Design of a 50M Transimpedance Amplifier with 0.98fa/Hz Input

Inferred Noise in a 0.18M CMOS Technology

William Wilson and Tom Chen

Department of Electrical and Computer Engineering, Colorado State University, Fort Collins, U.S.A.

Keywords: Biosensor, Electrochemical Detection, Electrochemistry Frontend, Low Noise, Low Power,

Transimpedance Amplifier (TIA), Switched Capacitor Integrator.

Abstract: Low noise and low power consumption are key requirements for high performance electrochemical

biosensors. Noise performance directly affects the sensor’s ability to detect small amounts of target

chemical compounds. These requirements present challenges for the design of frontend circuitry in

electrochemical biosensors. These challenges are especially apparent for integrated electrochemical

biosensor arrays, as sensor size is limited by tissue cell size and the desire to achieve a cellular scale

resolution. This paper presents a low-noise and low-power transimpedance amplifier (TIA) intended for (but

not limited to) use as an analog frontend in an electrochemical biosensor. The amplifier was designed on a

commercial 0.18µm CMOS process. The overall design achieves a 50M transimpedance gain with

981aA/Hz input inferred noise, 8.06µW power consumption at 0.9V power supply, and occupies an overall

silicon area of 0.0074mm

2

. To our best knowledge, the design presented in this paper achieved the best

noise performance and power consumption among transimpedance amplifier designs reported to date.

1 INTRODUCTION

Biosensor devices have found an increasingly broad

range of applications, including but not limited to

clinical testing, biological research, environmental

testing, and pharmaceutical testing. With ever

increasing applications for biosensors, the

requirements of detection hardware in biosensors are

covering an increasingly broad range of bio-signals.

These signals often require very specifically

designed detection hardware, for example, to

account for very weak input signal coupled with

high input noise.

Additionally, the ability to visualize the

molecules of cellular communication allows us to

further understand the biology that drives normal

and pathophysiological processes. Electrochemical

sensor arrays provide new opportunities for

chemical vision without the addition of labels, such

as chromophores or fluorophores. The growing

interest in high density electrochemical sensor arrays

(Xu et al., 2002; Qi et al., 2003) dictates a size

requirement for the sensor’s electronics which often

conflicts with achieving low noise and low power

consumption per read channel. This paper presents

the design of an electrochemical sensor frontend for

an integrated sensor array design. Given the

stringent constraints on physical size of sensor

electronics and low input signal level due to small

electrode sizes, the goal of the design is to achieve

low input inferred noise and low power

consumption. These goals must be met while also

maintaining the speed requirement of a 1 KHz input

signal bandwidth and small electronic footprint.

2 BIOSENSING TECHNIQUES

Sensing techniques currently in use include

fluorescence spectroscopy, bioluminescence and

chemilluminescence detection, and electrochemical

detection. Fluorescence spectroscopy is a process of

adding and tracking fluorescent light-responsive

dyes or “label” molecules in a sample. Bio and

chemilluminescence detection rely on the detection

of a naturally luminescent substance in an analyte.

Electrochemical detection uses a reduction or

oxidation reaction (i.e. a redox process) to detect an

electrochemically active analyte.

112

Wilson W. and Chen T..

Design of a 50MO Transimpedance Amplifier with 0.98fa/vHz Input Inferred Noise in a 0.18µM CMOS Technology.

DOI: 10.5220/0004786801120119

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 112-119

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

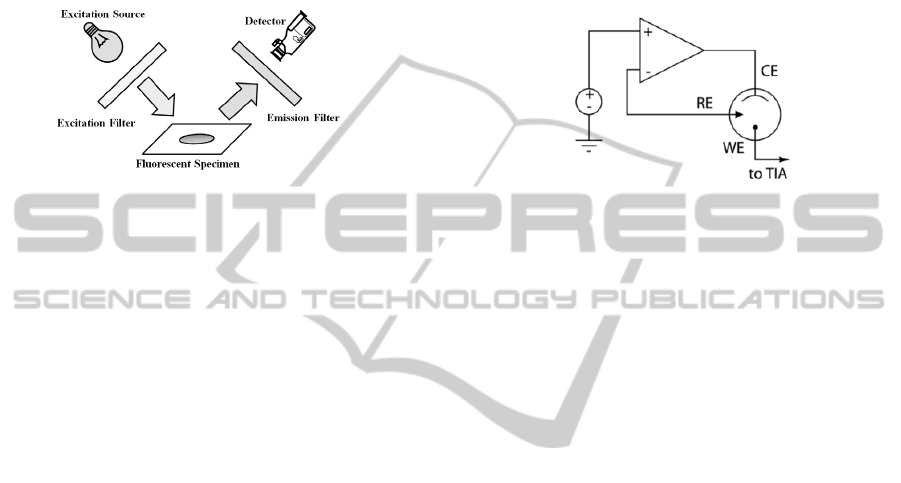

2.1 Fluorescence Detection

Fluorescence imaging detection involves adding a

fluorescent label to the sample material. As shown in

Figure 1, a filtered light source is used to create a

single frequency excitation light. Application of the

excitation light causes a photon emission at different

frequency, allowing detection of the fluorescent

label.

Figure 1: Fluorescence Detection Example.

