Designing CAx-process Chains

Model and Modeling Language for CAx-Process Chain Methodology

Pascal Schug and Alexandr Kotlov

Fraunhofer Institute of Production Technology IPT, RWTH Aachen University, Steinbachstraße 17, Aachen, Germany

Keywords: CAx, Process, Chain, Model, DSL.

Abstract: Product development and production processes are supported by software systems during the development

and planning phases. The usage of these software tools during or prior to and post the different process steps

is called CAx-processes. The combination of these CAx-processes form process chains, also known as

CAx-process chains (CAx-PCs), which mirror the production processes virtually. The content of this paper

introduces a solution for designing the software chains in conformity to the methodology for evaluation,

analysis and optimization of CAx-PCs. The solution includes the definition of DSL expressing the model

for CAx-PCs and the software prototype “CAx-process chain designer” for deriving the alternatives of

CAx-PCs from the expressed model.

1 INTRODUCTION

Typically, product development starts with a

conceptual idea and ends up as a final product.

However, the path between the conceptual idea and

the final product is complex because of the several

obstacles such as product complexity, manufacturing

technology constraints as well as the time and

resource limits. Therefore, the problem of the

increasing complexity of products was addressed by

various computer aided technologies also known as

CAx-technologies.

CAx-technologies mirror the traditional and

general product development. According to Werner

Dankwort’s paper (Werner Dankwort, 2004),

product development consists of three main phases:

creative, conceptual and engineering phase. These

phases are supported by different information

systems. Usually, these information systems are

called CAx-systems. CAx is an umbrella term for

computer aided processes and systems and their

respective technologies. For instance, CAD stands

for computer aided design and CAM for computer

aided manufacturing. In addition, different

simulation software systems are involved in product

development. As a result, CAx-technologies offer

advantages such as reduced expenses, resources and

time. This is caused by a virtual representation of

processes within the product life cycle, which allows

a quick and simple detection of deviations and errors

within processes. The implementation of CAx-

technologies is one of the factors that helps to

decrease the necessary time and costs of iterations in

the development, planning and optimizing phases.

(Brecher, 2006)

Hence, the deployment of CAx-based product

development is especially suitable in the case of

complex products and processes. This induces

companies to use a variety of specialized software

systems before and during the production.

1.1 CAx-process Chains

The CAx-based production includes many virtual

processes during the product life cycle phases,

which form a CAx-process chain (CAx-PC)

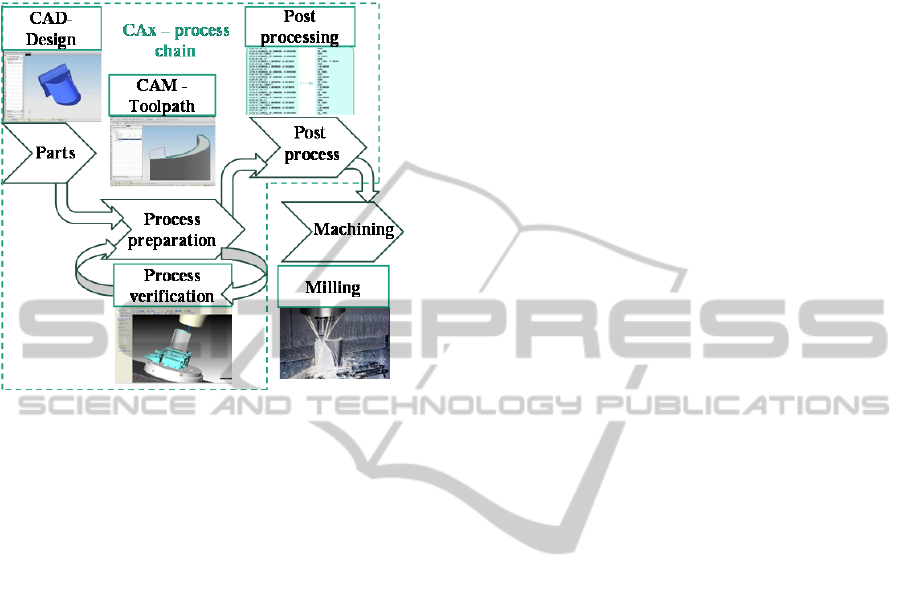

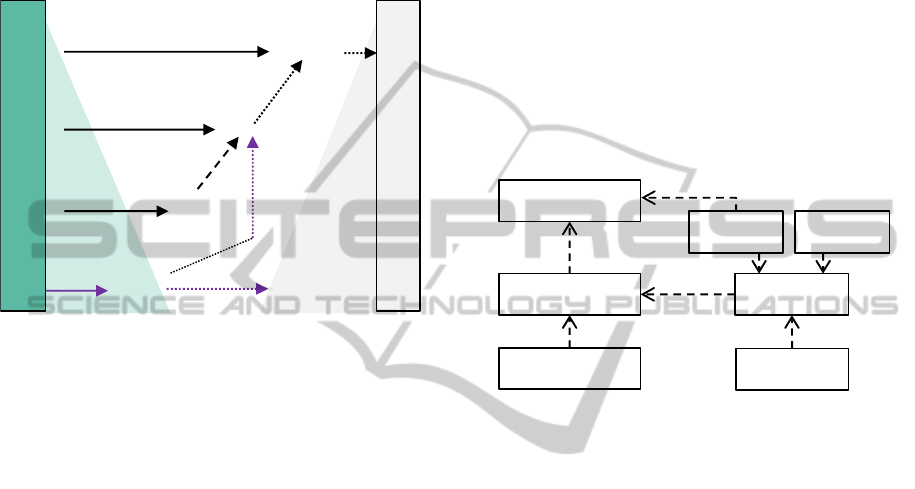

(Bullinger, 2008). A simplified case of a CAx-PC

for turbine blade production is illustrated in

Figure 1. The CAx-process chain starts with

designing of the turbine blade in CAD tools. This

CAD model is transferred to the process preparation

software which includes manufacturing and

verification tools (CAM). CAM tools create

toolpaths based on component geometry for milling,

which are represented in machine independent NC-

Code. Afterwards these toolpaths are verified by

various software tools with different analysis

focuses. The NC-Code is transfered to NC-Programs

for specific machines within the post processing

step. Finally, these specified NC-Programs are

724

Schug P. and Kotlov A..

