A Distributed Simulation Model of the Maritime Logistics in an Iron Ore

Supply Chain Management

Afonso C. Medina

1

, Luis G. Nardin

2

, Newton N. Pereira

1

, Rui C. Botter

1

and Jaime S. Sichman

2∗

1

Centro de Inovac¸˜ao em Log´ıstica e Infraestrutura Portu´aria, Universidade de S˜ao Paulo, S˜ao Paulo, Brazil

2

Laborat´orio de T´ecnicas Inteligentes, Universidade de S˜ao Paulo, S˜ao Paulo, Brazil

Keywords:

Distributed Simulation, Maritime Logistics, Iron Ore Industry, Supply Chain Management.

Abstract:

Supply chain management (SCM) has increased its importance in the last decades, accordingly demanding new

approaches to support its decision making processes. Simulation has been advised as an adequate approach

for fulfilling such demand. However, develop monolithic simulation models representing the whole supply

chain can be costly and time consuming. In the iron ore supply chain in which the seaports have the same

features, the use of generic models and distributed simulation may be a real alternative in order to reduce the

development time and costs. This paper presents a distributed simulation model of the maritime logistics in

an iron ore supply chain applied to support fleet management decisions. Such model was used to perform an

experiment in order to determine the maximum possible cargo volume supported by a ship fleet.

1 INTRODUCTION

Supply chain is a phenomenon that can be defined as a

set of three or more entities directly involved with the

flow of products, services, finances, and information

from a producer to a customer (Mentzer et al., 2001).

Such phenomenon became more critical and impact-

ing because of the globalization process that has been

happening in the last decades. Consequently, global

active companies realized that the efficiency of their

own businesses is highly dependent on the collabora-

tion and coordination with their suppliers as well as

with their customers (Hieber, 2002). Therefore, they

identified the need of implementing a more efficient

and effective supply chain management (SCM).

Among different industries, the mining industry is

one that depends mostly on SCM. Generally, because

its raw materials are placed in remote locations and

their customers are geographically distant from the

production centers. For instance, the biggest iron ore

mines are located in African countries, Australia and

Brazil. However,China is the main customer consum-

ing more than 50% of the world’s iron ore production

(Hoyt et al., 2007). In addition, the iron ore supply

chain has some characteristics similar to other com-

modities, such as a few numbers of products, a high

∗

Jaime S. Sichman is partially supported by CNPq and

FAPESP, Brazil.

cargo volume, high lead times and low price, which

makes the pipeline management a key factor of suc-

cess (Beresford et al., 2011).

Hence, the maritime transport is a key component

in the whole mining industry supply chain. Thus,

mining companies face several complex decisions in

order to improve their maritime logistics efficiency.

Among the available techniques supporting such de-

cision making process, simulation is one of the most

adequate as it is capable of providing what-if analy-

sis and answer quantitatively questions that typically

arise in these situations (Terzi and Cavalieri, 2004).

Moreover, it handles better complex scenarios in con-

trast to optimization tools as mathematical program-

ming (Ingalls, 1998).

Accordingly, many mining companies have been

developing simulation models focusing on specific

maritime logistics nodes in order to tackle particular

problems, such as terminal capacity (Bugaric et al.,

2012), flowability of products from/to the terminal

(Everett, 1995), and closed-loop maritime transporta-

tion (Silva et al., 2011). Nonetheless, a model with

extended boundaries shall be developed incorporating

material and information flow among all the nodes

involved in the maritime logistics in order to allow

drawing more accurate conclusions (Jain et al., 1999).

Basically, supply chain simulation uses two dif-

ferent approaches: monolithic or distributed (Taylor

et al., 2002). In the former, the whole chain is rep-

453

Medina A., Nardin L., Pereira N., Botter R. and Sichman J..

A Distributed Simulation Model of the Maritime Logistics in an Iron Ore Supply Chain Management.

DOI: 10.5220/0004488504530460

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 453-460

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

resented in a single model. In the latter, the supply

chain is represented by several models, each one cor-

responding to a different part of the chain. There-

fore, because the companies have already invested on

the development and validation of simulation mod-

els to tackle specific problems, it is more reasonable

to reuse them through the distributed simulation ap-

proach (Fujimoto, 1999).

This paper presents a distributed simulation ap-

plied to the maritime logistics of an iron ore supply

chain in order to support fleet management decisions.