Typical fluorescence detection systems use

either a high-performance single pixel detector with

a scanning excitation source, or a two-dimensional

array of detectors, such as a CCD sensor, with a

homogeneous excitation light source. In a

fluorescence detection system, possible array size is

determined by CCD implementation and the number

of photosensitive pixels (Agah, et al., 2005). In

optical based systems; however, lenses and strategic

illumination patterns can be utilized to achieve

single-molecule measurement resolutions without

the need to greatly reduce the scale of the detection

devices (Rosenstein et al., 2011).

2.2 Bio/chemilluminescence

Bioluminescence and chemilluminescence

techniques rely on the emission of light from the

analyte. Although generally (but not necessarily) in

the visible light spectrum, the small amount of light

emitted is usually not visible to the human eye.

Detection has been typically achieved with an

extremely sensitive CCD sensor and photomultiplier

tubes. CMOS image sensors have not been utilized

in bioluminescence until more recently due to poor

but improving performance and lower SNR (Agah,

et al., 2005)

2.3 Electrochemical Detection

Using a redox process, electrochemical detection can

be used in a wide range of measurements under the

condition that the analyte being measured is

electrochemically active (Wightman et al., 2006,

Villagrasa et al., 2013). Typical measurement

instrumentation includes a two or three electrode

system, where a potentiostat is used to hold a

specific potential across a sample. Setting a specific

potential between the reference (RE) and the

working electrode (WE) can be used to selectively

detect a specific analyte. The potentiostat also

sources or sinks the required current through the

counter electrode (CE). A typical three electrode

potentiostat system is shown in Figure 2.

Figure 2: Typical Three Electrode Potentiostat.

The popularity of electrochemical sensing stems

from its ability to detect a wide range of molecules.

These molecules include glucose (Liao et al., 2012),

Dopamine (Pihel et al., 1996), Nitric Oxide (Starkey,

et al., 2001), and

-Aminobutyric Acid (Niwa et al.,

1998). The electrical nature of this detection method

also makes electrochemical detection a more

suitable option for integrated sensors and sensor

arrays. The sensor circuit presented in this paper is

intended for use in high density electrochemical

sensor arrays, which provide cellular scale

resolution.

3 MOTIVATIONS FOR

INTEGRATED BIOSENSORS

Currently, typical biosensor implementations include

a custom made sensing device, ranging from single

pixel light detection sensors or single (working)

electrode electrochemical systems, all the way to

two dimensional light sensors such as CCD or

CMOS light detection sensors and multi-

dimensional electrode arrays. Many biosensor

systems must be further supported with a system of

electronics and/or software to supply the end user

with meaningful data and a useable interface. In

many implementations, designing or even setting up

the supporting electronic hardware can become more

involved or time consuming than the detection

device itself.

With discrete devices, external detection

hardware is often used, due to the readily available

forms of computer video recording devices for

Designofa50MOTransimpedanceAmplifierwith0.98fa/vHzInputInferredNoiseina0.18µMCMOSTechnology

113

CCD/CMOS video-based sensors, and the wide

range of computer interfaced potentiostat systems.

These readily available interfaces have some

limitations, including their size, lack of portability,

lack of spatial resolution, and need of trained

personnel with appropriate laboratory facilities.

3.1 Ease of Use

Many integrated solutions include supporting

hardware, such as a transimpedance amplifier (TIA)

for both photodiode based light detectors and

electrochemical detectors. Including the sensor and

detection hardware on a single chip or package with

either a wired or wireless interface simplifies the use

of the biosensor in research, and allows for greater

complexity in hardware. With an integrated system,

a user could easily connect an array of thousands of

electrodes to a computer for data acquisition using a

single connector or wireless interface, eliminating

the need for highly trained personnel and bulky

hardware. Complete sensor backend integration also

provides an abstraction of the sensor’s functionality.

This can eliminate time consuming setup and the

possibility of incorrectly connected devices.

3.2 Increased Resolution and

Applications

The use of small molecules to send signals between

cells is a hallmark of biological communication.

Understanding cellular communication allows for

greater insight regarding the biology that drives

normal and pathophysiological processes. One of the

major difficulties in understanding the actions of

small molecules is our inability to directly visualize

their release and diffusion through biological tissues.

Therefore, understanding cellular communication

through cellular level visualization is an important

goal in biomedical research. Cellular sizes of interest

typically lie within the range of a 20-50µm radius. It

is highly desirable to place electrodes with spacing

below 50µm (Henze, 2000; Hassibi, 2007). This puts

a physical limit on underlying electronics in

integrated sensor designs.

4 DESIGN CONSTRAINTS AND

REQUIREMENTS FOR

SENSOR INTEGRATION

Integrated sensors place much more stringent

physical constraints and performance requirements

on the supporting electronics. With many biological

experiments necessitating extremely small and

sensitive measurements, a high signal-to-noise ratio

(SNR) is often a high priority design requirement for

biosensor frontend circuitry.

4.1 Size and Power Constraints

Visualizing cellular communication with electrode

arrays requires the electrode pitch to be within in the

cellular scale. With parallel read channels, the

underlining electronics will have very restricted size

requirements to match electrode spacing at the

cellular scale. In addition, parallel read channels put

a greater burden on overall power consumption per

read channel for two reasons:

1. For implantable biosensors, the desirable power

consumption for the analog frontend is in the

range of a few µWatts to maximize battery life.

Low power consumption may also enable

alternative power sources such as wireless

power.

