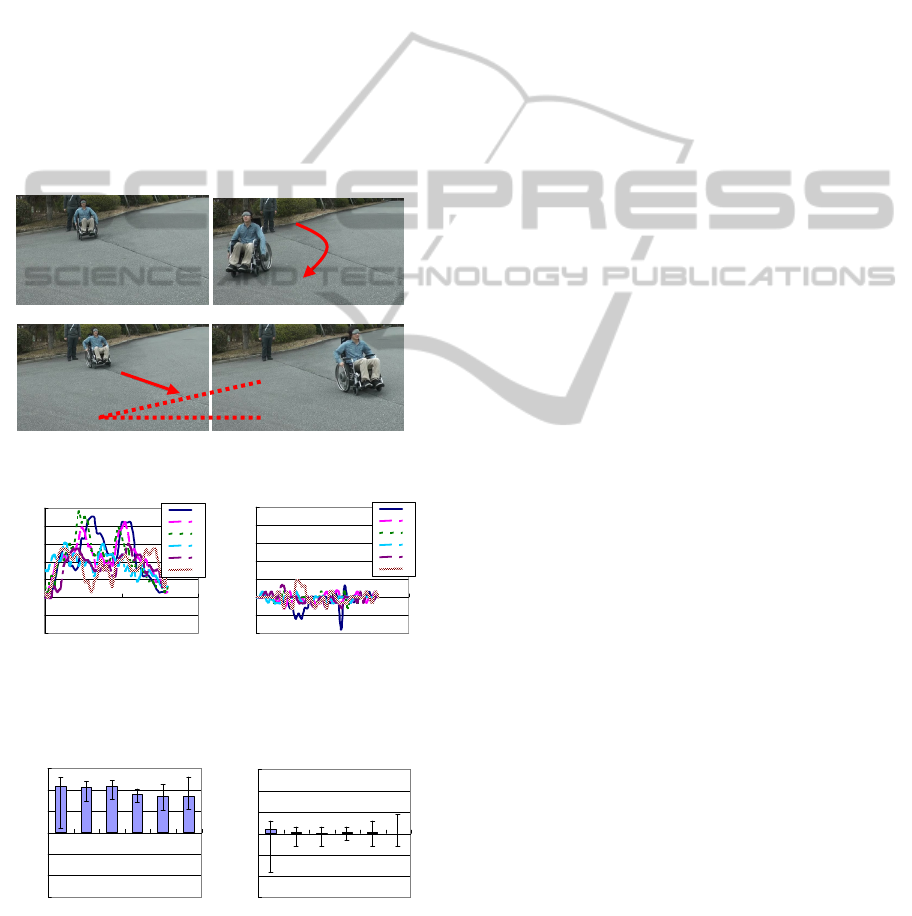

4.2.2 Running Test on the Slope

In this experiment, we test the performance of our

system in a typical high-risk situation to a

wheelchair user. The subject goes straight using a

wheelchair on a test load, which has 8deg inclination,

with our assistance scheme. Furthermore, for

verifying its effectiveness, the subjects do this

experiment without our system. In each case, six

subjects who are healthy young people test our

ADrivingAssistanceSystemforaManualWheelchairusingServoBrakes

265

prototype with an eye mask for removing the

influences by visual information.

As the result, the user can go straight with our

system as Fig.12(b). On the other hand, without our

assistance system, it is difficult to go straight by the

inclination as Fig.12(a). Fig.13 shows the difference

between the velocities of right and left wheel during

the experiment. When the difference is zero, the

wheelchair goes straight and when the difference is

the positive value, the wheelchair turns to the right

direction (the gravity direction) as Fig.12(a). From

Fig.13, the wheelchair goes straight with our

assistance. Fig.14 shows the average value of Fig.13.

In Fig.14(b), the maximum velocity difference is

almost same and we can verify that our controller

controls the wheels to realize the straight direction.

From these results, we can verify our system can

assist to fit the trajectory which its user wants.

(a) Without assistance

(b) With assistance

Figure 12: Test run on the slope (Subject A).

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

0510

Time [sec]

Velocity [m/sec]

A

B

C

D

E

F

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

0510

Time [sec]

Velocity [m/sec]

A

B

C

D

E

F

(a) Without assistance (b) With assistance

Figure 13: The velocity difference between a right and a

left wheel. Positive value means the wheelchair turns to

the right direction (The gravity direction).

