A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile

Maneuvering on Loose Surfaces

Manuel Acosta, Stratis Kanarachos and Michael E. Fitzpatrick

School of Mechanical, Aerospace and Automotive Engineering, Coventry University, Coventry, U.K.

Keywords:

Agile Maneuvering, Linear Quadratic Regulator, Drift Control, Motion Planning, ADAS.

Abstract:

This paper presents a novel Hybrid Hierarchical Autonomous system for improving vehicle safety based on

agile maneuvering and drift control on loose surfaces. Standard Electronic Stability Control Systems provide

stability by limiting the vehicle body slip, thus reducing the capability of the vehicle to generate lateral ac-

celeration and follow road segments and paths with high curvature on loose surfaces. The proposed system

overcomes this shortcoming. Furthermore, it is the first time where a solution for arbitrary road geometries is

proposed. The system described in this work consists of three layers. The first layer selects the driver model.

The second layer selects the path to be followed and the maneuver type using a Proportional controller and

motion planning strategies. The third layer coordinates the steering and driving functions of the vehicle to per-

form the maneuver, where a Gain-Scheduled Linear Quadratic Regulator is employed to achieve drift control.

The hybrid system is implemented in Matlab/Simulink

R

and tested in two scenarios: First, a Rally-like stage

formed by a combination of clothoid and arc segments is used to study the drift-path-following capabilities of

the system, and lastly, a lateral collision case is proposed to evaluate the suitability of the system as an ADAS

Co-Pilot system for lateral collision avoidance.

1 INTRODUCTION

Rallying stands out from other motorsport disciplines

due to the complexity and peculiarities associated

with Rally driving techniques. While Formula drivers

operate the vehicle linearly, with smooth and gentle

inputs, and seeking for quasi-static conditions, pro-

fessional Rally drivers exhibit an aggressive behavior.

They take advantage of the car non-linearities and ex-

cite the yaw dynamics to generate high yaw acceler-

ations and change the vehicle attitude fast (Blundell

and Harty, 2004). It is remarkable how Rally drivers

adapt their behavior to the road friction characteristics

(e.g. Tarmac, Gravel) and control the vehicle under

all kind of disturbances (e.g. roots, bumps). Using

an analogy with control systems, it can be stated that

Formula drivers are very precise controllers for track-

ing problems (racing line) whereas Rally drivers are

outstanding robust controllers (drift stabilization).

The problem of off-road autonomous maneuver-

ing has been adressed in (Lenain et al., 2017; Lenain

et al., 2012) employing kinematic and dynamic mod-

els for low-speed path tracking. In order to develop

autonomous vehicles capable of operating the vehi-

cle at higher speeds and more demanding conditions,

some authors have focused their research in the study

of the dynamics behind Rally driving techniques. In

(Acosta et al., 2016) the yaw acceleration required

to perform agile maneuvers such as Scandinavian

Flick or Trail Braking was studied employing the Mo-

ment Method Diagram (MMD), (Milliken and Mil-

liken, 1995), and a Finite State Machine (FSM) capa-

ble of performing these tasks autonomously was pro-

posed. In (Velenis et al., 2007) a mathematical anal-

ysis of these maneuvers was presented and different

trajectory optimization scenarios were studied using a

numerical scheme. A stability analysis of aggressive

driving techniques was presented in (Yi et al., 2012;

Li et al., 2011), and a stability phase portrait based on

the yaw rate and the rear wheel slip angle was pro-

posed.

The analysis of drifting techniques was ap-

proached in (Hindiyeh, 2013; Velenis et al., 2011;

Edelmann and Plochl, 2009). In (Edelmann and

Plochl, 2009), the unstable nature of the powerslide

motion was studied numerically using a two-track ve-

hicle model and root locus analysis. In (Velenis et al.,

2011), the stabilization of a Rear-Wheel-Drive (RWD)

vehicle around the steady-state drift equilibrium was

studied. A cascade control architecture formed by a

Linear Quadratic Regulator (LQR) and a Backstep-

ping controller was proposed for this purpose. The

216

Acosta, M., Kanarachos, S. and Fitzpatrick, M.

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces.

DOI: 10.5220/0006393002160225

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 216-225

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

same problem was investigated in (Velenis, 2011), but

this time a Front-Wheel-Drive (FWD) driveline archi-

tecture was employed. In (Hindiyeh, 2013), a nested-

loop structure was proposed, and an input coordina-

tion scheme was suggested to integrate the lateral and

longitudinal control actions.

Finally, the first pieces of evidence of autonomous

or semi-autonomous systems that replicate some pat-

terns exhibited by Rally drivers have been found in

(Cutler and J.P.How, 2016; Gray et al., 2012). In

the former, autonomous drifting is achieved using a

methodology to incorporate Optimal Control policies

into a Reinforcement Learning (RL) process. In (Gray

et al., 2012), authors proposed a hierarchical two-

level control framework composed of a high-level

motion planner and a low-level trajectory tracking

controller based on Model Predictive Control (MPC).

In this paper, a Rally-based driver model is pro-

posed for improving the vehicle safety based on the

autonomous execution of agile maneuvers and drift

control. The contribution of the paper is significant

in what concerns driver modeling, as the drift control

action is no longer restricted to constant radius turns

and is performed along clothoid and arc segments of

different radii instead. In Section 2, the formulation

employed to model the vehicle planar dynamics, tires,

and road, is presented. In addition, relevant back-

ground about the Drift Equilibrium Solutions and Lin-

ear Quadratic Optimal Control is provided. The struc-

ture of the driver model proposed in this paper is de-

scribed in Section 3. Simulation results for two sce-

narios: Rally-like stage and Lateral collision avoid-

ance are provided in Section 4. Finally, conclusions

and future intended steps are exposed in Section 5.

2 BACKGROUND

2.1 System Modeling

2.1.1 Single-track Vehicle Model

Following the approach proposed in previous works

to study the vehicle behavior in agile maneuvers and

drift-equilibrium problems, (Tavernini et al., 2013;

Velenis et al., 2010), a single track model is employed

in this research, expressions (1-3).

