Distributed Co-Simulation of Embedded Control Software with Exhaust

Gas Recirculation Water Handling System using INTO-CPS

Nicolai Pedersen

1,3

, Kenneth Lausdahl

2

, Enrique Vidal Sanchez

1

,

Peter Gorm Larsen

2

and Jan Madsen

3

1

MAN Diesel & Turbo, Teglholmsgade 41, 2450 Kbenhavn SV, Denmark

2

Department of Engineering, Aarhus University, Finlandsgade 22, Aarhus N, Denmark

3

Embedded Systems Engineering, Technical University of Denmark, Anker Engelunds Vej 1, Kgs. Lyngby, Denmark

Keywords:

INTO-CPS, Cyber-Physical-Systems, Co-Simulation, Parallel Simulation, Distributed Simulation, Embedded

Control System, Exhaust Gas Recirculation.

Abstract:

Engineering complex Cyber-Physical Systems, such as emission reduction control systems for large two-stroke

engines, require advanced modelling of both the cyber and physical aspects. Different tools are specialised for

each of these domains and a combination of tools validating different properties is often desirable. However, it

is non-trivial to be able to combine such different models of different constituent elements. In order to reduce

the need for expensive tests on the real system it is advantageous to be able to combine such heterogeneous

models in a joint co-simulation in order to reduce the overall costs of validation. This paper demonstrates how

this can be achieved for a commercial system developed by MAN Diesel & Turbo using a newly developed tool

chain based on the Functional Mock-up Interface standard for co-simulation supporting different operating

systems. The generality of the suggested approach also enables future scenarios incorporating constituent

models supplied by sub-suppliers while protecting their Intellectual Property.

1 INTRODUCTION

With increased complexity in physical dynamics, con-

trol and communication, the development of Cyber-

Physical Systems (CPS) require more advanced mod-

elling and specialized tools. For differential-equation

based continuous models, multiple tools are avail-

able (MathWorks, 2011; SYST

`

EMES, 2017; Kleijn,

2006), each with their specific specialization and va-

lidity. Discrete event models are often developed

within companies own software frameworks, or cre-

ated in one of the many tools available. The inter-

connection between the physical and cyber parts of

CPS is becoming more dependent and dynamical in-

fluences have to be considered. The main challenge

connecting these models comes from the fundamen-

tal differences in the underlying mathematical frame-

works, their simulation tools and how they are devel-

oped. In this regard one typically distinguishes be-

tween Discrete Event (DE) models based on discrete

mathematics and Continuous-Time (CT) models that

are based on differential equations. Many initiatives

for connection tools in a so called co-simulation have

been published (Fitzgerald et al., 2014; ITEA Office

Association, 2015). However, connecting the specific

tools making up the holistic simulation is often not the

only issue. Deviations in development platforms and

performance is as often the issue. A solution for this

is a distributed co-simulation, where models can be

executed, not only in the tool where they were devel-

oped, but also on the correct platform. Furthermore, a

distribution of the simulation makes it possible to in-

crease performance by utilizing additional hardware,

given that the models are prepared for it.

At MAN Diesel & Turbo (MDT) the conventional

approach for developing two-stroke combustion en-

gines with a distributed embedded control system is

being challenged. In particular for diesel engines pol-

lution is a key element that it is desirable to reduce

from a competitive perspective. New emission leg-

islation focuses on the reduction of especially NO

x

emission. Widely known emission reduction tech-

nologies for reducing NO

x

are selective catalytic re-

duction and Exhaust Gas Recirculation (EGR), both

being developed at MDT (MAN Diesel & Turbo,

2016). These systems require advanced algorithms

to control the complexity of the physical dynamics

of large engines. Historically, in the same way as

Pedersen, N., Lausdahl, K., Sanchez, E., Larsen, P. and Madsen, J.

Distributed Co-Simulation of Embedded Control Software with Exhaust Gas Recirculation Water Handling System using INTO-CPS.

DOI: 10.5220/0006412700730082

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 73-82

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

73

many other large organisations, MDT is divided into

different departments with different responsibilities.

