A Two-step Empirical-analytical Optimization Scheme

A Simulation Metamodeling Approach

Wa-Muzemba and Anselm Tshibangu

University of Maryland Baltimore County, Department of Mechanical Engineering,

1000 Hilltop Circle, Baltimore, Maryland 21250, U.S.A.

Keywords: Optimization, Robust Design, Simulation Meta-modeling.

Abstract: This paper presents a two-step optimization scheme developed to find the optimal operational settings of

operational systems seeking to optimize their operations using multiple performance measures. The study

focuses on two conflicting performance measures, the Throughput Rate (TR) and the Mean Flow Time

(MFT). First an empirical approach is used to uncover the near optimal values of the performance measures

using an experimental design procedure. Second, an analytical procedure is deployed to find the exact

optima using values the near optima found in the first step as target. The analytical procedure uses a non-

linear regression meta-model derived from simulation outputs and compromises the two conflicting targets

while minimizing the loss incurred to the overall system. This loss is expressed in the form of a multivariate

version of the Taguchi quadratic loss function. Although the framework as presented in this paper is derived

by analyzing a manufacturing system through discrete-event simulation, the procedure however, can

successfully be applied to any processing system in various industries including food production, financial

institutions, warehouse industry, and healthcare.

1 INTRODUCTION

The choice of performance measures in a processing

system depends highly on management policy and

decision-making. Multiple objective measures are

needed to describe the dynamic nature of a

production system. A single performance measure is

not enough to capture and characterize the overall

performance of a system. Also, optimizing a system

with respect to one single objective only may lead to

sacrificing other objective(s) of interest. For

example the objective of minimizing in-process

inventory might be in conflict with that of

maximizing a production rate. Literature on the

design and operation of flexible manufacturing

systems has shown that most of the past research

studies have used only a single performance measure

in their objective functions (Blogun et al., 1999).

From this point of view, the multi-objectives

approach has recently been of interest in a wide

range of design and control problems for

manufacturing systems, such as machine selection,

choice of the manufacturing or processing system

configuration architecture, control of automated

storage and retrieval systems, and overall scheduling

scheme.

The selection of the most appropriate setting of

input factors in order to attain the required process

objective/target (mean) is of major interest in a

variety of production environments. The problem is

referred to as the “optimal setting parameters”

because it is concerned with selecting the best

setting of parameters for an optimal operation of the

system. It worth it to mention that the generic term

of system is used in this study to designate a

process-oriented infrastructure including a

warehouse, a manufacturing system, or a operating

theater in a hospital. Selecting the optimal setting is

critically important since it affects not only

performance measures, operations and/or production

costs but also the loss incurred to the system in the

event of a performance deviation from the company-

identified target values. On the other hand, these

operational targets need to be frequently reviewed as

a result of the unpredictable variations in the shop

floor conditions and the fluctuating nature of the

market place.

Clearly, there is a true need and a real

opportunity to apply a combined scheduling

methodology to dynamic and stochastic scheduling

problems with the objective of reducing the overall

558

Tshibangu W. and Tshibangu A..

A Two-step Empirical-analytical Optimization Scheme - A Simulation Metamodeling Approach.

DOI: 10.5220/0004489105580565

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 558-565

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

production cost.

This paper analyzes a hypothetical flexible

manufacturing system using simulation and proposes

a unique and robust scheme in designing, modeling

and optimizing systems in a very effective way. The

reader is referred to other author’s publications

(Bardhan and Tshibangu, 2003), (Tshibangu, 2005),

(Tshibangu, 2006) for a detailed description of the

hypothetical manufacturing system considered in

this study. The system is modeled with a total

number of 9 workstations including a receiving and

a shipping stations. These 9 stations process are

served by a fleet of AGVs while processing fifteen

part types, each with a different processing time.

The optimization procedure as developed in this

paper is carried out at two levels. First an empirical

approach is used to uncover near-to-optimal values

of the individual performance criteria of interest.

These values are subsequently used as targets in the

second and more analytical level of the optimization

procedure during which a multi-criteria optimization

technique eventually uncovers the true optimal

setting of the system parameters. Specifically, the

analytical optimization is applied to a regression

model equation (meta-model) derived from

simulation output results. The approach used in this

study takes advantage of a robust experimental

design methodology to render the system immune to

noise. The purpose is to present a pragmatic

approach that may enhance the overall performance

of process-oriented systems including manufacturing

systems, warehouse, airport traffic and hospitals.