˙x

1

=

1

m

(F

x f

cos(u

1

) − F

y f

sin(u

1

) + F

xr

) + x

2

x

3

(1)

˙x

2

=

1

m

(F

y f

cos(u

1

) + F

x f

sin(u

1

) + F

yr

) − x

1

x

3

(2)

˙x

3

=

1

I

ψ

(F

y f

cos(u

1

)l

f

+ F

x f

sin(u

1

)l

f

− F

yr

l

r

) (3)

The vehicle longitudinal velocity (v

x

), lateral velocity

(v

y

), and yaw rate (

˙

ψ), form the state vector of the sys-

tem (x = {v

x

, v

y

,

˙

ψ}). The terms l

f

, l

r

correspond to

the distance from the front and rear axles to the center

of gravity respectively. The vehicle mass is denoted

by m and I

ψ

is the yaw inertia of the vehicle. The

steering wheel angle and the axle longitudinal slips

are considered inputs to the system (u = {δ, λ

f

, λ

r

}).

Wheel rotating dynamics modeling is avoided at this

stage of the research in order to simplify the prob-

lem formulation. The vehicle parameters employed

in this paper are presented in Table 1, and correspond

to a compact rear-wheel-drive vehicle. The tire forces

required to compute the system states are modeled us-

ing the nonlinear expressions (4-5).

F

x,i

= F

z,i

µ(λ

i

, α

i

), i ∈ { f , r} (4)

F

y,i

= F

z,i

µ(λ

i

, α

i

) (5)

The normal load proportionality principle is as-

sumed, and the tire friction coefficient is presented as

a nonlinear function that depends on the axle wheel

slips (α) and the axle longitudinal slips (λ). The for-

mer are obtained from the geometric equations (6-

7), using a small angle approximation (Kanarachos,

2012).

α

f

= u

1

−

x

3

l

f

x

1

−

x

2

x

1

(6)

α

r

= −

x

2

x

1

+

x

3

l

r

x

1

(7)

Finally, the tire vertical forces (F

z

) are calculated

using a simple steady-state longitudinal weight trans-

fer model (8).

F

z,i

= F

zi,st

±

mh

CoG

l

f

+ l

r

( ˙x

1

− x

2

x

3

) (8)

The height of the center of gravity is denoted by

h

CoG

, and the static vertical loads are designated by

F

z,st

.

Table 1: Parameters of the Single-Track model.

Sym. Value Unit Sym. Value Unit

l

f

1.35 m l

r

1.45 m

h

CoG

0.55 m I

ψ

1800 kgm

2

m 1500 kg Drive RWD −

2.1.2 Tire Friction Model

The tire friction coefficients (µ

x

, µ

y

) are approximated

with a simplified isotropic model that employs a

Magic Formula-based (MF) formulation. The theo-

retical longitudinal and lateral slips (σ

x

,σ

y

), as well as

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces

217

Table 2: Pacejka tire parameters representative of gravel and

asphalt surfaces, (Tavernini et al., 2013).

Surface B C D E

Gravel 1.5289 1.0901 0.6 -0.95084

Asphalt 6.8488 1.4601 1.0 -3.6121

the equivalent slip (σ) are computed from expression

(9), following the formulation presented in (Tavernini

et al., 2013; Pacejka, 2012).

σ

x

=

λ

1 + λ

, σ

y

=

tanα

1 + λ

, σ =

q

σ

2

x

+ σ

2

y

(9)

Once the equivalent slip is calculated, the longitu-

dinal and lateral friction coefficients are obtained us-

ing equations (10-11).

µ

x

=

σ

x

σ

D

λ

sin[C

λ

arctan{σB

λ

− E

λ

(σB

λ

− arctan σB

λ

)}]

(10)

µ

y

=

σ

y

σ

D

λ

sin[C

λ

arctan{σB

λ

− E

λ

(σB

λ

− arctan σB

λ

)}]

(11)

The MF tire parameters employed in this paper

are shown in Table 2, and were extracted from (Tav-

ernini et al., 2013). These parameters approximate the

shape of the friction-slip curves that are characteristic

of gravel and asphalt surfaces.

2.1.3 Road Modeling

The position of the vehicle with respect to the ref-

erence path is expressed in curvilinear coordinates,

(Tavernini et al., 2013). The position of the vehicle

along the reference path S

s

, the lateral deviation of the

vehicle with respect to the road centerline S

n

, and the

rotation of the vehicle with respect to the road tangent

ε, are computed using expressions (12-14).

˙

S

s

=

V cos(ε + β)

1 − S

n

κ

(12)

˙

S

n

= V sin(ε + β) (13)

˙

ε =

˙

ψ − κ

V cos(ε + β)

1 − S

n

κ

(14)

Where κ is the road curvature, V is the module of

the velocity, and β is the vehicle body slip angle.