2. Perhaps more importantly, in experiments with

living tissues, the tissue must be kept at specific

temperature, humidity, and pH levels. If the

supporting circuitry dissipates an excess of

power as heat, it can be more difficult to keep

tissue samples alive and in the proper

conditions.

The necessity of lower power consumption and

small physical size often comes at the cost of noise

(Toumazou, C., et al., 2002) and accuracy (Kinget,

2005). Therefore, design of integrated biosensors

often requires careful tradeoffs and novel circuits,

especially with respect to input inferred noise.

4.2 Noise Requirement

Depending on the application and specifics of the

sensor design, the analyte detection process will

have an inherent noise level. If the input inferred

noise level of the supporting circuitry can be pushed

below the noise level of the sensor itself, the

circuitry won’t impose a limitation on the resolution

of the measurements.

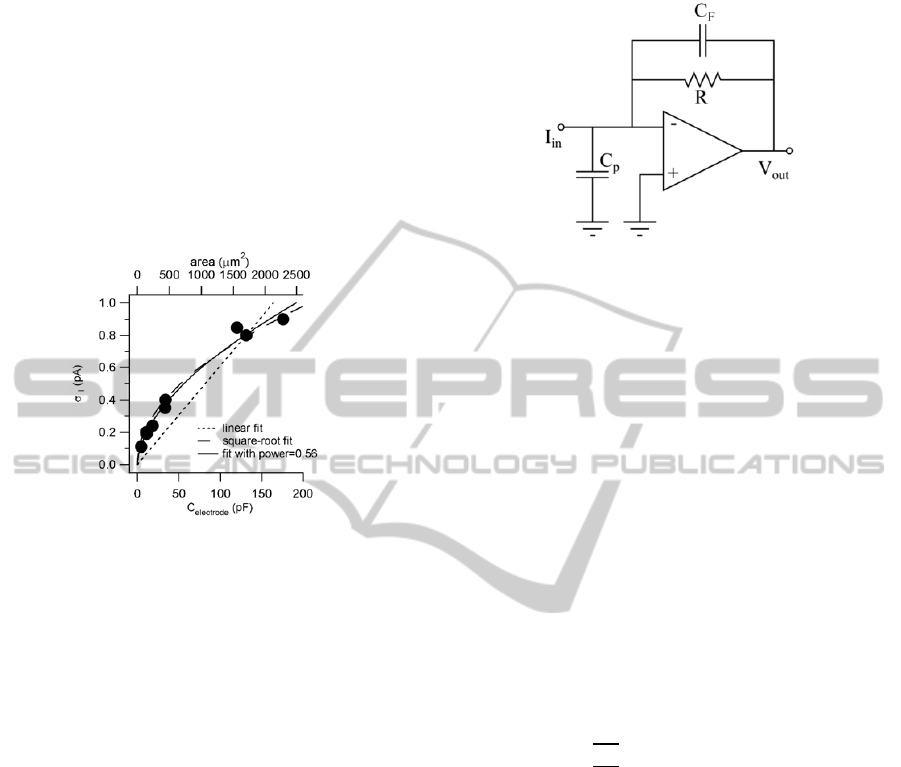

In electrochemical detection systems, noise

standard deviation has been shown to vary based on

electrode area. The noise standard deviation (

I

) on

indium tin oxide electrodes has been shown to

increase with the square-root of electrode area for

small electrodes, and linearly with area for larger

electrodes (Yao et al., 2012). Figure 3 shows noise

generated at the electrode-solution interface as a

function of electrode area for electrochemical

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

114

sensors. For electrodes used in highly integrated

sensors, their sizes typically range from a few m

2

to tens of m

2

(Pettine et al., 2012). The standard

deviation of the inherent noise from an electrode-

solution interface can be lower than 100fA. This

puts a limit on the amount of noise that analog

biosensor frontend circuitry can generate without

compromising sensitivity. The TIA design in this

paper focuses on achieving low input inferred noise

and low power consumption while meeting other

design requirements for electrochemical sensor

arrays.

Figure 3: Noise Standard Deviation vs. Electrode Area.

5 EXISTING TIA DESIGNS

TIAs have a wide range of applications from optical

communications to Micro-Electro-Mechanical

Systems (MEMS), to sensors. Therefore, design

requirements for TIAs cover a broad range from

GHz speed for optical communication systems, to

sub-MHz speed with low power for biosensors.

Different design requirements often result in

different circuit topologies and design trade-offs.

5.1 Conventional TIA Design

A typical transimpedance amplifier design consists

of an operational amplifier with a resistive feedback

path as shown in Figure 4. A compensation

capacitor, C

F

, is often added in parallel with the

resistor in the feedback path, to help improve

instability caused by the zero created by the resistor

(R) and the parasitic input capacitance (C

P

) from the

sensor electrode.

Assuming an infinitely high op-amp gain, the

DC Transimpedance gain can be calculated simply

as

V

ou

t

= -I

in

R (1)

While the design itself is simple, several

practical issues arise in implementation. The resistor

Figure 4: Simple Resistive Feedback TIA.

size, R, is a direct function of transimpedance gain.

With high transimpedance gain, the size of the

resistor quickly approaches the limits of on-die

components. Furthermore, the absolute accuracy of

on-die resistor values is not well controlled in

modern CMOS process.

