BAlGaN-based Vertical Cavity Surface Emitting Laser Operating in

Deep UV Region

X. Li

1,2

, S. Sundaram

2

, P. Disseix

3

, S. Bouchoule

4

, G. Le Gac

3

, G. Patriarche

4

, F. Réveret

3

,

J. Leymarie

3

, Y. El Gmili

2

, J. Streque

2

, F. Genty

5

, J-P. Salvestrini

2,6

, P. L. Voss

1,2

,

R. D. Dupuis

7

and A. Ougazzaden

1,2

1

School of Electrical and Computer Engineering, Georgia Institute of Technology, GT-Lorraine, 57070 Metz, France

2

UMI 2958, Georgia Tech - CNRS, 57070 Metz, France

3

Institut Pascal UMR 6602 CNRS, Université Blaise Pascal, 63171 Aubière, France

4

LPN CNRS, UPR20, 91460 Marcoussis, France

5

Supelec, LMOPS, EA4423, 57070 Metz, France

6

Université de Lorraine, LMOPS, EA 4423, 57070 Metz, France

7

Center for Compound Semiconductors and School of Electrical and Computer Engineering,

Georgia Institute of Technology, Atlanta, Georgia 30332, U.S.A.

1 RESEARCH PROBLEM

There is a strong demand for semiconductor light

sources emitting in the DUV region for a wide

variety of potential applications such as sterilization,

water/air purification, optical imaging systems,

spectroscopy, or high density storage systems.

However, the primary limitation of current

applications is the existing UV sources. The

conventional UV light sources are excimer lasers,

mercury lamps or Nd: YAG lasers. These sources

suffer from low level of performance, low reliability,

significant size, and the toxic substances. Compared

with conventional lasers, the semiconductor light-

emitting devices are an ideal choice due to their

reliability, compactness and high efficiency.

Besides, the wavelength could be tuned by changing

the compositions of the active region. UV

semiconductor light sources are of great

technological interest in our daily lives.

Among semiconductor laser devices, VCSEL is

one of the most attractive configurations: The

emission light from VCSEL is perpendicular to the

surface, so it could be integrated into two

dimensional arrays. 10000 devices could be

integrated on one wafer to give high output. Circular

beam makes it easy for coupling into the fiber. It

consists of high reflectivity distributed Bragg

reflector (DBR) mirrors, which enables low

threshold and high output. Besides, it could be tested

during processing which decreases the

manufacturing cost. Compared with EELs, it has low

temperature sensitivity due to its single longitudinal

cavity.

AlGaInN-based wide bandgap semiconductor

material systems have brought innovative changes in

photonic devices, which allow the operating

wavelengths of LEDs and lasers to reach a spectral

range spanning from blue to DUV. However, the III-

nitride VCSELs demonstrated so far operate in the

wavelengths of visible violet and blue spectral

range, while no efficient VCSELs emitting below

300 nm were reported. To extend the VCSEL

emission to the ultraviolet region, the challenges lie

in many aspects. Firstly, there is a degradation of the

structural quality of heteroepitaxial AlGaN materials

with increasing Al molar ratio and lack of high

quality AlN substrates. High dislocation density for

the structure grown on foreign substrates would lead

to low internal quantum efficiency (IQE). Secondly,

AlGaN MQWs suffer from the strong quantum-

confined Stark effect (QCSE) induced by

piezoelectric and spontaneous polarization, which

leads to the separation of electrons and holes and

reduces significantly the emission efficiency. C-

plane AlGaN alloys also exhibit anisotropic optical

polarization properties: E-field c polarized

emission (which will be referred to as TE

polarization) decreases when compared to the

emission polarized along the c axis (E-field // c) as

the Al composition increases for the deep UV

wavelengths, which is harmful to surface-emission.

Thirdly, high-reflectivity distributive Bragg reflector

26

LI X., Sundaram S., Disseix P., Bouchoule S., Le Gac G., Patriarche G., Réveret F., Leymarie J., Gmili Y., Streque J., Genty F., Salvestrini J., Voss P.,

Dupuis R. and Ougazzaden A..

BAlGaN-based Vertical Cavity Surface Emitting Laser Operating in Deep UV Region.

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

(DBR) with large bandwidth for the DUV VCSELs

is a big challenge, considering the limited refractive

index contrast and large lattice mismatch for

conventionally used AlGaN/Al(Ga)N structures.

Based on the challenges mentioned above, in the

framework of developing DUV VCSELs for this

work, TE-emission enhanced AlGaN MQWs

emitting at 280 nm grown on relaxed AlGaN buffer,

new BAlN material system which can have big

refractive index contrast with Al(Ga)N and its

applications to DBRs would be studied and

explored.

2 OUTLINE OF OBJECTIVES

The objective of this thesis is to develop efficient

vertical cavity surface-emitting lasers operating

below 300 nm. The final structure consists of

dielectric top mirror, AlGaN active region and

bottom DBR based on BAlGaN material system.

The first part of the work is addressed to the

AlGaN active region, including the study of AlGaN

epitaxial growth for the control of composition and

strain relaxation, the realization of TE-enhanced

MQWs design and the related characterizations. The

purpose is to develop efficient DUV MQWs with

improved TE emission.

The second part focuses on the growth of novel

BAlN material, in order to study the influence of

growth conditions and characteristics of the material.

The third part would be the design and

realization of DBRs, including both BAlGaN DBRs

and conventional AlGaN DBRs as reference.

The final goal is to realize DUV devices: laser

diodes, RC-LEDs and ultimate VCSELs.

3 STATE OF THE ART

Visible and UV-VCSELs and edge-emitting lasers

(EELs) based upon the wide bandgap

semiconductors including ZnSe- and GaN-based

material systems have been extensively explored for

the potential applications of high density optical

storage system, laser printer engines, full color

display systems, and large-area projector systems.

The ZnSe-based materials were the first material

system to provide continuous wave operation of

blue-green EELs (Ding et al. 1990). However,

serious reliability problems possibly arising from its

chemically and structurally unstable material system,

have hindered the application of ZnSe lasers in the

real-world systems. Later, AlGaInN-based wide

bandgap semiconductor material systems (Gil 1998;

McIntosh et al. 1996) have brought innovative

changes in photonic devices, which enable the

operating wavelengths of LEDs and lasers to reach a

spectral range from blue to UV (Shatalov et al.