2 RESEARCH METHODOLOGY

The various phases of the robust design

methodology as applied in this paper is the same as

proposed in the literature (Montgomery 2012),

(Taguchi, 1987) except that in this study, after

completing the simulation experiments and

collecting alll pertinent data the following additional

steps are taken in order to accommodate the

subsequent optimization procedures as proposed in

this research:

(1) Calculate the mean and the variance with respect

to noise factors

2

wrtnf(i)

for each treatment i (row

of the inner array) and for each performance

measure of interest; this variance measures the

variation in the performance criterion when there

is a change in noise factors.

(2) Compute and use log

2

wrtnf(i)

of each

performance measure to improve statistical

properties of analysis.

(3) Apply the normal probability plotting technique

to the calculated mean and the log

2

wrtnf

of each

control factor setting to determine the

significance of the main factors and their

interaction effects on each performance measure

of interest.

(4) Develop and implement the four-step

optimization procedure to predict the factors and

their associated settings that will simultaneously

minimize

2

wrtnf

and optimize the mean of the

performance measures. Adjust and fine-tune the

settings to the most appropriate economical

levels.

(5) Perfom a second analytical optimization

procedure using a Bi-variate Quadratic Loss

Funtion (BQLF) inspired from Taguchi

Methodology

(6) Run confirmatory simulation experiments.

(7) Make the conclusions on the multi-criteria

optimization procedure.

2.1 The Robust Design Formulation

Implementing the robust design formulation requires

the following steps:

Define the response or dependent variables

(performance measures of interest), the

independent variables (including the controllable

factors and the uncontrollable factors or source

of noise ).

Plan the experiment by specifying how the

control parameter settings will be varied and how

the effect of noise will be measured.

Carry out the experiment and use the results to

predict improved control parameter settings (e.g.,

by using the optimization procedure developed in

this study).

Run a confirmation experiment to check the

validity of the prediction.

This study takes advantage of a robust design

configuration inspired by the Taguchi robust design

methodology. However, because of the high amount

of criticism against Taguchi’s experimental design

tools such as orthogonal arrays, linear graphs, and

signal-to-noise ratios, this study avoids the use of

Taguchi’s statistical methods but rather uses an

empirical technique developed by the author.

The paper develops and proposes an optimization

scheme by studying an AGV-served FMS and

evaluating its overall performance using the mean

flow time (MFT) and the throughput rate (TR). The

study considers as controllable variables 5 design

parameters, designated by X

i

(i=1…5), namely: i) the

number of AGVs (X

1

), ii) the speed of AGV (X

2

), iii)

ATwo-stepEmpirical-analyticalOptimizationScheme-ASimulationMetamodelingApproach

559

the queue discipline (X

3

), iv) the AGV dispatching

rule (X

4

), v) and the buffer size (X

5

). These variables

have a direct impact on the performance of machines

and material handling (AGVs) as they are

considered in most literature not only as the most

expensive (some even as the most sensitive)

components of the overall system and also as

potential sources of operational disturbances. The

natural values assigned to these design variables are

displayed in Table 1. In this study, the controllable

parameters X

1

through X

5

to set and tested at two

setting levels (min and max).

The principal sources of noise tested in this study

(and also considered as the most commonly

investigated and documented in the reported

literature (Montgomery, 2013) are: i) the arrival rate

between parts (or orders), (X

6

), the mean time

between failures of the machines (X

7

) and the

associated mean time to repair (X

8

). These factors

are also tested at two levels in combination with

each control factor (X

1

through X

5

) at each setting

level.