Designing CAx-process Chains - Model and Modeling Language for CAx-Process Chain Methodology.

DOI: 10.5220/0005054507240733

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 724-733

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

interpreted by the machine control as actual physical

movements of machine tools. This example

illustrates a trivial case of deployment of CAx-

technologies in production.

Figure 1: CAx-process chain, adapted from (Minoufekr,

2013).

When CAx-processes are combined to one process

chain, gaps between the process steps and systems

occur. These gaps among other factors hinder the

necessary information for establishing a robust

process chain. (Brecher, 2006).

In order to establish a robust process chain, a

methodology is introduced to capture the CAx-PCs

(Schug, 2014). This methodology offers solutions

for deriving an optimized process chain by creating

alternatives for the existing process chain. Due to the

specific nature of the CAx-PC evaluation, analysis

and optimization methodology (CAx-PC

methodology), a suitable implementation is needed.

This paper presents the CAx-PC methodology

and it’s corresponding implementation. This

involves the development of a software application

and a model to design CAx-PCs according to the

methodology.

2 BACKGROUND

This section discusses the methodology for

capturing CAx-PCs. According to this methodology,

the software requirements for a software application

designing CAx-PCs are derived.

2.1 Capturing CAx-process Chain

For data tranfer between different software systems,

suitable interfaces need to be defined, which tranfer

all necessary information between the systems. An

interface in this case is the connection between

software which defines and guarantees combination

ability (Ludewig, 2007). Most of the information

losses can be found and fixed at the data level.

(Klocke, 2004)

Because of the individual combination of

different CAx-tools for each process a complete data

transfer via interfaces is not always guaranteed.

Different data formats or software settings and

requirements are the reason for the loss of data and a

main problem within the CAx-PC. During the data

transfer between systems a number of irreversable

conversions take place, such as the loss of tolerances

or dependencies, which hinder a continuous data

flow (Brecher, 2006). For example, information loss

may occur during the data exchange between

different CAD systems which use diverse data

formats to represent parts. Even neutral data formats

like STEP (Standard for the exchange of product

model data) do not transfer all the needed

manufacturing information (Sääski, 2005).

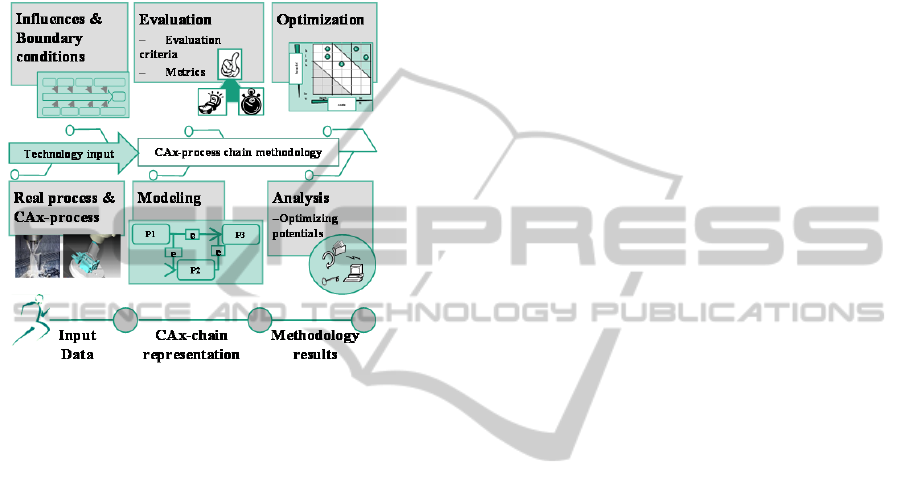

The CAx-PC methodology captures the current

state of the CAx-PCs which represents the CAx-PCs

during the various phases of the manufacturing

process. It is also extended by a metric based

approach for calculating different evaluation criteria,

which are used to evaluate the entire process chain.

Therefore, different process types are defined and

represented by their individual process

characteristics. For example, a CAD-process has

characteristics such as evaluation criteria (duration,

cost, quality, resource efficiancy), or other

characteristics that describe the process such as

interface definitions, software information or input

and output information. The CAx-processes are

connected by data flows. Each CAx-process has

CAx-products as outputs. In case of a CAD-process,

the product has specialized characteristics such as

geometry, file structure or additional information of

the CAD-model. Within the metrics, these different

characteristics and the related values are used for the

evaluation criteria such as costs, time, quality, and

resource efficiency of the processes and the process

chain. The customized weighting of these criteria

enables the methodology to react on the changing

requirements or boundary conditions in the CAx-PC.

Based on the captured state of the CAx-PC an

additional analysis of the process chain takes place.

