Modelling Complex Systems using the Pliant Cognitive Map

J´ozsef D. Dombi

1

and J´ozsef Dombi

2

1

Department of Software Engineering, University of Szeged, Arpad ter 2., Szeged, Hungary

2

Department of Computer Algorithms and Artificial Intelligence, University of Szeged, Arpad ter 2., Szeged, Hungary

Keywords:

Dynamic System, Pliant System, Cognitive Map, Fuzzy Operators.

Abstract:

Here, we present a tool for describing and simulating dynamic systems. Our starting point is the aggregation

concept, which was developed for multicriteria decision making. Using a continuous logic operator and a

proper transformation of the sigmoid function, we build positive and negative effects. From the input data we

can calculate the output effect with the help of the aggregation operator. Our approach is similar to that of the

Fuzzy Cognitive Map. We shall introduce a new technique that is more efficient than the FCM method. The

applicability of PCM is discussed and simulation results are presented.

1 INTRODUCTION

When we have to deal with a sophisticated system,

we are confronted by certain difficulties as we have

to represent it as a dynamic system. Using a dy-

namic system model can be hard computationally. In

addition, formulating a system using a mathematical

model may be difficult, or even impossible. Devel-

oping a model requires effort and specialized knowl-

edge. Usually a system involves complicated causal

chains, which might be non-linear. It should also be

mentioned that numerical data may be hard to obtain,

or it may contain certain errors, noise and incomplete

values. Our approach seeks to overcome the above-

mentioned difficulties. It is a qualitative approach

where it is sufficient to have a rough description of the

system and deep expert knowledge is not necessary.

A similar approach was proposed by Kosko (Kosko,

1986; Kosko, 1994; Kosko, 1992), and it is called

the Fuzzy Cognitive Map (FCM). FCMs are hybrid

methods that lie in some sense between fuzzy systems

and neural networks (Glykas, 2010; Salmeron et al.,

2012; Yaman and Polat, 2009; Salmeron and Lopez,

2012; Maio et al., 2011). Knowledge is represented

in a symbolic way using states, processes and events.

Every piece of information has a numerical value. In

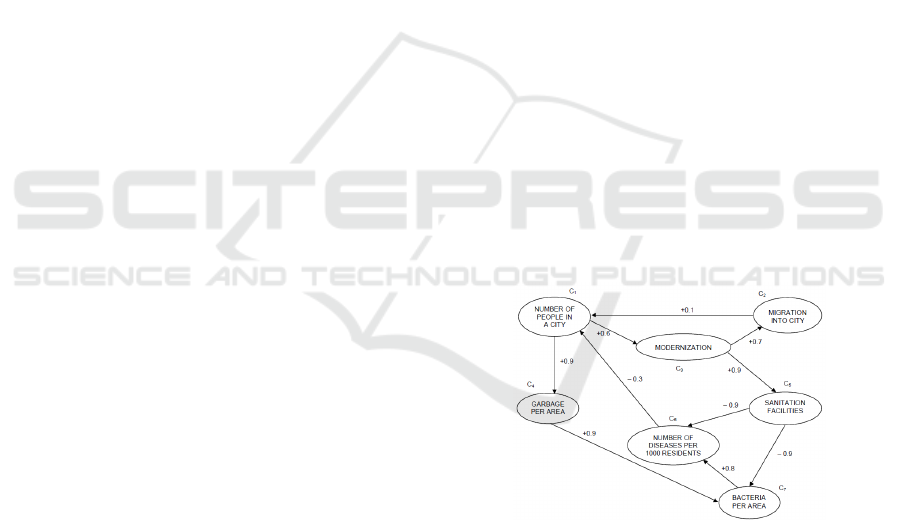

Figure 1 we can see a typical FCM model, which is a

directed graph.

The FCM approach allows us to perform qual-

itative simulations and experiment with a dynamic

model. It has better properties than expert systems

or neural networks, since it is relatively easy to use,

Figure 1: The FCM model.

it represents structured knowledge and inferences can

be computed by numeric matrix operations instead of

applying rules. In this paper, we will use a modifica-

tion of the FCM concept so that ours better matches

real-world modeling, which we call Pliant Cognitive

Maps (Jozsef Dombi, 2005) (J. Dombi, 2005). We

use cognitive maps to represent knowledge and to

model decision making, which was first introduced by

Axelrod (Axelrod, 1976). Kosko used fuzzy values

and matrix multiplication to calculate the next state

of a system. Here instead of values, we use time-

dependent functions that are similar to impulse func-

tions to represent positive and negative influences.