The underlying distributed model is composed of sev-

eral nodes representing the seaports and the naviga-

tion routes. Each seaport is represented by a specific

model, which is derived from a generic port model

able to represent any iron ore seaport from the prod-

uct’s reception via railways to their load and dispatch

through the vessels. All these models interact among

themselves through a navigation model supported by

a framework based on the High Level Architecture

(HLA) (Dahmann et al., 1998; IEEE, 2000). The

model was applied to simulate real-world scenario in

order to evaluate the fleet handling capacity.

This paper is organized in six more sections. Sec-

tion 2 contextualize and motivates this work, followed

by a brief review of supply chain management sup-

ported by simulation in Section 3. Next, the generic

port and the navigation models are detailed in Section

4, which integration are described in conjunction with

the specification of the implemented software archi-

tecture in Section 5. Section 6 describes the validation

models’ process and an experiment performed using

the validated model. Finally, Section 7 concludes the

paper and provides some possible future works.

2 MOTIVATION SCENARIO

The global iron ore industry is dominated by few

players and the Brazilian mining company Vale

1

is

the world’s largest producer and second largest ex-

porter (Choenni et al., 2011). In order to support

its operations, Vale owns several seaports in Brazil,

such as Port of Tubar˜ao (TU) - Esp´ırito Santo, Port of

Ponta da Madeira (TMPM) - Maranh˜ao, Port of Sep-

tiba (CPBS) and Port of Itaja´ı (TIG) - Rio de Janeiro.

Since 2007, Vale has been developing discrete

event simulation models in partnership with research

laboratories in order to have a decision support tool

for terminals flow capacity management. Particularly,

they have developed a Generic Port Model (described

in more detail in Section 4.1) able to represent any

1

http://www.vale.com.

iron ore seaport, which was validated with real oper-

ations data and is used nowadays to support the com-

pany’s Director of Ports decisions.

Back to 2008, the maritime transport costs was

constantly varying

2

and Vale was paying a high price

to transport the iron ore to its customers. Thus, in an

attempt to take an active role in the maritime logis-

tics and reduce its vulnerability, the company decided

to act as shipowner transporting part of its own pro-

duction using its own ship fleet. As a consequence, it

contracted the construction of 35 Valemax class ships,

each able to carry up to 400,000 tons of cargo (Pereira

and Brinati, 2012). Along with it, the company envi-

sioned the necessity to have a decision support system

to assist its integrated actions concerning the new ship

fleet and the remaining supply chain. In this scenario,

the ship fleet functions as links interconnecting the

seaports. Nevertheless, such links need to be flexible

in the sense that they may change in order to repre-

sent more realistically the maritime transport system

dynamics.

Since the simulation approach fulfills these mar-

itime transport dynamism and Vale had already devel-

oped a Generic Port Model that represents any of its

seaports, the more adequate solution would be inte-

grate all its models through the distributed simulation

approachinstead of developing a new monolithic sim-

ulation model representing the whole supply chain.

3 LITERATURE REVIEW

SCM has been studied extensively in the last decades

because of its increasing impact on enterprise oper-

ations. Generally, the approaches used to address

their complex formulations are physical experimen-

tations, mathematical programming and simulation

(Thierry et al., 2010). Usually, physical experimenta-

tion is scope limited due to technical issues and bud-

get availability. The mathematical programming ap-

proach uses methods, such as linear, mixed integer

linear and dynamic programming with an objective

function set to minimize cost or maximize profit. De-

spite its wide use in the supply chain’s optimization

(see (Sarmiento and Nagi, 1999) for a review of its

application on different production-distribution prob-

lems), it becomes impractical in complex scenarios

involving stochasticity aspects and dynamically inter-

connected nodes such as existent in supply chain. On

the other hand, the simulation approach uses different

methodologies to build models capable to represent

the complex supply chain’s nodes interconnections,

2

Source: Maritime Transport Cost Database (http://

stats.oecd.org/).

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

454

which are then used for replicating and analyzing the

system’s behavior.

Among these approaches, simulation can better

represent the SCM inherent complexities. For this

reason, it has been applied in several supply chain

studies. Ingalls (Ingalls, 1998) discusses advantages

and disadvantages of using simulation in SCM and

stresses its importance to deal with the random sig-

nals caused by demand forecast.