In the resistor-based topology, the zero created

by the input capacitance and feedback resistor may

need to be cancelled with a feedback capacitor for

overall stability. In a biosensor system, the parasitic

capacitance level can vary from one electrode to the

next, and change depending on the medium in which

the electrodes are placed, making this a difficult

design problem in large electrode arrays.

Noise performance of the resistor-based design

may not be suitable for biosensing applications.

Assuming a linear resistance, the noise current in a

50M resistor at room temperature can be

calculated as

i

n

=

= 33.23fA/Hz

(2)

This noise floor doesn’t consider the additional

noise generated in the OTA, but rather the just the

noise in the feedback network itself. This noise floor

is considered higher than the acceptable level,

depending on the inherent noise level determined by

the electrode area and chemical reaction.

5.2 Novel Continuous Time TIA

Designs

One method of avoiding the large resistor needed for

high gain and high sensitive TIA design is the use of

a resistor T-network to generate a large effective

feedback resistance with smaller physical resistors.

This topology can be used to achieve both a high

transimpedance gain and low noise. (Sharma et al.,

2007). Although this topology requires significantly

less total resistance on chip than its equivalent

Designofa50MOTransimpedanceAmplifierwith0.98fa/vHzInputInferredNoiseina0.18µMCMOSTechnology

115

single-resistor counterpart, the overall size reduction

is often still not at the level required by designs of

highly integrated biosensor arrays.

An alternative TIA implementation employs the

use of an active current reducing circuit in place of

the resistor (Ferrari, et al., 2009). This type of design

can be used to emulate very high equivalent

resistances of hundreds of G with relatively high

linearity. This design implements the current

reducing circuit using a series of operational

amplifiers which can increase power consumption

while still maintaining a reasonable die area. This

increased level of power consumption may not be

suitable due to the stringent operating temperature

requirements of live tissue on our biosensor

applications. This design does manage to achieve an

extremely low input noise level.

Two other continuous time implementations

involve using an active load and ratio of capacitors

to generate high effective transimpedance gains

(Razavi, 2000; Salvia, 2009). These designs tend to

rely on extremely high impedance input biasing

circuits, which can consume large amounts of die

area. Despite this fact, this topology does tend to

produce respectable input noise specifications.

5.3 Switched-Capacitor TIA Designs

Since large resistors (several to tens of M’s) can

consume large amounts of die area and can be

inaccurate once fabricated, an alternative is to

replace the resistor with a “switched capacitor.” This

can be useful in larger scale voltage amplifiers, as

well as transimpedance amplifiers. Switched

capacitor implementations are also referred to as

charge integrating transimpedance amplifiers.

Special considerations such as charge injection and

switch noise minimization or cancellation must be

taken into account when using switching circuits

with high sensitivity current measurements.

Although switching can have undesirable effects

in high sensitivity transimpedance amplifiers, it can

be used to the designer’s advantage, providing a

means to effectively cancel undesired 1/f noise and

amplifier offset through correlated double sampling.

One such design uses a slow integrator,

integrating the input current onto a capacitor and

sampling the output voltage periodically (Tang et al.,

2012). Integrator designs eliminate the need for a

large capacitor, and allow for low noise

performance. This type of design has achieved spot

noise specifications as low as 25fA/Hz.

A reduced noise floor is one of the main

advantages of low-speed switched integrator

designs. Allowing the signal to integrate over an

extended period of time produces a reduction in

switching noise and charge injection, leading to the

potential for a lower overall input inferred noise

current.

