More Time for the Doing, Having Made the Thinking

3D Printing for Knowledge Circulation in Healthcare

Federico Cabitza

1,3

, Angela Locoro

1

, Aurelio Ravarini

2

and Vittorio Satta

2

1

Università degli Studi di Milano–Bicocca, Milano, Italy

2

Università Carlo Cattaneo – LIUC, Castellanza, Italy

3

IRCCS Istituto Ortopedico Galeazzi, Milano, Italy

Keywords: DiDIY, Medical 3D Printing, Diagnostic, Training, and Surgical Tools, Knowledge Circulation in Healthcare.

Abstract: This paper investigates the phenomenon of the Digital Do-It-Yourself (Di-DIY) in the medical domain. In

particular, the main contribution of the paper is a conceptual framework based on the notion of DiDIY in

healthcare. To help focus on the main actors and assets composing the 3D printing innovation roles in

healthcare we model: the DiDIY-er as the main initiator of the practice innovation; the available technology

allowing the envisioning of new practices; the specific activities gaining benefits from the innovative

techniques introduced; and the knowledge community continuously supporting and evolving knowledge

practices. A general introduction on the notion of Knowledge Artifacts (KAs) and on the use of 3D printing

(3DP) in medicine will be followed by our research questions and by a more detailed analysis of diagnostic,

training and surgical planning activities for clinicians and patients. Observations carried out in a hospital in

Italy are reported to exemplify activities based on 3DP bone models in the radiological and orthopaedic fields.

These observations can be considered a second contribution of the paper, although secondary with respect to

the conceptual framework. They also help proof how knowledge sharing and circulation in the community of

healthcare professionals may be improved by the introduction of tangible and intangible KAs around the

practice of DiDIY. Our framework is then presented in the end.

1 INTRODUCTION

A knowledge artifact has been defined (Cabitza et al.

2014c) as any artifact that is purposely designed to

support knowledge-related activities in any practice.

Although this is an (intentionally) broad definition, it

allows to exclude most of the tools that are used in the

human activities where users do not rely on these

tools to take decisions, access a body of notions that

are useful to interpret or understand a situation, or to

solve a problem and complete a task relying on past

experiences and solutions.

After a comprehensive survey of the varied

literature available on this matter, Cabitza and Locoro

(2014a) identified two main perspectives along which

to conceive this class of artifacts: objectivity and

situativity. These are seen as two extremes of a broad

spectrum of application solutions, which often offer

functionalities that cannot be traced back to only one

extreme but rather lie in between. What do these two

terms refer to? At the former extreme, there lies the

idea that knowledge can be expressed in explicit and

linguistic forms, in terms of guidelines, procedures,

rules and notions. As such, knowledge is somehow

quantifiable (e.g., in terms of how many statements,

rules, notions constitute it); it exists independently of

any possible consumers, like a book on a library shelf;

and it can be transferred from one place to another,

e.g., by email or a courier. Therefore knowledge is

seen as if it were an object for any practical purpose

(hence the name of the approach). At the situativitist

extreme, instead, knowledge is assimilated to a

knowledgeable behavior that competent people

exhibit during a specific situation and within a social

practice. This latter is seen as a set of activities where

more or less explicit rules and conventions that are

shared within a social group stipulate and normate the

right way to have things done, and where an often

totally ineffable know-how allows the practitioners to

accomplish their tasks. In the situativist case, KAs are

those artifacts that enable the sharing of ideas, the

learning process and the mediation of collective

activities of problem framing, agreement reaching

and decision making, without knowledge being

Cabitza, F., Locoro, A., Ravarini, A. and Satta, V.

More Time for the Doing, Having Made the Thinking - 3D Printing for Knowledge Circulation in Healthcare.

DOI: 10.5220/0006095402890298

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 3: KMIS, pages 289-298

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

289

objectified in any form (neither as written facts nor

written rules) as above.

This objective-situative spectrum regards the

degree of specification (high in objective KAs and

low in situative KAs – Cabitza et al. 2013) and the

very way in which knowledge is conceived (cf.

objectivism vs constructivism – Vrasidas, 2000). In

this contribution, to this dimension we add two

further dimensions regarding interactivity, and

tangibility. KAs can be either passive or interactive.

And they can be either tangible or intangible.

The latter dipole allows to distinguish, quite

sharply, between software applications and physical,

tangible objects. The former KAs are certainly

“physical” (and often even material) in that their users

can perceive them, but their way to show themselves

is through patterns of energy and matter that could

hardly be touched (in this light a mouse is just a

tangible controller to move a pointer on the screen,

but the real application regards bit of energy in

memory modules or pixel grids). Tangible objects,

which we all are very familiar with, are usually

passive, but this is not necessarily always the case: a

washing machine, for instance, can be touched

(indeed, it is even quite heavy) but through some

controllers it can also respond to the users’ commands

and settings and through sensors can “take decisions”

on how to proceed in carrying out its washing

programs. On the other hand, not all of the intangible

(software) objects are interactive in the same way, nor

necessarily so their level of interaction matters. For

instance, the Wikipedia, although it is a very

comprehensive and convenient source of knowledge

(in an objectivist viewpoint), responds to the user’s

textual query and allows just to open new pages from

the links of another one, that is a sort of basic

interaction; but it is not proactive in its provision of

knowledge nuggets, facts, taxonomies and

procedures, as an expert system would be; rather it is

reactive. To the other extreme, there are decision

support systems, that is software systems that, once

been fed in with the available information about a

case, suggest ways to classify, treat or manage it (e.g.,

in the healthcare domain, in the legal one and in

Customer Relationship Management). These are very

interactive intangible KAs, which can even surprise

its users (and indeed rightly so they consult it to get

indications they still ignore).