Specifically in the maritime logistics, simulation

has been used for a long time in the study of port

systems (Wadhwa, 1992; Hassan, 1993; Botter et al.,

1998; Bugaric et al., 2012). Nonetheless, these stud-

ies are focused on dimensioning and planning port’s

capacity, while maritime logistics is a much more

complex system that involves other components other

than ports. Terzi and Cavalieri (Terzi and Cavalieri,

2004) present a survey of 80 works related to sup-

ply chain simulation and they classify them in two

major paradigms: local and parallel or distributed

simulation. The local simulation paradigm consists

in the use of a single model to represent all the sup-

ply chain and it usually runs in a single machine. On

the other hand, the parallel or distributed paradigm

considers the existence of several models represent-

ing a more complex system and it runs in separate

machines. They advocate that SCM would have sev-

eral advantages by applying the distributed simulation

paradigm, such as no need for new developmentas the

models of specific nodes are already available and the

possibility of having these models running geograph-

ically distributed. Moreover, in the case of complex

systems made up of autonomous entities, multiagent-

based simulation techniques may be used (Marietto

et al., 2003).

Although the recognition of its advantages, most

of the literature on parallel or distributed simula-

tion focus on frameworks to parallelize or distribute

the simulation, yet just a few present the application

of the paradigm in real scenarios (Terzi and Cava-

lieri, 2004). Among these few, Duinkerken et al.

(Duinkerken et al., 2002) is the only one that reports

the application of distributed simulation in the study

of the maritime logistic. However, the main focus of

their work is still to demonstrate the benefits of using

a distributed structure in the transparency and main-

tainability of the simulation model. Hence, to the best

of our knowledge, this work is the first one apply-

ing the distributed simulation approach in the analy-

ses of a real scenarios supporting fleet management

decisions in the maritime logistics domain.

4 SIMULATION MODELS

This section presents the simulation models used in

the development of the maritime logistics distributed

simulation model. In Section 4.1, it is presented the

Generic Port Model capable to represent any iron ore

seaport. Next, the Navigation Model responsible for

simulating the behavior of vessels navigation is pre-

sented in Section 4.2.

4.1 Generic Port Model

Generic models are a well know approach to develop

simulation models (Robinson et al., 2004; Monks

et al., 2009; Mackulak et al., 1998; Lung et al., 1994).

They are based on the concept that some class of mod-

els may represent a wide range of similar scenarios,

hence they could be used on a frequent and recurrent

basis. In contrast, a particular model is developed to

answer questions for a very specific system and they

cannot be easily reused, not even in similar scenarios.

Usually, a generic model is more expensiveto develop

in the short-term than a particular model, but as the

former has more chance to be reused in new projects,

it generally provides a better return on investment in

the long-term (Doss and

¨

Ulgen, 2004).

Envisioning this long-term benefit, the Generic

Port Model (GPM) was developed based on the

generic models approach as the result of a three

years project. Such development involved interviews,

workshops, and meetings with professionals of the

maritime sector, more specifically, specialists of sea-

port sector. Its main purpose is to be a comprehensive

simulation model to represent any iron ore seaports

operational behavior. As a consequence, it is struc-

tured in a way to support decisions regarding termi-

nals capacity. Such aim is achieved through the pos-

sibility to represent different iron ore seaports con-

figurations and scenarios, including seaport’s equip-

ments and stockyards configurations, company’s de-

mands and products, as well as vessels and ground

vehicles arrivals.

The GPM is structured in 4 subsystems:

• Ships Arrival – Controls all the ships arrival pro-

cesses, such as cargo required and estimated time

to arrival. Moreover, it is also responsible for con-

trolling all processes from the actual vessel arrival

in the bay up to the begin of the loading operation,

such as tide control, berth allocation, navigation

through the channel to the harbor, berthing, and

vessel pre-loading and loading operations.

• Cargo Transfer – Performs the vessels loading

operation including the selection and transporta-

tion of products from stockyard to the vessels in

ADistributedSimulationModeloftheMaritimeLogisticsinanIronOreSupplyChainManagement

455

a guaranteed maximum loading rate (or minimum

operation time).

• Storage – Represents all resources used to store

the products at stockyard and, if present, the per-

formance of some semi-industrial operations like

screening, pellet production or products blending.

• Dispatch and Ground Reception – Responsible

for cargo reception through trains guaranteeing

mass balance between arrived and dispatched

cargo. It generates the trains arrival sequence

and control the processes from full train arrival

to empty train departure. Additionally, it controls

cargo transfer from train to stockyard considering

car dumpers and stackers. It attempts to ensure the

best disposition of the products at the stockyard

in order to guarantee the maximum ships loading

rate.