In the control department at MDT, control algorithms

are created directly in the target software framework

with the possibility of performing Software In the

Loop (SIL) simulation during development. Models

of the physical behaviour are created in other depart-

ments of MDT using the tools most suitable for the

specific constituent system. For control system de-

velopment, the physical dynamics models are imple-

mented in an internally developed tool for CT simula-

tion called Dynamic Simulation Environment (DSE)

which is part of the software framework. The primary

focus in DSE is SIL/Hardware In the Loop (HIL),

and the physics models implemented here are often

an abstraction of high-fidelity models. Historically it

has been challenging inside MDT to enable heteroge-

neous collaborations between the different teams pro-

ducing models in different departments.

The software framework and DSE are based on

C++ and run on a 32-bit Linux platform while

the physical modelling tools often require Win-

dows. In this paper the current simulation process

at MDT is compared with an alternative using co-

simulation utilizing the Functional Mock-up Inter-

face (FMI) standard and the Co-simulation Orches-

tration Engine (COE) from the Integrated Tool Chain

for Model-based Design of Cyber-Physical Systems

(INTO-CPS) project. The aim with the approach sug-

gested in this paper is to reduce redundancy in the

development process and reuse models from differ-

ent departments. One of the main challenges is to

enable co-simulation across different hardware archi-

tectures and Operating System (OS) platforms due to

constraints from software frameworks, physical sim-

ulation tools and version compatibility.

In section 2 the overall system is presented. sec-

tion 3 describes the previous simulation of a specific

subsystem for EGR, and section 4 describes the ap-

proach taken to enable co-simulation. Afterwards,

section 5 describes the co-simulation results for the

EGR system. Finally, the paper concludes with sec-

tion 6.