2.2 Drift Equilibrium Solutions

The reference solutions necessary for the drift control

task are obtained following the approach presented in

(Velenis et al., 2011). Steady-state conditions are im-

posed on the vehicle planar motion states, and the ve-

hicle body slip angle (β) and the road radius (R) are

fixed. The Matlab

R

function fsolve is used to solve

the vehicle dynamic equations (1-8). The tire rolling

resistance is neglected, and the front axle longitudinal

slip is set to zero (λ

f

= 0). In order to study the in-

fluence of the tire friction characteristics on the drift

equilibrium solutions, the process was repeated using

the gravel and asphalt parameters presented in Table

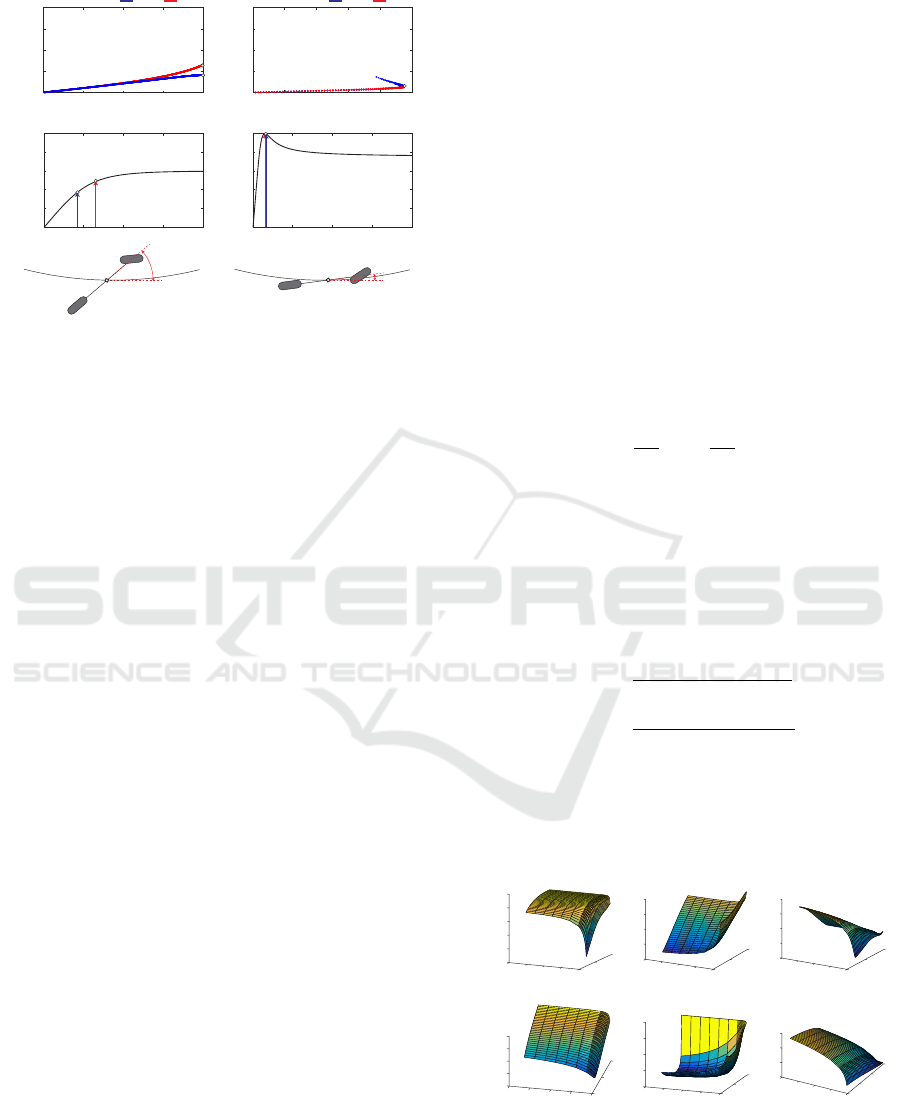

2, and the results depicted in Fig. 1 were obtained.

0

200

400

-200

SWA (deg)

-400

2 4 6 8 10

A

yc

(m/s

2

)

2 4 6 8 10

A

yc

(m/s

2

)

(deg)

1 2 3 4

A

yc

(m/s

2

)

0

200

-200

SWA (deg)

-400

400

1 2 3 4

A

yc

(m/s

2

)

(deg)

0

10

-10

-20

-30

-40

Gravel Asphalt

0

10

-10

-20

-30

-40

Figure 1: Vehicle Equilibrium Solutions in gravel and as-

phalt, R = 20m. In blue regular solution, in orange drift

solution. The steering wheel angle is denoted by SWA and

the centripetal acceleration by A

yc

.

The multiplicity of solutions in asphalt is related

to the shape of the friction-slip curve, Fig. 2 right,

where a one-to-one mapping between the friction co-

efficient (µ) and the equivalent slip (σ) does not ex-

ist (same friction values can be obtained for small

”before-peak” and large ”after-peak” slips). A unique

equilibrium solution characterized by a large body

slip angle at the limit is obtained in gravel, Fig. 1

left. In order to maximize the centripetal accelera-

tion, it is necessary to stabilize the vehicle around a

body slip angle of -35 degrees approximately. This

change in behavior is due to the different shape of the

friction-slip curve in gravel, Fig. 2 left. In this case,

the grip scaling approach described in (Pacejka, 2012)

and employed to approximate the friction forces in

low µ rigid surfaces is no longer valid, and the maxi-

mum grip is developed for high slip values.

As can be noticed in Fig. 2 right, the equivalent

slips required to achieve maximum centripetal accel-

eration in asphalt remain close to 0.15 (peak friction

force). On the other hand, these values are consider-

ably higher in gravel (0.4-0.7), Fig. 2 left, and have a

notable influence on the final equilibrium body slip

angle. Results might differ when employing more

elaborated tire, chassis, and driveline models, but the

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

218

1

0.6

0.2

0.8

0.4

0.5 1.51.0 2.0

!

0.5 1.51.0 2.0

!

1

0.6

0.2

0.8

0.4

Gravel Asphalt

1 2 3 4

A

yc

(m/s

2

)

0

!

0.5

1.0

1.5

2.0

(a)

(b)

RearFront

(a)

(b)

RearFront

!

0.5

1.0

1.5

2.0

2 4 6 8 10

A

yc

(m/s

2

)

Figure 2: (a) Equivalent slip equilibrium solutions, R =

20m. (b) Friction-slip curves for each surface.

physical explanation behind the large drifts exhibited

by World Rally Cars (WRC) in Finland or Argentina

remains the same.

2.3 Linear Quadratic Regulator

Linear Quadratic Control is often employed in multi-

input problems to determine the optimal feedback

gain based on the optimization of a performance ob-

jective function. In the following, the Infinite Time

Horizon case (LQR) is presented. For the formulation

of the LQR, a Linear Time-Invariant (LTI) system ex-

pressed in state-space form (15) is considered.

˙

x = Ax + Bu (15)

Assuming that the n states of the system are avail-

able for the controller, the optimal control vector that

stabilizes the plant around the origin is given by the

expression (16).

u(t) = −Kx(t) (16)

Where K is the optimal feedback gain obtained

from the optimization of the objective performance

function (17).

J =

Z

∞

0

(x

T

Qx + u

T

Ru)dt (17)

The terms Q and R are positive-definite Hermitian

matrices that account for the relative importance of

the regulation error and actuator energy expenditure

respectively. Substituting the control law (16) in the

cost function (17), and following the derivation pre-

sented in (Ogata, 2010), the control law can by refor-

mulated as:

u(t) = −R

−1

B

T

Px(t) (18)

Where the constant matrix P is the unique

positive-definite solution to the associated steady-

state Riccati equation (19).

PA + A

T

P − PBR

−1

B

T

P + Q = 0 (19)

The Positive-definite solution of this equation (P)

always exists provided that the matrix (A − BK) is a

stable matrix (i.e. the closed-loop poles of the system

lie on the left side of the complex plane).