In order to guarantee the model reuse, the subsys-

tems were modeled in a way that they may be con-

figured for use in a wide range of situations. Table 1

lists a partial set of the input and the output param-

eters divided by subsystems in order to demonstrate

the flexibility of the model.

Strategically, its development started with a con-

ceptual model of a simpler terminal. Along the

project, more complex features were incorporated

into the model considering an iterative process in

which every new feature incorporated was validated

using real data. This iterative process allowed the in-

corporation of a great degree of complexity into the

model requiring a reduced validation time at each im-

provement.

Nowadays, the model is used as a decision support

tool in a recurrent basis for answering questions con-

cerning capacity, new capital investments and design

of new port systems.

4.2 Navigation Model

The Navigation Model (NM) was developed to rep-

resent the vessels movement behavior and available

routes. This model performs an interconnection

among all the instantiated GPMs in the system. The

vessels are represented as entities that flow from one

GPM to another through specific routes configured in

the NM. Since the iron ore production usually flows

from an export to an import seaport and the vessels re-

turn empty from the import seaport to the export sea-

port, the NM considers the existence of three classes

of routes: (i) a route that interconnects an export to an

import seaport, (ii) a ballast route that interconnects

an import seaport to a check point and (iii) a route

that interconnects a check point to an export seaport.

Figure 1: Process at iron ore pipeline.

In addition to the vessels and routes, the NM has an

additional entity named check point, which represents

the point that a ballast vessel (ship without cargo) re-

ceives the definition of its next export and import sea-

port destinations as well as the products to transport.

Figure 1 presents the steps followed by a vessel

beginning in the moment it leaves an import seaport

up to the moment it leaves an export seaport towards

its assigned import seaport. The sequence is:

1. At the import seaport, the vessel is unloaded and

after its unberthing, it starts its navigation in bal-

last to the check point.

2. At the check point, the vessel is allocated to its

next export and import seaports and the product(s)

to transport are assigned (Algorithm 1 describes

the decision algorithm). At this moment, the mine

is informed about the vessel’s Early Time Arrival

(ETA), cargo and assigned product(s).

Algorithm 1: Allocate vessel to route.

1: Vessel v arrives at Check Point

2: MinGAP ← MINIMUM INTEGER

3: for all Route (r) that v can operate do

4: i ← r export seaport

5: j ← r import seaport

6: for all Product p possible on r do

7: Estimate the product gap using Equation 1

gap(p, r) = (D(t) ∗ (1+ ∆) − A(t))/

(D(t) ∗ (1+ ∆)) (1)

where

t = simulation time

D(t) = demand of p at j until t

A(t) = attempt demand of p at j until t

∆ = accepted gap

8: if gap(p, r) > MinGAP then

9: Estimate gain using

10: Max gain(p,r) = vessel cargo capacity

11: VRP ← v to r with product p

12: MinGAP = gap(p, r)

13: end if

14: end for

15: end for

16: return VRP

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

456

Table 1: Input and output parameters of the GPM’s main subsystems.

Subsystem Input parameters Output parameters

Ship arrivals

- Demand by destiny and product - Ships queue, turnaround,

- Ships class distribution berthing/unberthing times

- Time to stock the cargo at the - Waiting times

yard before the ship arrival - Export demand/ships attended

- Berthing/unberthing times - Dispatch/demurrage calculation

- Channel (capacity, times, tides)

Cargo transfer

- Ship unloaders (capacity and - Occupancy of resources (reclaimers,

maximum rates by product) ship loaders, berths, lines)

- Berths - Cargo transfer by product, line and berth

- Layout disposition (berth x yard

and resources x berths)

Storage

- Number of yards, piles, - Occupancy of resources (yards, stacker,

capacity by product reclaimers, lines, pellet unit)

- Layout disposition, access to

berths and car dumpers

- Screening (number, production

rates, yards)

- Pellet production (number,

production rates, yards)

- Number of car dumpers - Occupancy of resources (car dumpers,

Dispatch and ground - Rates by product stacker)

reception - Setup times - Total cargo transferred to yards

- Railway yard capacity - Trains queue time

- Trains capacity by product

3. In the mean time between the vessel arrival to

the export seaport, the mine dispatches the trains

to attend the ETA considering also that the total

cargo should be available at the seaport in advance

to the beginning of vessel’s loading operation.