2 EXHAUST GAS

RECIRCULATION WATER

HANDLING SYSTEM

The EGR system presented in this paper recirculates

exhaust gas to the intake manifold thereby reduc-

ing environmental impact while maintaining efficient

combustion. The unclean exhaust gas is potentially

Run/Running

WTS

RTU

EGR Unit

Water Mist

Catcher

Cooler

Buffer Tank

Circulation Pump

Receiving Tank

Pre-Spray

Exhaust Gas

EGR Blower

Mixing

Chamber

Cleaned Exhaust Air

Process Water

Sealing Valve

Receiving Tank

Level Valve

Spray Water

Sealing Valve

Supply Pump

Scavenge Air

Fresh Water

WTS Pump

WTU

Ocean

Drain

Tank

Sludge

Tank

Ambient Air

Externally Controlled

EGR Control Unit

Tank Level

Setpoint/Feedback

Run/Running

Setpoint/

Feedback

Setpoint/

Feedback

WTS Communication

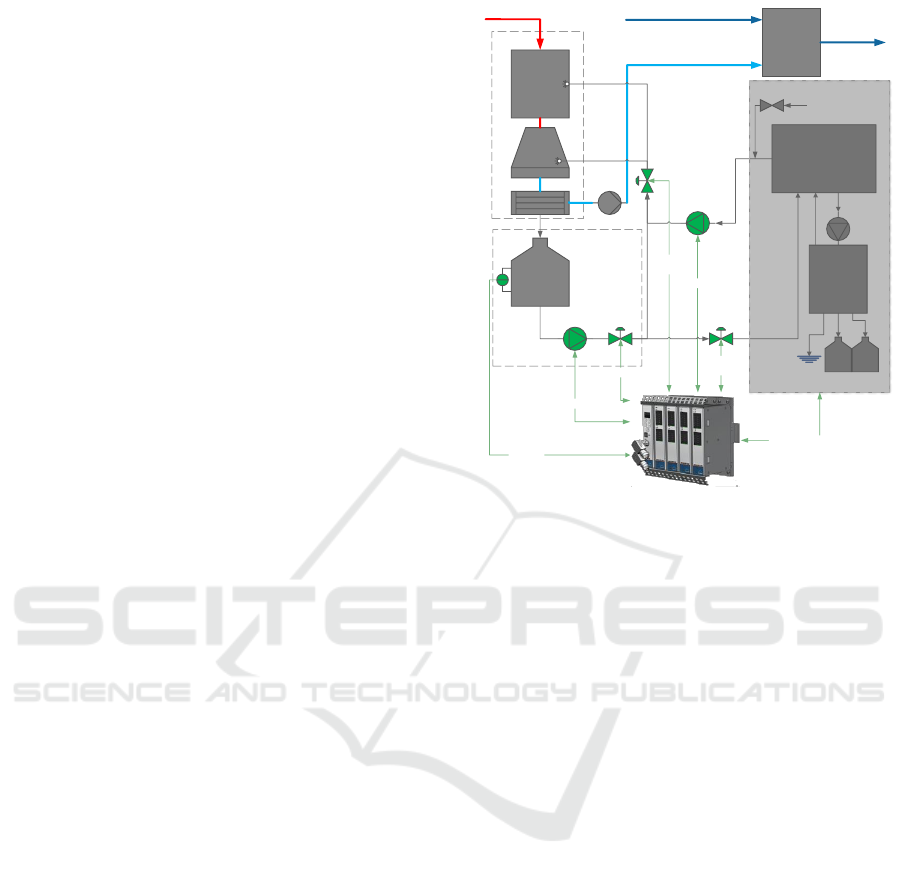

Figure 1: Water Handling System Setup.

damaging to the engine and has to be cleaned before

return, which is the purpose of the Water Handling

System (WHS). The system is shown in Figure 1

where the exhaust gas is drawn into the EGR Unit

using an EGR blower, it is then sprayed with water

and cooled so that a Water Mist Catcher (WMC) can

collect the damaging particles. Before the gas is re-

turned, the water is collected in the WMC and led to

a receiving tank. The water level in this tank is one of

the important variables that the WHS controls, as dis-

cussed in section 3.4. The water is pumped from the

receiving tank to an external constituent system (Wa-

ter Treatment System (WTS)) for processing where

the water is either cleaned and pumped back to the

EGR Unit, pumped overboard or stored for treatment

at a harbour.

At the chemical level, EGR is based on exchange

of the in-cylinder oxygen (O

2

) with carbon dioxide

(CO

2

) from the exhaust gas, which is re-circulated

into the scavenged air. The exchange of O

2

with CO

2

leads to a decrease of combustion speed, resulting

in lower peak temperatures during combustion. Fur-

thermore the exchange of O

2

with CO

2

results in a

higher in-cylinder heat capacity of the gas which also

lowers the combustion temperature. Lower combus-

tion temperatures and especially lower peak temper-

atures result in lower formation of thermal NO

x

dur-

ing the combustion process. The recirculated exhaust

gas is hotter and not as clean as the residual ambient

scavenge-air. To prevent Sulphur (SO

2

) and other par-

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

74

ticles from damaging the engine, cleaning and cool-

ing of the recirculated exhaust gas is required. A

WHS provides the water used for cleaning the ex-

haust gas in the EGR unit. To control the flow of

exhaust gas to the mixing chamber, an EGR blower

is installed. Water from the EGR unit is drained to

the Receiving Tank Unit (RTU) and recirculated to

the EGR unit. Part of the recirculated water is led

to the WTS to be cleaned and returned to the EGR

unit. The surplus of water originating from the com-

bustion process is drained from the WTS as bleed-

off water and discharged to the sea. The residuals

from the cleaning process are discharged to the sludge

tank. Depending on engine load and ambient condi-

tions the combustion process will accumulate water

in the system, which must be discharged as bleed-

off water. If discharged to the sea, the bleed-off wa-

ter must meet the quality criteria required by Interna-

tional Maritime Organization (IMO)

1

, presently de-

fined in the 2015 Guidelines for Exhaust Gas Clean-

ing Systems, MEPC 259 (68). Bleed-off water, which

does not meet the discharge criteria or cannot be dis-

charged to sea due to local restrictions, is drained to a

drain tank for delivery at port.

Vessels operating within an emission control area

have to comply with the Tier III emission require-

ments (IMO, 2015). This is achieved by activating

EGR, at which point the water handling system is re-

quired to run. The control system for the WHS is di-

vided into two parts, the EGR control which is part

of the distributed engine control system and the WTS

control which is delegated to the producer of the aux-

iliary system. The engine control system consists of

several multi-purpose controllers. Each controller is

composed of a power module, multiple I/O chassis

and an Field-Programmable Gate Array (FPGA). All

controllers on the engine are identical but the software

running on the FPGA determines the specific con-

trol objective. The controller controlling the WHS is

called the EGR Control Unit (EGRCU) and is seen in

Figure 1, with the connections relevant for this simu-

lation. This paper focuses on the control of the WHS.