2002). The first nitride-based injection laser centered

at around 390 nm was demonstrated in 1995

(Akasaki et al. 1995). AlGaN-based UV LEDs for

wavelength shorter than 360 nm was initiated in

1998 (Han et al. 1998). Then UV and DUV light

devices have undergo tremendous evolution through

rapid progress in material growth, device fabrication

and packaging. In the DUV range, the LEDs and

EELs have progressed a lot. The group of Sensor

Electric Technology has reported high external

quantum efficiency of 10.4% at 20 mA continuous

current with output power up to 9.3 mW for

encapsulated AlGaN LEDs emitting at 278 nm

(Shatalov et al. 2012). UV Craftory has developed

commercial production of 50 mW AlGaN LEDs

with wavelength ranging from 255 nm to 355 nm

which have 10% external quantum efficiency (EQE)

and over 10000 hours life time (Ippommatsu et al.

2013). For AlGaN lasers, the group of Technische

Universität Berlin has reported laser grown on AlN

bulk emitting at 279 nm with threshold of 50 mJ/cm

2

(IQE 20~30%), and laser grown on ELO (epitaxially

laterally overgrown) AlN/sapphire template emitting

at 272 nm with threshold of 65 mJ/cm

2

(IQE

10~20%). Both of two are TE-polarization dominant

(Martens et al. 2014). (Xie et al. 2013) reported low

threshold power of 84 kW/cm

2

for lasing at 280.8

nm and (Johnson et al. 2012) demonstrated lasing at

266 nm with threshold of 41 kW/cm

2

. Both of

devices are based on the AlGaN MQWs grown on

single crystal AlN bulk substrates. To achieve IQE

higher than 60%, AlN bulk single crystal can be

used since its threading dislocation density is below

510

8

cm

-2

(Hirayama et al. 2014), but it suffers

from high impurity absorption, high cost and limited

availability. Riken group has used ammonia pulsed-

flow multilayer growth to fabricate AlN template on

sapphire to obtain IQE of 60% from AlGaN QWs

(Hirayama et al. 2007; Hirayama et al. 2014).

Recently, for the devices grown on AlN templates

on sapphire, simulated emission was observed at

wavelengths of 256 nm and 249 nm with thresholds

of 61 kW/cm

2

and 95 kW/cm

2

at room temperature,

as reported by (X.-H. Li et al. 2014).

The development of III-nitride-based VCSELs

includes optically-pumped devices at blue

wavelengths (Redwing et al. 1996; Krestnikov &

Ledentsov 1999), and room temperature CW lasing

BAlGaN-basedVerticalCavitySurfaceEmittingLaserOperatinginDeepUVRegion

27

VCSELs by current injection for blue/violet

wavelengths (Higuchi et al. 2008; Lin et al. 2014;

Kasahara et al. 2011). So far, no efficient VCSELs

operating below 300 nm were reported.

One of the biggest challenges for UV VCSELs

lies in the need for high reflectivity DBRs.

Conventional AlInGaN based DBRs have been

explored to give high reflectivity from blue to the

near-UV region. For example, 25-pair

Al

0.18

Ga

0.82

N/Al

0.8

Ga

0.2

N has a reflectivity as high as

99% with bandwidth of 26 nm at central wavelength

of 347 nm (Mitrofanov et al. 2006). Below 300 nm,

(Moe et al. 2006) have demonstrated reflectivity of

66% and 83% for the shortest wavelengths of 245

nm and 279 nm, using 10 and 21 pairs of

AlGaN/AlN, respectively. It is difficult to achieve

high reflectivity requirement due to large absorption

and small refractive index contrast of the materials

in DUV region. Conventionally used AlGaN layers

exhibit large lattice mismatch as high as ~2.4%

between GaN and AlN to achieve only small

refractive index contrast in the mirror structure. The

high reflectivity requiring large number of pairs was

accompanied by the dislocations, cracks or rough

interfaces. So the novel system is necessary to build

efficient DBR structures below 300 nm.

In this thesis, BAlGaN material system would be

used to achieve the target. The primary reason for

the B incorporation is that a very small amount of B

in AlN could introduce a strong refractive index

contrast (Watanabe et al. 2003; Abid et al. 2012).

For example, BAlN with only 1.2% B can have a

refractive index contrast of 0.17 with AlN. Besides,

BAlN system exhibits less optical absorption than

AlGaN due to its large bandgap. Additionally, both

the large refractive index contrast and strain-

compensated structure could be obtained at the same

time by alternating BAlN and AlGaN layers in the

DBR.

4 METHODOLOGY

The growth was performed in a MOVPE T-shape

reactor (Gautier et al. 2007) under 100 Torr.

Hydrogen was used as carrier gas. Trimethyl-

aluminum (TMAl), thrimethyl-gallium (TMGa),

triethylborane (TEB) and NH

3

were used as

precursors for aluminum, gallium, boron and

nitrogen, respectively. 900-nm thick AlN templates

on c-axis sapphire and 3 μm GaN templates on c-

axis sapphire were used as substrates.

High resolution X-ray diffraction (XRD)

measurements were performed in a Panalytical

X’pert Pro MRD system with Cu Κα radiation to

determine composition and other structural

information. The depth concentration profiles for

different elements were performed by secondary ion

mass spectroscopy (SIMS) analysis.

Surface morphology was characterized by atomic

force microscope (AFM) and scanning electron

microscope (SEM). The sample was then prepared

for scanning transmission microscopy (STEM) using

focused ion beam (FIB) thinning and ionmilling. 100

nm carbon was deposited before FIB in order to

protect the surface. High-angle annular dark field

scanning transmission microscopy (HAADF-STEM)

characterizations were performed on aberration-

corrected JEOL 2200FS electron transmission

microscope.

The optical properties were investigated by

photoluminescence (PL) and depth-resolved

cathodoluminescence (CL) techniques. The PL

excitation at 266 nm was provided by the second

harmonic generation of a continuous laser. The

emission is analyzed by a 1 m focal length

monochronometer and detected by a CCD camera.

Both the optical excitation and light collection are

from sample surface. Optical transmission

measurements were performed under Xenon arc

lamp excitation for determination of the absorption

band-edge and absorption coefficients in the wells.

5 EXPECTED OUTCOME

This work is in the framework of developing DUV

VCSELs based on new BAlGaN material system.

The main research work includes AlGaN active

region, bottom DBR based on new BAlGaN material

and final laser devices. The expected outcome of this

thesis contains following part:

MOVPE growth study for AlGaN layers

including a careful control of composition and

strain state.

Design and growth of AlGaN MQWs structure

which preserves the oscillator strength of TE-

polarized transition.

MOVPE growth study for new BAlN material

including its growth conditions and structural

characteristics.

Achievement of DUV DBRs based on

BAlN/Al(Ga)N system.

Realization of AlGaN-based DUV lasers, and

BAlGaN-based RCLEDs and VCSELs.