4. Once at the export seaport, the vessel is loaded

with the assigned products and navigates to its de-

signed import seaport.

Basically, Algorithm 1 checks the fulfilled de-

mands on each import seaport up to the current simu-

lation time. This is performed by calculating a param-

eter named gap. For any product p and any route r,

gap(p,r) represents the difference between the prod-

uct demanded by the import seaport in the period and

the total product p already delivered to that seaport.

Thus, among all possible routes, the check point al-

locates the ballast ship to the route in which the gap

falls mostly behind. In order to choose the best op-

tion, the check point also considers the constraints

about demand and vessels capacity, export seaport

product availability and allowance of vessels in the

seaports. However, if no reduction is identified on any

products gap, then the vessel waits at the check point

and verifies periodically until a gap is identified.

5 DISTRIBUTED SIMULATION

The distributed simulation model performs the inter-

connection of several General Port Models and one

Navigation Model. It is structured according to the

High Level Architecture (HLA) (IEEE, 2000), which

is a general purpose architecture to support distributed

simulation allowing the communication among sim-

ulation models running on distributed heterogeneous

computational platforms. A HLA distributed simu-

lation may have one or several Federations. Each

Federation is composed of one or more Federates,

each representing a simulation model. The Federates

are interconnected through the Runtime Infrastructure

(RTI), which provides common communication and

synchronization services to them. In order to archi-

tect our distributed simulation adherent to the HLA,

two kinds of Federates are defined: Arena Federate

and Distributed Simulation Coordinator.

5.1 Arena Federate

The Arena Federate is the architectural module that

encapsulates a single simulation model in the dis-

tributed environment. It is composed of a Feder-

ate and an Arena Adapter. The Federate corre-

ADistributedSimulationModeloftheMaritimeLogisticsinanIronOreSupplyChainManagement

457

sponds to the actual simulation model, which is rep-

resented by a GPM running in the Arena

R

discrete-

event simulator. The Arena Adapter enables the

communication between the Federate and the other

components of the distributed environment. Be-

sides, the Arena Adapter implements two HLA com-

ponents: Federate-Ambassador that implements the

communication interface with the Federate and RTI-

Ambassador that enables the communication between

the Federate and the RTI.

The communication with Arena

R

is performed

through DLL (Dynamic Link Library) functions de-

veloped in C++ language. The set of Arena

R

’s

communication functions implemented are: init-

Process, shutdownIPC, readIPCQueue, writeIPC-

Queue, userInitializeMaxTimeAdvance and userGet-

MaxTimeAdvance.

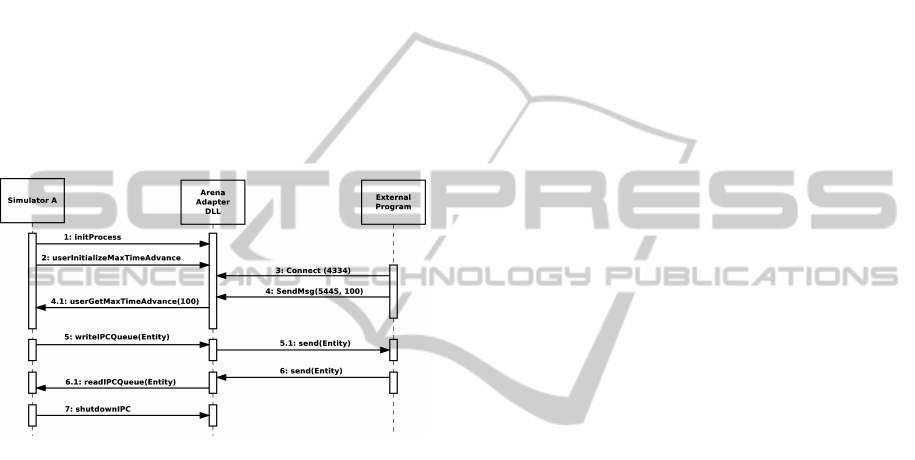

Figure 2: Communication sequence diagram.