In our studies, we identified two extreme

examples of KA: shapes produced with 3D Printing

(3DP) technology, in particular bones and anatomical

parts printed by radiologists and orthopaedic

surgeons. And social media that support the practices

of the professional roles mentioned above, by

providing videos, blog articles, guides and a place for

DIYers, makers and 3DP enthusiasts in the

orthopaedic surgery domain to ask questions and

exchange advice. This latter case also regards the

increasing use of intangible and interactive KAs that

can support (in a more less objectivist/situativist

manner) the pioneers and early-adopters of 3DP

technologies for their delicate and often very difficult

work (consisting in very complex surgery aimed at

correcting important deformities and alleviating

multiple pathological conditions).

Although both cases are important and worthy of

further research, in this paper we will focus on the

former case, 3DP, in order to both keep the scope of

the paper circumscribed, and also to acknowledge the

increasing relevance of the literature contributions on

embodiment (Dourish, 2001; Lakoff & Johnson,

1999; Varela et al., 1991), which argues for a close

link between physical activity and cognition and on

the role of physical manipulative materials in

supporting learning (Rybarczyk & Fonseca, 2012;

Hornecker & Buur, 2006; Pernin et al., 2012). In the

same vein, we observed how relying on situativist,

tangible and passive KAs, rather than only 2D

representations, improved planning, communication

and decision making in the orthopedic settings we

studied. In what follows, we will interpret these

observations referring to the concept of Digital Do-

It-Yourself (DiDIY), that is a complex phenomenon

that we are characterizing within the DiDIY EU

funded project (DiDIY, 2016) in which either an

amateur or a professional (which we call DiDIYer)

builds up material artifacts by herself with 3D

printing technologies for her job and daily work,

without the aid of specialists.

1.1 Research Questions

Our research topic focuses on the impact of Digital

Do-It-Yourself (DiDIY) and 3D printing (3DP) on the

healthcare practices, training and communication

processes. All of these ambits have in common the

exploitation of knowledge and knowledge artifacts in

different forms (Cabitza et al. 2014c). Healthcare

practitioners rely most of the time on a kind of tacit

knowledge based on their training, “situation specific

wisdom”, and narrative exchange of real cases with

their peers (Greenhalgh and Wieringa, 2011).

Traditional training techniques in health education

are mostly based on human cadavers dissection and

inspection, either for school teaching or pre-operative

simulations (McMenamin et al., 2014; Regier et al.

2010). Finally, pre-surgical, intra-operative and

patient-specific communication are well known to be

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

290

delicate moments where improving the awareness for

patient consenting (de Mel, 2016; Starosolski et al.,

2014; Regier et al., 2010), the shared understanding

in surgical rehearsal (Mitsouras et al. 2015) and the

rapid decision-making during the ongoing operation

may be of vital importance.

Consequently, our research questions regard

whether and how DiDIY processes and artifacts may

influence, enhance and guide the mechanisms of

knowledge circulation (Cabitza et al., 2014b) in

medical settings, and in particular in radiological

practice either by single doctors or in cooperation

with other clinicians. In summary, they are the

following:

Do 3DP artifacts modify diagnostic and

therapeutic decision making?

Do 3DP artifacts modify training and teaching in

radiology?

What are the dynamics of knowledge circulation

between members of hybrid communities and the

hospitals where they work?

Some preliminary answers can be found in this study,

where we elaborate a DiDIY framework tailored on

the specific healthcare domain that should help focus

on the main actors, technologies, activities and

communities involved.

We report in this study some early reflections, on the

basis of the specialistic literature and of the existing

online communities, mentioned in Section 2, and in

observational studies carried out in an Italian hospital,

from which some vignettes have being extracted and

are reported in Section 3 and discussed in Section 4

where we introduce our framework; Section 5 draws

some conclusions on our study.

2 BACKGROUND

2.1 The Technology at Hand

In the healthcare literature, 3D printing is finding its

place in different facets of the professionals practice.

We will shed light in particular on the practice of

surgery, orthopaedics and radiologists, starting from

the technical process of medical 3DP.

For reproducing patient-specific anatomy, 3DP

objects are generated from medical imaging acquired

through either Computer Tomography (CT) in its

several variants (e.g., Multidetector Computer

Tomography (MDCT), Single Photo Emission

Computer Tomography (SPECT), and so on) and

Magnetic Resonance Imaging (MRI). A second step

of this elaborate acquisition is the saving of imaging

data into Digital Imaging and Communication in

Medicine (DICOM) format. A further step consists in

the 3D rendering of the image, by segmentation

techniques, which can be manual, automatic or semi-

automatic (Auricchio and Marconi, 2016), depending

on the complexity of the data managed. Segmentation

allows to place regions of interests on the images for

further volumetric refinement (Mitsouras et al.,

2015). During segmentation, a 3D model of the

acquired image is rendered as a geometrical

transformation into a set of triangles (called mesh),

which allows the data to be readable by a 3D printer.