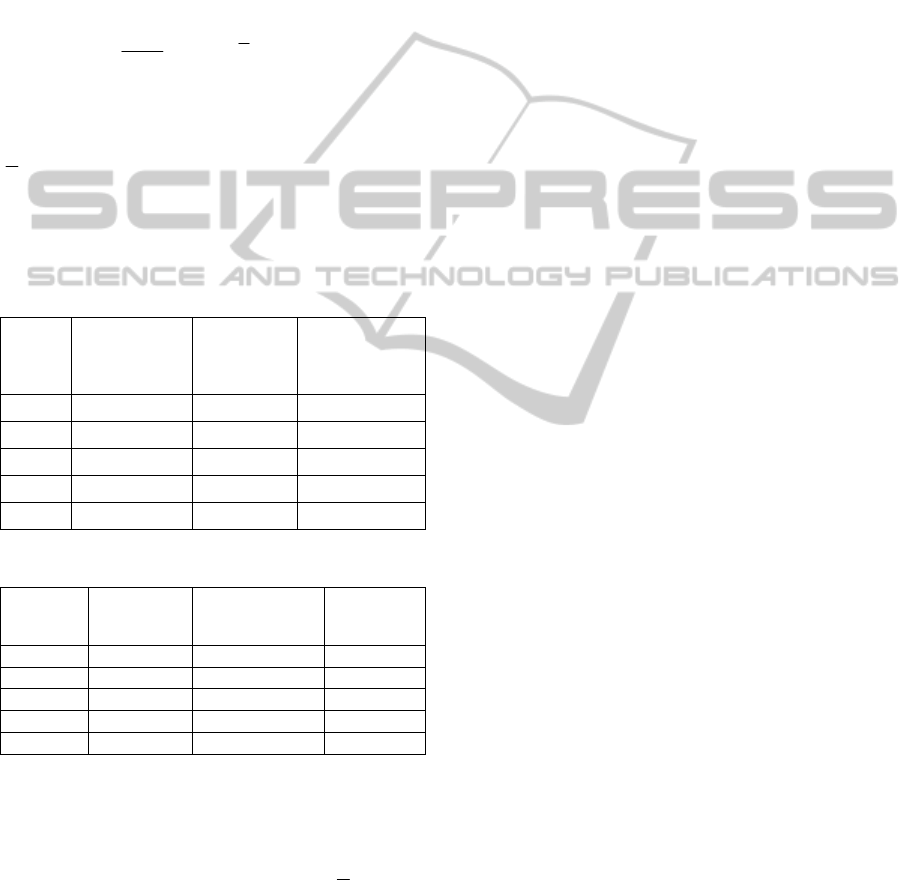

Table 1: Natural values and setting of control factors.

Designation Control Factor

Low

Level (-1)

High

Level (+1)

X

1

Number of AGVs 2 9

X

2

Speed of AGV 100 200

X

3

Queue Discipline FIFO SPT

X

4

AGV Dispatching Rule FCFS SDT

X

5

Buffer Size 8 40

Table 2 depicts settings and natural values for noise

factors as assigned and simulated in the experiments.

For both controllable and noise factors, the coded

levels are (-1) and (+1) for the low and high level,

respectively.

2.2 Planning the Experiment

Planning the experiment is a two-part step that

involves deciding on how to vary the parameter

settings and how to measure the effect of noise

(Kacker and Shoemaker, 1986). Using a full

factorial experimental design with the 5 controllable

factors X

1

, X

2

, X

3

, X

4

, and X

5

set at two levels in

combination with three noise factors X

6

, X

7

, and X

8

,

varied at two settings would require 2

5

x 2

3

= 256

simulation runs.

Two-level, full factorial or fractional factorial

designs are the most common structures used in

constructing experimental design plans for system

design variables. Montgomery (2013) recommends

appropriate fractional factorial designs of resolution

IV or V in the design of robust manufacturing

systems. In this study a two-level fractional factorial

design of resolution V, denoted 2

v

5-1

has been used.

This design requires only 16 runs. Across the full set

of noise factors, the implemented robust design

leads to a total of 16 x 8 = 128 simulation runs

(instead of 256 as required by a full factorial

design). The study also decides to use a robust

design of resolution V in order to allow an

estimation of both main factors and two-way

interactions effects, as they are necessary and very

crucial for the first step of the proposed optimization

scheme, and referred to as the empirical step.

A standard statistical experimental design, also

known as a data collection plan is normally

advocated and recommended when conducting

simulation experiments. The data collection plan

used in this study was inspired from Genichi

Taguchi’s strategy for improving product and

process quality in manufacturing (Taguchi, 1986). It

has been first used and proposed by Wild and

Pignatiello (Wild et al., 1991). Their proposed

design strategy includes simultaneous changing of

input parameter values. Therefore, the uncertainty

(noise) associated with not knowing the effect of

shifts in actual parameter values such as shifts in

mean inter-arrival times, mean service times, or the

effect of not knowing the accuracy of the estimates

of the input parameter values, is introduced into the

experimental design itself. Tshibangu, 2003, 2005

provides detailed information about this specific

data collection plan. This plan has been also used in

this study to run the simulation experiments and

effectively collect the statistics thereof.