Another improvement is that we drop the concept of

matrix multiplication. On the one hand, matrix mul-

tiplication is not well suited in continuous logic (or

fuzzy logic), where the true value is one and the false

value is zero. On the other hand, general operators are

more efficient for calculating the next step of a simu-

lation. Logic and the cognitivemap model correspond

506

D. Dombi J. and Dombi J..

Modelling Complex Systems using the Pliant Cognitive Map.

DOI: 10.5220/0004478205060512

In Proceedings of the 15th International Conference on Enterprise Information Systems (ICEIS-2013), pages 506-512

ISBN: 978-989-8565-59-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

to each other in the PCM case. It is easier to construct

a PCM and after we have run PCM simulations and

compared them with the real world, extracting knowl-

edge is much easier. Combining cognitive maps with

logic helps us to extract knowledge more efficiently,

in contrast to when we use rule-based systems. The

standard knowledge representation in expert systems

is achieved through a decision tree. This form of

knowledge representation in most cases cannot model

the dynamic behaviour of the real world. The cog-

nitive map describes the whole system by a graph

showing the cause-effects that connect concepts. It

is a directed graph with feedback that describes the

real world concepts and the causal influences between

them. From a logic point of view, causal concepts are

unary operators of a continuous valued logic contain-

ing negationoperators in the case of inhibition effects.

The value of the node reflects the degree of system ac-

tivity at any given time. Concept values are expressed

on a normal [0,1] range. Values do not denote exact

quantities, but the degree of activation. The inverse

of the normalization might express the values com-

ing from the real world, i.e. using a sigmoid func-

tion. Unlike the Fuzzy Cognitive Map, we do not use

thresholds to force it to take values between zero and

one. The mapping is a variation of the ”fuzzification”

process in fuzzy logic, and it always hinders our de-

sire to get quantitative results. In Pliant logic we map

the real world into the logical model. These maps are

continuous, strictly monotonous increasing functions,

and so the inverse of these functions yields data about

the real world. This paper is organized as follows.

Section II describes the representation and mathemat-

ical formulation of the PCM concept compared to the

FCM concept. Section III describes the components

of the PCM, while Section IV describes how to create

the PCM model. In Section V we discuss the develop-

ment of a FCM model for the heat exchanger system

that is common in the process industry. Section VI

presents the features and potential use of the PCM for

modeling complex systems. Lastly, in Section VII.,

we summarize our findings.

2 PLIANT COGNITIVE MAPS

In the FCM, a causal relationship is expressed by ei-

ther positive or negative functions that have differ-

ent weights. As we mentioned earlier, this will be

replaced by unary operators in the PCM. First, let

{C

1

, . . . ,C

m

} be a set of concepts. Define a directed

graph over the concepts. A directed edge has a weight

w

ij

from conceptC

i

to concept C

j

. This weight mea-

sures the influence of C

i

on C

j

, where

• 0.5 is the neutral value,

• 0 is the maximum negative and

• 1 is the maximal positive influence or causality.

In the FCM, the weight value w

ij

∈ [−1, 0, 1] . In

our case,

• w

ij

> 0.5 means there is a direct (positive) causal

relationship between concepts C

i

and C

j

. That is,

the increase (decrease) in the value of C

i

leads to

an increase (decrease) in the value of C

j

.

• w

ij

< 0.5 means there is an inverse (negative)

causal relationship between concepts C

i

and C

j

.

That is, the increase (decrease) in the value of C

i

leads to a decrease (increase) in the value of C

j

.

• w

ij

= 0.5 means there is no causal relationship be-

tween C

i

and C

j

.

During the simulation, the activation level a

i

of

concept C

i

is calculated in an iterative way. In the

FCM, the calculation rule that was initially introduced

to calculate the value of each concept based only on

the influence of the interconnected concepts is

A

t

i

= f

∑

i6= j

A

t−1

j

·W

ji

!

,

where A

t

i

is the value of concept C

i

for time step t,

A

t−1

j

is the value of conceptC

j

for time step t − 1, W

ji

is the weight of the causal interconnection from the

jth concept toward the ith concept and f is a threshold

function. One of the most popular threshold functions

is the sigmoid function, where λ > 0 determines the

steepness of the continuous function f and squashes

the contents of the function into the interval [0,1]:

f(x) =

1

1+ e

−λx

. A more general FCM formula was proposed By

Stylios et al. (Stylios and Groumpos, 2004) to calcu-

late the valuesof concepts for each time step. Namely,

A

t

i

= f

k

i

1

∑

i6= j

A

t−1

j

·W

ji

+ k

i

2

A

t−1

i

!