One of the most common 3D files format for 3D

object printing is the Standard Tessellation Language

(STL), which refers to the property of the image to be

represented as a set of triangles, at different degree of

precision (or smoothing). Commonly, a 3D model is

then virtually cut into equally-thin horizontal slices,

and each slice can be printed in various materials

(e.g., “powder, resins, filaments and hydrogels” – see

de Mel, 2016 and Mitsouras et al., 2015) and laid

down as a layer of the 3D object. Each slice is then

fused together with the just printed layers, according

to disparate techniques using chemical and physics

processes (e.g., photopolymerization, material

jetting, material extrusion, powder bed fusion, sheet

lamination, direct energy deposition, and so on –

Auricchio and Marconi, 2016; Rengier et al., 2010;

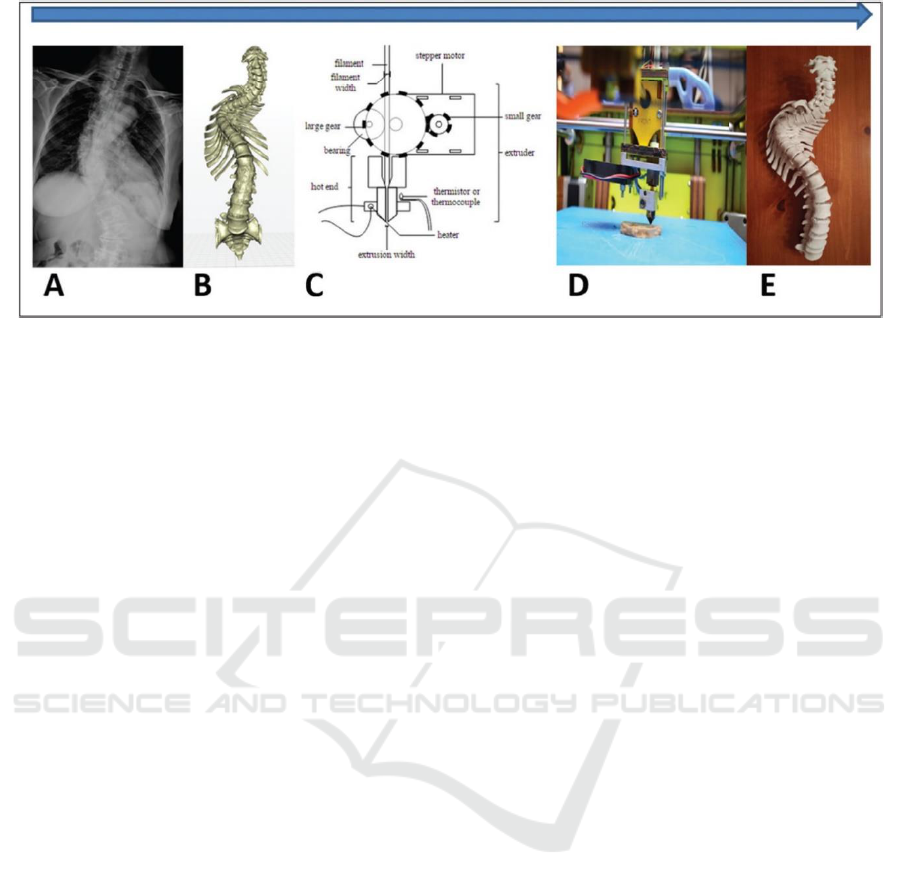

Malik et al., 2015). Figure 1 depicts some main

passages from the acquiring of an image to the printed

object.

2.2 A Quick Glimpse at the Literature

A 3D printed object is very different from a 3D virtual

object. Recent comparative studies of 3D virtual and

material objects in manipulation tasks have shown

that “performance during the activities was

significantly higher when using tangible representa-

tions” (Cuendet et al., 2012). In healthcare domain,

this has proven to give a pre-operative visuo-haptic

capability to physicians of unprecedented flexibility

and precision (de Mel, 2016). 3DP objects can be

exploited to gain a huge amount of patient-specific

detailed and clear information before a complex

surgery takes place, for example in case of

deformities correction. Obviously, not all the

activities need the use of 3DP, and this is especially

evident in diagnostics and classification tasks

(Mitsouras et al., 2015). A literature survey (Malik et

al., 2015) on around 500 papers retrieved from

Medline, Embase and PsychInfo databases, helps

detect the three main areas where 3DP is currently

exploited in surgery. They are: anatomic models,

More Time for the Doing, Having Made the Thinking - 3D Printing for Knowledge Circulation in Healthcare

291

Figure 1: The process from the virtual image to the printed object, taken from Eltorai et al. (2015).

medical devices like surgical instruments and

implants, and prostheses. Anatomic models are used

by doctors to familiarize with the patient anatomy in

surgery planning, and help them reflect on the

challenging and risky passages of an operation well

in advance. This patient-specific appreciation

overcomes traditional simulations (see, for example

Malik et al. 2015; Rengier et al., 2015). In some cases,

for example cardiothoracic surgery, bespoke heart

models are exploited either for planning and for intra-

operation activities. Young surgeons can be trained

(Malik et al., 2015) through the manipulation of these

objects besides traditional virtual patients

environments (Cabitza et al., 2016), which help

“simulate in vivo conditions and real tissues without

any risk of patient complications” (Rengier et al.,

2015). Also patients and their family may be better

informed on the pathology at hand and the necessary

therapy, and this helps the psychological conditions

under which a surgery can be understood, accepted

and perceived as satisfactory (Malik et al., 2015).