This analysis considers the processes as well as the

DesigningCAx-processChains-ModelandModelingLanguageforCAx-ProcessChainMethodology

725

overall CAx-process chain. The analysis operates on

the captured characteristics and the values via

metrics that calculate the evaluation criteria of each

process as well as the entire process chain. During

this analysis phase, optimization potentials within

the CAx-PC are categorized into potentials which

are related to software, interfaces, organization,

strategy and non-standard processes.

Figure 2: CAx-PC methodology (Schug, 2014).

The optimization potential depends on the occurring

conflicts within the chain and the possible outcome

of using alternative processes or process chains.

Based on this categorization and on the evaluation,

the optimization steps are derived.

This methodology is pictured in Figure 2.

Boundary conditions and influences are company

preferences which depend on the existing real

processes and the CAx-processes such as time and

cost demands as well as fixed conditions such as

installed machines or software systems. This

information is used as an input for the methodology

during analysis. As a result of this methodology,

opitmizing potentials can be identified and selected

based on a Cost-Benefit analysis.

2.2 Software Requirements

To utilize the methodology, a software application

(tool) is needed for designing CAx-PCs. For this,

software requirements are established which capture

the essence of the methodology.

According to Wiegers, well defined requirements

provide the foundation for quality software

(Wiegers, 2000). To ensure that, Wiegers describes

ten requirement traps and the solutions to avoid

these traps. In this description, three levels of

requirements are offered. The top level contains

business requirements which represent high-level

objectives of organizations or required systems or

products. The second level deals with user

requirements. The final third level includes specific

software functional requirements which are derived

from the use cases and describe specific software

behaviors. The functional and nonfunctional

requirements form the software requirements

specification. Based on these notions and the

methodology, the software requirements are defined

for the tool that designs CAx-PCs.

In our case, the business requirement states that a

tool is required for designing CAx-process chains

according to the methodology. With such tool, the

user, who is a CAx-expert, is able to derive an

optimized process chain by designing alternatives of

process chain. The tool has several user

requirements which derive respective functional

requirements from the usage scenarios or use cases.

The first usage scenario states the user must be

able to design CAx-PCs with the tool. This produces

the first functional requirement that claims that the

tool has to scheme the chains by drawing,

manipulating and editing the CAx-processes within

the designed process chains.

According to the second usage scenario, the user

must perform the evaluation of designed process

chains with the software application. Therefore, the

second functional requirement is calculation, which

implies that the tool has to implement calculations of

the process data to estimate the evaluation criteria

such as costs, time, quality and resource efficiency

of the CAx-PCs. Based on the evaluation criteria,

additional metrics for calculating the process related

characteristics provide an evaluation of the entire

process chain.

The last usage scenario states that the user must

locate optimization potentials within the process

chains. Thus, the third functional requirement is

process analysis, which according to the

methodology, implies that process chains have to be

analyzed for optimization potentials based on

different categories. Also, they have to be compared

with alternative process chains. Therefore, the third

functional requirement claims that the tool has to

compare and analyze processes within the process

chains to identify optimization potentials. Feedback

is the last functional requirement which implies that

the tool has to notify the user about changes of

optimization potentials within the designed process.

To recapitulate, the following software requirements

for the tool designing CAx-PCs have to be applied:

Scheme chains: the tool has to plan the chains

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

726

by drawing, manipulating and editing the

CAx-processes within the designed process

chains;

Calculation: the tool has to implement

calculations of the process data to estimate the

evaluation criteria;

Process analysis: the tool has to compare and

analyze the processes within the process

chains to identify the optimization potentials;

Feedback: the tool has to notify the user

about the changes of the optimization

potentials within the designed process chains.

In practice, there exist several diagramming

tools, which can be considered for designing process

chains. Therefore, we will review some existing

tools in the following section.

2.3 Existing Tools

CAx-experts use various tools to capture process

chains. This section reviews existing tools which

could be used to design process chains. Previously,

software requirements for the tool designing CAx-

PCs were discussed. These software requirements

will be used as comparison criteria to identify an

appropriate tool for designing CAx-PCs according to

the introduced methodology. The comparison

criteria include calculation, process analysis and

feedback. The functional requirement “Scheme

chains” is excluded from the comparison criteria.

Because all reviewing tools are capable to scheme

the chains by drawing, manipulating and editing the

CAx-processes within the designed process chains.

Table 1: Overview of tools.

Tool

Functional requirements

Calcu-

lation

Process

analysis

Feedback

Visual Paradigm

(visual-paradigm.com)

not

explicit

yes,

manual

no

MS Visio

(office.microsoft.com)

not

explicit

yes,

manual

no

Aixperanto

(wzl.rwth-aachen.de)

not

explicit

yes,

manual

no

Activiti

(activiti.org)

no

yes with

reports

no

ARIS Express

(activiti.org)

no yes no

ADONIS

(boc-group.com)

yes yes no

MagicDraw

(nomagic.com)

no yes no

Umodel

(altova.com)

no

not

explicit

no

Table 1 provides examples of several diagramming

and modeling tools and shows how the different

requirements are fulfilled in regard to the CAx-PC

methodology. The demonstrated tools in Table 1

satisfy some functional requirements for designing

CAx-PCs according to the introduced methodology.

As indicated in Table 1, all tools lack feedback.

Besides, only half of the tools are able to implement

calculations with the process data, and the majority

depends on the external tools. Hence, an alternative

tool needs to be developed to satisfy the software

requirements. The first prototype of an alternative

tool will be introduced in the following section 4.2

“CAx-process chain designer”.