PHOTOPTICS2015-DoctoralConsortium

28

6 STAGE OF THE RESEARCH

The whole work can be divided into three sections:

AlGaN active region, BAlGaN DBRs and final

devices. Obtained results are presented in subsection

6.1 and 6.2, while the next plans are listed in

subsection 6.3.

6.1 DUV AlGaN MQWs

The first part was concentrated in the optimization

of AlGaN layers and AlGaN MQWs emitting at 280

nm.

6.1.1 AlGaN Composition and Relaxation

In order to obtain a good control over composition

and relaxation for AlGaN growth, a series of AlGaN

single layers were grown on AlN templates. The

relationship between composition and TMAl/III

ratio as wells as thickness and relaxation has been

established. For the fully-strained thin layers below

critical thickness, Al composition in the solid phase

varies linearly with the TMAl relative concentration

shown in Fig. 1. Additionally, the AlGaN growth

rate, shown in the inset, varies linearly with the total

III elements flow (TMAl+TMGa) while the V/III

ratio remains constant, which indicates that the

growth occurs in a mass transport limited regime.

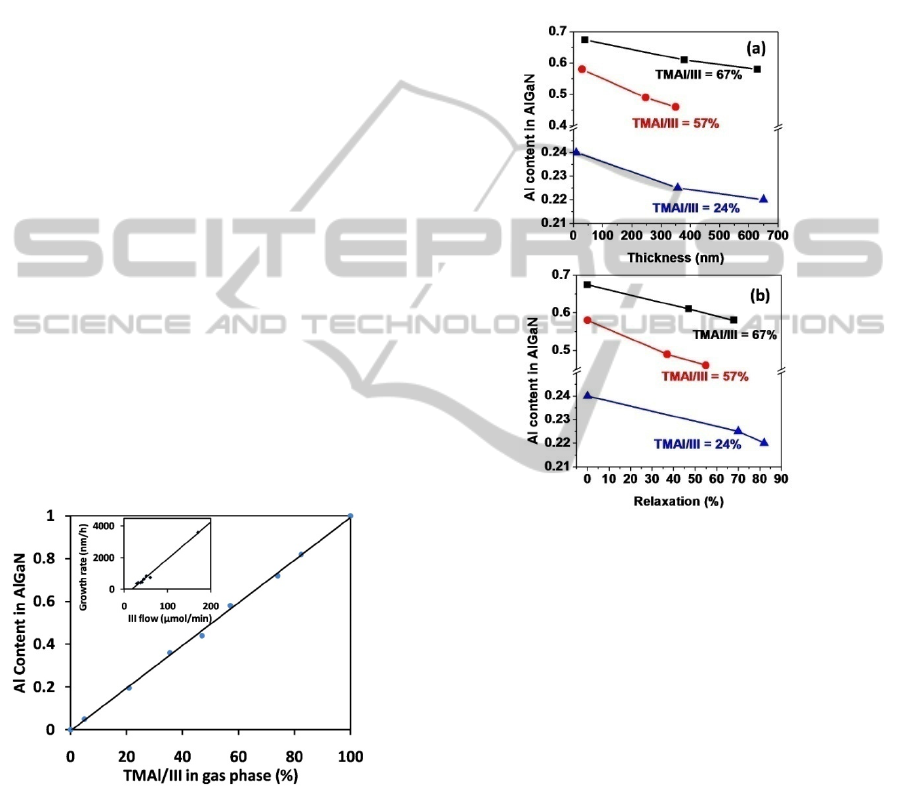

Figure 1: Al composition of AlGaN layers fully-strained

on AlN templates Vs. TMAl/(TMAl+TMGa) ratio. The

inset shows the growth rate versus total flow rate of

(TMAl+TMGa).

However, when the thickness of the single AlGaN

layer was increased under the same TMAl/III ratio

so that the layer relaxed, it was observed that the

average Al content in the layer decreased. This

composition fluctuation during AlGaN relaxation

has generally been ascribed to the composition

pulling effect. G.B. Stringfellow et al. explained that

the excess lattice mismatch energy would perturb the

solid composition towards the composition which

minimizes mismatch (G.B.Stringfellow 1993). The

smaller adatoms will be incorporated preferentially

at steps having relative compressive strain, and

larger adatoms under relatively tensile strain

(Tersoff 1996; Venezuela et al. 1999).

Figure 2: Al content in the AlGaN single layers plotted as

a function of (a) layer thickness, and (b) corresponding

layer relaxation for three different TMAl/(TMAl+TMGa)

ratios.

Very few studies have considered AlGaN layers

grown on AlN template which would be under

compressive strain. In the present investigation, as

shown in Fig. 2, a decrease in the Al composition of

AlGaN layers is evidenced when the layer thickness

(and hence the layer relaxation) is increased. For

three different TMAl/III ratios in the gas phase, a

clear Al content drop can be observed, confirming

the composition pulling effect. In our case, AlGaN is

under compressive strain on AlN, so in the initial

stage when the layer is fully strained, AlGaN has a

tendency towards higher Al content in order to

minimize mismatch, while for the relaxed layer case,

we see a lower Al content. Since Ga-N has a smaller

bond energy than Al-N, Ga incorporation would be

more controlled by the strain state than Al

incorporation (Reuters et al. 2012; Bogusławski et al.

2000), which means that Ga atoms are expelled out

for the initial stage under high compressive strain,

BAlGaN-basedVerticalCavitySurfaceEmittingLaserOperatinginDeepUVRegion

29

and Ga incorporation increases when the layer is

relaxed with lateral lattice increasing.

6.1.2 TE-enhanced AlGaN MQWs Design

C-plane AlGaN alloys exhibit anisotropic optical

polarization properties: E-field c polarized

emission (TE polarization) decreases when

compared to the emission polarized along the c axis

(E-field // c) as the Al composition increases for the

deep UV wavelength, which is detrimental to

surface-emission. This is attributed to the

arrangement of the valence bands at the Γ point of

Brillouin zone and Γ

7

symmetry becomes the upper

valence band for an aluminum composition typically

higher than 10% (Ryu et al. 2013; Kolbe et al. 2010;

Nam et al. 2004; Leroux et al. 2004; Leroux et al.

2002). However, it is possible to restore the

amplitude of the oscillator strength by imposing

some strain in the AlGaN QW, which can affect the

valence band states and the selection rules (Chuang

& Chang 1996; Northrup et al. 2012; Ivanov et al.

2014; Murotani et al. 2011). The strain is due to the

lattice mismatch between barriers and wells which

have different Al content. Thus, the barrier

composition can be chosen to provide sufficient

compressive strain in the wells in order to enhance

the TE-polarized optical transition.