2.3.1 Gain-scheduled Linear Quadratic

Regulator

In order to implement the LQR controller presented

previously, the vehicle dynamics equations (1-8) were

linearized around the Vehicle Equilibrium Solutions

(x

ss

, u

ss

). The axle friction forces were linearized us-

ing a first order Taylor series expansion (20).

F

i

(λ, α) = F

i,0

+

∂F

i

∂α

∆α +

∂F

i

∂λ

∆λ

= F

i,0

+C

i,α

∆α +C

i,λ

∆λ, i ∈ {x, y}

(20)

Where the axle longitudinal stiffness (C

x,λ

) and

the axle cornering stiffness (C

y,α

) were calculated

for each equilibrium solution using a finite differ-

ences approach (21-22), and the cross-stiffness terms

(C

x,α

,C

y,λ

) were neglected.

C

x,λ

≈

F

x,λ

ss

+∆λ

− F

x,λ

ss

−∆λ

2∆λ

(21)

C

y,α

≈

F

y,α

ss

+∆α

− F

y,α

ss

−∆α

2∆α

(22)

The Vehicle Equilibrium Solutions were found for

a grid of operating conditions (β

ss

= {0 : 5 : 30}, R

ss

=

{10 : 10 : 400}), and the plant (A

ss

) and input (B

ss

)

matrices obtained after the system linearization were

particularized at each operating point.

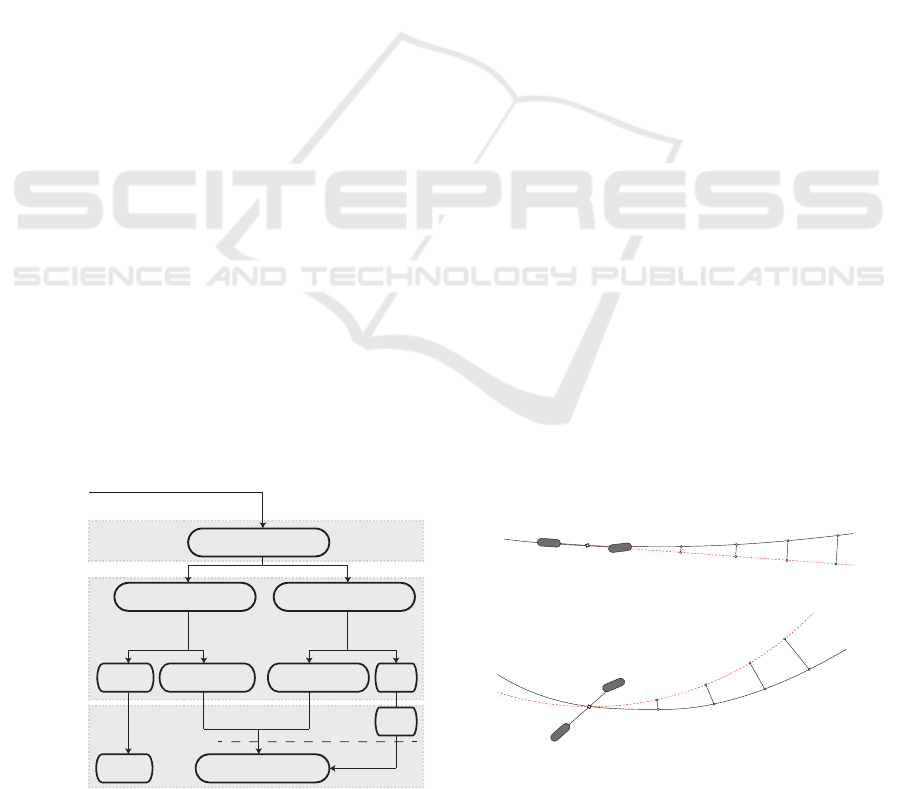

1,1

1,2

1,3

2,1

2,2

2,3

800

600

400

200

0

-40

-20

0

0.15

0.35

0.30

0.25

0.20

800

600

400

200

0

-40

-20

0

800

600

400

200

0

800

600

400

200

0

0

-10

-20

-30

-40

-20

0

-40

-20

0

800

600

400

200

0

800

600

400

200

0

0

1

2

3

0.15

0

-0.05

0.05

0

-0.05

-0.10

-0.15

0.05

0.10

0

-0.1

-0.2

-0.3

-0.4

0

-0.1

-0.2

-0.3

0.1

-40

-20

0

Figure 3: Gain surfaces of the Gain-Scheduled LQR.

Finally, the gain surfaces depicted in Fig. 3 were

obtained for each operating point. Following the same

formulation as (Velenis et al., 2011), the final steering

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces

219

and rear longitudinal slip control inputs were com-

puted using expression (23).

u = u

ss

+ K

ss

(x − x

ss

) (23)

Where the regulation terms are added to the

steady-state open-loop inputs (u

ss

). In order to avoid

chattering, the input weighting matrix was set ten

times greater than the process weighting matrix (R =

10Q,Q = I

n

).

3 DRIVER MODEL STRUCTURE

The structure of the driver model proposed in this

work is depicted in Fig. 4. A Hierarchical Hybrid

modeling approach inspired by previous works (Ka-

rimoddini et al., 2014) has been followed to combine

the path following and drift control tasks. The oper-

ation of the hierarchical automaton can be described

briefly in the following manner.

• Supervision Layer: The driver model is selected

depending on the road geometry (radius) and the

road friction characteristics. Two driver models

are considered in this work: a regular or low body

slip driver model, and a drift or high body slip one.

• Path planning Layer: Four blocks are distin-

guished in this layer: Straight Look-Ahead (SLA),

Step Transitions (ST), Agile Transitions (AT), and

Curved Look-Ahead (CLA). The blocks SLA and

CLA compute the look-ahead points necessary for

the path following task. A Predictive Trajectory

algorithm is employed to minimize the lateral de-

viation error during fast transitions (change in cur-

vature sign, Agile Transitions) and abrupt radius

reductions (e.g. from straight line driving to Hair-

pin turn, Step Transitions).

Supervision

Layer

DRIVER SELECTOR

REGULAR DRIVER DRIFT DRIVER

Low slip path following

Drift path following

CLAAgile TransitionsStep Transitions

Gain-Scheduled LQR

Drift control

Path planning

Layer

Regulation

Layer

P Sat.