For the realization of the tool, a model driven

engineering approach is applied. Thus, a model for

CAx-PCs has to be developed, before implementing

the tool.

2.4 Model Driven Engineering

Model Driven Engineering (MDE) is an approach in

software development. MDE provides an abstract

way to hide the complexity of software by using

models. The core of MDE is a model, which eases

the understanding, specification and maintenance of

complex systems (Hutchinson, 2011).

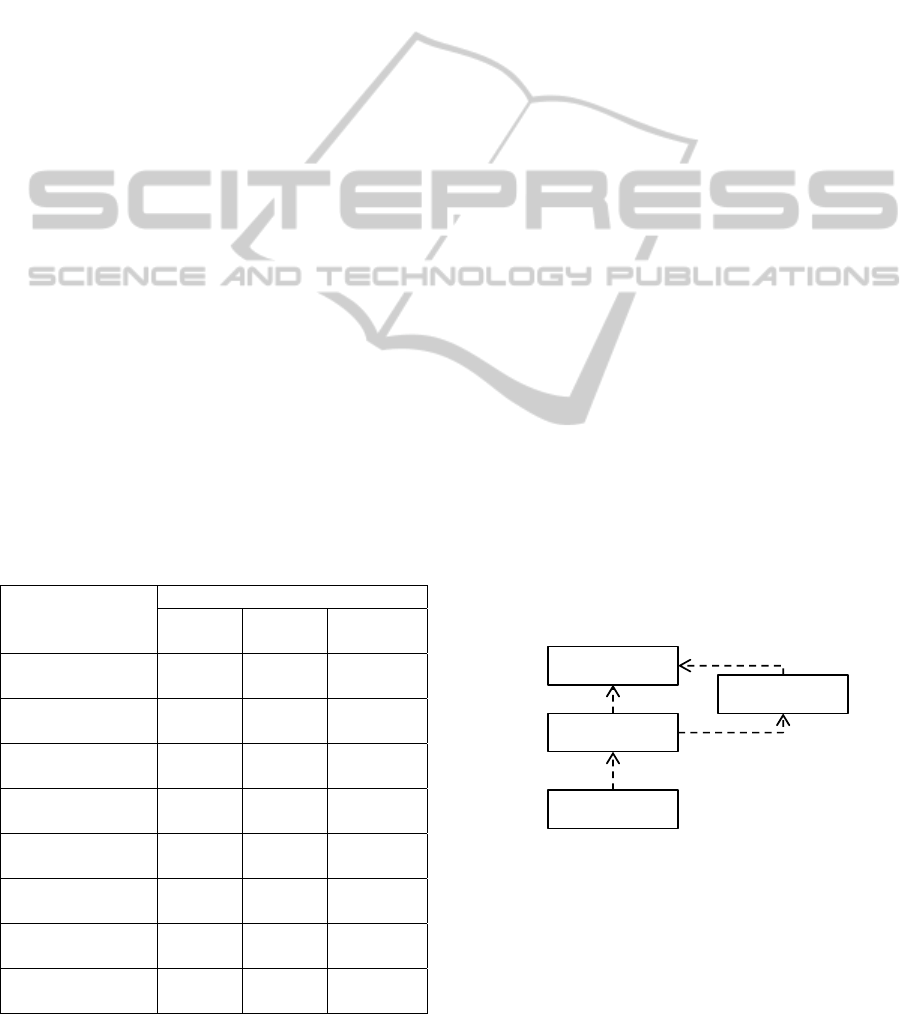

Bézivin describes relations between a system and

a model in the basic notations of MDE as

demonstrated in Figure 3. According to this

description, a system can be represented by a model.

This system itself conforms to a metamodel and is

expressed by a modeling language (Bézivin, 2005).

Based on these notations, it is possible to identify

key elements such as system, model, metamodel and

modeling language, which are used to obtain the

model for CAx-PCs.

Figure 3: Basic notations, adapted from (Bézivin, 2005).

In the case under consideration, a model for CAx-

PCs will be used as a basis for designing CAx-PC

alternatives for further iterative analyses and

optimization steps.The system that has to be

modeled is CAx-PCs. Additionally, other elements

of the basic notations such as model, metamodel and

conforms to

System

Model

Metamodel

Modeling

language

represented by

represented by

conforms to

DesigningCAx-processChains-ModelandModelingLanguageforCAx-ProcessChainMethodology

727

modeling language need to be defined.

3 RESEARCH AREA

In order to obtain a model for CAx-PCs, the

definition of a metamodel is needed. This section

addresses questions to CAx-PC modeling and

describes solutions for the metamodel and modeling

language.

3.1 Problem Definition and Research

Questions

The implementation of the CAx-PC methodology

requires a development of a software application.

The MDE approach is applied to realize the software

application for designing CAx-PCs. This approach

requires a model for CAx-PCs. The definition of a

model includes the definition of a metamodel and a

modeling languge. In order to model CAx-PCs, the

following steps have to be fulfilled.

Firstly, the model for CAx-PCs has to be

specified.

Secondly, entities and relationships of CAx-PCs

have to be defined in a respective metamodel.

Lastly, the modeling language which expresses

the model needs to be defined.

The following section will describe these steps.

3.2 CAx-process Chain Modeling

In the case under consideration, the purpose of the

modeling is evaluation and analysis of CAx-PCs

according to the CAx-PC methodology. Therefore,

the CAx-PC methodology has to be analyzed to

obtain the necessary information for the definition of

the metamodel and the modeling language.