In orthopaedic surgery, where “radiographs are

used routinely […] yet they provide inadequate

information on the precise 3D extent of bone defects”

(Auricchio and Marconi, 2016), 3D models are

exploited to assess tools trajectories, to measure and

prepare materials for fixing bone fractures and

placing plates and screws in advance (e.g., assessing

surgical manoeuvres for the placement of pedicle

screws in spinal surgery). Patient-specific guides and

templates are also printed in 3D and used during the

operation as supportive devices that are removed at

the end. In the maxillofacial reconstruction or in the

implants placement, for example, these kind of

devices have reduced the time of operation and

improved the efficacy of the outcomes (Malik et al.

2015).

In low error-tolerance scenarios, such as for

example in neurosurgery, the 3D reproduction of the

skull or of the tumors may help understand the exact

resection boundaries and provide a level of accuracy

that reduce risks, operation time and the number of

errors and adverse events (Mitsouras et al., 2015).

A pivotal factor in favour of the manipulation of

medical imaging for 3DP technology adoption is that

radiologists and radiographers, as more and more

“image guided surgeries call for radiology to become

strongly integrated in a therapeutic team together with

different surgical specialists” (Rengier et al., 2010)

are acquiring prominent roles. However, open issues

rise in the passage from data images into 3D

prototypes as this encompasses “a multidisciplinary

array of fields involving knowledge ranging from

data acquisition, image post-processing and

manufacturing of the prototype by various

techniques” (ibidem). The authors contend that

although radiologists may facilitate the introduction

of additive manufacturing in healthcare, this

integration would result difficult, if feasible at all,

without a close cooperation with other roles such as

computer scientists, material experts, clinicians and

other healthcare professionals.

At the frontier of 3D printing technologies we also

mention bioprinting, i.e., the reproduction of cellular

tissues and the related organs for implantation in

human bodies. Since research studies are still

preliminary, we do not treat them here and refer the

interested reader to the overview by Mok et al.

(2016).

2.3 Online Communities in the Medical

Field

Communities in the field are those of physicians who

meet periodically with 3DP professionals in their

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

292

universities, institutions and research centers, where

a broad spectrum of experimental activities takes

place. This aspect is witnessed for example by our

observational studies reported in Section 3.

Virtual communities of makers exist and gather

around online platforms such as 3D Slicer (Fedorov

et al., 2015), an MIT initiative, which provides a

mature, open source, and fully-fledged software

platform specialized in “image guided therapy”.

Intelligent online platforms such as POIGO (Popescu

et al., 2015) aim to integrate medical expertise with

the manufacturing of tools for the so called

personalized surgical templates, an increasing

popular range of tools for helping surgeons customize

their operations around their patients, and reduce

costs, risks and adverse events.

Other kind of tools are online blogs and reference

websites that help gain knowledge on specific health

topics and techniques, and are tailored for specialists

of different kind; for example: the Italian blog

“Fermononrespiri” (http://fermononrespiri.com/)

where discussions on MRI, CT, and diagnostic by

images are the main topics discussed by the

participants to the online forum that the website

provides; “Embodi3D” (http://www.embodi3d.com),

where a virtual community gathers around virtual

spaces such as blogs, forums, textual tutorial and

“how-tos” for 3DP, a marketplace where to buy and

sell biomedical models, and a training section with

training models, realized with the aid of health

professionals (e.g., 3D vascular models such as

venous models and arterial models).

3 OBSERVATIONAL STUDIES

In our study, we had the opportunity to carry out two

observational studies in the Marino hospital in

Cagliari, Italy. This hospital is near to be dismissed,

since the recent regional policy making decision of

cutting administrative costs. However, currently the

hospital hosts healthcare figures of both professional

and academic kind, in the two local specializations of

traumatology and emergency surgery. The hospital is

one of the only two hospitals in the Sardinia Island

equipped with hyperbaric chambers. Its main areas of

orthopaedic expertise are hip and knee surgery, upon

which we will focus our investigation. In particular,

we will examine a case where the introduction of

additive manufacturing (3DP) has been used to

support the planning and pre-operative training of a

knee prosthetic surgery.

This is not the case of an ex-novo, patient-specific

3D printing of a knee prosthesis (re)production, but

of a traditional bone-prosthesis replacement, with the

support of an anatomic model of the patient bones,

exploited to support and enhance the outcome of a

traditional surgical practice.

We depict in the following two vignettes on how

3DP is used to inform and educate the patient to know

more of his pathology and of the subsequent therapy,

as well as for surgical rehearsal.

3.1 The Patient Informed Consent

It is Monday morning. Today Prof. Bones will

explain the pros and cons of the procedure of knee

replacement surgery that Marco Poli (male, 58 years

old) will decide to undertake or not. In case he decides

to do it, he will sign the informed consent form.

Prof. Bones, the orthopaedic surgeon, met Mr.

Poli previously and, during that occasion, he

prescribed to him routinely examination tests such as

blood, urine, drugs intolerance, and a radiography. By

reporting the radiologist report of this last exam Prof.

Bones realized the morphological deformities and

damages affecting the patient’s knee joint and the

need for Mr. Poli to undergo a surgery.