To achieve emission at a wavelength of around

280 nm, the Al composition of the well was chosen

to be x

Al

= 0.37 and the well thickness was fixed to

1.7 nm in the calculations. The thickness of barriers

was fixed to 10 nm. Envelop function simulations

taking into account strain and built-in electric fields

have been performed for AlGaN/AlGaN MQWs

structure. The optimal Al content in barriers is

designed to be 0.57 (0.01), for which the strain (-

0.5%) introduced in the wells is sufficient to

preserve the oscillator strength of TE-polarized

optical transition and therefore surface emission.

6.1.3 Growth and Characterizations of

MQWs

In order to release the strain in the barriers, a relaxed

Al

0.58

Ga

0.42

N buffer was grown on AlN template as a

pseudo-substrate. Then, 4-period Al

0.57

Ga

0.43

N /

Al

0.38

Ga

0.62

N MQWs were grown on top based on

the design. HAADF-STEM cross-section images of

MQWs and upper part of the relaxed buffer were

shown in Fig. 3(a) and 3(b). The barriers thickness is

measured to be 10 ~ 11 nm from intensity profiles

and the wells thickness is of 1.6 ~ 1.8 nm. The

average composition of barriers could be determined

from EDX quantitative analysis and was found to be

0.57 ( 0.015). Since the spatial resolution of the

EDX analysis is typically of 2 nm, in order to

determine the composition of ultra-thin wells, high-

resolution Z-contrast HAADF-STEM image was

transformed into quantitative composition mapping

by following a procedure proposed in (Pantzas et al.

2012). The background intensity has been subtracted

and thickness variation has been corrected. The

complete analysis results in a chemical mapping

were shown in Fig. 3(c). The average Al content in

the barriers is accord with EDX value (x

Al

~0.57)

and the average Al content in the wells is estimated

to be x

Al

~0.38 ( 0.015). The thickness and

composition values obtained from Figs. 3(a)-3(c) fit

well the XRD experimental data.

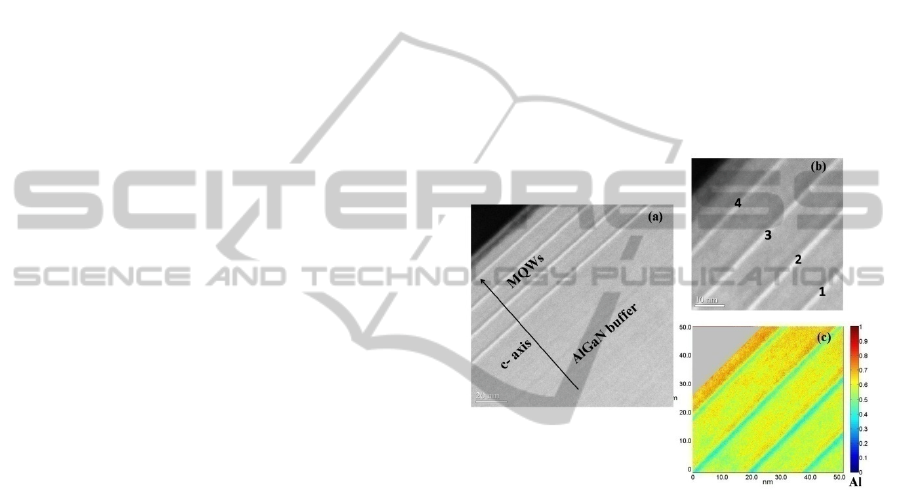

Figure 3: (a) Cross-section High-angle Annular Dark Field

Scanning Transmission Electron Microscopy (HAADF-

STEM) images taken along the <1 1 -2 0> zone axis for

MQWs and buffer layer; (b) High magnification of

HAADF-STEM images; (c) Al composition map obtained

from (b).

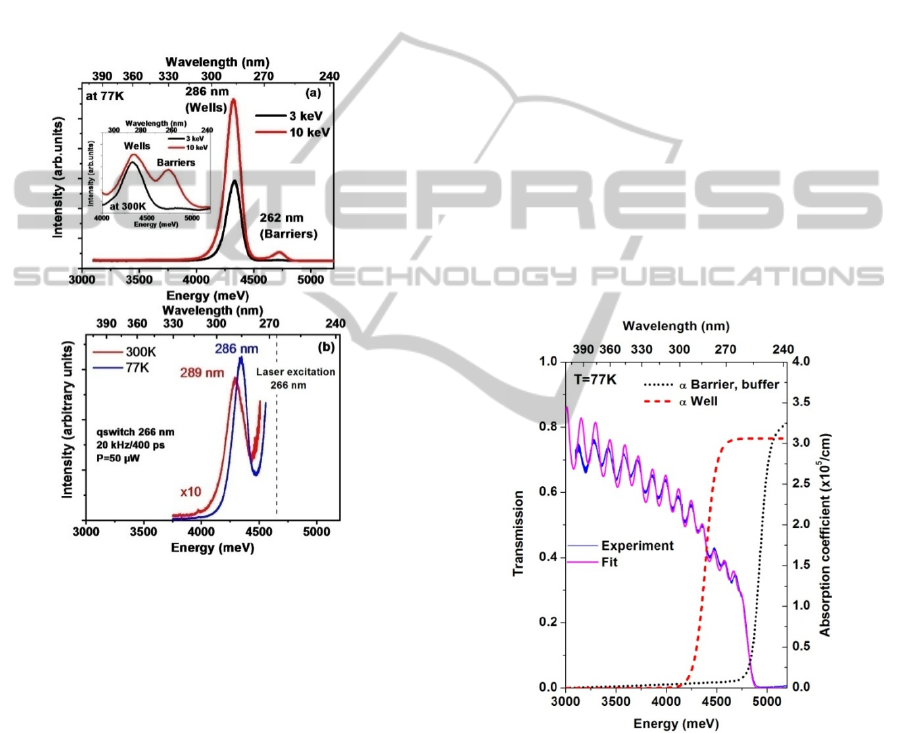

Cathodoluminescence (CL) spectra at 77 K under

different excitation energy have been shown in Fig.