This section describes the essential concepts for

modeling (section 3.2.1) as well as the metamodel

for CAx-PCs (section 3.2.2) and the modeling

languages (section 3.2.3). A CAx-PC modeling

language will be introduced in (section 3.2.4).

3.2.1 Concepts

To specify the model, the CAx-PC methodology

needs to be taken into account (Schug, 2014).

According to the methodology, a state of the

CAx-PCs has to include technological, evaluative

and analytical information not only for each process

but also for the whole chain. In addition, the

methodology offers structual information for the

CAx-PCs. Based on this information, CAx-PC

definitions are identified as following:

CAx-PC: The CAx-PC unites the CAx-processes

by the data flows which exchange technological

information. In terms of graphs notation, the

processes and data flows are represented by the

nodes and edges.

CAx-process: Each CAx-process has several

individual characteristics depending on the process

type. These characteristics include technical process-

related requirements and attributes for the evaluation

and analysis steps. The process-related requirements

describe for example, interface definitions, software

information or input and output information. The

attributes reflect the evaluation criteria, optimization

potentials and process description. In addition, each

CAx-process produces and consumes CAx-products.

CAx-product: The process type dictates the

characteristics of the CAx-product which are

attributes for the evaluation and product-related

requirements that include the information about the

product which represents the produced output during

a process.

Evaluation step: The evaluation is applied on

the individual processes by calculating different

evaluation criteria such as duration, cost, quality,

and resource efficiency. These evaluation criteria

provide an evaluation of the entire process chain.

Analysis step: The analysis is applied on the

entire CAx-process chain. In this step, the

optimizing potentials are identified as occurring

conflicts within the chain which are related to

software, interfaces, organization, strategy and non-

standard processes.

Optimization step: Based on the information

from the evaluation and analysis steps, the

optimization of CAx-process chains is possible by

designing alternative process chains.

These CAx-process chain definitions specify the

information which has to be represented in the

model.

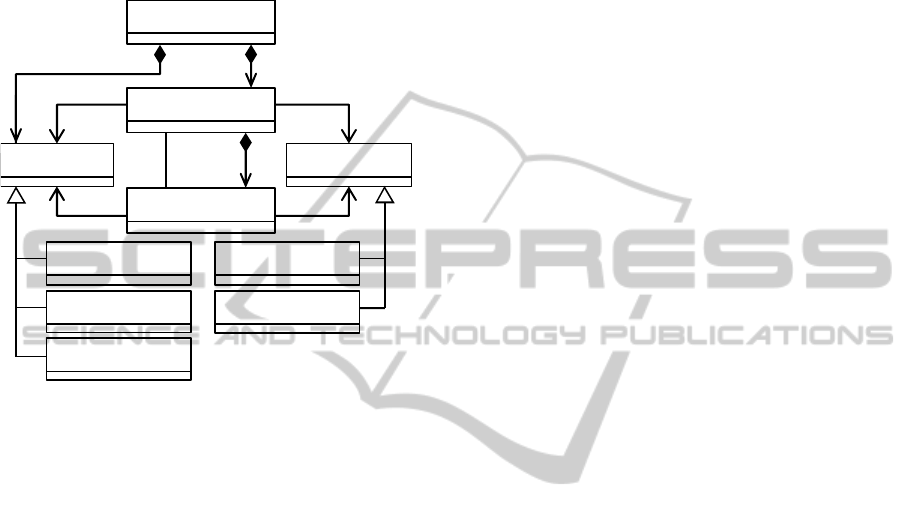

3.2.2 Metamodel

Based on the obtained information from CAx-PC

definitions, it is possible to identify what has to be

represented by the metamodel. In general, the

metamodel describes entities and relations of a

domain. A metamodel, applied to the system, yields

a model of the system (Bézivin, 2005). Thus, the

metamodel is a basis for the model and modeling

language. Figure 5 illustrates the metamodel for

CAx-PCs. Several entities are identified in this

metamodel such as process, product, attribute and

requirement. A process chain might contain many

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

728

processes and attributes. Besides, each individual

process has many attributes and requirements.

Moreover, each process contains products which are

related to the processes as inputs or outputs. The

requirements can be broadly classified into two

classes i.e. process-related and product-related

requirements.

Figure 5: Metamodel.

The attributes are general, evaluative and analytical

attributes which are necessary for the evaluation and

analysis of process chains.

This metamodel provides definitions for the

modeling languages which expresses the model for

CAx-PCs.

3.2.3 Modeling Language

In order to express the model for CAx-PCs, a

modeling language has to be utilized. For this, it is

necessary to select or define a modeling language to

express the metamodel. Modeling languages are

divided into general-purpose languages (GPL) and

domain-specific languages (DSL).

An example of GPL is Unified Modeling

Language (UML) that is used for general and broad

modeling (OMG, 2005). The notations of UML such

as classes, associations and relations are used for the

description of metamodels. For example, the

metamodel for CAx-PCs in Figure 5 is expressed by

such notations.

DSL is used for domain specific modeling. One

definition of DSL is given in the book about

domain-specific languages by Martin Fowler

(Fowler, 2010). The definition states “Domain-

specific language (noun): a computer programming

language of limited expressiveness focused on a

particular domain”. Further, the author claims that

the basic idea of DSL is to target a particular aspect

or kind of problem in the domain. In the case under

consideration, the problem in the domain is the

modeling of CAx-process chains in conformity with

the methodology. According to Fowler (Fowler,

2008), the DSLs have two main forms such as the

external and internal (embedded). The internal DSLs

are based on the host languages. They use the host

languages in specific ways which resemble some

form of application programming interfaces (APIs).