For this reason, once the surgeon analyzed the

report, he prescribed to Mr. Poli a second and more

complete diagnostic examination: a CT, with the aim

to obtain from it a 3D dataset in DICOM format and,

hence, to use addictive manufacturing to create a

patient-specific anatomical model before the meeting

with him during the day hospital session. In so doing,

Prof. Bones could further investigate the patient-

specific problem and let Mr. Poli see and touch first

hand the tangible representation of his condition,

through the replica of his irreversibly injured

articulation.

Monday it’s the day where other tests are done,

more extensive and specific, to gather information

about the patient’s anamnesis. In particular, physical

examinations are aiming at assessing movement,

stability, strength, and alignment of the patient’s

joint, and a more specific test (an MRI) was aimed to

better analyze the anatomy of his soft tissue (muscles,

tendons, and cartilage).

The study of Mr. Poli’s anamnesis already

showed a compound fracture dating back to when he

was 32, which involved the femur to come closer to

the same left knee region now under examination. In

addition, during these last exams, Prof. Bones

evaluates the condition of the damage caused by post-

traumatic arthritis, which severely limits the patient

in articular functionality by afflicting him with

persistent pain, and pronounce himself in favour of

the joint replacement as a treatment of election.

More Time for the Doing, Having Made the Thinking - 3D Printing for Knowledge Circulation in Healthcare

293

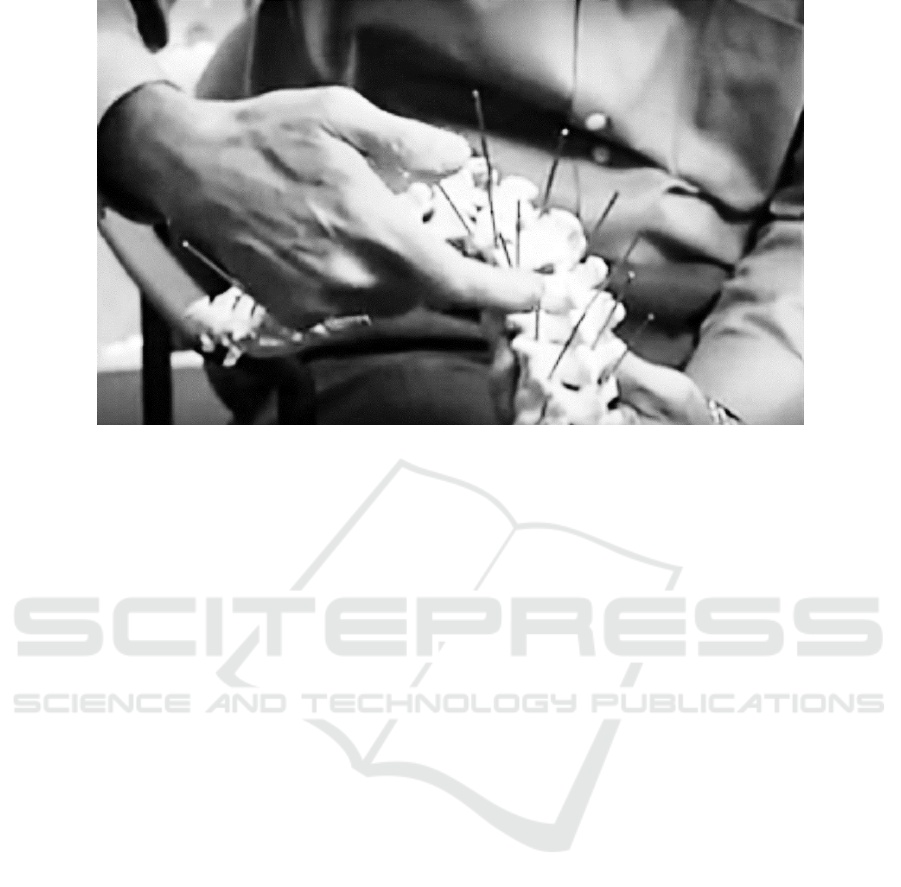

Figure 2: A 3DP spine with implanted nails for pre-surgical rehearsal.

Now Prof. Bones is ready to talk to Mr. Poli, who

may appreciate his own case also with the aid of

anatomic models reproducing his articulations, and

that the surgeon made ready before their meeting.

Thanks to them, the surgeon can show with precision

to the patient which parts of his knee are irreducibly

deteriorated, which operation Mr. Poli should

undergo to his bottom femur and top tibia to let the

articulation work out again, and to hypothesize with

him the exploitation of the proper traditional

prosthesis having the best dimensions similar to his

original bones.

In so doing, Mr. Poli understands vividly his case,

and is able to integrate these information with those

reported in the informed consent form. Mr. Poli,

under a mood of psychological relief for the

awareness gained during the meeting with the

surgeon, agrees to the operation.

3.2 The Surgical Planning

The Friday before, the orthopaedic surgeon met the

radiologist to discuss in more details the case at hand

and asked him whether he recommended to run a

further test in order to use additive manufacturing

with the case at hand. The radiologist proposed to do

an MRI scan, and to call Dr. Bolt, who is a

professional consultant in the field of additive

manufacturing and 3D technologies applied to

prosthetic surgery, with the aim to print a 3D model

of the patient’s joint bones. In particular, the

radiologist asked Dr. Bolt to do an evaluation of the

most appropriate acquisition parameters, in order to

optimize the effectiveness of the dataset for later use

with additive manufacturing technologies.