The coefficients k

i

1

and k

i

2

must satisfy the condi-

tions 0 ≤ k

i

1

≤ 1 and 0 ≤ k

i

2

≤ 1. The coefficient k

i

1

ex-

presses the influence of the interconnected concepts in

the configuration of the new value of concept A

i

. The

coefficient k

i

2

represents the proportion of the contri-

bution of the previous value of the concept in the com-

putation of the new value. The FCM approach has the

advantage that we get a new state vector by multiply-

ing the previous state vector a by the edge matrix W,

which shows the effect of the change in the activation

ModellingComplexSystemsusingthePliantCognitiveMap

507

level of one concept on another. In the Pliant con-

cept, we aggregate the influences instead of summing

up the values. The result always lies between 0 and

1, so we do not need normalization as an additional

step. Aggregation in Pliant logic is a general oper-

ation, which contains conjunctive operators and dis-

junctive operators as well. Depending on the param-

eter called the neutral value of the aggregation opera-

tor, we can build logical operators like Dombi opera-

tors. Using PCMs (Pliant Cognitive Maps) we answer

”what if” questions based on an initial scenario. Now

let A

i

be the initial state vector. The new state is cal-

culated repeatedly with the aggregation operator until

the system converges

A

t

i

− A

t−1

i

< ε. Eventually we

get the equilibrium vector, which provides a set of an-

swers to our ”what-if” questions. The PCM approach

can be used in every area covered by the FCM ap-

proach.

3 COMPONENTS OF THE PCM

Now we will introduce the components of the Pliant

Cognitive Maps.

3.1 Aggregator Operator

Besides the logical operatorsconstructed in fuzzy the-

ory, a non-logical operator also appears. The reason

for this is the insufficiency of using either conjunc-

tive or disjunction operators for real-world situations

(Zimmermann and Zysno, 1980). The rational form

of an aggregation operator is (Dombi, 1982):

a(x

1

, . . . , x

n

) =

1

1+

1−ν

0

ν

0

·

ν

1−ν

∑

w

i

−1

·

∏

n

i=1

(

1−x

i

x

i

)

w

i

We can model conjunctive and disjunctive opera-

tors with the aggregation operator. If v is close to 0

then the operation has a disjunctive characteristic and

if v is close to 1 then the operation has a conjunctive

characteristic. From this property it can be seen that

by using aggregation we have more possibilities than

by simply using the sum function in FCM. By varying

the neutral values at the nodes, different operations

can be performed.

3.2 Creating Influences

In the Pliant Cognitive Map, we define influences.

The sigmoid function naturally maps the values to the

(0,1) interval. Positive (negative) influences can be

built with the help of two sigmoid functions and the

conjunctive operator. Hence we get the generalized

positive impulse function

c(t, u, v, a, b) =

1

1+ u∗ e

−λ

1

(t−a)

+ v∗ e

−λ

2

(t−b)