As per Fowler, the programming languages such as

Ruby, Java and C# are examples of internal DSLs.

Another form of DSLs is the external which has its

own syntax and requires an parser to process such

external DSLs. The examples of the external DSLs

are XML configurations, CSS, Regular Expressions

and domain specific modeling languages (DSMLs).

In order to define modeling language, a couple of

assumptions have to be considered in conformity

with the methodology.

The first assumption is that the model must be

specific. This implies that the model must take into

account the context of CAx-PCs. This includes data

flow of the process steps in the corresponding CAx-

PCs based on information such as CAD data, NC

Programs or analysis data. For example, the CAD-

process contains many part design parameters. These

parameters include many attributes and requirements

such as information regarding the part geometry,

color, physical properties, manufacturing etc

(Feldhusen, 2013). Consequentially, the modeling

language expressing the model should be specific to

these kinds of contexts within the CAx-PC. The

GPL such as UML or UML-based Business Process

Model and Notation (OMG, 2011) can express

various domians. This implies that such languages

are not specific to the domain of CAx-process chain

methodology. As for the DSLs, the definition of

DSL indicates that a DSL is specific to the

respective domain. Therefore, a DSL for modeling

of CAx-PCs will be devoted only to the domain of

CAx-PC methodology.

The second assumption is the level of abstraction

between the problem domain and solution domain.

On one hand, the modeling language should be

abstract from the complexities of the software

application. On the other hand, the model expressed

by the modeling language should be easily

integrated into the software application which will

used to derive CAx-PC alternatives from the model.

In his work, Jackson describes the differences

between the domain idea and the program code. He

concludes that each aspect has different experts,

input 0..*

0..* output

0..*

Chain

Process

Product

1..*

*

Requirement

General Process-related

Evaluative Product-related

Analytical

Attribute

0..*

0..*

0..*

1..*

DesigningCAx-processChains-ModelandModelingLanguageforCAx-ProcessChainMethodology

729

ways of thinking and languages for the domain

description (Jackson, 1995). As a result, the domain

idea is interpreted several times. Kelly S. et al.

explain the transition of the domain idea to the

finished product in domain-specific modeling

(Kelly, 2000). The Figure 6 illustrates the possible

bridges from the problem (domain idea) to the

solution (a finished product or software application).

Figure 6: Moving from the problem domain to solution

domain, adapted from (Kelly, 2000).

In the domain specific modeling, a domain model

does not require mapping of the problem because the

solution for the problem is expressed by respective

DSL that uses the problem domain terms. This raises

the level of abstraction and narrows the abstraction

gap between the problem domain and the solution

domain. In comparison, a model expressed by GPL

such as UML requires, solving of the problem in the

domain terms first and then mapping the solution to

the model. Still, the domain model expressed by

DSL requires generation of code or reuse of existing

components. However, the generation of code is a

tedious task. Fortunally, this can be done with the

help of tools for DSL definition which will be

discussed in the section 4 “Implementation”.

As discussed above, a DSL offers benefits such

as a higher abstraction and usage of domain

concepts. These benefits provide the advantages in

the quality of the model by involving the domain

experts in the communication with the actual domain

model in their language. Kosar et al. conducted the

empirical study to compare GPLs and DSLs. The

results of the study proves the advantages and

superiority of DSLs over GPLs in the cognitive

dimensions such as closeness of mappings,

diffuseness, error-proneness, role-expressiveness,

and viscosity (Kosar, 2010).

Based on this, a DSL will be used for expressing

the model for CAx-PC. Therefore, a DSL for CAx-

PCs must be defined.

3.2.4 CAx-process Chains Modeling

Language

Fowler provides guidelines for the definition of a

new DSL (Fowler, 2005). The first step is to define

abstract syntax which is a scheme of abstract

representations. The next step is to define editing

environments for the language. The last step is to

define semantics for the language by defining a

generator to interpret abstract representations

(Fowler, 2005). Based on this, we recall the basic

notations from section 3.2.1 “Concepts” to update

basic notations as it illustrated in Figure 7.

Figure 7: Modeling with DSL, based on (Bézivin, 2005).

According to this updated description, a CAx-PC

can be represented by a model. The model conforms

to a metamodel which defines an abstract syntax of

DSL. The abstract syntax describes concepts and

relationships of a model independently from any

representations. The abstract and concrete syntaxes

of DSL express the model. The concrete syntax of a

DSL can be specific, textual or graphical. The

meaning of concepts and relationships is defined in

the semantics of a DSL which is used for a code

generator that interprets representations of DSL. The

listing below describes the model for CAx-PCs

which is expressed by the CAx-PCs modeling

language.

Chain - CAx {

Process – CAD {

Attribute.Evaluative: "Duration"

Attribute.Analytical: "Potential"

Requirement: "I/O format" {...}

Input: CAD

Output: CAD, CAM

Product - CADmodel{

Requirement: "model type"{...}

}

}

}

map to

UML

Code

map to code,

implement

Assembler

Problem

Solution

solve problem in domain terms

UML

model

Domain

model

generate

calls

Components

map to code,

implement

generate,

generate

code

Abstraction gap

add bodies

no

map

defined by

expresses

CAx-process

chain

Model

Metamodel

DSL

represented by

conforms to

Abstract

syntax

Concrete

syntax

Semantics

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

730

This modeling language is an external DSL

which expresses the model that conforms to the

metamodel for CAx-PCs. In this model, the CAx-PC

contains a CAD process with attributes,

requirements, inputs, outputs and the product of the

process. Note that this is not a complete model for

CAx-PCs. Nonetheless, the model is expressed by

the language which is comprehensible by CAx-PC

methodology experts. Furthermore, the model will

be changed, extended and aligned to the scope of

CAx-PC modeling.