Both MRI and CT results are exploited in order to

obtain the most accurate reproduction of both the hard

and soft tissues of the patient-specific anatomical

model.

The surgeon then calls the professional

consultant, with whom he agrees upon which are most

appropriate materials and processes to be used. An

anatomical replica of the patient’s hard tissues should

be produced by using Fused Deposition Modeling

(FDM) technology and Polyethylene terephthalate

glycol-modified (PETG) material, as this can be

submitted to antibacterial sanitizing processes, if

necessary. An anatomical replica of soft tissues

should be produced by stereolitography (SLA) and

photosensible resin, which is a soft and flexible

material that could be also compatible with some

sanitizing procedures.

Thanks to the 3DP custom-made models the

surgeon and his team may start the surgical planning.

The surgeon studies the osteotomy planes, performs

measures of trajectories and lengths of the necessary

perforations by simulating them directly in the

anatomical models.

In so doing, the surgeon may transfer all the

necessary data to the consultant, so that he can in his

turn create the anatomic replicas, the surgical guides

and all the supporting material for the operation. For

example, he may prepare the osteotomy planes in the

custom-made models with the cuts and the holes

already performed on them, through FDM and SLA

technologies, and under the direct supervision of the

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

294

surgeon, who can simulate the operation moments in

minute detail.

The software used in this phase allows the

application of osteotomy planes and holes, the

creation of scaffolds for dimes and the 3D models

availability of virtual existing surgery environments.

Furthermore, in case that a prostheses has

undergone a 3D scanning process or simply its 3D

models are available from the manufacturer, it is

possible to pre-operatively overlap 3D prosthesis

models with custom-made anatomical models, so that

the prostheses fitting the patient’s bones size can be

easily selected.

After this surgical rehearsal, some comparisons

and verifications of the obtained results are still

possible. In this sense, the surgeon verifies all the pre-

operative process details by applying a real prosthesis

of the same size of the one used in the surgical

planning phase.

3.3 Some Cost-effort Data and Lessons

Learnt

3DP is not cost nor effort free. In the specific cases,

different phases before the printing were carried out,

namely: image of bones acquisition; DICOM data

storage and transfer (after the clinicians’ decision on

what to print); rendering, segmentation and triangula-

tion for the generation of the 3D model; further

editing and preparation (with the aid of the clini-

cians); slicing and G-code generation (for program-

ming the printer). These pre-printing activities takes

on average from 4 to 20 working hours. The printing

of the patient-specific bones took around 50 hours.

The costs depend on the printing technologies (e.g.,

either Stratasys or MakerBot printers, whose costs

vary from 60.000 to 4.000 euros, respectively), on the

materials used, and on the level of standardisation of

these materials with respect to standards such as ISO

and so on. For the case at hand, these may vary from

an average of 50 to 250 euros per kilo. In the specific

case, the 3DP bones were accurate enough to

guarantee similar material characteristics (e.g.,

density and resistance).

The most critical and error-prone passage was the

activity of conversion from ERM raw data into

DICOM data. In general, this is the most delicate

passage and the one where both radiologists,

engineers and other experts are requested to cooperate

and coordinate their work and competences. As a

general lesson from our experience, we may report

that costs and efforts were considered affordable and

the exploitation of the cheapest printer (the MakerBot

one) did not compromise the quality of the work and

the satisfaction of both the patient and the clinicians

in manipulating the 3DP bones.

4 A DIDIY FRAMEWORK

The DiDIY project (http://www.didiy.eu/) defines

DiDIY as human-centered phenomenon

characterized by the diffusion of:

• a mindset among individuals: the “DiDIYers”;

• a set of activities enacted by DiDIYers: the

“DiDIYing”.

The latter activities are intended as pragmatically

translating in a context the abstraction of mindset of

an individual and, as a consequence, natively

overcoming the level of analysis of the single

individual. In DiDIY digital technology is an

“enabler”, but the very existence of DiDIY does not

depends on the presence of digital technology, as its

core properties are human-centric, thus related to

individuals’ mindsets and activities.

In short, according to this approach an individual

can be defined as a DiDIYer when, due to her

mindset: (i) she uses to “do things” on her own that

had been previously carried out by experts or

specialized companies (this aspect deals with the

traditional notion of Do-It-Yourself, or “DIY”), and

(ii) these “things” could not be “done” without digital

technology (“Di”DIY).

Under this premise, an operational definition

which enables the identification of DIDIY activities

is the following:

a) a DiDIYer, i.e., certain organizational roles

b) carries out on their own certain activities,

c) by exploiting certain digital technologies;

d) possibly exploiting the knowledge sharing within

a certain knowledge community (Cabitza et al.

2014c)

According to this definition and to our

preliminary research, we instantiate its four

dimensions in the medical domain, as follows:

DiDIYers: are the healthcare professional whose

skills are those of a digital craftsman. This role can be

played for example by doctors, surgeons, nurses,

technical clinicians (e.g., radiographers). In particular

our research focused on two main roles and activities:

the Radiologist, in her diagnostic and prognostic

activities, who runs examinations with proper

technologies and acts directly or highlights to her

colleagues actions to be taken, based on all the

medical information gathered during the analysis

More Time for the Doing, Having Made the Thinking - 3D Printing for Knowledge Circulation in Healthcare

295

of examinations results. State-of-the-art

information are bi-dimensional representations

(axial, coronal and sagittal planes) of the

analyzed anatomical parts or, at last, 3D

visualizations available thanks to 3D dashboards

provided by the ultimate diagnostic tools.