Figure 2 depicts the communication sequence be-

tween Arena

R

and an external program. The se-

quence starts with the initialization of Simulator

A that calls the initProcess and userInitializeMax-

TimeAdvance DLL functions (messages 1 and 2) in

order to initialize, respectively, the communication

and the Simulator A clock. Next, it waits the sig-

nal from the External Program to start the simula-

tion execution (message 3). After receiving the sig-

nal, the model is executed synchronized to the simu-

lation time received from the External Program (mes-

sages 4 and 4.1). During the simulation, if Simula-

tor A wants to send an entity to another simulator, it

calls the element TASKS, which triggers a call to the

writeIPCQueue DLL function that receives the entity

data and send it to the External Program (messages

5 and 5.1). In order to transfer such data to another

simulator, the External Program sends the data to the

target’s Arena Adapter, which triggers the readIPC-

Queue DLL function to send the new entity data to the

model’s ARRIVALS element. Once received, the en-

tity is created in the simulation (messages 6 and 6.1).

At the end of the simulation, Simulator A calls the

shutdownIPC DLL function that finalizes the commu-

nication and the simulation (message 7).

5.2 Distributed Simulation Coordinator

The Distributed Simulation Coordinator (DSC) is a

Federate developed in Java programming language

and it has the following functions: (i) store the scenar-

ios information, (ii) coordinate the transfer of ships

(entities) from one Arena Federate to another, and

(iii) synchronize the clock among the several Arena

Federate. Each Federation has only one DSC and

it is structured in an architecture composed of lay-

ers: High Level Architecture, Distributed Simulation

Planning and Graphical User Interface.

The High Level Architecture layer enables DSC to

communicate with the Arena Federates in the Federa-

tion. In this layer, the communication and clock syn-

chronization mechanisms are implemented. Among

these functions, the synchronization is the most criti-

cal, which in this work was implemented as a conser-

vative clock synchronization.

The Distributed Simulation Planning performs all

the route planning functions according to the config-

ured demands in the scenario. It also controls the re-

strictions imposed concerning the possibility to allo-

cate a ship to a route.

The Graphical User Interface (GUI) layer allows

the users to interact with the system inputing data and

extracting simulation results. This layer is supported

by a database responsible to store the configured sce-

narios and output simulation results.

5.3 Distributed Integrated Model

The Distributed Integrated Model is an integration

of all the components described in the previous sec-

tions, which may be configured differently in order

to support different scenarios. In this work, the sce-

nario used to simulate the seaports network and fleet

is comprised of one Federation composed of 1 Dis-

tributed Simulation Coordinator and 7 Arena Feder-

ates, 4 representing export seaports using the Generic

Port Model (Ports A, B, C and D), 2 representing the

import seaports (Ports E and F) and 1 representing the

navigation system which uses the Navigation Model.

This integrated model was used to perform the exper-

iments described in the next section. Therefore, it is

worth noting that since this model can be configured

differently in order to represent different scenarios in

the same context of maritime logistics, it is reusable.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

458

6 EXPERIMENT

In order to perform the experiment, the developed

distributed model was first validate using real data,

which process overview is provided in Section 6.1.

Then, the proposed experiment was conducted and its

results analyzed as described in Section 6.2.

6.1 Validation

The validation process was carried out considering a

base scenario and one year of real operations data for

its calibration. The base scenario was composed of

the components described in Section 5.3 and 28 ves-

sels ranging from 89,000 DWT to 270,000 DWT. The

validation process was performed by comparing the

output of 10 simulation runs against the real data out-

put taking into account the following parameters: im-

ported and exported total cargo by product, number of

berthing, number of unberthing and queue time. The

model was assumed to be valid when the error of the

simulated and real average parameters values was un-

der 2%.

6.2 Simulated Scenario

Based on the validated model, an experiment was per-

formed using an IBM Blade Center S

3

(1 Blade 2-

processors Intel Xeon 2.0 GHz) configured with 04

virtual machines (1 processor 2.0 GHz and 2 GB

memory) running Rockwell Arena

R

v12 on Windows

XP and 03 PCs (1 processor Intel iCore i7 2.93 GHz

and 4 GB memory) running Rockwell Arena

R

v12 on

Windows 7.

The experiment aimed to identify the maximum

transport capacity of a fictitious ship fleet composed

of 32 ships ranging from 150,000 DWT to 400,000

DWT and considering 4 export seaport (Ports A, B,

C and D), and 2 import seaport (Ports E and F). The

strategy used to achieve this objective was to perform

several simulations beginning with a small supply and

demand cargo and increasing them proportionally un-

til the ships waiting time on the check point was zero.

The latter condition indicates that during the whole

simulation none ship was idle, which means that the

maximum ship fleet transport capacity was reached.

Table 2 presents the supply and demand cargo in

which the condition described was achieved.