4 IMPLEMENTATION

As was settled in previous section 3, CAx-PC

modeling language will be used to obtain the model

for CAx-PCs. The abstract syntax of DSL was

defined in the first step of DSL definition. In order

to finish this definition, the editing environments

and language semantics must be provided. Thus, this

section describes some tools which are used for the

definition of DSLs. Moreover, the software

architecture and the user interface of “CAx-process

chain designer” are discussed in this section for

further software development.

4.1 DSL Definition

The language workbenches are described in the

additional work by Fowler (Fowler, 2005). Usually,

a language workbench is equipped with an editing

environment for the language where a DSL is

manipulated. There are several projects dealing with

language workbenches which are used for the DSL

definition. For example, Microsoft offers Visual

Studio DSL Tools (Cook, 2007). Other projects are

Graphical Modeling Framework based on Eclipse

Modeling Framework (Steinberg, 2009) and Xtext

framework which is the part of Open Architecture

Ware (Efftinge, 2006). Also, MetaEdit+ Workbench

is used for designing of modeling languages

(Tolvanen, 2003).

Since, the metamodel is established, any of these

projects can define a new DSL. Moreover, these

projects offer functionalities for abstract syntax and

semantics definition. As a result, CAx-PC modeling

language can be implemented by any mentioned

project. By itself, the model does not evaluate and

analyze CAx-PCs. For this, the model has to be

integrated into the prototypical tool “CAx-process

chain designer” which will be able to design,

evaluate and analyze the CAx-PC alternatives. This

is achieved by defining an interpretator or a code

generator in the language workbench that transforms

the model into program code and configuration files.

4.2 CAx-process Chain Designer

In order to utilize the model for CAx-PCs, the

“CAx-process chain designer” (the system) has to be

developed. Accordingly, the software requirements,

which were defined in section 2.2, have to be

applied in the system development. Additionally, the

quality requirements or non-functional requirements

(NFRs) have to be added to the final software

requirements specification. NFRs affect the software

architecture and graphical user interface (GUI) of

the software.

A multitude of factors such as the technical

environment, architect’s experience and the business

goal influence the software architecture (Bass,

2003). In addition, the NFRs have influence on the

software architecture for the prototypical

implementation of the system. Applying FURPS+

system for classifying requirements (Grady, 1992)

(Eeles, 2005), extensibility and usability of the

system are required for the “CAx-process chain

designer”.

Primarily, the system has to be extensible to

changes in and additions to the model for CAx-PCs.

This implies that the software system is modifiable

at run time. Commonly, XML based configuration

files are suited for this requirement.

Furthermore, the usability has to ensure a user-

friendly interface for the system. To assure this, the

development will use the iterative design approach

with the ten usability heuristics for user interface

design (Nielsen, 2005).

Based on NFRs, the architecture of the system is

designed by using the Model-View-Controller

design pattern (MVC) (Deacon, 2009). This pattern

was described in the first time by Reenskaug

(Reenskaug, 1979). In this design pattern, the model

represents knowledge which can consist of

application data, logic or business rules. In addition,

the model is represented or visualized by the view.

The controller manipulates the model state and

notifies the view which provides the link between

the user and the systems. This pattern can potentially

fulfill the software requirements for the architecture

and GUI of the system. The clear separation of

model data from the elements of GUI allows

implementing the extensible system. Moreover, the

elements of user interface can be modified and

improved apart from the model. Figure 8 displays

DesigningCAx-processChains-ModelandModelingLanguageforCAx-ProcessChainMethodology

731

the architecture for the “CAx-process chain

designer”.

Figure 8: Architecture.

In this case, the model consists from the nodes and

edges which contain information about CAx-PC

(chain data). The model notifies the view through

the controller about any changes in chain data. The

model is initiated by the generated XML

configuration files and program code. The chain data

is stored in the model and external data storages.

User Interface elements display the state of the

model. The controller translates the user actions into

commands which change the state of the model and

view’s perception of the model. The user interface

includes the main elements such as a canvas,

dynamic menus, process control elements and a

property panels to display detailed information about

the processes.

Figure 9: The prototypical GUI for CAx-process chain

designer.

These elements form the GUI of “CAx-process

chain designer”. The first prototype of GUI is

illustrated in Figure 9. This implementation of

“CAx-process chain designer” is prototypical.

Currently, the prototype is capable of visualizing

and manipulating the CAx-PC model. After several

iterative development cycles the research prototype

will analyse and evaluate CAx-PCs for designing the

alternatives of CAx-PC.

5 CONCLUSIONS

This paper introduces a solution for designing CAx-

PC in conformity to the CAx-PC methodology for

evaluation, analysis and optimization of CAx-PC.

The solution includes the definition of DSL,

expressing the model and the tool for deriving the

alternatives of process chains from the model. The

CAx-PC methodology is based on the knowledge

that has been extracted throughout different use

cases within the turbo machinery and automotive

industries. Further use cases from other industry

sectors might lead to extensions of the methodology

as well as the redefinition of the model, metamodel

and modeling language.However, the presented

solution requires a detailed description of DSL

definition. Therefore, the future work will be

concentrated on the DSL definition. Also, the GUI

of the “CAx-process chain designer” will be

iteratively adapted to software requirements.