4(a). Under a low excitation power of 3 keV

corresponding to a penetration depth of the electron

beam of typically 30 nm, a single emission peak

from wells at 286 nm indicates that the carriers are

mostly confined in the wells. When the excitation

power is increased to 10 keV and the penetration

depth of the excitation beam reaches 230 nm, a

luminescence signal at 262 nm appears in addition to

the emission of the wells, which is attributed to the

barriers and buffer layer. The emission at 262 nm

indeed corresponds to a bandgap energy of 4.73 eV,

which is in agreement with the experimental

composition of the barriers and buffer layer (x

Al

~

0.57). At room temperature the increase of the

PHOTOPTICS2015-DoctoralConsortium

30

barrier luminescence with respect to 77K is

attributed to the thermal activation of carriers in the

AlGaN layers (barriers or buffer layers). In the case

of an optical in-well pumping (excitation at 266 nm)

as displayed in Fig. 4(b), the laser beam is mainly

absorbed in the QWs and not in the barriers. Thus,

only the luminescence of the wells is observed.

However, it is found that both classical

photoluminescence and cathodoluminescence

provide the same QW emission line. The linewidth

is 9.5 nm for PL at 77 K and 11.9 nm for PL at 300

K.

Figure 4: (a) Cathodoluminescence (CL) spectra at 77 K

(and at 300 K in the inset) for two different values of

excitation power; (b) Photoluminescence (PL) at 77 K and

300 K under excitation of 266 nm.

Figure 5 shows the macro-transmission

measurements (E-field c configuration) at 77 K

together with numerical simulations based on

transfer matrix formalism. The experimental

spectrum reveals the absorption edge of the barriers

at 260 nm, while a 10% drop of transmission is

observed at 281 nm due to absorption in the wells. It

is worth noting that calculations fit the experimental

results in a satisfying way. The absorption

coefficients used in the simulation are also displayed

in Fig. 5 for both barriers and wells. A weak

absorption with linear energy dependence has been

added in the barriers and the buffer in order to

reproduce the overall decrease of the transmission

signal. The latter might be caused by defects

originated from the AlN template. The absorption

coefficient in the wells is found to be as high as

310

5

cm

-1

, which implies that the oscillator strength

is preserved in the QWs despite the high aluminium

composition.

It is noted that the splitting between Γ

7CH

-CB

(fundamental) and Γ

9

-CB transitions is evaluated to

be equal to 32 meV. By considering the AlGaN

broadening which is due to intrinsic alloy disorder

and extrinsic inhomogeneities such as QW thickness

fluctuations, it appears that the

7CH

-CB and

9

-CB

transitions lie in the same energy range. The energy

difference between these two transitions depends on

several parameters (band offset, deformation

potentials, effective masses…). So the absorption

signal accounts for both transitions. However, it has

been established through calculations that the strain

preserves the oscillator strength of the fundamental

transition (

7CH

-CB). Therefore it can be concluded

that our MQW design with the use of relaxed buffer

is promising for the fabrication of surface-emitting

LED or lasers in DUV region.

Figure 5: Macro-transmission measurements and transfer-

matrix simulation of MQWs together with absorption

coefficients (α

well

, α

barrier, buffer

) used in the simulation.

More details can be found in (X. Li, Sundaram,

Disseix, et al. 2015).

6.2 MOVPE Growth Study of BAlN

The second part of this work focuses on the study of

BAlN layers grown by MOVPE.

BAlGaN-basedVerticalCavitySurfaceEmittingLaserOperatinginDeepUVRegion

31

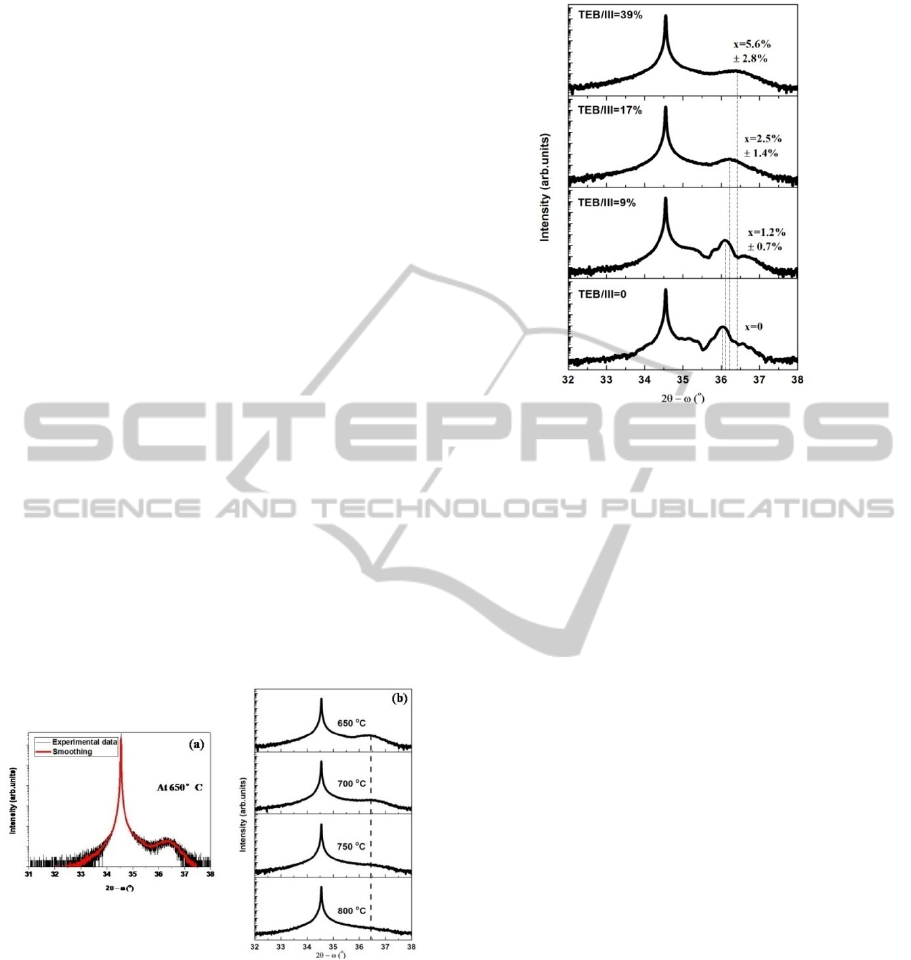

6.2.1 BAlN Thin Layers

Wurtzite BAlN layers with boron composition as

high as 12% were successfully grown by MOVPE.

The growth was performed at 650˚C and then

annealed at 1020˚C. Under high TEB/III ratio of

39%, as shown in Fig. 6(a), BAlN single layer

grown on GaN templates at 650˚C with 20 nm

thickness demonstrates an X-ray diffraction peak at

36.38˚ ( 0.17˚), which indicates that the layer has

smaller lattice c than AlN due to boron substituting

Al atoms in the crystal structure. We can assume the

layer is fully-relaxed considering the large lattice

mismatch between BAlN layer and GaN template. In

this case, the c-lattice constant is 4.935 Å ( 0.022

Å), which corresponds to boron composition of

5.6% ( 2.8%) by applying Vegard’s Law. The

complete relaxation of the layer can be confirmed in

Fig. 7: when we stop TEB flow and only grow AlN

layer, the 2θ-ω peak of the layer is located at 36.02˚

corresponding to completed relaxed AlN layer.