Using this experiment scenario, the simulation

was executed 10 times and it was identified that the

ship fleet was able to transport20,236,144tons of iron

ore as presented in Table 3.

3

http://www-03.ibm.com/systems/bladecenter/

hardware/chassis/blades/index.html.

Table 2: Cargo supplied and demanded per seaport.

Seaport Supply (tons) Demand (tons)

Port A 4,398,195 –

Port B 11,194,190 –

Port C 7,055,643 –

Port D 18,393,006 –

Port E – 39,187,197

Port F – 2,607,837

Table 3: Maximum ship fleet transport capacity.

Cargo Quantity (tons)

Unloaded 20,236,144

Loaded 23,386,314

In Transit 3,150,170

7 CONCLUSIONS

Simulation has been advised as an adequate approach

to analyze SCM behaviors. However, develop mono-

lithic models representing the whole supply chain can

be costly and time consuming in the long-term. In the

iron ore industry in which the seaports have the same

features, the use of generic models and distributed

simulation can be considered a real alternative in or-

der to reduce its modeling development time.

Hence, this work presented a Generic Port Model,

a Navigation Model and a Distributed Integrated

Model in order to develop a maritime logistics dis-

tributed simulation based in the High Level Architec-

ture. The main identified technical challenges along

the distributed simulation implementation were the

interoperability among the simulators and the clock

synchronization tasks.

The developed system was applied in the fictitious

scenario in order to determine the maximum transport

capacity of a specific ship fleet. The results showed

the usefulness of the model as a tool to support deci-

sion making and the applicability of distributed simu-

lation. Additionally, its usefulness for decision mak-

ing training of operational, tactical and strategical per-

sonnel was identified during its development.

As future work, we intend to carry out further sim-

ulations incorporating other supply chain nodes, such

as distribution center, mine production and railway.

Specifically concerning the distribution centers, we

expect to study an interesting aspect which is how the

service level of the system – measure by queue time

at its output side – is affected by the number of ves-

sels at the loop circuit between import seaports and

the distribution centers and estimate the trade off be-

tween the number of ships and services level at the

distribution center.

ADistributedSimulationModeloftheMaritimeLogisticsinanIronOreSupplyChainManagement

459

REFERENCES

Beresford, A., Pettit, S., and Liu, Y. (2011). Multimodal

supply chains: iron ore from australia to china. Sup-

ply Chain Management: An International Journal,

16(1):32–42.

Botter, R. C., Mendes, A. B., and de Souza, R. F. (1998).

Simulation model for the redesign of a supply distri-

bution system. In Proceedings of the 1998 Summer

Computer Simulation Conference.

Bugaric, U. S., Petrovic, D. B., Jeli, Z. V., and Petrovic,

D. V. (2012). Optimal utilization of the terminal for

bulk cargo unloading. Simulation, 88(12):1508–1521.

Choenni, A., Lehmann, J., Sewerski, M., Huber, R., and

Kirk, R. (2011). Iron ore: The competition between

brazil and australia for asian markets. Technical re-

port, Fundac¸˜ao Get´ulio Vargas.

Dahmann, J., Fujimoto, R. M., and Weatherly, R. M. (1998).

The DoD High Level Architecture: an update. In Pro-

ceedings of the 30th conference on Winter simulation,

pages 797–804, Los Alamitos, US. IEEE Computer

Society Press.

Doss, D. L. and

¨

Ulgen, O. M. (2004). A case for generic,

custom-designed simulation applications for material

handling and manufacturing industries. In Proceed-

ings of the 2004 Brooks Automation’s Worldwide Au-

tomation Symposium.

Duinkerken, M. B., Ottjes, J. A., and Lodewijks, G. (2002).

The application of distributed simulation in TOMAS:

Redesigning a complex transportation model. In

Y¨ucesan, E., Cheng, C.-H., Snowdon, J. L., and

Charnes, J. M., editors, Proceedings of the 2002 Win-

ter Simulation Conference.

Everett, J. E. (1995). Improving the quality of iron ore ship-

ments. In International Congress on Modelling and

Simulation, pages 320–325.

Fujimoto, R. M. (1999). Parallel and Distribution Simu-

lation Systems. John Wiley & Sons, Inc., New York,

US, 1st edition.

Hassan, S. A. (1993). Port activity simulation: an overview.

SIGSIM Simul. Dig., 23(2):17–36.