Table 2: Natural values and setting of noise factors.

Designation Noise Factor Low Level (-1) High Level (+1)

X

6

Inter-arrival EXPO(15) EXPO(5)

X

7

MTBF EXPO(300) EXPO(800)

X

8

MTTR EXPO(50) EXPO(90)

3 EMPIRICAL OPTIMIZATION

Because flexible manufacturing systems and any

other process-oriented systems are subject to various

uncontrollable factors that may adversely affect their

performance, a robust design of such systems is

crucial and unavoidable. The author has developed a

four-step optimization procedure to be used

simultaneously with the robust design as first step of

the optimization scheme as proposed in this study:

Let

i

y

represent the average performance

measure across all the set of noise factors

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

560

combination, averaged across all the simulation

replications for each treatment combination (or

design configuration) i. Let log

2

wrtnf(i)

be the

associated logarithm of the variance with respect to

noise for that particular treatment i. Kacker and

Shoemaker, 1986 recommend to use the logarithm

of the variance in order to improve statistical

properties of the analysis, and to employ the

“effects” values and/or graphs in association with

normal probability plots and or ANOVA procedures

to identify and partition the following three

categories of control factor vectors:

Assuming that we have partitioned three

categories of control vectors as non-empty sets X

v

T

containing the factors that have a significant effect

on the variances, X

m

T

containing factors significant

on the means (and their interactions), and X

0

T

as the

set of the factors that affect neither the mean nor the

variance, respectively, then a four-step empirical

optimization procedure may be implemented as

follows:

1. Step 1

Identify the vector X

v

T

and adjust the controllable

factors members of this set to their values that

minimize

2

wrtnf

.

of the performance measure y.

2. Step 2

Identify vector (X

m

T

)

1

of factors having a significant

effect on the mean

y

and set the controllable factors

members of this set to their level values that

optimize the mean

y

of the objective performance

y. Also, identify (X

m

T

)

2

vector of factors having a

significant effect on mean

y

and on the variance

2

wrtnf

simultaneously and set the factor members of

this set to their level values that optimize the mean

y

if this setting does not act in opposition with the

minimization of the variance. Otherwise, find a

compromise between minimizing the variance and

optimizing the mean as suggested in Step 4 where

the final setting is to be decided.

3. Step 3

Identify the vector X

0

T

and set the control factors

members of this set to the values of their interaction

with members of vector X

v

T

that minimize the

variance or log

2

wrtnf

or the values of their

interaction with members of X

m

T

that optimize the

mean

y

. Otherwise, set the factors at their

economical settings.

4. Step 4

Conduct a small follow-up experiment to find trade-

off between members of (X

m

T

)

2

B

containing factors

with effects on variance and mean acting in

opposition and or the overall economical settings. A

suggestion from this study is that in finding the

overall economical setting, the step involves only

those factors that have the greatest effect on either

the variance

2

wrtnf

or the mean

y

.

Using the above-developed procedure with

related plots and tables, and applying it to the data as

derived from the experiments for the two

performance measures, i.e., Mean Flow Time (MFT)

and Throughput Rate (TR) performance measures,

the following coded results are obtained: MFT =

0.3666 units time/part and TR = 3000 parts/month

(100 parts/day). These values will be considered as

the optimal target values to be achieved in the

second level of the optimization procedure (multi-

criteria optimization).

3.1 Simulation Meta-modeling

Tshibangu (2005) redefines the purpose of meta-

modeling as the method by which to measure the

sensitivity of the simulation response to various

factors that may be either decision (controllable)

variables or environmental (non-controllable)

variables (Kleijnen, 1977).

After completing the robust design process, the

128 simulation experiments were carried out as

initially recommended in the experiment plan and

the main statistics describing the system were

collected following the proposed data collection

plan. These values were subsequently fed into a non-

linear regression meta-model to derive the estimate-

equations

ˆ

TR

y

and

ˆ

M

TF

y

for the throughput rate

(TR) and the mean flow time (MFT), respectively.

Meta-models are usually constructed by running a

special RSM (Response Surface Methodology)

experiment and fitting a regression equation that

relates the responses to the independent variables or

factors.