,

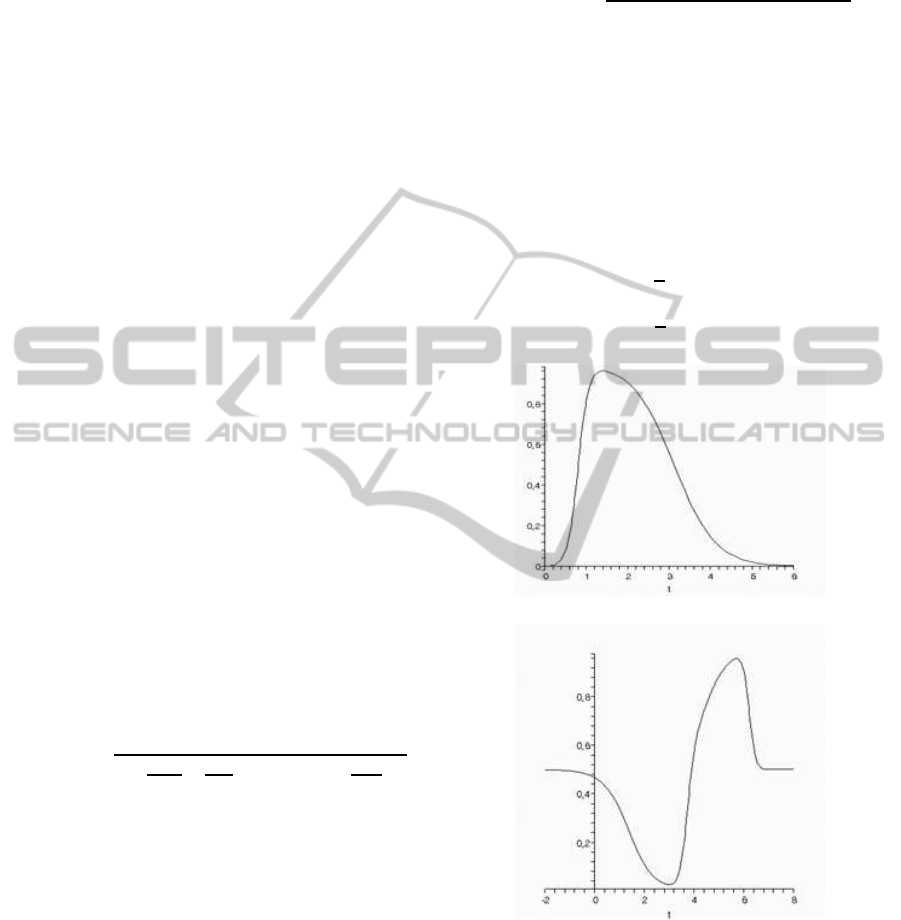

where u and v are weights. In Figure 2 we can see

a basic influence, as mentioned in (Jozsef Dombi,

2005). If the influence is neutral, we can represent

it by a 1/2 value. If there are no influences, then we

continuously order 1/2 values in the system. If we

want to model positive influences, we order a value

which is larger than 1/2, and whose maximal value is

1. The negative influence is the negation of the posi-

tive influence. To create these influences, we use the

following transformations:

P(t, u, v, a, b) =

1

2

(1+ c(t, u, v, a, b))

N(t, u, v, a, b) =

1

2

(1− c(t, u, v, a, b))

Figure 2: An average influence.

Figure 3: The aggregation of two influences.

In Figure 3, we have plotted the aggregation of a

positive and a negative effect.

4 CONSTRUCTION OF THE PCM

To simulate the system, the only thing we have to do

is to aggregate the influences. The aggregation oper-

ator is a guarantee that we will use influences in the

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

508

right way. The following steps should be carried out

to simulate the system:

1. Collect the concepts.

2. Define the expectation values of the nodes (i.e.

threshold values of the aggregations).

3. Build a cognitive map (i.e. draw a directed graph

for the concepts).

4. Define the influences (i.e. whether they are posi-

tive or negative)

In the iterative method we

1. Use the proper function or supply a data list for

the input nodes.

2. Calculate the positive and negative influences us-

ing step 4.

3. Aggregate the positive and negative influences,

where the aggregation parameter ν

0

value is the

previous value of the concept C

j

.

5 HEAT EXCHANGER

APPLICATIONS

A heat exchanger is a standard device in the chemi-

cal and process industries (M. Fischer and Isermann,

2000). In this task, the temperature control is still a

major challenge as the heat exchanger is used over a

wide range of operating conditions. The behaviour of

the system, which is non-linear, strongly depends on

the flow rates and on the temperature of the medium.

A cross-flow water/air heat exchanger is envisaged,

which is subject to immeasurable or non-modeleddis-

turbances that require the use of knowledge-based

techniques. In this problem, we wish to develop a be-

havioural model for the heat exchanger system, that

will control the water outlet temperature by manipu-

lating the flow rate of the air.