The remaining control of the EGR system will not be

covered.

The WHS is controlled and monitored by the EGR

control, so that water can be provided to clean and

cool the exhaust gas. There are two main water

loops that can be distinguished. The recirculation

loop where the water from the EGR unit is sent to

the RTU and back again by the ’Circulation pump’

via the ’Process Water Sealing Valve’ and ’Spray Wa-

ter Sealing Valve’. The other loop is where part of

the water from the recirculation loop is sent via the

1

http://www.imo.org.

’Receiving Tank Level Valve’ to the externally con-

trolled system, the WTS. The water from the WTS

is sent back to the recirculation loop with the ’Supply

Pump’. The WTS receives the processed water from

the RTU and is collected in the buffer tank. A separate

system in the WTS treats the water of the buffer tank.

Any excess of water is either sent to the sludge/drain

tank or, if the water quality parameters are met, the

water can be sent overboard.

The objective of the control loop discussed in this

paper is to maintain the water level of the ’Receiv-

ing Tank’ within specified limits. During start up

and shutdown of the WHS the actuation timing of the

components has a direct impact on the water level.

During running mode, the water level is controlled by

the ’Receiving Tank Level Valve’ and compensates

for deviations in the water flow due to e.g. engine

load, exhaust gas and scavenge air pressure changes.

3 WHS SIMULATION

This section describes the development process of the

primary WHS control strategy. The approach and

tools used for the first edition of the control system

are described and the solution is evaluated.