REFERENCES

Bass, Len and Clements, Paul and Kazman, Rick (ed.),

2003, Software architecture in practice, Addison-

Wesley Professional.

Bézivin, J., 2005, ‘On the unification power of models’,

Software & Systems Modeling, Springer(4(2)), 171–

188.

Brecher, C., Vitr, M. & Wolf, J., 2006, ‘Closed-loop

CAPP/CAM/CNC process chain based on STEPand

STEP-NC inspection tasks’, International Journal of

Computer Integrated Manufacturing 19(6), 570–580.

Bullinger, H. J., et al. (eds.), 2008, Handbuch

Unternehmensorganisation: Strategien, Planung,

Umsetzung, 3rd edn., Springer Berlin, Berlin.

Cook, S. (ed.), 2007, Domain-specific development with

Visual Studio DSL tools, Addison-Wesley, Upper

Saddle River, NJ.

Deacon J., 2009, ‘Model-view-controller (mvc)

architecture’ 2009, from http://www. jdl. co.

uk/briefings/MVC. pdf.

Eeles P., 2005, Capturing architectural requirements,

from http://ibm.com/developerworks/rational/library.

Efftinge S., Völter M., 2006, ‘oAW xText: A framework

for textual DSLs’, Workshop on Modeling Symposium

at Eclipse Summit 32.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

732

Feldhusen, J. & Grote, K.-H., 2013, ‘Pahl/Beitz

Konstruktionslehre: Methoden und Anwendung

erfolgreicher Produktentwicklung’, Pahl/Beitz

Konstruktionslehre 2013.

Fowler, M., 2008, Domain-specific languages, from

http://martinfowler.com/bliki/DomainSpecificLanguag

e.html.

Fowler, M., 2005, ‘Language workbenches: The killer-app

for domain specific languages’ 2005.

Fowler, M., 2010, Domain-specific languages, Pearson

Education.

Grady, R. B., 1992, Practical software metrics for project

management and process improvement, Prentice Hall,

Englewood Cliffs, NJ.

Hutchinson, J., Rouncefield, M. & Whittle, J., 2011,

‘Model-driven engineering practices in industry’, in R.

N. Taylor, H. Gall, & N. Medvidović (eds.),

Proceeding of the 33rd international conference,

Waikiki, Honolulu, HI, USA, pp. 633–642.

Jackson, M., 1995, ‘Requirements and specifications: a

lexicon of software practice, principles and

prejudices’, Addison Wesley, Wokingham 1995.

Kelly, S., & Tolvanen, J. P., 2000, ‘International

Workshop on Model Engineering: Visual domain-

specific modeling: Benefits and experiences of using

metaCASE tools’, ECOOP 2000.

Klocke, F. & Straube, A.M., 2004, ‘Virtual Process

Engineering – An approach to integrate VR, FEM, and

simulation tools in the manufacturing chain’,

Mécanique & Industries 5(2), 199–205.

Kosar, T., Oliveira, N., Mernik, M., Pereira, V.,

Crepinsek, M., Da, C. & Henriques, R., 2010,

‘Comparing general-purpose and domain-specific

languages: An empirical study’, Computer Science

and Information Systems 7(2), 247–264.

Ludewig, J. & Lichter, H., 2007, Software Engineering:

Grundlagen, Menschen, Prozesse, Techniken, 1st edn.,

Dpunkt-Verl., Heidelberg.

Minoufekr, M.; Glasmacher, L. & Adams, O. (2013),

Macroscopic Simulation of Multi-axis Machining

Processes., in Jean-Louis Ferrier; Oleg Yu. Gusikhin;

Kurosh Madani & Jurek Z. Sasiadek, ed., 'ICINCO (2)'

, SciTePress, , pp. 505-516 .

Nielsen, J., 2005, ‘Ten usability heuristics’ 2005.

OMG, 2005, Unified Modeling Language (UML), from

http://www.omg.org/spec/UML/2.0.

OMG, 2011, Business Process Model and Notation

(BPMN), from http://www.omg.org/spec/BPMN/2.0.

Reenskaug, Trygve Mikjel H, 1979, ‘The original MVC

reports’ 1979.

Sääski J., Salonen T. and Jukka P., 2005, ‘Integration of

CAD, CAM and NC with Step-NC’, VTT 2005.

Schug P., Glasmacher L., Klocke F., 2014, ‘Modeling und

Evaluation of CAx-Process chains’, Innovations of

Sustainable Production for Green Mobility, 3rd

International Chemnitz Manufacturing Colloquium

ICMC 2014(1), 872–891.

Steinberg, D. (ed.), 2009, EMF: Eclipse Modeling

Framework, 2nd edn., Addison-Wesley, Upper Saddle

River, NJ.

Taylor, R. N., Gall, H. & Medvidović, N. (eds.), 2011,

Proceeding of the 33rd international conference.

Tolvanen, J.-P. & Rossi, M., 2003, ‘MetaEdit+: defining

and using domain-specific modeling languages and

code generators’, Companion of the 18th annual ACM

SIGPLAN conference on Object-oriented

programming, systems, languages, and applications

2003, 92.

Werner Dankwort, C., Weidlich, R., Guenther, B. &

Blaurock, J. E., 2004, ‘Engineers' CAx education—it's

not only CAD’, Computer-Aided Design 36(14),

1439–1450.

Wiegers, K. E., 2000, ‘Karl Wiegers describes 10

requirements traps to avoid’, Software Testing &

Quality Engineering 2(1).

DesigningCAx-processChains-ModelandModelingLanguageforCAx-ProcessChainMethodology

733