Road geometry

Road friction

SLA

P

Figure 4: Hierarchical Hybrid Structure, driver model.

• Regulation Layer: If the regular driver action is

required (straight line or large radius), the steer-

ing control action is carried out by a Proportional

controller with saturation functions (Casanova,

2000). On the other hand, during lower radius

where large body slips maximize the lateral ac-

celeration, Fig. 1, a Gain-Scheduled LQR is used.

The tracking references necessary for the regula-

tion task are provided by an upper-level Propor-

tional controller P, which produces an output pro-

portional to the lateral deviation error. Finally,

during ST or AT, the drift control action is trig-

gered to change the vehicle heading fast or stabi-

lize the vehicle around a certain body slip.

3.1 Supervision Layer

For simplicity, constant road friction characteristics

are considered in this paper, specifically a gravel sur-

face. Thus, the driver model is selected according

to the road segment’s curvature. During large radii

(R > 400m) and straight line driving, the low body

slip driver is selected. For lower radius where drift is

advantageous for maximum centripetal acceleration,

the drift driver is used.

3.2 Path Planning Layer

3.2.1 Regular Driver

In the regular driving mode, two blocks are active:

SLA and ST.

• Straight Look-Ahead (SLA): This block computes

the lateral deviation error of a set of future path

coordinates (S

i

) considering a straight trajectory,

(Casanova, 2000). A proportional controller with

saturation functions regulates the path following

function (Casanova, 2000).

0

1

2

3

0

1

2

3

!

0

!

1

!

2

!

3

!

0

!

1

!

2

!

3

"

0

"

1

"

2

"

3

0

1

2

3

Straight Look-Ahead (SLA)

Curved Look-Ahead (CLA)

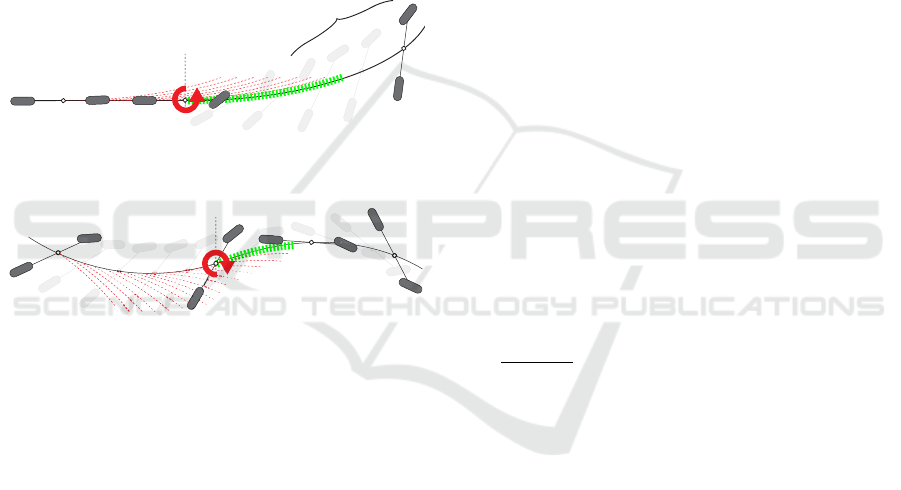

Figure 5: Calculation of the lateral deviation error. Straight

Look-Ahead approach (Regular driver) and Curved Look-

Ahead approach (Drift Driver).

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

220

• Step Transitions (ST): The aim of this block is to

achieve a fast transition with a minimum lateral

deviation between straights and short-radius turns.

This behavior is often seen in Rally drivers during

Trail braking or Scandinavian Flick maneuvers,

(Acosta et al., 2016), when a high yaw moment

is applied to build up a large body slip and initi-

ate the drift condition. In order to model this be-

havior in the autonomous system, the closed loop

response of the Gain-Scheduled LQR was com-

puted off-line under a series of Step changes in

the reference radius. The trajectories obtained in

these tests were normalized and stored in Look Up

Tables. The test was repeated for different radii

(R = {10 : 10 : 400m}), and the target body slip

during the drift stabilization was set to 20 degrees.

Step transitions

Agile transitions

Minimum

Drift Control

Minimum

Drift Control

!

"

!

"

Figure 6: Step transitions and agile transitions. Optimum

timing for the application of the yaw moment M

z

.

In order to determine the optimum timing to trig-

ger the Step Transition, the area (A) enclosed be-

tween the predicted trajectory and the reference

path is computed. When the minimum value is

found, the step input (yaw moment M

z

) is applied

and the drift control is switched on. A memory

block is employed for this purpose, and the area

computed at the current time-step (A

k

) is com-

pared to the minimum value calculated in pre-

vious steps A

min

. If the current value is lower,

A

min

is updated. Otherwise, the minimum is

found and the Step Transition is triggered. It is

assumed that a priori information regarding the

arc radius after the transition is available, and

thus the trajectory τ

i

corresponding to this radius

can be selected from the total set of trajectories

(Ω = {τ

10

, ..., τ

400

}). In future investigations, this

requirement will be eliminated by evaluating a

larger number of candidate trajectories.

3.2.2 Drift Driver

Two blocks are active during the action of the drift

driver: CLA and Agile Transitions.

• Curved Look-Ahead (CLA): The action of this

block is analogous to the SLA block. As the drift

driver is active during short radii, it is necessary

to consider the curvature of the vehicle trajectory

in order to avoid large errors, Fig. 5. The mathe-

matics and geometry involved in the calculation of

the lateral deviation error are omitted due to space

limitations.

• Agile Transitions (AT): The purpose of this block

is to concatenate body slip angles of opposite sign

with minimum lateral deviation, Fig. 6. This ac-

tion is performed by Rally drivers when short-

radius turns of opposite sign are concatenated

(e.g. a sequence of Hairpin Turns). The block

is implemented following the same principle than

the ST block, and the closed loop response of

the Gain-Scheduled LQR is evaluated off-line for

a range of radii. At each radius, the simulation

starts in drift equilibrium conditions, with the ve-

hicle body slip stabilized around 20 degrees. The

sign of the target body slip is changed suddenly,

and the closed-loop response of the system is sim-

ulated. The trajectories are then normalized and

stored in Look Up tables. At each time-step, the

candidate trajectory (τ

i

) is translated to the vehi-

cle center of gravity and rotated according to the

vehicle heading angle.