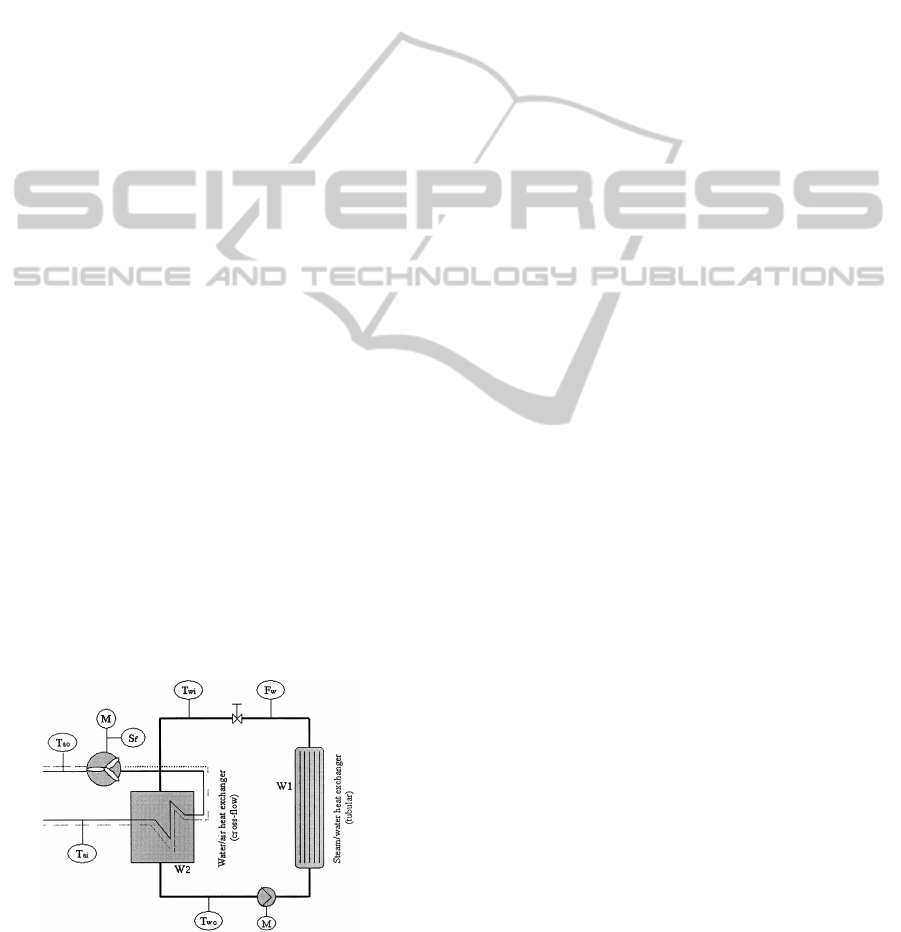

Figure 4: Typical heat exchanger system.

Here, in Figure 4 we can see a typical set-up for

the system. It is well known that the FCM can be

used to model and control the heat exchanger process

(Stylios and Groumpos, 2004). In most process indus-

tries the thermal plant comprises two heat exchangers,

but in our example (see Figure 2) we will just con-

sider the secondary circuit. Our system contains two

circuits W

1

and W

2

. W

1

is a circuit, which is a tubular

steam/water heat exchanger, and W

2

is the cross-flow

water/air exchanger. The water in this circuit is heated

by means of W

1

. On the left hand side, the water is

cooled in the cross-flow water/air heat exchanger W

2

.

A fan sucks in cold air from the environment (temper-

ature Tai). After passing through the heat exchanger

and the fan, the air is blown back out into the envi-

ronment. The water temperature Two is controlled by

manipulating the fan speed S f. The control variable

Two depends on the manipulated variable Sf and the

measurable disturbances: the inlet water temperature

Twi, air temperature Tai and water flow rate Fw. In

most systems, the water flow rate is usually regulated

by a PI-controlled pneumatic valve which strongly in-

fluences the behaviour of the heat exchanger W2 and

it is a major challenge to design a temperature con-

troller for Two when the flow rates vary over a wide

range (Bittanti and Piroddi, 1997), (Ernst and Hecker,

1996). The operators of the heat exchanger gather

experience that can be used to build a model. To

construct an FCM system, we have to determine the

concepts. Here, concepts stand for the input and out-

put variables of the process. Earlier the thermal plant

was described, and the concepts of the FCM were de-

rived from a Stylios analysis (Stylios and Groumpos,

2004). Experts define five concepts for this situation:

• Concept1: The fan speed Sf, which is the manip-

ulated variable.

• Concept2: The water flow rate Fw.

• Concept3: The water inlet temperature Twi.

• Concept4: The air inlet temperature Tai. The en-

vironmental temperature cannot be manipulated

as it depends on the weather and season.

• Concept5: The water outlet temperature Two,

which is the output of the model.

In the next step, the causal interconnectionsfor the

concepts have to be determined. Experts can describe

the relation between any two concepts based on the

system. The connections for the concepts are

• Linkage1: It connects concept1 (fan speed S f)

with concept5 (water outlet temperature Two).

When the value of Sf increases, the value of Two

decreases.

• Linkage2: It connects concept2 (flow rate Fw)

with concept5 (water outlet temperature Two).

ModellingComplexSystemsusingthePliantCognitiveMap

509

When the value of Fw increases, the value of Two

increases.

• Linkage3: It connects concept2 (flow rate Fw)

with concept1 (fan speed Sf ). When the value

of Fw increases, the value of Sf increases.

• Linkage4: It connects concept3 (water inlet tem-

perature Twi) with concept5 (water outlet temper-

ature Two). When the value of Twi increases, the

value of Two increases.

• Linkage5: It connects concept3 (water inlet tem-

perature Twi) with concept1 (fan speed S f ).

When the value of Twi increases, the value of S f

increases.

• Linkage6: It connects concept3 (water inlet tem-

perature Twi) with concept2 (flow rate Fw).