Whenever there are strong interpretation

misalignments of diagnostic examinations, for

example in case of congenital deformities, the

radiologist joins the surgeon (or her

collaborators) in order to analyze the

examination together, so as to reconcile meaning

and proceed the activity with the aid of a complex

however complete set of information;

the Surgeon, in her therapeutic activities, who

applies her surgical specialty methodologies. She

needs to collect the most part of information

before taking decisions and actions that are

neither diagnostic nor prognostic, hence they are

not at all repeatable. For this reason, the surgeon

needs the support from her colleagues, and in

most complex scenarios, even from other

healthcare professionals, such as for example

clinical engineers, other specialists, consultants

and so on.

Technology: is the elective tool of the DiDIY-er to

improve her activities or to face them in innovative

ways and under unusual perspectives. The

technologies involved in the healthcare domain

encompass: 3D datasets from physical objects

through scanning and diagnostic image acquisition;

2D visualizations of physical objects, through

DICOM files or CAD software; 3D manufacturing of

physical objects. In this sense, 3DP amplifies the

capabilities to go from bits to atoms back and forth

(blinded reference).

Activity: is the (knowledge) practice of the DiDIYer;

it is the daily routine that a professional carries out

alone or as a part of a community. The use of

technology should improve and innovate her daily

activities, so that a virtuous circle can be triggered,

and creativity and new skills can emerge and flow

freely, also thanks to her network community.

Medical practice is peculiarly “practical”, and

tangible and intangible information concur to define

the logic of “knowing how to do it” or DIY. In the

words of an orthopaedic surgeon (Malik et al., 2015)

that we adapted to emphasize the importance of tools

that improve the situated awareness and support more

critical scenarios during surgical operations:

“Having the chance to perform on a 3D model all

the necessary steps preoperatively, valuable time is

saved and surgeons have more time to focus on the

present moments: you have more time for the doing,

having made the thinking”

Community: can be offline, online or both, and

encompasses individuals who are either

contextualized in physical meetings and workshops

or in the virtual spaces of an online environment. In

communities people can find inspiration for new

ways of doing things while exchanging and sharing

knowledge. The community is the vehicle to share

experiences, results and open new ways and

directions to practical problems.

In the medical domain, cross-fertilization has a

pivotal role: during conferences or pre-operative

meetings, surgeon together with radiologists,

biomedical engineers, and other medical team

members may share heterogeneous knowledge and

competences and find a synergy to solve problems,

propose solutions or simply hypothesize new

healthcare trajectories and allies.

5 CONCLUSIONS

In this paper we have investigated how healthcare

professionals may be helped in sharing knowledge

and cooperating thanks to 3DP resources and 3D

objects, seen as either intangible and tangible

(respectively) Knowledge Artifacts (KAs).

In so doing, we have illustrated as the printing of

virtual 3D objects into tangible material artifacts does

not regard only the transition “from bits to atoms”

(Bull & Garofalo, 2009). Rather it also pertains the

transition from digital objects to “matters of fact”

(i.e., physical objects) and eventually to “matters of

concerns” (Latour 2004), that is things, to discuss

both about and around. The physical availability in

an increasing number of work settings of this kind of

things, through a making-oriented and DIY attitude,

creates opportunities also for other kinds of social

making, like sense making and decision making (in

our case, among health practitioners) and enrich these

activities in ways that are still to be explored.

In particular, we illustrated this phenomenon in

two vignettes taken from our observational study:

1) the orthopaedic surgeon talks with the patient,

who is going to undergo a surgery for the replacement

of his knee joints, by showing him details of his injury

and the necessary operation details with the aid of a

custom-made 3D anatomical model. This KA helps

the patient “see” his situation more clearly and take a

more informed decision on the surgical operation;

2) the orthopaedic surgeon talks with his team

members to discuss the details of the surgical

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

296

operation and to test in advance the prosthesis against

the patient-specific 3D reproduction of the knee joint

articulation (the KA). In so doing, a relevant amount

of time can be saved for settings and measurements,

and the KA can help reduce the operation time,

improve safety and lead to better outcome.

As purported in the specialist literature and

confirmed in our observational studies, 3DP has got a

potential to change the work of surgeons, both in

regard to surgery planning, and in educational

activities with novices, as well as in the

communication with the patient. In this sense,

medical 3DP objects represent a new toolkit of KAs

available to prosthetic practitioners, as these artifacts

allow for the patient-specific configuration and

setting of the main parameters and measurements that

can be tested before the surgery takes place. In this

light, further research should be aimed at

understanding whether prototype replicas can help

practitioners replace the more traditional “diagnostics

by imaging” paradigm with a complementary, if not

alternative, one: a “diagnostics by volumes”, which

would enable the emergence of new knowledge

circulation practices and habits.

ACKNOWLEDGEMENTS

This article has been developed under the DiDIY

project funded from the European Union’s Horizon

2020 research and innovation programme under grant

agreement No 644344.

REFERENCES

Auricchio, F., & Marconi, S., 2016. 3D printing: clinical

applications in orthopaedics and traumatology. EFORT

Open Reviews, 1(5), 121-127.