*Remark: As was shown in (Velenis et al., 2011),

the body slip at which the lateral acceleration is maxi-

mized varies with the radius of the turn. Thus, in order

to guarantee minimum time maneuvering it would be

necessary to adjust the target body slip angle accord-

ing to the current radius. For simplicity, it is assumed

that near optimal conditions are achieved for a unique

target body slip angle.

3.3 Regulation Layer

Two driver models are implemented in the regulation

layer: low body slip steering control and high body

slip drift control.

3.3.1 Low Body Slip Steering Control

The low body slip steering control was extracted from

(Casanova, 2000), and its construction is oriented to

racing-line path following problems. In essence, the

controller attempts to minimize the heading and lat-

eral deviation errors using proportional gains and sat-

uration functions. The gain values were obtained

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces

221

from (Casanova, 2000). Concerning the longitudinal

control action, a PID is employed to track a target

speed profile. The generation of the target speed pro-

file is omitted due to space limitations. For simplicity,

a constant target speed was considered during the ac-

tion of the Regular driver.

3.3.2 High Body Slip Drift Control

The function of the high body slip drift controller

is more involved, and two blocks are implemented

in cascade to achieve the path following and drift

control tasks: path following P controller and Gain-

Scheduled LQR, Fig. 7.

P

Target

Drift Equilibrium Solutions

!!

target

-

+

"

#!!

$

!!

CLA

vehicle trajectory

Ref. path

#

!!

%

!!

Gain-Scheduled LQR

$ "

#

&

0

'

0

&

1

'

1

&

(

'

(

.

.

.

.

∑

&

2

'

2

Proportional Curvature correction

DRIFT REGULATION

Figure 7: High body slip regulation. Proportional curvature

controller and Gain-Scheduled LQR.

• Path Following (P) Controller: As was seen in

Section 2.2, for each pair (β

ss

,κ

ss

) a set of Vehi-

cle Equilibrium states (x

ss

) and equilibrium inputs

(u

ss

) exist. In this paper, the path following task is

situated in an upper level, and the final target cur-

vature is formed by the reference curvature (κ

re f

)

and a correction term (∆κ), proportional to the lat-

eral deviation error (24).

κ = κ

re f

− ∆κ (24)

The curvature imposed by the upper level P con-

troller is used in combination with the target

body slip (β

ss

) to determine the reference states

and reference inputs of the Gain-Scheduled LQR

(β

ss

, λ

r,ss

, δ

ss

, r

ss

,V

ss

).

• Gain-Scheduled LQR: This block tracks the ref-

erence states (x

ss

) and inputs (u

ss

) dictated by the

upper level path-following controller, Fig. 7. De-

tails regarding the implementation of this block

were provided in Section 2.3.1.

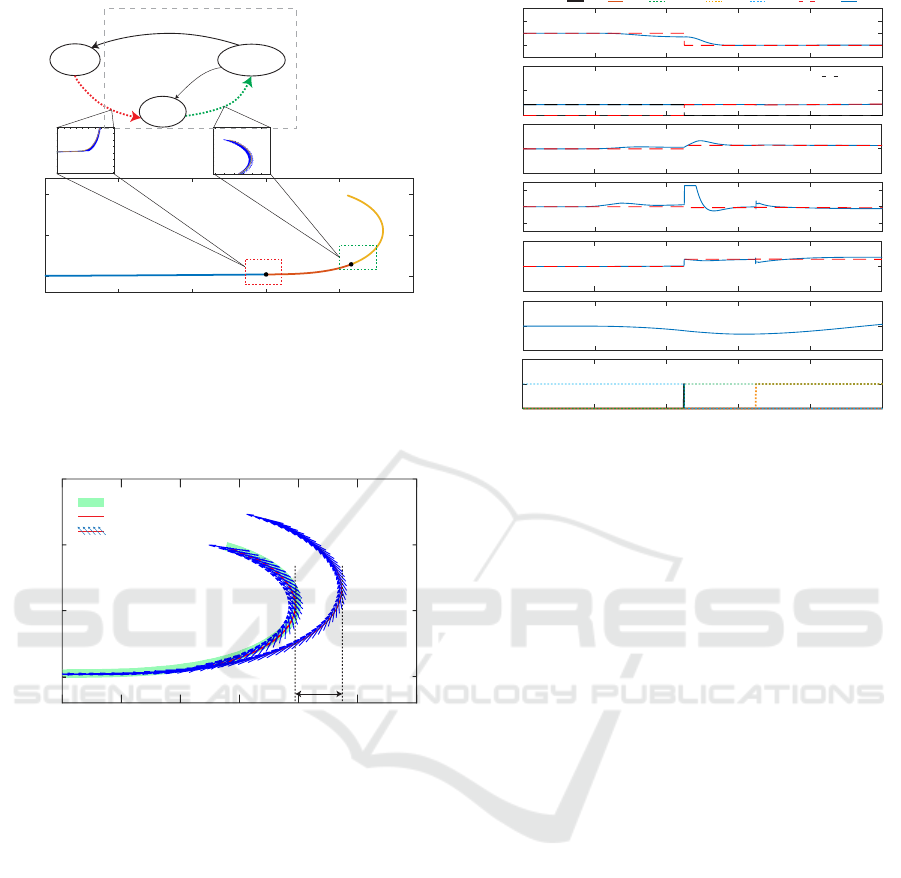

4 RESULTS

4.1 Rally Stage

The driver model was implemented in

Matlab/Simulink

R

using the vehicle and tire

parameters presented in Tables 1 and 2. At this

research stage, perfect knowledge of the vehicle pa-

rameters, road-friction characteristics, and full state

feedback is assumed. The robustness of the controller

against uncertainties in the vehicle parameters and

road friction characteristics will be addressed in

futures stages of this research. A Rally-like stage was

constructed using a combination of clothoid, arc, and

straight line segments to test the performance of the

Hybrid Driver model, Fig. 8.

0 100 200 600

-600

-400

-200

0

200

S1

S2

S3

x (m)

y (m)

-800

300 400 500 700

ST

AT

ST

Figure 8: Rally-like segment. Detail of Agile transitions AT

and Step transitions ST.