When the value of Twi increases, the value of Fw

decreases.

• Linkage7: It connects concept4 (air inlet tempera-

ture Tai) with concept5 (water outlet temperature

Two). When the value of Tai increases, the value

of Two increases.

• Linkage8: It connects concept4 (air inlet tempera-

ture Tai) with concept1 (fan speed Sf ). When the

value of Tai increases, the value of S f decreases.

• Linkage9: It connects concept5 (water outlet

temperature Two) with concept2 (flow rate Fw).

When the value of Two increases, the value of Fw

decreases.

• Linkage10: It connects concept5 (water outlet

temperature Two) with concept1 (fan speed S f ).

When the value of Two increases, the value of Sf

increases.

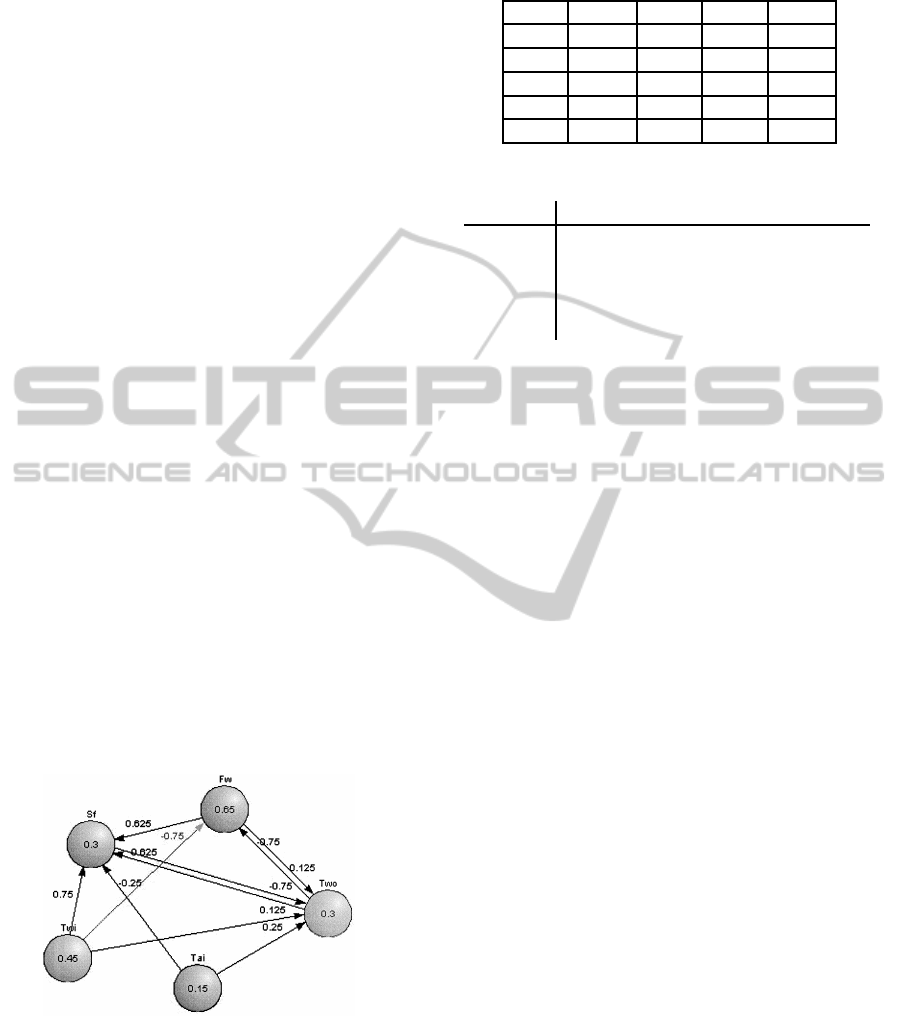

Figure 5: The FCM model for the heat exchanger system.

Figure 5 shows our system which describes, mod-

els and controls the heat exchanger system. The FCM

model for the heat exchanger is in accordance with the

models and experiments described in (M. Fischer and

Isermann, 2000) (Ernst and Hecker, 1996). It is also

possible to create an influence matrix for the system

like that in Table 1.

Table 1: The weighted matrix of the model.

Sf Fw Twi Tai Two

0 0.625 0.75 -0.25 0.625

0 0 -0.75 0 -0.75

0 0 0 0 0

0 0 0 0 0

-0.75 0.125 0.25 -0.75 0

Table 2: Simulation results for the FCM.