6 PROPOSED TIA DESIGN

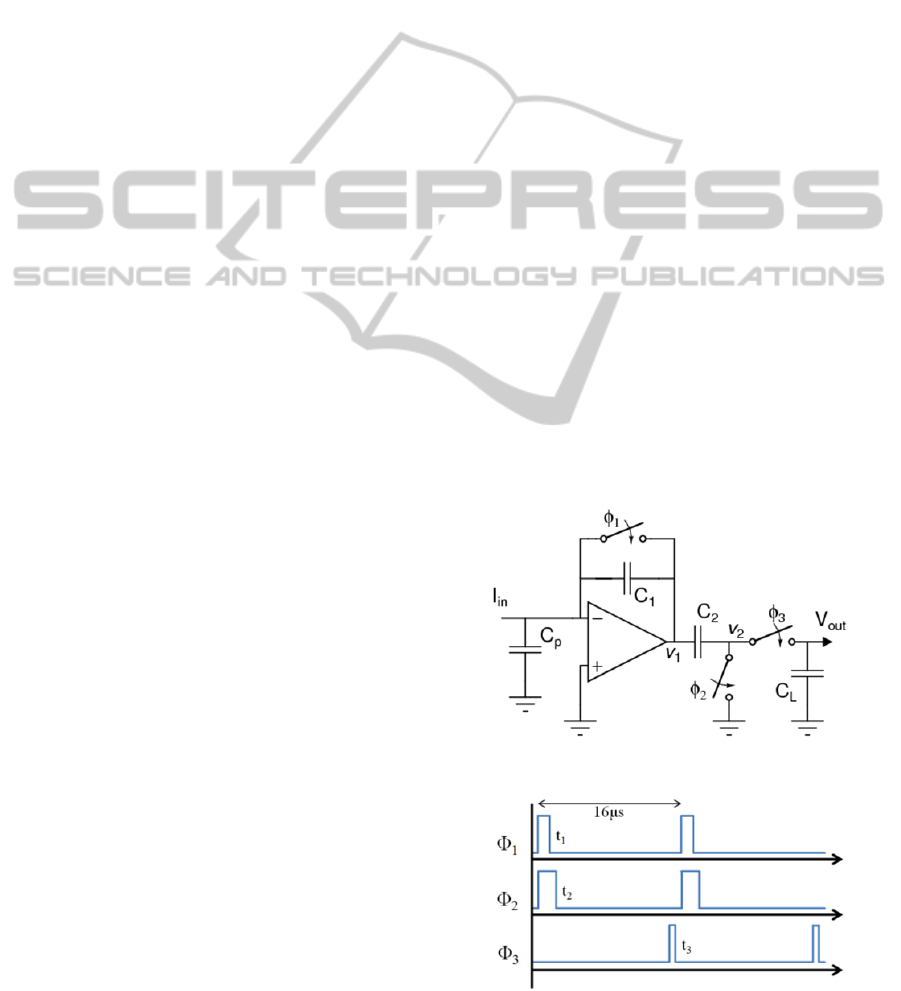

The proposed TIA design consists of a switched

capacitor transimpedance amplifier (SCTIA) design

with a dedicated three-phase clock scheme to

perform correlated double sampling. An optimized

Class-C inverter based operational amplifier is used

in a slow integrating switched capacitor topology.

The TIA topology is shown in Figure 5. Although

this circuit topology has been proposed before by

Tang et al. (Tang et al., 2012), our design uses an

optimized Class-C inverter based operational

transconductance amplifier (OTA) to further reduce

the input inferred noise. The optimized OTA

achieves improved noise performance as we

illustrate it in this section.

Clock phase timing is shown in Figure 6, and

example input response is shown in Figure 7. Basic

circuit operation is as follows: during

1

, the

charges on C

1

and C

2

are set to 0. During the time

that

1

is low, C

1

is charged with the input current.

The voltage V

1

changes with a slope proportional to

the magnitude of the input current. V

2

follows the

change in V

1

after

2

goes low.

Figure 5: Top level SCTIA schematic.

Figure 6: Clock Phase Timing.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

116

Figure 7: Example Input Response.

During

2

, the OTA offset as well as 1/f noise is

stored as a voltage V

err

on C

2

. At the end of

2

, the

opamp output is subtracted by v

err

, effectively

removing the low frequency noise and offset. At this

point, the voltage V

2

consists only the desired signal.

The switch controlled by

3

along with the circuit

load (next amplification stage, or output

capacitance) serves as a sample and hold, which

holds the output voltage until the end of the next

period. With t

2

and t

3

indicated in Figure 6, the TIA

output voltage at the end of each clock period can be

expressed as

1

(3)