3.1 Software Application Framework

Application development at MDT is carried out in

a comprehensive in-house C++ software application

framework. The framework is developed to enable

development of DE control models. The main ad-

vantage of the software application framework is the

possibility of cross compiling the same application to

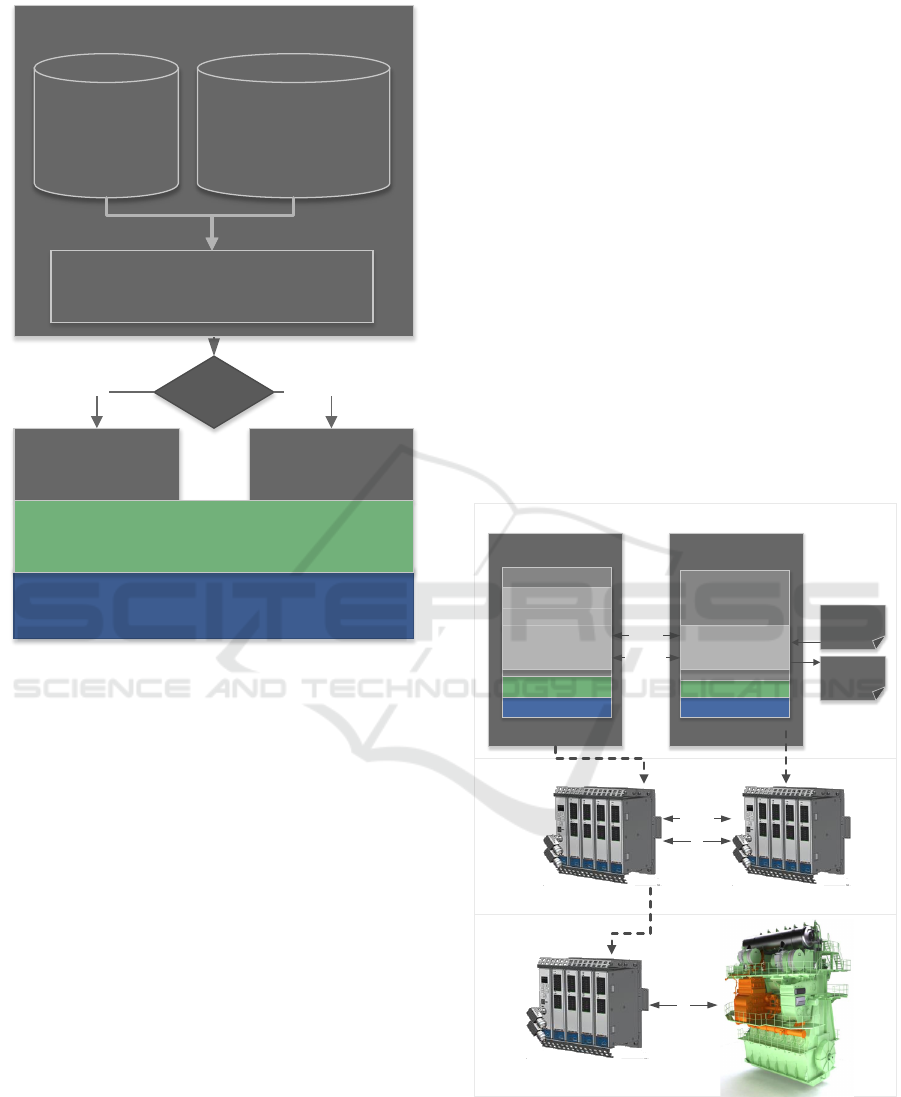

both SIL, HIL and target platform, see Figure 2. SIL

simulation of target code is made possible by compil-

ing the Board Support Package (BSP) and the Real

Time Operating System (RTOS) to an x86 platform.

With the SIL simulation, engineers are able to test

their application on their own PC. When moving to

HIL or target, the same application code, the BSP and

the RTOS, are simply cross-compiled to the embed-

ded core of the controller. The primary focus of the

framework is control development, where algorithms

are directly implemented in C++ with a vast amount

of reusable components and macros available, aiding

engineers. For CT models, an extension to the frame-

work can be utilized, called DSE. DSE includes a ker-

nel for execution, an ODE solver and a model library

of physical components. Models created in DSE are

executable on both PC (SIL) and the HIL platform,

given that the abstraction of the models allow for real-

time execution.

Distributed Co-Simulation of Embedded Control Software with Exhaust Gas Recirculation Water Handling System using INTO-CPS

75

BSP

(Board Support Package)

x86-Core Embedded Core

Cross Compiler

SIL HIL & Target

Application Environment

RTOS

(Real Time Operating System)

Control

Component

Library

DSE

Execution Kernel

ODE Solver

Model Library

Control Application

Figure 2: Software Application Framework.

When challenged with a new application, con-

trol engineers at MDT often start studying the phys-

ical dynamical challenges of the system in MAT-

LAB/Simulink. When a sufficient understanding of

the system is achieved, the control strategy is formu-

lated in the software application framework and tested

against a DSE model implementation of the MAT-

LAB model. DSE is designed with HIL execution in

mind, and while it can simulate complex CT systems,

the models implemented are often at a lower abstrac-

tion level than e.g. the MATLAB models.

3.2 WHS Model

The WHS model is divided into a control algorithm

created in the software application framework and

a model of the physical components in DSE. The

control algorithm is created as a component in the

controller EGRCU along side the additional compo-

nents that comprise the entire engine control. The

control model consists of a Proportional Integral

(PI)-controller regulating the ’Receiving Tank Level

Valve’ set-point from the ’Process Water Receiving

Tank’ level sensor feedback. Besides controlling the

receiving tank level, the control algorithm also has to

ensure that transitions between states in the system is

possible, according to signals from engine operators

and the WTS control system. This control strategy is

formulated in a state-machine running in the EGRCU.

The DSE model describes the pressures and flow of

all the components illustrated in Figure 1. The model

resembles the preliminary model developed in MAT-

LAB but without details such as pressure build-up in

piping, water accumulation in components and pres-

sure loss over valves. The main purpose of the DSE

is to test the control strategy, ensuring that all state

transitions are possible and that the regulator works

correctly. To prepare for HIL simulation, the DSE

model is placed in a separate controller called the En-

gine Simulation Unit (ESU), shown in Figure 3. The

ESU controller is installed in the HIL platform as a

representation of the real engine. Data exchange be-

tween the EGRCU and ESU imitate the actual com-

munication with the real engine through analog and

digital IOs. In SIL, a software implementation of vir-

tual IOs and network simulate the communication.