For simplicity, a target body slip of ±20 degrees

was set during this simulation. Further steps in this

research will explore the combination of path follow-

ing and non-constant body slip tracking. The stage

consists of 3 Sectors: S1, S2, S3, and the results ob-

tained in Matlab

R

are presented in the following.

In order to explain the behavior of the Hybrid sys-

tem, the following nomenclature has been employed

for the FLAGS shown in Figures 9-11: (ST) Step

transitions, (AT) Agile transitions, (P) Proportional

controller ON, (DRIFT) Drift driver model ON, and

(REG) Regular driver model ON. The LQR reference

signals are denoted as (Ref ), the Regular driver speed

reference by (REGspd), and the vehicle states and in-

puts by (Sim).

During the first sector, the vehicle starts in a

straight line and executes a ST to follow a large left-

handed turn (t ≈ 18). The vehicle is stabilized in

DRIFT mode and the P controller switches on to start

the path following task (t ≈ 19.5). After (t ≈ 40),

an AT is performed to track a large right-handed

clothoid. The P controller is switched off during the

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

222

stabilization of the vehicle around the new operating

condition and becomes active in (t ≈ 42) to track the

clothoid transition (R = 200 to R = 100).

(deg)

time (s)

10 20 30 40 50 60 70

20

-20

1

0

FLAGS

(kph)

200

! (deg/s)

100

-100

SWA (deg)

200

-200

"

!

(-)

1

-1

#

$

(m)

5

-5

100

0

0

0

0

Ref. Sim.

P. REG.

AT. DRIFT.ST.

REGspd

Figure 9: Results of Sector 1.

time (s)

70 80 90 100 110 120

(deg)

20

-20

1

0

FLAGS

(kph)

200

! (deg/s)

100

-100

SWA (deg)

200

-200

"

!

(-)

1

-1

#

$

(m)

5

-5

100

0

0

0

0

Ref. Sim.

P. REG.

AT. DRIFT.ST.

REGspd

Figure 10: Results of Sector 2.

In the second sector, the system tracks a concate-

nation of turns. The following sequence (AT - P OFF

- Stabilization - P ON) is repeated through the sec-

tor. As can be noticed in Fig. 10, the Hybrid system

generates large yaw accelerations (yaw rate peaks) to

change the vehicle attitude fast. This behavior resem-

bles the driving style of Rally drivers (yaw-sideslip

excitation, (Blundell and Harty, 2004)), in which the

time (s)

120 130 140 150 160 170 180 190

Ref. Sim.

P. REG.

AT. DRIFT.ST.

(deg)

20

-20

1

0

FLAGS

(kph)

200

! (deg/s)

100

-100

SWA (deg)

200

-200

"

!

(-)

1

-1

#

$

(m)

5

-5

100

0

0

0

0

REGspd

Figure 11: Results of Sector 3.

vehicle is operated in the upper and lower regions of

the yaw acceleration versus lateral acceleration plot.

Finally, the results obtained in the third sector are

portrayed in Fig. 11. During the first part of the

sector, the system tracks a concatenation of R = 50m

turns (t ≈ 120 to t ≈ 150), followed by a clothoid tran-

sition and an arc segment (R = 60m). After that, the

REG driver model switches on to drive the vehicle in

the straight segment (t ≈ 165) and goes off again in

(t ≈ 170) when the ST action is triggered. Overall, the

Hybrid System exhibited a remarkable performance

to track the reference body slip angle with minimum

lateral deviation.

4.2 ADAS System for Lateral Collision

Avoidance

During the previous subsection, the Hybrid System

(Fig. 4) was studied as an entire Autonomous Sys-

tem. In this subsection, however, the system is pre-

sented as an ADAS, which takes control of the vehicle

during critical situations. Now, it is assumed that the

responses from the Regular Driver block approximate

the behavior of a vehicle equipped with a stability sys-

tem that tries to mitigate the maximum body slip (i.e.

ESP, (Zanten, 2002)).

In order to compare the performance of the vehi-

cle equipped with a ”traditional” stability system, and

that using the proposed ADAS system, the test case

presented in Fig. 12 is evaluated. The car circulates

at a constant speed and approaches a left-handed turn

(R = 50m) in a gravel surface. An initial test is per-

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces

223

REG

ST

R>400

Straight line

Clothoid transition

Arc segment

200 250 300 350

150

400

x(m)

y(m)

150

50

0

P+LQR

LQR

DRIFT STABILIZATION

AT

ADAS operation

Figure 12: State-Transition diagram of the ADAS hybrid

system.

formed switching off the drift driver model (”tradi-

tional” stability system) and the same simulation is

repeated with the full ADAS system active.

50

100

300 420

320 340

360

380 400

0

() ADAS ON

( ) ADAS OFF

x (m)

y (m)

lateral deviation

Reference path

Vehicle trajectory

Vehicle heading

Figure 13: Vehicle trajectories obtained for (a) ADAS ON,

(b) ADAS OFF.

As can be noticed in Fig. 13, the vehicle mini-

mizes the lateral deviation when the ADAS system is

active. The system triggers the ST action, (t ≈ 26.5,

Fig. 14) and switches on the drift control. As was

explained in Section 2.2, large body slips are required

in gravel in order to maximize the lateral acceleration

(Figures 1-2). On the other hand, when the ADAS is

OFF and the Regular driver model is active, the latter

system tries to minimize the heading error, keeping

the vehicle attitude parallel to the tangent of the path

(low body slip). This results in a low lateral acceler-

ation, and the vehicle deviates abruptly from the ref-

erence path. In order to negotiate the turn, the vehicle

should approach the curve with a much lower speed,

thus limiting the lateral acceleration demand.

To summarize, when the ADAS system is active,

the centripetal acceleration is maximized, and the ve-

hicle can negotiate the turn at a higher speed than

when the system is switched off. This could po-

tentially prevent the risk of lateral collision in loose

time (s)

22 24 26 28 30 32

Ref. Sim.

P. REG.

AT. DRIFT.ST.

REGspd

(deg)

20

-20

1

0

FLAGS

(kph)

200

! (deg/s)

100

-100

SWA (deg)

200

-200

"

!

(-)

1

-1

#

$

(m)

5

-5

100

0

0

0

0

Figure 14: Results obtained with the ADAS ON.

surfaces (deep snow or gravel) when a vehicle ap-

proaches a turn at an excessive speed.