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

ABCDE F

Subject

Velocivt [m/sec]

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

ABCDE F

Subject

Velocivt [m/sec]

(a) Without assistance (b) With assistance

Figure 14: The average value of the difference between

the velocities of a right and a left wheel. Positive value

means the wheelchair turns to the right direction (The

gravity direction).

5 CONCLUSIONS

In this paper, we develop a novel assistance control

for a passive-type wheelchair for healthy users who

have enough upper body strength. For realizing the

assistive wheel control, we develop the estimation

scheme for the user’s intention and our system

controls its wheels based on the estimated results.

Using our system, the user can move with the

wheelchair easily to the direction he wants.

In our future work, we will improve the user’s

motion estimation scheme. In the experiments in

section 4.2.1, the errors of the estimated trajectory

tend to be large when the subject changes the motion

rapidly. From our experiments, these motions are

characteristic and we will classify them considering

with the character of the wheelchair movement

during these motions.

ACKNOWLEDGEMENTS

This work is supported in part by Kawanishi

Memorial ShinMaywa Education Foundation.

REFERENCES

National Consumer Affairs Center of Japan, 2002.

Considering the safety of self-propelled manual

wheelchairs, In NCAC News, Vol.14, No.3, pp.4.

Japan Institute of Construction Engineering, 2008. A

Sidewalk guideline for smooth mobility, 2nd edition,

ISBN: 4802893922. (in Japanese)

Yamaha Motor Co., Ltd., 2012. JW

II, http://www.yamaha-motor.jp/wheelchair/unit/jw2/

(Available at Feb., 2013)

D. P. Miller and M. G. Slack, 1995. Design and Testing of

a Low-Cost Robotic Wheelchair Prototype, In

Autonomous Robots, Vol.2, pp.77-88.

N. I. Katevas, N. M. Sgouros, S. G. Tzafestas, G.

Papakonstantinou, P. Beattie, J. M. Bishop, P.

Tsanakas and D. Koutsouris, 1997. The Autonomous

Mobile Robot SENARIO: A Sensor-Aided Intelligent

Navigation System for Powered Wheelchairs, In IEEE

Robotics and Automation Magazine, Vol.4, No.4,

pp.60-70.

Y. Murakami, Y. Kuno, N. Shimada and Y. Shirai, 2001.

Collision avoidance by observing pedestrian’s faces

for intelligent wheelchairs, In Proc. of IEEE/RSJ Int.

Conf. on Intelligent Robots and Systems, pp.2018-

2023.

A. Goswani, M. A. Peshkin and J. Colgate, 1990. Passive

robotics: An exploration of mechanical computation,

In Proc. of IEEE Int. Conf. on Robotics and

Automation, pp.279-284.

8[de

g

]

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

266

A. J. Rentschler, R. A. Cooper, B. Blaschm and M. L.

Boninger, 2003. Intelligent walkers for the elderly:

Performance and safety testing of VA-PAMAID

robotic walker, In J. of Rehabilitation Research and

Development, Vol.40, No.3, pp.423-432.

Y. Hirata, A. Hara and K. Kosuge, 2007. Motion Control

of Passive Intelligent Walker Using Servo Brakes, In

IEEE Trans. on Robotics, Vol.23, No.5, pp.981-990.

S. Katsura and K. Ohnishi, 2004. Human Cooperative

Wheelchair for Haptic Interaction Based on Dual

Compliance Control, In IEEE Trans. on Industrial

Electronics, Vol.51, No.1, pp.221-228.

K. Sakai, T. Yasuda and K. Tanaka, 2010. Power assist

effects of a new type assist unit in a one hand drive

wheelchair with a triple ring, In Proc. of the IEEE/RSJ

Int. Conf. on Intelligent Robots and Systems, pp.6040-

6045.

Y. Takahashi, S. Ogawai and S. Machida, 2000. Step

climbing using power assist wheel chair robot with

inverse pendulum control, In Proc. IEEE Int. Conf. on

Robotics and Automation, pp.1360-1365.

T. Flash and N. Hogan, 1985. The coordination of arm

movements: an experimentally confirmed

mathematical model, In J. of Neurosicence, Vol.5,

No.7, pp.1688-1703.

H. Seki and S. Tadakura, 2004. Minimum Jerk Control of

Power Assisting Robot based on Human Arm

Behavior Characteristics, In Proc. of IEEE Int. Conf.

on Systems, Man and Cybernetics, pp.722-727.

ADrivingAssistanceSystemforaManualWheelchairusingServoBrakes

267