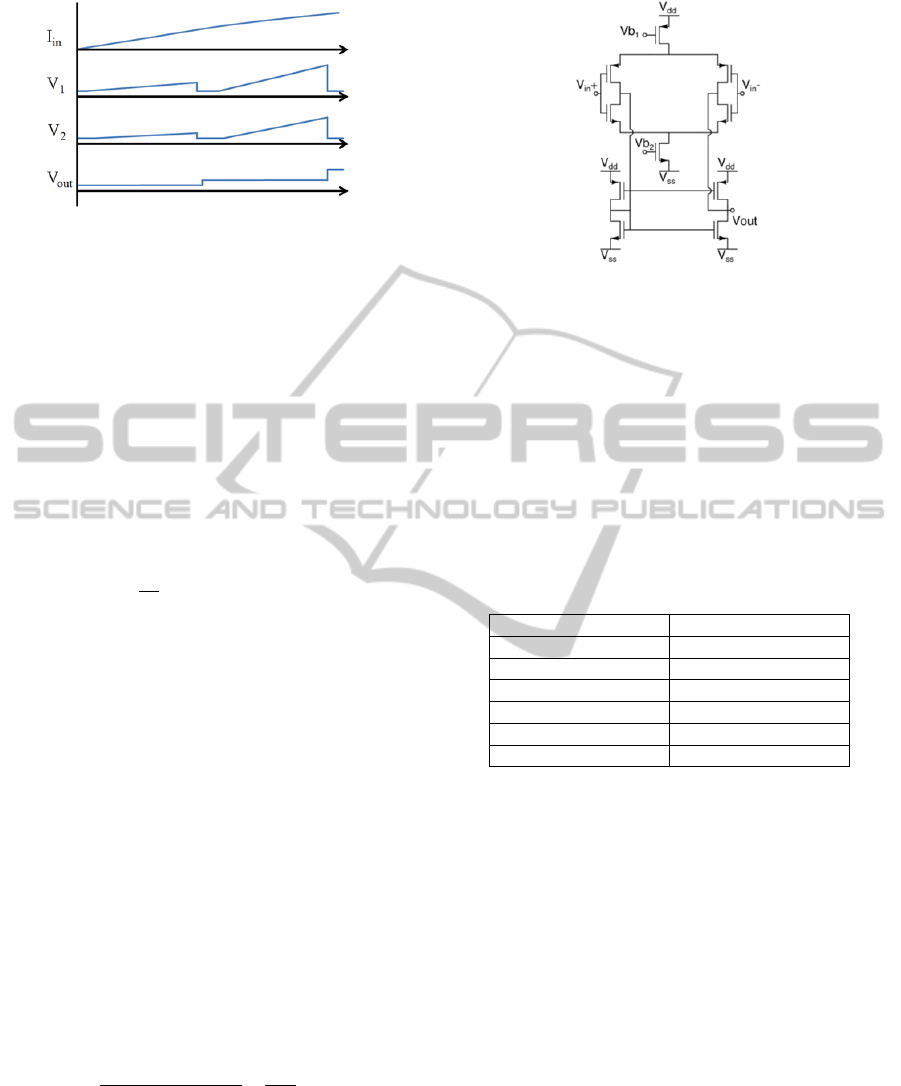

The Class-C inverter-based OTA topology is

shown in Figure 8 (Wilson, et al., 2013). To reduce

power consumption, the OTA is operated at 0.9V

supply voltage as opposed to the nominal 1.8V

supply voltage for the 0.18m CMOS process. Table

1 summarizes OTA performance. The enhanced

transconductance of the inverter-based OTA

topology allows greater stability and lower power

consumption without compromising its DC gain and

bandwidth.

The inverter-based topology uses both p and n-

type input transistors, effectively achieving double

the transconductance of a single input transistor

(Figueiredo et al., 2010). Assuming the p and n

transistors are balanced, and the equivalent noise

resistances for the n and p type transistors are R

Nn

,

and R

Np

, respectively, the equivalent noise resistance

for the inverter based amplifier is

2

(4)

Since the noise of the TIA is a function of both

OTA noise and feedback network noise (Wilson, et

al.), this lowered equivalent noise resistance leads to

a decreased overall noise.

Figure 8: Inverter-Based OTA Topology.

When designing the OTA, the load and input

inverters should be sized in such a way that

and

are balanced, and the output is biased at half the

supply voltage when the input is set to half the

supply voltage. The input transistors should be large

enough to sufficiently reduce voltage offset, and all

transistor pairs should be matched in layout. The tail

transistors should be used to control the current

through the input transistors and provide common

mode rejection.

Table 1: OTA Performance Specifications.