When the deposition temperature is increased,

shown in Fig. 6(b), the BAlN peak is weakened, and

then disappears when it is increased to 800˚C. It

indicates that under this high TEB/III ratio the

crystallinity is worse when the layer is grown at

higher temperature. Low temperature growth can

alleviate B-rich phase poisoning issue under high

TEB/III ratio.

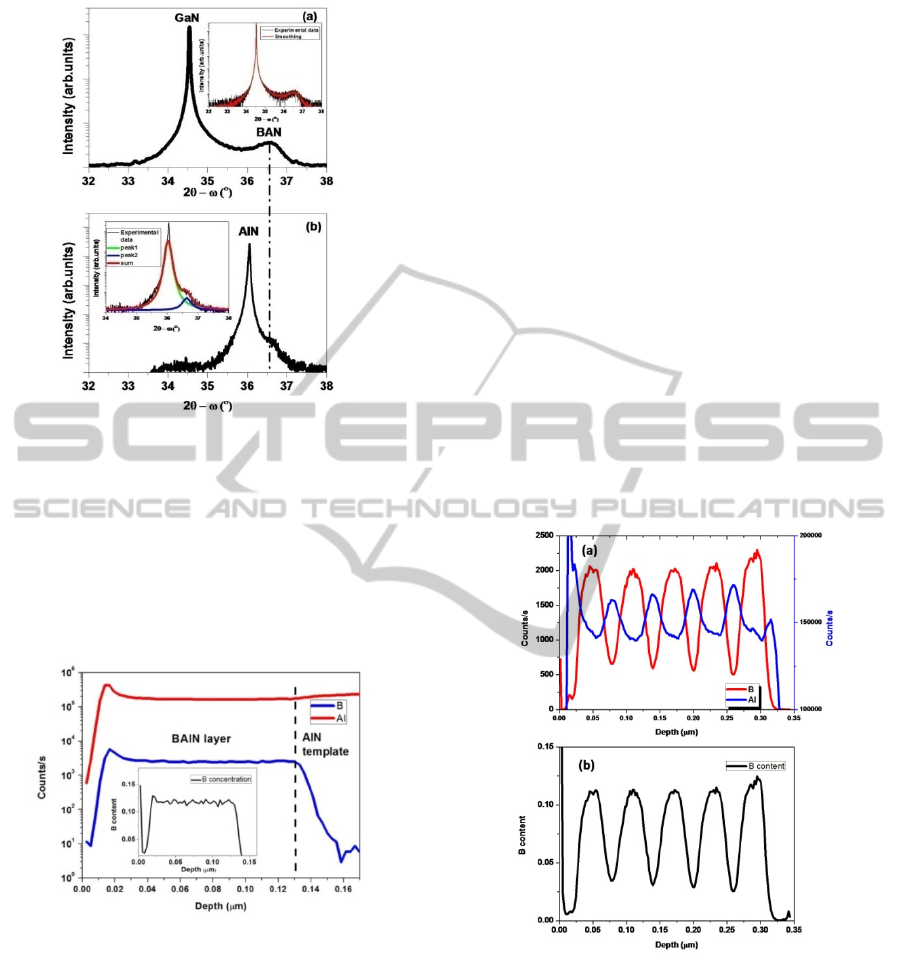

Figure 6: (a) HR-XRD 2θ-ω scan of 20 nm BAlN layers

grown on GaN template at 650 °C under TEB/III=39%; (b)

shows the influence of growth temperature which was

varied between 650°C to 800°C.

In order to have different amount of boron

incorporation, a series of samples were grown on

GaN templates by continuous method, and TEB/III

ratio was changed run to run. As shown in Fig. 7,

when TEB/III ratio is increased from 0 to 39%, the

peak of the layer shifts gradually towards greater

diffraction angles (0 to 5.6% boron). The peak is

Figure 7: HR-XRD 2θ-ω scans of 20 nm BAlN grown on

GaN templates by continuous method under different

TEB/III ratio.

broadened with fringes missing due to

polycrystalline nature of BAlN.

BAlN single layers with clear defined X-ray

diffraction peaks were also achieved by flow-

modulate method on AlN templates which are

appropriate substrates for deep UV devices, as well

as on GaN templates in order to distiguish the XRD

peak of BAlN from the substrate peak. As shown in

Fig. 8, clear XRD peaks can be identified at 36.59˚

( 0.20˚) on both GaN and AlN templates. Lattice c

is 4.908 Å ( 0.025 Å) and the corresponding boron

content is 9% ( 3.2%). Since BAlN peak is very

close to AlN template peak, the deconvolution of

substrate peak and layer peak is shown in the inset

figure.

The concentration calculated by XRD has a large

error range because of the broadness of the BAlN

diffraction peak and uncertainty of the lattice

parameters and strain. These all influence

calculation of the composition from diffraction peak

positions, especially for the layer with high boron

content. So the boron incorporation into the layer

was also analysed by SIMS profile along the growth

direction in Fig. 9. The Al signal is decreased in the

BAlN layer compared with the signal of the template

indicating that boron atoms were substitutionally

incorporated into AlN lattice. Boron has a uniform

distribution along the growth direction. The

concentration of boron can be calculated based on

atomic concentration obtained by SIMS. In order to

calibrate the SIMS signal for quantitative

measurements, a boron-implanted AlN sample with

PHOTOPTICS2015-DoctoralConsortium

32

Figure 8: HR-XRD of 70 nm BAlN on (a) GaN template

and (b) AlN template by FME growth (TEB/III=39%).

Inset figures show the smoothing and deconvolution of

two peaks.

known boron content was used as a reference. The

concentration of boron calculated from the SIMS

signal is 12% with 0.6% error (inset of Fig. 9),

which agrees with the composition range given by

XRD diffraction peak positions (6% ~12%).

Figure 9: SIMS elemental concentration depth profiles of

B and Al for the sample grown on AlN template; inset

shows the boron concentration obtained by using boron

implanted AlN as calibration sample.

More details can be found in (X. Li, Sundaram, El

Gmili, et al. 2014). The promising results advance

prospects for MOVPE-grown boron alloys, which

can result in more freedom in bandgap, strain

engineering with tailoring of refractive index of

DBR structures for eventual deep-UV sources.