Iteration Sf Fw Two Improvement:

1 0,77 0,52 0,56 0,8577

2

0,85 0,44 0,54 0,1906

3 0,85 0,43 0,51 0,0419

4

0,85 0,43 0,5 0,0107

5 0,85 0,43 0,5 0,0036

To simulate a real environment in the FCM, the

values of concepts correspond to real measurements

that have been transformed to the interval [0,1]. A

corresponding mechanism is needed that will trans-

form the measures of the system to their represen-

tative values of concepts in the FCM model and

vice versa. The initial measurements of the heat

exchanger system were transformed to concept val-

ues and the initial vector of the FCM is A

0

=

[0.3 0.65 0.45 0.15 0.3]. In Figure 5, it also shows

the initial values of each concept and the interconnec-

tions with their weights. With these initial values of

concepts, the FCM starts to simulate the behaviour of

the process. For the FCM area, a running step is de-

fined as the time step during which the values of the

concepts are calculated. The value of each concept is

defined by taking all the causal linkage weights point-

ing to this concept and multiplying each weight by

the value of the concept that causes the linkage, and

adding the last value of each concept. Then the sig-

moid function with λ = 1 is applied and the result falls

into the range [0,1]. The results of the simulation are

listed below.

This table does not contain input node values

where the value is the same all time. Evaluating the

results, we see that the value of fan speed Sf has in-

creased, the value of flow rate Fw has decreased, and

after the third step, the water outlet temperature Two

falls below the value of 0.50. We also see that the

value between any two simulation steps decreases, but

this decrease is not uniform, which is not as good as

we first thought. Because concepts control physical

devices, we should vary the values as smoothly as

possible.

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

510

6 EVALUATE WITH THE PCM

Our method works with real data measurements,

which means that we do not need to transform real

values between [0,1] in order to run the simulation. In

our model we use the same concepts and connections,

and the initial values of the concepts are the same as

before. So first of all to evaluate our method we need

to identify the range values of the concepts. Because

previous articles do not mention these values, we will

choose the following values:

Table 3: The range values of the concepts.

Concept Minimum Maximum Default

Sf 100 500 250

Fw 2 20 6

Twi 20 50 30

Tai 18 35 24

Two 20 40 30

The default value is used to specify the real values

of the first step. Using the above-mentioned ranges

we define a sigmoid function that will be used for the

calculations. For example, the initial value of the Sf

concept is 0.3, and we apply the following sigmoid

function:

S

f

(x) =

1

1+ e

−

4

500

(x−250)

In this case, the real value of Sf should be 144.08.

Based on these calculations, we can compute the ini-

tial values of the concepts:

Table 4: The initial values of the concepts.

Sf Fw Twi Tai Two

144.08 3.7 27.5 8.8 21.52

This method also shows that with each simula-

tion step it is easy to recover the real value. In the

classical FCM method, the influence does not change

during the simulation. In order to compare it with

our method, we will also define a constant influence.

Hence in a simulation step we calculate the new con-

cept value in the following way. For each node in

the set we create a set that contains all the incoming

nodes. Also, we will use the following expression to

calculate the strength of the incoming node:

1− x

i

x

i

w

ij

,

where x

i

is the actual value of the node and w

ij

is the

value of the influence between concept C

i

and C

j

. Af-

ter, we calculate this method for each node in the set,

then we use the aggregation operator to calculate the

Table 5: Simulation results for the PCM.

Iteration

Sf Fw Two Improvement:

1 0.53 0.68 0.75 0.7262

2 0.81 0.33 0.59 0.7870

3

0.52 0.46 0.31 0.7024

4 0.42 0.67 0.57 0.5787

5

0.71 0.47 0.67 0.5881

6 0.66 0.40 0.42 0.3810

7

0.46 0.59 0.46 0.4327

8 0.60 0.56 0.63 0.3492

9 0.69 0.43 0.53 0.3310

10

0.54 0.51 0.44 0.3176

11 0.54 0.58 0.56 0.1951

12

0.65 0.48 0.57 0.2203

13 0.60 0.47 0.47 0.1590

14

0.54 0.55 0.51 0.1829

15 0.61 0.52 0.57 0.1602

16

0.63 0.47 0.51 0.1224

17 0.56 0.52 0.49 0.1266

18

0.58 0.53 0.55 0.0833

19 0.62 0.49 0.54 0.0908

20

0.59 0.50 0.50 0.0734

21 0.57 0.53 0.52 0.0712

22

0.60 0.51 0.54 0.0675

23 0.60 0.50 0.52 0.0405

24

0.58 0.52 0.51 0.0462

25 0.59 0.52 0.54 0.0337

26

0.60 0.50 0.53 0.0380

27 0.59 0.51 0.51 0.0336

28

0.59 0.52 0.53 0.0256

29 0.60 0.51 0.53 0.0264

30 0.60 0.51 0.52 0.0174

31

0.59 0.51 0.52 0.0191

32 0.59 0.51 0.53 0.0155

33

0.60 0.51 0.52 0.0148

34 0.59 0.51 0.52 0.0141

35

0.59 0.51 0.53 0.0084

new value of the concept. For example, the new value

of Fw is obtained by computing

1

1+

1−0.45

0.45

−0.75

1−0.3

0.3

−0.75

Now we can run the simulation until it exceeds a

limit. The following table shows the results of our

simulation.