3.2 Determination of Variances, Main

and Interaction Effects

A well-planned experiment makes simple the

analysis subsequently needed to predict the

improved (optimal) parameter settings. In this study,

for each of the simulated design configurations i,

eight measurements (over the set of noise factor

combinations) were taken for each performance

measure of interest and averaged across the

replications to obtain

i

y

for each i

th

row of the inner

array. Sixteen design configurations and five center-

points (for a total of 21) designs were simulated over

a set of eight noise factor combinations, leading to

ATwo-stepEmpirical-analyticalOptimizationScheme-ASimulationMetamodelingApproach

561

21x8 =128 runs. The results of these various

simulation experiments, too large to be displayed in

this paper, but available upon request, were

subsequently averaged up across the three

replications.

This research intends to minimize the variances

of the performance measures with respect to the

noise factors for each run. The reported variances

across the text, denoted [

2

(wrtnf)

] is calculated as

follows:

2

(wrtnf)

i

2

1

1

, 1, 2,... ,

1

f

ij

i

j

yy j f

f

(1)

where y

ij

is the observed value of a given

performance measure for a particular design

configuration i and a noise factor configuration j;

y

is the average value of a given performance

criterion considering that particular design

configuration i. In this study, f = 8 (eight noise

combinations).

Table 3: Effects of Control Factors MFT Variance.

Control

Factors

Effect on MFT

log

2

wrtnf

at Level (+1)

Effect on

MFT log

2

wrtnf

at Level (-1)

Absolute Value

Difference

between High

and Low levels

X

1

1.6159 1.657502 0.04155

X

2

1.6081 1.558286 0.04982

X

3

1.4921 1.781325

0.28920

X

4

1.6338 1.639566 0.00568

X

5

1.6032 1.670230 0.06701

Table 4: Effects of Control Factors on MFT Mean.

Control

Factors

Effect on MFT

Average

Level (+1)

Effect on MFT

Average

at Level

(-1)

Absolute

Value

Difference

X

1

8.238767 25.97234

17.73358

X

2

12.62954 20.89605 8.26650

X

3

13.86047 20.35063 6.49016

X

4

16.97108 17.24002 0.26893

X

5

17.61093 16.60017 1.01076

The objective is to make the variances of the

responses (performance measures) as small as

possible while the means are brought to their

optimum settings, which would consists of a

minimum for the MFT and a maximum for the TR.

The study then computes the values of

i

y

and log

2

(wrtnf)i

at each design configuration. Subsequently,

the effects of each control factor on the overall mean

and the variance (or log

2

wrtnf

) are calculated by

using the normal probability data plotting technique

(Box et al., 1978). Tables 3 and 4 display the effects

on the MFT variance and mean, respectively.

As it can be seen, these effects on the mean and

the variance are also partitioned into high level and

low level effects. The same procedure is applied to

the throughput rate TR and the results, not displayed

in this paper, are available upon request. The process

is conducted for all the control factors. Then each

controllable factor is tested at two levels, the

magnitude of its effect on variability is measured by

the difference between the average values of log

2

wrtnf

at those settings. The computed effects at high

and low levels will be used in identifying those

controllable factor levels (settings) that have the

largest effect on log

2

wrtnf

. The same procedure is

also applied to the mean values to determine the

effects of the control parameters. Note that a visual

summary of the magnitude of each control factor’s

effect can also be used for analysis of various

effects. From analysis of the results in Table 3 for

example, it can be seen on one hand for instance (in

bold) that the parameter X

3

(queue discipline) has

the most significant effect on the MFT variability.

These results agree with previous findings (Egbelu

and Tanchoco 1984); (Sabuncuoglu, 1989);

(Bardhan and Tshibangu 2003). On the other hand,

the effect at high level is compared to the effect at

low level, and the better setting of each control

parameter is the one that gives the smaller average

value of log

2

wrtnf

. Table 4 results indicate that

factor X

1

(the number of AGVs), when set at its high

level, has the most significant effect on the mean

value of the MFT (see results in bold). Once

identified, these factors will be set at the settings

(levels) that minimize log

2

wrtnf

., i.e., X

1

and X

3

at

high settings. Proceeding the same way for the TR

similar results are obtained and the settings

implemented.