6.2.2 BAlN Heterostructure

Low temperature growth can alleviate the boron

poisoning issue, but it does not facilitate AlN growth

for the heterostructure. The fabrication of the

heterostructure is an important issue which needs to

be further developed no matter for BAlGaN-based

MQWs or for DBRs. In this subsection, 5-period

AlN/BAlN heterostructure was grown at 1000˚C.

Flow-modulate method was applied during BAlN

growth.

The boron concentration in the BAlN layers

along growth direction was evaluated by SIMS

profile, as shown in Fig. 10(a). It was clear that B

profile varies anti-phase with Al, which indicates

that Boron atoms substitute Al atoms on the III sites

of lattice to form alloy. 5-period AlN/BAlN layers

exhibit good uniformity except that the first AlN

layer has lower AlN intensity which is due to some

Ga contamination from the sample holder and the

reactor (Kim et al. 2014). The boron content

distribution along the growth direction was

presented in Fig. 10(b). Under our growth conditions,

11% ( ± 0.6%) boron incorporation has been

obtained.

Figure 10: (a) SIMS elemental concentration depth

profiles of B and Al for the sample grown on GaN

template; (b) Boron content in solid layers calculated from

SIMS by using boron implanted AlN sample as reference.

In order to investigate structural quality of this

heterostructure and also crystalline characteristics,

the cross-section STEM was performed along <1 1 -

2 0> zone axis. As shown in Fig. 11(a), the bright-

field STEM image shows that the AlN/BAlN

heterostructure has columnar polycrystalline features,

such as the part in the rectangle box. By looking into

BAlGaN-basedVerticalCavitySurfaceEmittingLaserOperatinginDeepUVRegion

33

the higher magnification image of the interface

between 1

st

AlN and 1

st

BAlN in Fig. 11(c), it is

clear that the 1

st

AlN layer is still monocrystalline.

When BAlN growth starts, the lattice is oriented

along c-axis for around 5 nm, and then the tilt as

large as 60˚ can be observed which means the

structure tends to be polycrystalline and columnar

growth starts. Better contrast of AlN and BAlN

layers can be observed by Z-contrast HAADF-

STEM image shown in Fig. 11(b), where layers with

higher brightness represent AlN layers and darker

layers represent BAlN.

Figure 11: (a) STEM images (bright field) of 5-period

AlN/BAlN heterostructure and columns are clearly

observed in the structure; (b) HAADF-STEM image to

show better contrast of BAlN and AlN layers; (c) high

magnification of the zone where the 1

st

BAlN layer start to

grow.

The polycrystalline feature was caused by the short

diffusion length of boron atoms, which would

challenge the applications of this material. From

STEM image, we observed that the monocrystalline

critical thickness for BAlN with 11% boron is

around 5 nm, above which the polycrystalline

growth occurs. Meanwhile, the monocrystalline

critical thickness is around 500 nm for BAlN

containing 2% boron as reported in the literature

(Akasaka & Makimoto 2006). The more boron is

incorporated, the smaller monocrystalline thickness

of BAlN is. Therefore, for different applications, a

compromise can be achieved between thickness and

boron composition. For example, for deep UV DBRs,

boron incorporation no more than 5% is enough to

achieve high refractive index contrast (Watanabe et

al. 2003; Abid et al. 2012). So the boron content can

be decreased to maintain BAlN layers (30~40nm)

monocrystalline. For ultra-thin layers such as

MQWs or strain engineering superlattices, high

boron incorporation can be used allowing a large

design freedom and it can still be kept as

monocrystalline for its thin thickness (below 10 nm).

More details can be found in (X. Li, Sundaram,

El Gmili, et al. 2014).

6.3 Next Plans

Based on the preliminary results obtained, the next

steps would involve:

1. Design and realization of BAlN/AlGaN DBRs

with reflection at 280 nm. DBRs with high

boron content and polycrystalline feature will

be grown firstly. Then low boron would be

used in order to reduce the interface and

surface roughness. Meanwhile, AlGaN/AlN

DBRs would also be optimized as a reference.

2. Fabrication and tests of final laser devices

including laser diodes, RC-LEDs and VCSELs.

ACKNOWLEDGMENT

This work is supported by French ANR (Agence

Nationale de la Recherche) in the framework of

VESUVE project (ANR-11-BS03-0012). The

authors would like to thank David Troadec from

IEMN in Lille for FIB preparation.

REFERENCES

Abid, M. et al., 2012. Distributed Bragg reflectors based

on diluted boron-based BAlN alloys for deep

ultraviolet optoelectronic applications. Applied

Physics Letters, 100(5), p.051101.

Akasaka, T. & Makimoto, T., 2006. Flow-rate modulation

epitaxy of wurtzite AlBN. Applied Physics Letters,

88(4), p.041902.

Akasaki, I. et al., 1995. Stimulated emission by current

injection from an AlGaN / GaN / GaInN quantum

well device. Japanese Journal of Applied Physics, 34,

p.1517.

Bogusławski, P., Rapcewicz, K. & Bernholc, J.J., 2000.

Surface segregation and interface stability of

AlN/GaN , GaN/InN , and AlN/InN {0001} epitaxial

systems. Physical Review B, 61(16), pp.820–826.

Chuang, S.L. & Chang, C.S., 1996. KP Method for

strained wurtzite semiconductors. Physical Review B,

54(4), pp.2491–2504.

Ding, J. et al., 1990. Laser action in the blue-green from

optically pumped (Zn,Cd)Se/ZnSe single quantum

well structures. Applied Physics Letters, 57(26),

pp.2756–2758.

G.B.Stringfellow, 1993. Compositional ordering in

semiconductor alloys. Mater. Res. Soc. Symp. Proc.,

312, pp.35–46.

PHOTOPTICS2015-DoctoralConsortium

34

Gautier, S. et al., 2007. GaN materials growth by MOVPE

in a new-design reactor using DMHy and NH3.

Journal of Crystal Growth, 298, pp.428–432.

Gil, B., 1998. Group III nitride semiconductor compounds,

Clarendon Press.

Han, J. et al., 1998. AlGaN/GaN quantum well ultraviolet

light emitting diodes. Applied Physics Letters, 73(12),

p.1688.

Higuchi, Y. et al., 2008. Room-temperature CW lasing of

a GaN-based vertical-cavity surface-emitting laser by

current injection. Applied Physics Express, 1,

p.121102 1–3.

Hirayama, H. et al., 2007. 231–261 nm AlGaN deep-

ultraviolet light-emitting diodes fabricated on AlN

multilayer buffers grown by ammonia pulse-flow

method on sapphire. Applied Physics Letters, 91(7),

p.71901.