SIL Simulation Manager – Developer PC

EGRCU

(EGR Control Unit)

Share Library (.SO)

ESU

(Engine Simulation Unit)

Share Library (.SO)

BSP (x86)

RTOS (x86)

Application

Component X

Component Y

WHS Control

BSP (x86)

RTOS (x86)

Application

DSE

WHS Physics

Virtual I/O

Network

Simulation

Configuration

Simulation

Results

HIL Simulation – HIL Test Bench

EGR Control Unit Engine Simulation Unit

Target – Engine Test Bench

EGR Control Unit

I/O

Network

I/O

Figure 3: SIL WHS Simulation setup.

3.3 Simulation and Verification Process

SIL simulation is achieved by compiling controllers

to an x86 platform and into shared libraries. The

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

76

shared libraries are executed by a simulation man-

ager ensuring temporal execution and correct data ex-

change between controllers. How the embedded con-

trol software has been adapted to enable determinis-

tic simulation has been described in (Pedersen et al.,

2016) and will not be further explained in this paper.

A simulation scenario is provided to the DSE model

through a simulation configuration file and the results

are delivered in a simulation results file.

When the system has been properly tested in the

SIL environment, the models are moved to the HIL

platform by cross-compiling to the embedded system.

On the HIL test bench additional tests of computation

overhead, communication and additional temporal is-

sues are performed.

For final testing, an engine test bench is physi-

cally available at the MDT research center in Copen-

hagen. Only a single test bench is available due to

the immense cost and sheer size of the engine. Avail-

able time-slots on the test engine are very limited and

extremely costly, due to the fuel consumption and

amount of operators required, so the proper modelling

and testing of the previous steps is desirable.

3.4 Simulation Evaluation

The SIL simulation was used to develop a function-

ing PI controller that regulates the process water tank

level and a state machine for actuating valves and

pumps according to a number of states for starting

and stopping the WHS system. The system was

tested on the HIL test bench, ensuring that the systems

worked properly on the controller hardware. Finally,

a test session was performed on the engine test bench.

This test showed that the PI controller worked as in-

tended, however, an unsuspected situation occurred

when stopping the WHS system.