Evaluating the results we notice that they are dif-

ferent from those got by using the FCM method. In

Figure 6, we see how the values vary.

The value of the fan speed Sf has decreased, the

value of flow rate Fw has decreased and the water

outlet temperature Two is below the value of 0.50.

We also see that the differences between two simu-

lation steps decreases (see Figure 7), but this decrease

ModellingComplexSystemsusingthePliantCognitiveMap

511

Figure 6: Results for the PCM model.

Figure 7: Sum of value change for each step.

is smooth, and this is why it requires more simulation

steps.

7 CONCLUSIONS

In this paper, we made use of numerical methods to

model complex systems based on positive and nega-

tive influences. This concept is similar to the FCM

concept, but the functions and the aggregation proce-

dures are quite different. It is based on a continuous-

valued logic and all the parameters have a semantic

meaning. Here, we showed that we can apply this

method in a real environment. The values of the sim-

ulation steps smoothly decrease, but it requires more

simulation steps. In this example, we used the same

influence for each concept all the time, but it is also

possible to vary the strength of the influence, and then

we can model a real-world situation better.

REFERENCES

Axelrod, R. (1976). Structured of Decision: the cognitive

maps of political elites. Princeton University press,

New Jersey.

Bittanti, S. and Piroddi, L. (1997). Nonlinear identification

and control of a heat exchanger: a neural network ap-

proach. J. Franklin Inst., page 135153.

Dombi, J. (1982). A general class of fuzzy operators, the De

Morgan class of fuzzy operators and fuzziness mea-

sures induced by fuzzy operators. Fuzzy Sets and Sys-

tems, 8:149–163.

Ernst, E.-J. and Hecker, O. (1996). Predictive control of a

heat exchanger. Proc. Seminar Theory Applications

Model Based Predictive Control, pages 1–18.

Glykas, M. (2010). Fuzzy Cognitive Maps Advances in The-

ory, Methodologies, Tools and Applications. Springer-

Verlang.

J. Dombi, J. D. D. (2005). Pliant cognitive map using con-

junctive operator. Proceedings of IEEE International

Workshop on Soft Computing Applications, page 11.

Jozsef Dombi, J. D. D. (2005). Cognitive maps based on

pliant logic. 16TH European Simulation Symposium,

page 63.

Kosko, B. (1986). Fuzzy entropy and conditioning. Infor-

mation Sciences, 40:165–174.

Kosko, B. (1992). Neural Networks and Fuzzy Systems.

Prentice Hall, Englewood Cliffs.

Kosko, B. (1994). Fuzzy Thinking. Flamingo. hardcopy.

M. Fischer, O. N. and Isermann, R. (2000). Knowledge-

based adaptation of neurofuzzy models in predictive

control of a heat exchanger. Soft Computing and In-

telligent Systems, page 469489.

Maio, C. D., Fenza, G., Gaeta, M., Loia, V., and Orciuoli, F.

(2011). A knowledge-based framework foremergency

DSS. Knowl.-Based Syst, 24(8):1372–1379.

Salmeron, J. L. and Lopez, C. (2012). Forecasting risk im-

pact on ERP maintenance with augmented fuzzy cog-

nitive maps. IEEE Trans. Software Eng, 38(2):439–

452.

Salmeron, J. L., Vidal, R., and Mena, A. (2012). Rank-

ing fuzzy cognitive map based scenarios with TOP-

SIS. Expert Syst. Appl, 39(3):2443–2450.

Stylios, C. D. and Groumpos, P. P. (2004). Modeling com-

plex systems using fuzzy cognitive maps. IEEE Trans-

actions on Systems, Man, and Cybernetics, Part A,

34:155–162.

Yaman, D. and Polat, S. (2009). A fuzzy cognitive map

approach for effect-based operations: An illustrative

case. Inf. Sci, 179(4):382–403.

Zimmermann, H. J. and Zysno, P. (1980). Latent connec-

tives in human decision making. Fuzzy Sets and Sys-

tems, 4(1):37–51.

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

512