Now that the first empirical optimization step has

revealed the near optimal settings of the system, it

becomes appropriate to move to the second step of

the optimization procedure, referred to in this study

as the analytical phase of the proposed optimization

scheme. For one to perform the analytical

optimization step, a mathematical model of the

system is required. This paper proposes to feed the

simulation results into a non-linear regression meta-

model to derive the mathematical model. Applying

the meta-modeling technique to the flexible

manufacturing system under study in this research

yield the following equations for the estimates of

two performance measures of interest,

ˆ

TR

y

and

ˆ

M

TF

y

.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

562

12

22

3512

222

34512

13 23 34

ˆ

90.7617 20.6726 2.5357

2.6977 0.5617 4.712 9.042

8.732 4.712 7.923 7.458

3.5513 0.5315 0.3304

TR

yxx

x

xxx

x

xxxx

xx xx xx

(2)

12

345

222

123

22

4512

13 14 15

23 24 35

45

ˆ

4.6503 8.8668 4.4760

3.2451 0.1345 0.5054

14.1731 1.5309 1.3399

0.4519 1.4569 5.3816

0.7952 0.0335 0.504

0.1457 0.3251 0.4863

0.7655

MFT

yxx

xxx

xxx

xxxx

x

xxxxx

x

xxxxx

xx

(3)

where

54321

,,,, xxxxx are the coded units for the

operating variables X

1

, X

2

, X

3

, X

4

, and X

5

,

respectively.

4 ANALYTICAL APPROACH

The Taguchi’s loss function discussed in the

literature (Montgomery, 2013) for a single objective

criterion can be extended to the case of multiple

quality characteristics or objective performances,

and then referred to as a “multivariate quality loss

function”. The author (Tshibangu, 2006) shows how

the traditional and simple QLF can be extended to a

multivariate QLF.

Let y

j

, and T

j

be the performance measures of

interest (j =1 to Q, where Q is the total number of

performance measures), and the target for objective

performance

j

y

, respectively, and be denoted by y =

(y

1

, y

2

,…, y

Q

)

T

and T = (T

1

, T

2

,…, T

Q

)

T

under the

assumption that L(y) is a twice-differentiable

function in the neighborhood of T.

Assuming that each objective performance has a

mean

(x)

i

and a variance

(x)

i

2

, then, after some

mathematical developments and manipulations

(Tshibangu, 2005), (Ribeiro and Elsayed, 1995) the

expected value of the quadratic loss function for a

bivariate QLF can be derived and written as follows:

2

2

2

12

1

12 1 1 2 2

(, )

iii i

i

ELy y T

yTyT

(4)

The first term of the second hand side of Eqn. (4) is

known as a weighted sum of mean squares, while

the second term is called the gradient term. It is

important to note that three aspects are of interest in

formulating robust design systems:

(i) deviation from targets; (ii) robustness to

noise; (iii) robustness to process parameters

fluctuations. A weighted sum of mean squares is

appropriate to capture (i) and (ii), while gradient

information is necessary to capture (iii). This

research is particularly interested in deviation from

target and robustness to noise. Therefore, only the

first term of Equation (9) is needed.

The next step consists of applying the derived

QLF to the FMS meta-models Eqns. (2) and (3)

obtained from simulation outputs. In order to

determine the optimal input parameters, an objective

function is developed from Eqn. (4), following a

framework adopted by Ribeiro and Elsayed (1995).

Because of the robust design configuration

adopted during the experiments, it can be assumed

that the variability of the system due to fluctuations

of the operating parameters is negligible, then, for a

given treatment, the loss incurred to a system as the

result of a departure of the system performance

j

y

from the target T

j

can be estimated as:

2

1

ˆˆ

()

Q

j

jj yj

i

i

Li w y T

(5)

where

()

L

i

is the loss at treatment i;

j

w

is a weight

to take into account in order to consider the relative

importance of a individual performance measure

j

y

(j=1,2,…Q),

ˆ

,

jyj

y

are respectively the

predicted (estimate) mean and standard deviation of

the performance measures of interest

j

y

, and

j

T

is

the target for the system performance measure

j

y

.

L(i) is the objective function to be minimized. In this

particular form, the objective function has two

terms. The first term of the objective

function,

2

ˆ

jj

y

T , accounts for deviations from

target values. The second term,

2

ˆ

yj

accounts for

the source of variability due to non-controllable

factors (noise).