5 CONCLUSIONS

In this paper, an innovative Hierarchical Hybrid

Driver model for autonomous vehicles has been pre-

sented. The aim of the structure is to reproduce the

behavior of professional Rally drivers, and employ

advanced driving skills such as drift control to en-

hance vehicle safety when path following is required

under tight conditions.

The main contribution of this work is that the drift-

like driving control is no longer restricted to constant

radius turns, but to complex paths formed by clothoid,

arcs, and straight line segments. In order to inte-

grate robustly the body slip control and path follow-

ing tasks, a hierarchical structure formed by a P con-

troller and a Gain-Scheduled LQR has been proposed.

The path planning modules (Agile transitions) and

(Step transitions) have been incorporated in the sec-

ond layer of the structure, in order to drive the vehi-

cle through a concatenation of turns and alternate the

body slip fast with minimum lateral deviation, such as

Rally Drivers do.

The system has been implemented in Simulink

R

,

and tests have been carried out in a Rally-like stage

and a lateral collision scenario. Results evidence the

ability of the system to track complex paths while op-

erating the vehicle with large body slips.

Finally, it has been demonstrated that when the ve-

hicle is driven on loose surfaces (centripetal acceler-

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

224

ation is maximized with large body slip angles), the

drift control action can reduce the risk of lateral colli-

sion and prevent the vehicle from lane departure. The

refinement of the motion planning algorithms and the

evaluation of the robustness of the system under un-

certain friction characteristics will be pursued during

the next steps of this research.

ACKNOWLEDGEMENTS

This project is part of the Interdisciplinary Train-

ing Network in Multi-Actuated Ground Vehicles

(ITEAM) European program and has received fund-

ing from the European Unions Horizon 2020 research

and innovation program under the Marie Skodowska-

Curie grant agreement No 675999. M. E. Fitzpatrick

is grateful for funding from the Lloyds Register Foun-

dation, a charitable foundation helping to protect life

and property by supporting engineering-related edu-

cation, public engagement and the application of re-

search.

REFERENCES

Acosta, M., Kanarachos, S., and Blundell, M. (2016). Agile

maneuvering: From rally drivers to a finite state ma-

chine approach. In IEEE Symposium Series on Com-

putational Intelligence.

Blundell, M. and Harty, D. (2004). Multibody Sys-

tem Approach to Vehicle Dynamics. ELSEVIER

Butterworth-Heinemann.

Casanova, D. (2000). On minimum time vehicle maneu-

vering: The Theoretical Optimal Lap, Ph.D Thesis.

School of Mechanical Engineering, Cranfield Univer-

sity.

Cutler, M. and J.P.How (2016). Autonomous drifting using

simulation-aided reinforcement learning. In IEEE In-

ternational Conference on Robotics and Automation.

Edelmann, J. and Plochl, M. (2009). Handling character-

istics and stability of the steady-state powerslide mo-

tion of an automobile. Regular and Chaotic Dynam-

ics, 14:682–692.

Gray, A., Gao, Y., Lin, T., Hedrick, K., Tseng, H., and

Borrelli, F. (2012). Predictive control for agile semi-

autonomous ground vehicles using motion primitives.

In American Control Conference.

Hindiyeh, R. (2013). Dynamics and Control of Drifting in

Automobiles, Ph.D Thesis. Stanford University.

Kanarachos, S. (2012). A new min-max methodology for

computing optimised obstacle avoidance steering ma-

neuvers of ground vehicles. International Journal of

Systems Science, (45):1042–1057.

Karimoddini, A., Lin, H., Ben, M., and Tong, H. (2014).

Hierarchical hybrid modeling and control of an un-

manned helicopter. International Journal of Control.

Lenain, R., Deremetz, M., Braconnier, J., Thuilot, B., and

Rousseau, V. (2017). Robust sideslip angles observer

for accurate off-road path tracking control. Advanced

Robotics, 31(9):453–467.

Lenain, R., Thuilot, B., Cariou, C., Bouton, N., and Berd-

ucat, M. (2012). Off-road mobile robots control: an

accurate and stable adaptive approach. In Interna-

tional Conference on Communications, Computing,

and Control Applications.

Li, J., Yi, J., Zhang, Y., and Liu, Z. (2011). Understanding

agile-maneuver driving strategies using coupled lon-

gitudinal / lateral vehicle dynamics. In ASME Dynam-

ics and Control Conference.

Milliken, W. and Milliken, D. (1995). Race Car Vehicle

Dynamics. SAE International.

Ogata, K. (2010). Modern Control Engineering. Prentice

Hall.

Pacejka, H. (2012). Tire and Vehicle Dynamics.

Butterworth-Heinemann.

Tavernini, D., Massaro, M., Velenis, E., Katzourakis, D.,

and Lot, R. (2013). Minimum time cornering: the

effect of road surface and car transmission layout. Ve-

hicle System Dynamics: International Journal of Ve-

hicle Mechanics and Mobility, 51(10):1533–1547.

Velenis, A., Katzourakis, D., Frazzoli, E., Tsiotras, P., and

Happee, R. (2011). Steady-state drifting stabiliza-

tion of rwd vehicles. Control Engineering Practice,

19(11):1363–1376.

Velenis, E. (2011). Fwd vehicle drifting control: The

handbrake-cornering technique. In IEEE Conference

on Decision and Control and European Control Con-

ference.

Velenis, E., Frazzoli, E., and Tsiotras, P. (2010). Steady-

state cornering equilibria and stabilisation for a vehi-

cle during extreme operating conditions. International

Journal of Vehicle Autonomous Systems, 8.

Velenis, E., Tsiotras, P., and Lu, J. (2007). Modeling ag-

gressive maneuvers on loose surfaces: The cases of

trail-braking and pendulum-turn. In IEEE European

Control Conference.

Yi, J., Li, J., Lu, J., and Liu, Z. (2012). On the stability and

agility of aggressive vehicle maneuvers: A pendulum-

turn maneuver example. IEEE Transactions on Con-

trol Systems Technology, 20(3).

Zanten, A. (2002). Evolution of electronic control systems

for improving the vehicle dynamic behavior. In Inter-

national Symposium on Advanced Vehicle Control.

A Hybrid Hierarchical Rally Driver Model for Autonomous Vehicle Agile Maneuvering on Loose Surfaces

225