DC Gain 58.6dB

-3dB Bandwidth 22kHz

Unity Gain Freq. 10.2MHz

Power 8.06µW@0.9V

Phase Margin 53.06°

PSRR 50.4dB

Layout Area 75µm x 51.5µm

7 SIMULATION RESULTS AND

PERFORMANCE

COMPARISON

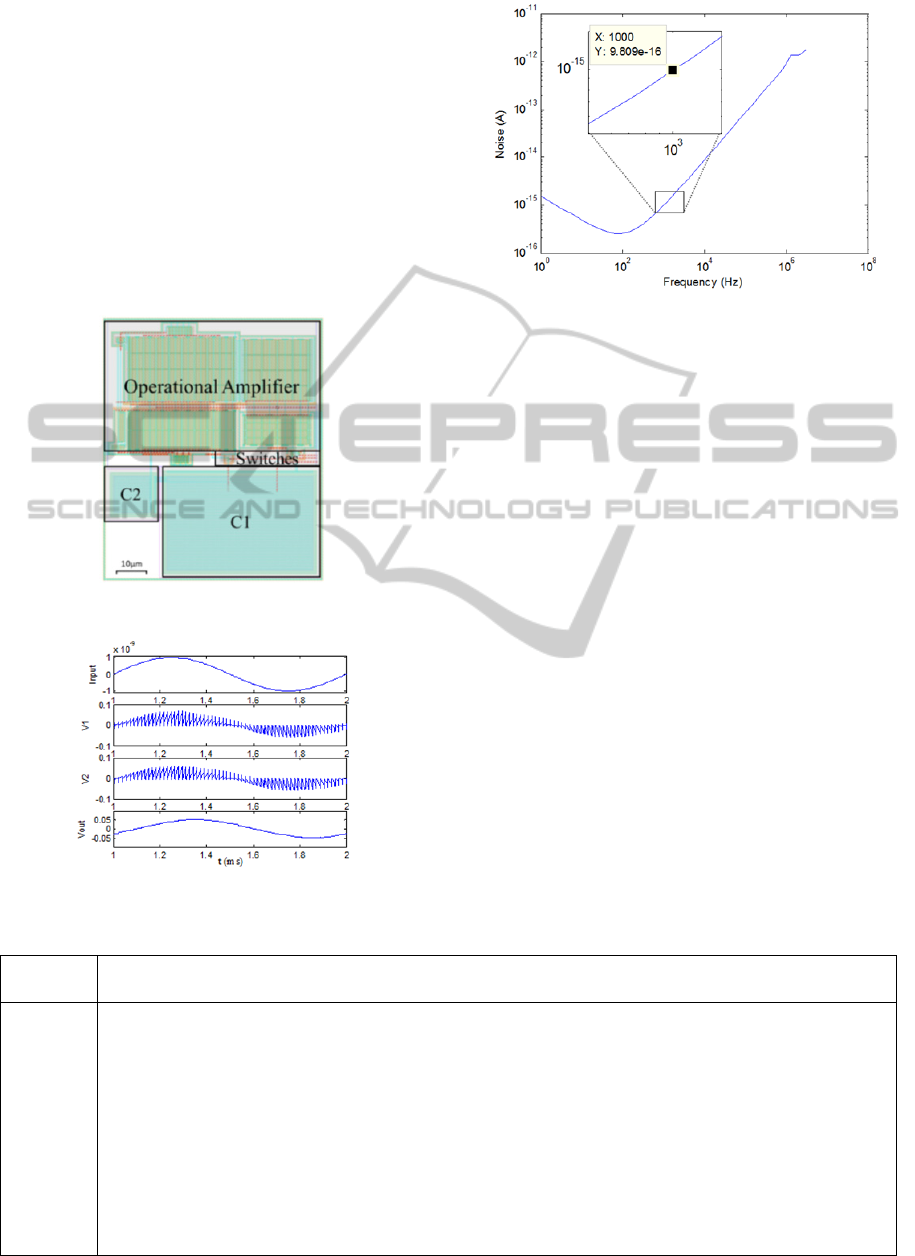

The proposed TIA circuit was implemented using a

commercial 0.18µm CMOS process. Figure 9 shows

the layout of the overall circuit, measuring 93.5µm

by 78.5µm. Figure 10 shows simulation of

sinusoidal current input on the layout extracted

netlist. The input current has a peak value of 1nA

with 1 kHz frequency. This signal magnitude and

frequency are derived by the maximum requirement

for amperometry signals from a number of chemical

compounds, including dopamine, norepinephrine,

and nitric oxide. The overall peak-to-peak output

voltage is approximately 100mV, showing a

transimpedance gain of 50M. A low power

consumption of 8.06µW is achieved by operating the

Designofa50MOTransimpedanceAmplifierwith0.98fa/vHzInputInferredNoiseina0.18µMCMOSTechnology

117

OTA deep in subthreshold. The power consumption

of the circuit is also greatly reduced by the use of a

low power supply voltage. The input inferred noise

(shown in Figure 11) was found using a periodic

steady state (PSS) analysis.

The circuit is run with a 62.5 kHz clock,

allowing ample time for input current integration.

Due to the high transimpedance gain and low power

supply, the circuit output voltage can begin to

saturate, causing a high level of distortion with a

current input of about 5nA.

The measured performance for the designs

discussed in this paper is included in Table 2.

Figure 9: Overall Layout of SCTIA Design.

Figure 10: Extracted Layout Simulation Results.

Figure 11: Input Inferred Noise vs. Frequency.

8 CONCLUSIONS

In this paper a low power switched capacitor

integrating transimpedance amplifier design was

presented. This design uses an optimized Class-C

inverter-based amplifier in a switched capacitor

topology to achieve a low noise floor. The

cancellation of errors due to 1/f noise and amplifier

offset through the use of correlated double sampling

also contributed to the overall low input inferred

noise. To our best knowledge, this design has the

best noise and power performance among TIAs

reported in literature so far.

ACKNOWLEDGEMENTS

The authors would like to thank NSF for their

financial support (DGE0841259). Generous

technical support and silicon fabrication by

Texas

Instruments is also greatly appreciated.

Table 2: CMOS Transimpedance Amplifier Performance Comparison.

Work Razavi Salvia Ferrari Tang Sharma Zand Balasubramanian

This Work

(Simulation)

Power

30mW@3

V

436µW@

1.8V

45mW@3

V

3.2mW 400µW 30mW@3V

90µW@

1.8V

8.06µW@

0.9V

Gain

8.7k 56M 60M 88M

up to

25M

33k 150K - 550K

50M

Spot Noise

n/a

65fA/

Hz

4fA/

Hz

25fA/

Hz

88fA/

Hz @

1.6M

n/a n/a

981aA/

Hz @ 1kHz

Avg. Noise

4.5pA/H

z

n/a n/a n/a n/a

6.8pA/

Hz

1.6pA/Hz

1.08pA/Hz

Area

n/a n/a n/a n/a n/a

300µm x

155µm

n/a

93.5µm x 78.5µm

Process

0.6µm 0.18µm 0.35µm 0.35µm 0.6µm 0.35µm 0.18µm

0.18µm

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

118

REFERENCES

Agah, A., Hassibi, A., Plummer, J., Griffin, P., 2005.

Design requirements for integrated biosensor arrays.

In Proc. SPIE 5699, Imaging, Manipulation, and

Analysis of Biomolecules and Cells: Fundamentals

and Applications III.

Balasubramanian, V., Ruedi, P.-F., Temiz, Y., Ferretti,

A., Guiducci, C., Enz, C.C., 2013. A 0.18

mbiosensor front-end based on 1/f noise, distortion

cancelation and chopper stabilization techniques. In

Biomedical Circuits and Systems, IEEE

Transactions on, vol.PP, no.99, pp.1,14.

Ferrari, G., Gozzini, F., Molari, A., Sampietro, M., 2009.

Transimpedance Amplifier for High Sensitivity

Current Measurements on Nanodevices. In Solid-

State Circuits, IEEE Journal of, vol.44, no.5,

pp.1609,1616.

Figueiredo, M., Santin, E., Goes,J., Santos-Tavares, R.,

Evans, G., 2010. Two-stage fully-differential

inverter-based self-biased CMOS amplifier with

high efficiency. In Circuits and Systems (ISCAS),

Proceedings of 2010 IEEE International Symposium

on , vol., no., pp.2828-2831, May 30 2010-June 2

2010.

Hassibi, A., Vikalo, H., Hajimiri, A., 2007. On Noise

Processes and Limits of Performance in Biosensors.