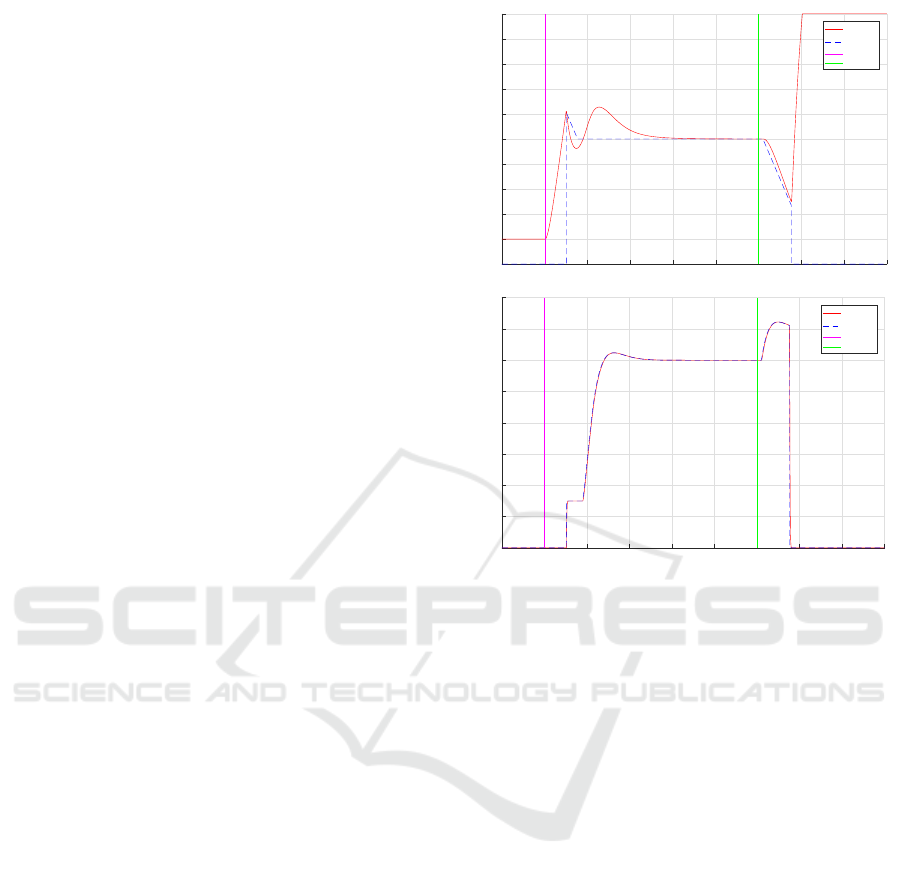

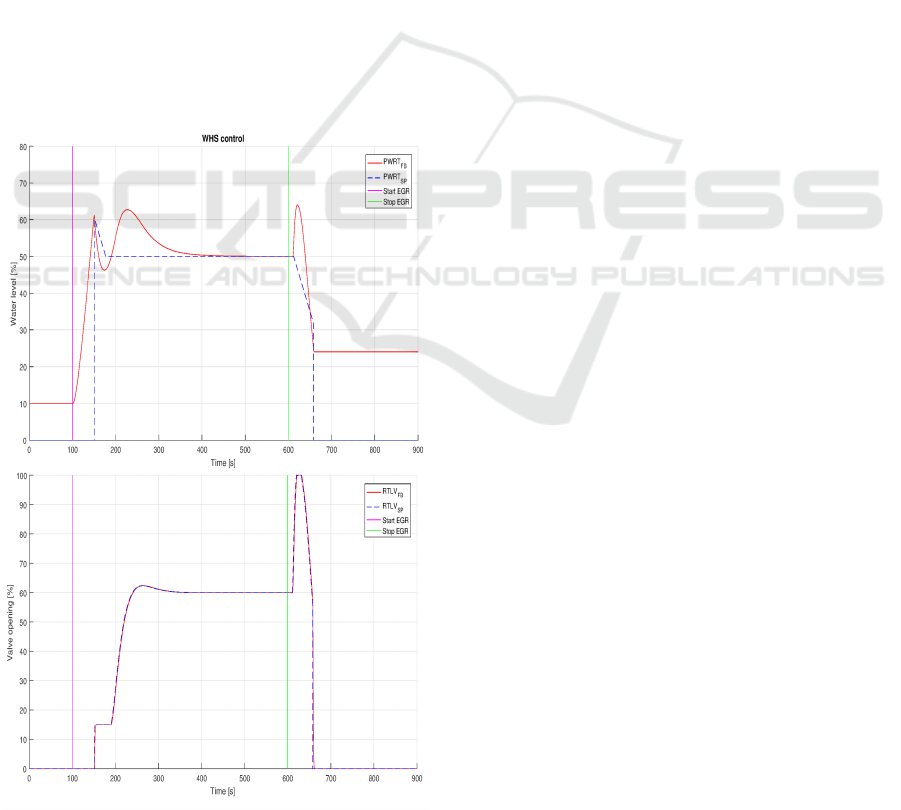

Figure 4 shows the results of running the initial

control strategy on the real system. After 100 seconds

the EGR control system ordered the WHS system to

prepare for EGR operation. Then after 50 seconds the

state-machine was finished starting different pumps

and opening of valves. At this point the Process Wa-

ter Receiving Tank (PWRT) control is fully engaged.

The bottom figure in 4 shows how the Receiving Tank

Level Valve (RTLV) is regulated to redirect water

from the process circuit to the WTS for cleaning and

stabilizing the PWRT level. The top figure in Figure 4

shows the water level in the PWRT and how it became

stable after a transient period, proving that the PWRT

control worked correctly during WHS operation. Ves-

sels are not always required to use EGR, so shut-down

of the system should be possible during engine oper-

ation. After 600 seconds a command from the engine

0 100 200 300 400 500 600 700 800 900

Time [s]

0

10

20

30

40

50

60

70

80

90

100

Water level [%]

WHS control

PWRT

FB

PWRT

SP

Start EGR

Stop EGR

0 100 200 300 400 500 600 700 800 900

Time [s]

0

10

20

30

40

50

60

70

80

Valve opening [%]

RTLV

FB

RTLV

SP

Start EGR

Stop EGR

Figure 4: WHS Control results.

operator was ordered, from an operating panel, for the

EGR system to shutdown and WHS to stop operation.