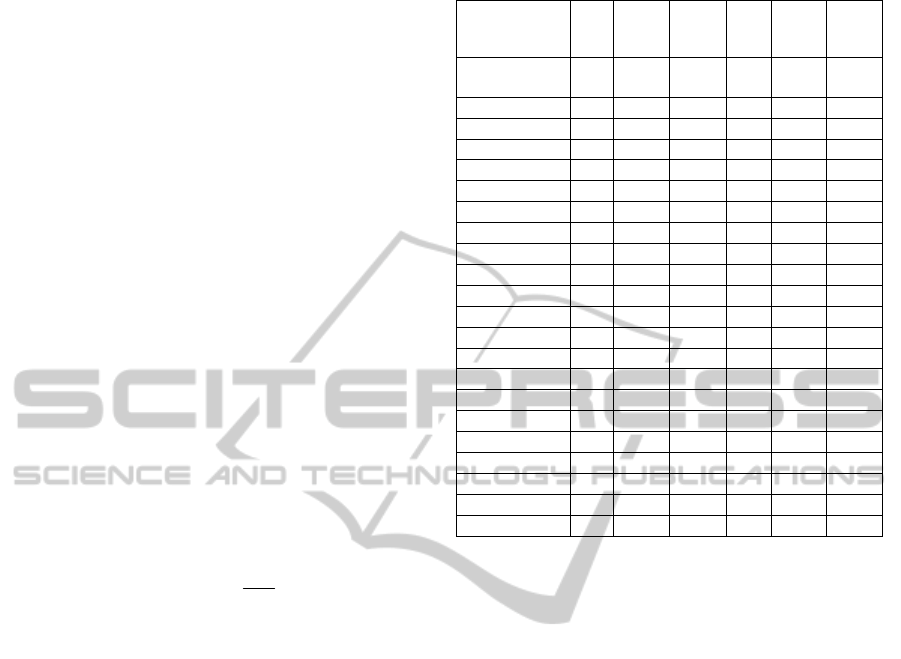

5 RESULTS

For the twenty-one treatment combinations

simulated in this study, the resulting normalized

values are displayed in Table 5 showing the values

ATwo-stepEmpirical-analyticalOptimizationScheme-ASimulationMetamodelingApproach

563

of

j

y

and

2

log

yj

at each design configuration

for each of the two primary performance criteria of

interest in this study. Note that only the throughput

rate (TR) seeks a maximization. The mean flow time

(MFT) and the variances of both TR and MFT need

be minimized. Therefore, the normalization

procedure of these values will consist of maximizing

the inverse. Further analysis of output results

indicates that design configurations labeled #3, 7,

16, 20, and 21 are the most cost effective as they

yield the least cost. This finding suggests that

operating the studied system under any of these

design settings would be far more economically

attractive than operating the same system under

other design settings even when they are also

identified as the most robust designs. For example,

the difference between the most cost-effective

design (configuration design #3) and the most

expensive one (design #13) represents

approximately 56 monetary units in normalized

values. This may represent a significant amount of

money if the value of the monetary loss coefficient

factor is important. Using for example $10.00 value

for the loss coefficient will lead to a difference of

$123.00 in expected losses between design # 3 and

design # 13 representing

38

(1 ) *100 76%

161

of

savings when operating under design # 3 setting

parameters. Design #13 has been used for the

comparison because it is among the strongest design

candidates in terms of robustness of the system (i.e.,

insensitivity to noise factors). This example shows

that significant savings (e.g. 76%) can be generated

when switching ample from design #13 to design #3.

6 CONCLUSIONS

This stud first uses an empirical optimization

procedure to avoid the controversial Taguchi

statistical tools. Then a metamodel is derived from

the simulation outputs. The study also derives a

multivariate quadratic loss function (QLF) from the

traditional Taguchi loss function in order to capture

the loss incurred to the overall system when

attempting to optimize a set of two objective

performances (throughput rate TR and mean flow

time MFT). Hence, the QLF is referred in this study

to as a bivariate quadratic loss function (BQLF).

Table 5: Normalized input data and predicted loss.

Design

Configuration

TR

TR log

(Var)

MFT

MFT

log

(Var)

Pred.