In Journal of Applied Physics, vol. 102, issue 1,

2007.

Henze, D. A., Borhegyi, Z., Csicvari, J., Mamiya, A.,

Harris, K. D., Buzsáki, G., 2000. Intracellular

Features Predicted by Extracellular Recordings in

the Hippocampus in Vivo. In Journal of

Neurophysiology, Jul. 2000, pp. 390-400.

Kinget, Peter R., 2005. Device Mismatch and Tradeoffs

in the Design of Analog Circuits. In IEEE JSSC,

Vol. 40, No. 6, June 2005.

Liao, Y., et al., 2012. A 3-µW CMOS Glucose Sensor

for Wireless Contact-Lens Tear Glucose Monitoring.

In IEEE JSSC, Vol. 47, No. 1, Jan. 2012.

Niwa, O., et al. 1998. Small-Volume On-Line Sensor for

Continuous Measurement of -Aminobutyric Acid.

In Analytical Chemistry, 1998, 70, 89-93.

Pettine, W., Jibson, M., Chen, T. Tobet, S., Henry, C.,

2012. Charaterization of novel microelectrode

geometries for detection of neurotransmitters. In

IEEE Sensors Journal, Vol.12, No. 5, May, 2012.

Pihel, K., et al., 1996. Overoxidized Polypyrrole-Coated

Carbon Fiber Microelectrodes for Dopamine

Measurements with Fast-Scan Cyclic Voltammetry.

In Anal. Chem. 1996, 68, pp. 2084-2089.

Qi, P., et al., 2003. Toward Large Arrays of Multiplex

Functionalized Carbon Nanotube Sensors for Highly

Sensitive and Selective Molecular Detection. In

Nano Lett, 2003, No. 2. 2003.

Razavi, B., 2000. A 622 Mb/s 4.5 pA//spl radic/Hz

CMOS transimpedance amplifier [for optical

receiver front-end]. In Solid-State Circuits

Conference, 2000. Digest of Technical Papers.

ISSCC. 2000 IEEE International , vol., no.,

pp.162,163, 9-9 Feb. 2000.

Rosenstein, J., Sorgenfrei, S., Shepard, K.L., 2011.

Noise and bandwidth performance of single-

molecule biosensors. In Custom Integrated Circuits

Confer

ence (CICC), 2011 IEEE , vol., no., pp.1,7,

19-21 Sept. 2011.

Salvia, J., Lajevardi, P., Hekmat, M., Murmann, B.,

2009. A 56M CMOS TIA for MEMS applications.

In Custom Integrated Circuits Conference, 2009.

CICC '09. IEEE , vol., no., pp.199,202, 13-16 Sept.

2009.

Sharma, A., Zaman, M.F., Ayazi, F., 2007. A 104-dB

Dynamic Range Transimpedance-Based CMOS

ASIC for Tuning Fork Microgyroscopes. In Solid-

State Circuits, IEEE Journal of , vol.42, no.8,

pp.1790,1802, Aug. 2007.

Starkey, S., et al., 2001. A rapid and transient synthesis

of nitric oxide (NO) by a constitutively expressed

type II NO synthase in the guinea-pig

suprachiasmatic nucleus. In British Journal of

Pharmacology (2001) 134, 1084-1092.

Tang,Y., Zhang, Y., Fedder, G.K., Carley, L.R., 2012.

An ultra-low noise Switched Capacitor

Transimpedance Amplifier for parallel Scanning

Tunneling Microscopy. In Sensors, 2012 IEEE , vol.,

no., pp.1,4, 28-31 Oct. 2012.

Toumazou, C., et al., 2002 Tradeoffs in Analog Circuit

Design. Springer, 2002.

Villagrasa, J.P., Colomer-Farrarons, J., Miribel P.L.,

2013. Bioelectronics for Amperometric Biosensors,

State of the Art in Biosensors - General Aspects, Dr.

Toonika Rinken (Ed.), ISBN: 978-953-51-1004-0,

InTech.

Wilson, W., Chen, T., Selby, R., 2013. A current-starved

inverter-based differential amplifier design for ultra-

low power applications. In Circuits and Systems

(LASCAS), 2013 IEEE Fourth Latin American

Symposium on, vol., no., pp.1,4, Feb. 27-March 1,

2013.

Wightman, R Mark, 2006. Probing Cellular Chemistry

in Biological Systems with Microelectrodes. In

Science, 17 March 2006, Vol. 311.

Xu, C., Lemon, W., and Lui, C., 2002. Design and

Fabrication of a High Density Metal Microelectrode

Array for Neural Recording. In Sensors and

Actuators, Vol. A 96, Issue. 1. pp. 78-85, Jan. 2002.

Yao, J., Gillis, K., 2012. Quantification of Noise Sources

for Amperometric Measurement of Quantal

Exocytosis Using Microelectrodes. In Analyst, vol.

137, issue 11, pp.2674-2681. ROYAL SOCIETY OF

CHEMISTRY.

Zand, B., Phang, K., Johns, D.A., 2001. A

transimpedance amplifier with DC-coupled

differential photodiode current sensing for wireless

optical communications. In Custom Integrated

Circuits, 2001, IEEE Conference on. , vol., no.,

pp.455,458, 2001.

Designofa50MOTransimpedanceAmplifierwith0.98fa/vHzInputInferredNoiseina0.18µMCMOSTechnology

119