Hieber, R. (2002). Supply Chain Management: A Collabo-

rative Performance Measurement Approach. Research

reports for industrial practice. vdf, Hochschulverlag

AG an der ETH Z¨urich.

Hoyt, D., Lee, H., and Singh, S. (2007). Rio tinto iron ore:

Challenges of globalization in the mining industry. In

Global Supply Chain Management Forum. Stanford

Graduate School of Business.

IEEE (2000). IEEE Standard for Modeling and Simulation

(M&S) High Level Architecture (HLA) - Framework

and Rules. IEEE Std. 1516-2000, 0:i–22.

Ingalls, R. G. (1998). The value of simulation in modeling

supply chains. In Proceedings of the 30th conference

on Winter simulation, pages 1371–1376, Los Alami-

tos, US. IEEE Computer Society Press.

Jain, S., Lim, C.-C., Gan, B.-P., and Low, Y.-H. (1999).

Criticality of detailed modeling in semiconductor sup-

ply chain simulation. In Proceedings of the 31st con-

ference on Winter simulation: Simulation—a bridge

to the future - Volume 1, pages 888–896, New York,

US. ACM.

Lung, C.-H., Cochran, J. K., Mackulak, G. T., and Urban,

J. E. (1994). Computer simulation software reuse by

generic/specific domain modeling approach. Interna-

tional Journal of Software Engineering and Knowl-

edge Engineering, 4(1):81–102.

Mackulak, G., Lawrence, F., and Colvin, T. (1998). Effec-

tive simulation model reuse: a case study for amhs

modeling. In Simulation Conference Proceedings,

1998. Winter, volume 2, pages 979–984.

Marietto, M. B., David, N., Sichman, J. S., and Coelho, H.

(2003). Requirements analysis of agent-based simula-

tion platforms: State of the art and new prospects. In

Sichman, J. S., Bousquet, F., and Davidsson, P., edi-

tors, Multi-Agent-Based Simulation II, volume 2581

of Lecture Notes in Computer Science, pages 125–

141. Springer.

Mentzer, J. T., DeWitt, W., Keebler, J. S., Min, S., Nix,

N. W., Smith, C. D., and Zacharia, Z. G. (2001).

Defining supply chain management. Journal of Busi-

ness Logistics, 22(2):1–25.

Monks, T., Robinson, S., and Kotiadis, K. (2009). Model

reuse versus model development: Effects on credibil-

ity and learning. In Proceedings of the 2009 Winter

Simulation Conference (WSC), pages 767–778.

Pereira, N. N. and Brinati, H. L. (2012). Onshore ballast

water treatment: A viable option for major ports. Ma-

rine Pollution Bulletin, 64(11):2296–2304.

Robinson, S., Nance, R. E., Paul, R. J., Pidd, M., and Taylor,

S. J. E. (2004). Simulation model reuse: definitions,

benefits and obstacles. Simulation Modelling Practice

and Theory, 12(7–8):479–494.

Sarmiento, A. M. and Nagi, R. (1999). A review of in-

tegrated analysis of production-distribution systems.

IIE Transactions, 31(11):1061–1074.

Silva, R. C. d. S., Brito, T. B., Botter, R. C., and Pereira,

N. N. (2011). Modeling of a closed-loop maritime

transportation system with discrete event simulation

and multi-criteria decision analysis. In Ao, S. I., Dou-

glas, C., Grundfest, W. S., and Burgstone, J., ed-

itors, Proceedings of the World Congress on Engi-

neering and Computer Science 2011 Vol II, WCECS

2011, October 19 - 21, 2011, San Francisco, USA,

Lecture Notes in Engineering and Computer Science,

pages 956–961. International Association of Engi-

neers, Newswood Limited.

Taylor, S., Bruzzone, A., Fujimoto, R., Gan, B. P., Strass-

burger, S., and Paul, R. (2002). Distributed simula-

tion and industry: potentials and pitfalls. In Simu-

lation Conference, 2002. Proceedings of the Winter,

volume 1, pages 688–694.

Terzi, S. and Cavalieri, S. (2004). Simulation in the supply

chain context: a survey. Comput. Ind., 53(1):3–16.

Thierry, C., Bel, G., and Thomas, A. (2010). The role

of modeling and simulation in supply chain manage-

ment. SCS M&S Magazine, 4:1–8.

Wadhwa, L. C. (1992). Planning operations of bulk loading

terminals by simulation. Journal of Waterway, Port,

Coastal, and Ocean Engineering, 118(3):300–315.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

460