Hirayama, H. et al., 2014. Recent progress and future

prospects of AlGaN-based high-efficiency deep-

ultraviolet light-emitting diodes. Japanese Journal of

Applied Physics, 53(10), p.100209.

Ippommatsu, M. et al., 2013. Development of AlGaN

DUV-LED. In 10th Conference on Lasers and

Electro-Optics Pacific Rim (CLEO-PR).

Ivanov, S.V. et al., 2014. Plasma-assisted molecular beam

epitaxy of Al(Ga)N layers and quantum well

structures for optically pumped mid-UV lasers on c-

Al

2

O

3

. Semiconductor Science and Technology, 29(8),

p.084008.

Johnson, N.M. et al., 2012. In paper presented at the 9th

International Symposium on Semiconductor Light

Emitting Devices, Berlin.

Kasahara, D. et al., 2011. Demonstration of blue and

green GaN-based vertical-cavity surface-emitting

lasers by current injection at room temperature.

Applied Physics Express, 4(7), p.072103 1–3.

Kim, J. et al., 2014. Origins of unintentional incorporation

of gallium in InAlN layers during epitaxial growth,

part II: Effects of underlying layers and growth

chamber conditions. Journal of Crystal Growth, 388,

p.143-149.

Kolbe, T. et al., 2010. Optical polarization characteristics

of ultraviolet (In)(Al)GaN multiple quantum well

light emitting diodes. Applied Physics Letters, 97(17),

p.171105.

Krestnikov, I.L. & Ledentsov, N.N., 1999. Photopumped

InGaN / GaN / AlGaN Vertical Cavity Surface

Emitting Laser Operating at Room Temperature.

phys. stat. sol., 511, pp.511–516.

Leroux, M. et al., 2004. About some optical properties of

Al

x

Ga

1−x

N /GaN quantum wells grown by molecular

beam epitaxy. Superlattices and Microstructures, 36,

pp.659–674.

Leroux, M. et al., 2002. Optical characterization of

Al

x

Ga

1-x

N alloys ( x<0.7 ) grown on sapphire or

silicon. Physica Status Solidi (b), 234(3), pp.887–891.

Li, X., Sundaram, S., Disseix, P., et al., 2015. AlGaN-

based MQWs grown on a thick relaxed AlGaN buffer

on AlN templates emitting at 285 nm. Optical

Materials Express, 5(2), pp.380-392.

Li, X., Sundaram, S., El Gmili, Y., et al., 2014. BAlN thin

layers for deep UV applications. In E-MRS Spring

Meeting.

Li, X., Sundaram, S., El Gmili, Y., et al., 2014. MOVPE

grown periodic AlN/BAlN heterostructure with high

boron content. Journal of Crystal Growth, pp.3–6.

Li, X.-H. et al., 2014. Low-threshold stimulated emission

at 249 nm and 256 nm from AlGaN-based multiple-

quantum-well lasers grown on sapphire substrates.

Applied Physics Letters, 105(14), p.141106.

Lin, B.C. et al., 2014. Design and fabrication of a InGaN

vertical-cavity surface-emitting laser with a

composition-graded electron-blocking layer. Laser

Physics Letters, 11(8), p.085002.

Martens, M. et al., 2014. Performance characteristics of

UV-C AlGaN-based lasers grown on sapphire and

bulk AlN substrates. IEEE Photonics Technology

Letters, 26(4), pp.342–345.

McIntosh, F.G. et al., 1996. Growth and characterization

of AlInGaN quaternary alloys. Applied Physics

Letters, 68(1), p.40.

Mitrofanov, O. et al., 2006. High-reflectivity ultraviolet

AlGaN⁄AlGaN distributed Bragg reflectors. Applied

Physics Letters, 88(17), p.171101.

Moe, C.G. et al., 2006. AlGaN/AlN distributed bragg

reflectors for deep ultraviolet wavelengths. Physica

Status Solidi (a), 203(8), pp.1915–1919.

Murotani, H. et al., 2011. Silicon concentration

dependence of optical polarization in AlGaN

epitaxial layers. Applied Physics Letters, 98(2),

p.021910.

Nam, K.B. et al., 2004. Unique optical properties of

AlGaN alloys and related ultraviolet emitters.

Applied Physics Letters, 84(25), pp.5264–5266.

Northrup, J.E. et al., 2012. Effect of strain and barrier

composition on the polarization of light emission

from AlGaN/AlN quantum wells. Applied Physics

Letters, 100(2), p.021101.

Pantzas, K. et al., 2012. Nanometer-scale, quantitative

composition mappings of InGaN layers from a

combination of scanning transmission electron

microscopy and energy dispersive x-ray spectroscopy.

Nanotechnology, 23(45), p.455707.

Redwing, J.M. et al., 1996. An optically pumped GaN–

AlGaN vertical cavity surface emitting laser. Applied

Physics Letters, 69(1), pp.1–3.

Reuters, B. et al., 2012. Relaxation and critical strain for

maximum In incorporation in AlInGaN on GaN

grown by metal organic vapour phase epitaxy.

Journal of Applied Physics, 112(9), p.093524.

Ryu, H.-Y. et al., 2013. Investigation of light extraction

efficiency in AlGaN deep-ultraviolet light-emitting

diodes. Applied Physics Express, 6, p.062101.

Shatalov, M. et al., 2012. AlGaN deep-ultraviolet light-

emitting diodes with external quantum efficiency

above 10%. Applied Physics Express, 5, p.082101.

Shatalov, M. et al., 2002. Deep ultraviolet light-emitting

diodes using quaternary AlInGaN multiple quantum

wells. IEEE Journal of Selected Topics in Quantum

Electronics, 8(2), pp.302–309.

BAlGaN-basedVerticalCavitySurfaceEmittingLaserOperatinginDeepUVRegion

35

Tersoff, J., 1996. Stress-driven alloy decomposition during

step-flow growth. Physical review letters, 77(10),

pp.2017–2020.

Venezuela, P. et al., 1999. Self-organized growth of alloy

superlattices. Letters to nature, 397, pp.678–681.

Watanabe, S. et al., 2003. Refractive indices of B

x

Al

1−x

N

(x= 0-0.012) and B

y

Ga

1−y

N (y= 0-0.023) epitaxial

layers in ultraviolet region. Physica Status Solidi (c),

0(7), p.2691-2694.

Xie, J. et al., 2013. Lasing and longitudinal cavity modes

in photo-pumped deep ultraviolet AlGaN

heterostructures. Applied Physics Letters, 102(17),

p.171102.

PHOTOPTICS2015-DoctoralConsortium

36