Loss

e.g. K=

$10.00

Norm Norm Norm Norm L(i)

Loss in

$

Design 1 0.056 -0.001 0.034 0.008 21.158 212

Design 2 0.020 0.845 0.009 0.032 59.481 594

Design 3 0.068 -0.007 0.079 0.075 3.792 38

Design 4 0.018 -0.212 0.012 0.007 57.632 576

Design 5 0.056 -0.002 0.036 0.010 18.947 189

Design 6 0.032 -0.097 0.030 0.013 54.482 545

Design 7 0.068 -0.007 0.079 0.075 3.792 38

Design 8 0.034 -0.795 0.021 0.046 53.631 536

Design 9 0.035 -0.299 0.020 0.051 52.277 522

Design 10 0.065 -0.004 0.095 0.114 6.142 61

Design 11 0.019 0.477 0.011 0.010 58.599 586

Design 12 0.033 1.429 0.023 0.026 54.035 540

Design 13 0.057 -0.002 0.087 0.088 16.118 161

Design 14 0.049 -0.001 0.026 0.006 31.707 317

Design 15 0.066 -0.005 0.081 0.076 4.958 50

Des 16 0.068 -0.007 0.079 0.075 3.792 38

Design 17 0.058 -0.002 0.087 0.088 15.599 156

Design 18 0.049 -0.001 0.026 0.006 31.137 311

Design 19 0.019 -0.295 0.009 0.043 59.900 599

Design 20 0.068 -0.007 0.079 0.075 3.792 38

Design 21 0.068 -0.007 0.079 0.075 3.792 38

Next (second level of the optimization scheme), the

BQLF is analytically applied to the metamodel

derived from the simulation outputs to fine-tune the

ptimization process em with respect to the two

objective performances. From the results obtained in

step 1 of the optimization scheme as developed in

this paper, optimum/target values of 100 parts/day

and 0.3666 units time/part (in coded data) have been

fixed for the TR, and MFT, respectively.This two-

level optimization procedure lead to a solution that

yield a minimum cost to be incurred to the overall

system as a penalty for missing the objective targets.

The values of 98 parts/day (-2% from target) and

0.3459 units time/part (+5.6% from target) are

obtained as optima, for TR and MFT, respectively.

These maximum outputs will be otained under a

overal system configuration that is considered to be

the most robust and economical, leading to the

following settings in natural values: Number of

AGVs (X

1

): 6; Speed of AGV (X

2

): 150 feet/min;

Queue discipline (machine rule) (X

3

): SPT; AGV

dispatching rule (X

4

): STD; Buffer size: (X

5

): 4.

Although, conceptually validated on a flexible

manufacturing system, the above-developed and

proposed optimization scheme can be easily

extended to other process-oriented industries

including banks, warehouse, ticketing lines at

airports, restaurants, healthcare facilities,

phamaceutical industries, and others.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

564

REFERENCES

Bardhan, T. K, and Tshibangu W. M. A. 2003. Analysis of

an FMS with Considerations of Machine Reliability,

Proceedings of 8

th

Annual IJIE Engineering Theory,

Applications and Practice, Las Vegas, Nevada, US

Kacker, R. N., Shoemaker, A. C., Robust Design, 1986. A

Cost Effective Method for Improving Manufacturing

Processes., AT&T Technical Journal, Volume 65, 51-

84.

Kleijnen, J. P. C., Design and Analysis of Simulations,

1977. Practical Statistical Techniques, SIMULATION,

Volume 28, no.3, 81-90.

Montgomery, D. C., 2013, Design and Analysis of

Experiments, (Eighth Edition, New York: John Wiley

& Sons Inc.

Ribeiro, J. L., and Elsayed, E. A., 1995. A Case Study on

Process Optimization Using the Gradient Loss

Function, International Journal of Production

Research, Volume 33, no. 12, .

Taguchi, G., 1986. Introduction to Quality Engineering-

Designing Quality Into Products and Processes, Asian

Productivity Organization, Tokyo.

Tshibangu W. M. A., 2005. A Framework for Designing a

Robust Material Handling Using Simulation and

Experimental Design, Proceedings of the 10

th

IJIE

Conference Florida.

Tshibangu, W. M. 2006, Robust Design of an FMS: S. M.

Proceedings of the GCMM, COPEC, Council of

Researches in Education and Sciences November19-

22, Santos, Brazil.

Wild, R. H., and Pignatiello, J. J., Jr., 1991.An

Experimental Design Strategy for Designing Robust

Systems Using Discrete-Event Simulation,

SIMULATION, Volume 57, no.6, 358-368.

ATwo-stepEmpirical-analyticalOptimizationScheme-ASimulationMetamodelingApproach

565