Bull, G., & Garofalo, J., 2009. Personal Fabrication

Systems: From Bits to Atoms. Learning & Leading with

Technology, 36(7), 10-12.

Cabitza, F., Colombo, G., & Simone, C. 2013. Leveraging

underspecification in knowledge artifacts to foster

collaborative activities in professional communities. Int

J Hum-Comput St, 71(1), 24-45.

Cabitza, F., Fogli, D., & Locoro, A., 2016. Virtual patients

for knowledge sharing and clinical practice training: a

gamified approach. GALA 2015, LNCS, 329-335.

Cabitza, F., Locoro, A., 2014a. Made with knowledge:

Disentangling the IT Knowledge Artifact by a

qualitative literature review. In KMIS 2014, 64-75.

Cabitza, F., Cerroni, A., Locoro, A., Simone, C. 2014b. The

knowledge-stream model: A comprehensive model for

knowledge circulation in communities of

knowledgeable practitioners. In KMIS 2014, 367-374.

Cabitza, F., Cerroni, A., & Simone, C. 2014c. Knowledge

artifacts within knowing communities to foster

collective knowledge. In AVI 2014, ACM, 391-394.

Cuendet, S., Bumbacher, E., and Dillenbourg, P. 2012.

Tangible vs. virtual representations: when tangibles

benefit the training of spatial skills. In NordiCHI '12.

de Mel, A., 2016. Three-dimensional printing and the

surgeon. British Journal of Surgery, 103(7), 786-788.

DiDIY, D3.1-1.2, Deliverable Doc no 3.1 of the DiDIY

project, Sept 2016.

Dourish, P. 2001. Where the Action is: The Foundations of

Embodied Interaction. MIT Press, Cambridge, USA.

Eltorai, A. E., Nguyen, E., & Daniels, A. H. 2015. Three-

Dimensional Printing in Orthopedic Surgery.

Orthopedics, 38(11), 684-687.

Fedorov A., Beichel R., Kalpathy-Cramer J., … Kikinis R.,

2012. 3D Slicer as an Image Computing Platform for

the Quantitative Imaging Network. Magnetic

Resonance Imaging, 30(9), 1323-41.

Greenhalgh, T., & Wieringa, S., 2011. Is it time to drop the

‘knowledge translation’metaphor? A critical literature

review. Journal of the Royal Society of Medicine,

104(12), 501-509.

Hornecker, E. & Buur, J. 2006. Getting a grip on tangible

interaction: a framework on physical space and social

interaction. In: Procs of ACM CHI 2006. 437-446.

Lakoff, G., & Johnson, M. 1999. Philosophy in the flesh:

The embodied mind and its challenge to western

thought. Basic books.

Latour, B., 2004. Why has critique run out of steam? From

matters of fact to matters of concern. Critical inquiry

30(2), 225-248.

Malik, H. H., Darwood, A., … & Baskaradas, A., 2015.

Three-dimensional printing in surgery: a review of

current surgical applications. Journal of Surgical

Research, 199(2), 512-522.

McMenamin, P. G., Quayle, M. R., McHenry, C. R., &

Adams, J. W., 2014. The production of anatomical

teaching resources using three-dimensional (3D)

printing technology. Anatomical sciences education,

7(6), 479-486.

Mitsouras, D., Liacouras, P., ... & Ho, V. B., 2015. Medical

3D printing for the radiologist. RadioGraphics, 35(7),

1965-1988.

Mok, S. W., Nizak, R., ... & Malda, J., 2016. From the

printer: Potential of three-dimensional printing for

orthopaedic applications. Journal of Orthopaedic

Translation, 6, 42-49.

Pernin, J. P., Michau, F., Mandran, N., & Mariais, C. 2012.

ScenLRPG, a board game for the collaborative design

of GBL scenarios: qualitative analysis of an

experiment. In Proc. of the 6th European Conference

on Games Based Learning, 384-392.

Popescu, D., Laptoiu, D., Hadar, A., Ilie, C., & Pârvu, C.,

2015. Workflow for additive manufacturing of an

individualized surgical template. Procs in

Manufacturing Systems, 10(3), 131-140.

More Time for the Doing, Having Made the Thinking - 3D Printing for Knowledge Circulation in Healthcare

297

Rengier, F., Mehndiratta, A., von Tengg-Kobligk, H.,

Zechmann, C. M., Unterhinninghofen, R., Kauczor, H.

U., & Giesel, F. L., 2010. 3D printing based on imaging

data: review of medical applications. International

journal of computer assisted radiology and surgery,

5(4), 335-341.

Rybarczyk, Y. and Fonseca, J. 2011. Tangible interface for

a rehabilitation of comprehension in aphasic patients.

In: Association for the Advancement of Assistive

Technology in Europe.

Starosolski, Z. A., Kan, J. H., Rosenfeld, S. D.,

Krishnamurthy, R., & Annapragada, A., 2014.

Application of 3-D printing (rapid prototyping) for

creating physical models of pediatric orthopaedic

disorders. Pediatric radiology, 44(2), 216-221.

Varela, F.J., Rosch, E., Thomson, E. 1991. The Embodied

Mind. MIT Press.

Vrasidas, C. (2000). Constructivism versus objectivism:

Implications for interaction, course design, and

evaluation in distance education. IJET, 6(4), 339-362.

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

298