The state machine started emptying the tank to reach

a stable offline level around 20-25% in the tank. At

676 seconds a behaviour not seen in either the SIL or

HIL simulation was observed. When the WHS system

started, water in the WMC started to accumulate grad-

ually. At a point in time an equilibrium was achieved

due to increased water pressure resulting in a consis-

tent flow through the WMC (without increased water

accumulation in the WMC as a consequence). During

shutdown, when the desired water level in the PWRT

was achieved and RTLV control stopped, the accumu-

lated water in the WMC started to flow to the PWRT

tank. As seen in Figure 4, the amount of residual wa-

ter in the WMC is so large that it overfills the PWRT.

From the engine test bench it was discovered that

the controller actuating the RTLV was working prop-

erly, but the state-machine was not properly handling

the emptying of the WMC. Engine tests are very

costly and MDT would like to investigate if a more

efficient development process can be achieved. In

the DSE model used for development of the state-

machine, the accumulation of water in the WMC had

not been modelled. To improve the control strategy of

the WHS, a higher-fidelity model should be used. In-

stead of simply extending the DSE model to include a

Distributed Co-Simulation of Embedded Control Software with Exhaust Gas Recirculation Water Handling System using INTO-CPS

77

more detailed WMC model, a co-simulation solution

was chosen (Gomes et al., 2017). The co-simulation

should not only include a detailed WMC model but be

so generic that changes to the system layout and more

advanced models of components can be easily imple-

mented. The argument for the choice of co-simulation

is given in the following section.

4 TARGETING CO-SIMULATION

The software application framework and DSE is cen-

tral for development because they are designed for the

target platform of the final system, and directly enable

validation through both SIL and HIL. Keeping this in

mind it is rational to keep the control systems in the

framework. However, there are a number of options

for enhancing physics modelling that would be bene-

ficial:

• Porting the controller software to a notation that

can be used in the MATLAB environment, where

it is easier to express the physical model. This

would however, just shift the issue to the con-

troller, that then needs to be ported back to the

software application framework.

• Enhancing the physical model in DSE, while the

standard approach, it is more time consuming than

using a dedicated modelling tool like MATLAB,

but it enables faster simulation speeds.

• Use a generic solution that enables co-simulation

between the control system expressed in the soft-

ware application framework and a physical mod-

elling tool like MATLAB. This will not require

any changes to software development at MDT, but

would enable physical models to be created using

the desired modelling tool. It would potentially

run slower than a complete model expressed in

DSE but would be more flexible. This solution

would make the representation of the physical dy-

namics more detailed in SIL simulation. The co-

simulation model would not be able to run on the

HIL platform, however. The purpose of the HIL

test is not to test functionality already verified in

the SIL simulation, but to ensure computational

overhead and investigate temporal aspects.

The latter approach was chosen because it is

generic and it allows well known modelling tools in

the physical domain to be used. To interface between

models, the FMI is used, which provides a standard-

ised model interface. The last constraint on the co-

simulation is that it needs to be performed across ar-

chitectures and platforms. The software application

framework is required to run as a Linux 32bit pro-

cess. The reason for this is, as previously mentioned,

because the framework is developed to build directly

to the embedded system which is a 32bit architec-

ture. It is also a requirement that the physical mod-

elling environment be a Windows 64bit application.

The control developers working in e.g. MATLAB do

so in Windows 64bit and management-wise, introduc-

ing co-simulation to the current tool-chain would be

preferable. Another reason for the choice of deviation

in platform is the lack of 32bit support for MATLAB

on Linux.

It must be possible to run the simulation using

Linux 32bit for the software application framework

and Windows 64bit for MATLAB. Therefore a solu-

tion is to use the free FMI COE from the INTO-CPS

research project since it supports both. However, the

co-simulation cannot span architectures or platforms.

Therefore an extension is presented in section 5.1 that

enables co-simulation in a distributed setting, span-

ning both architectures and platforms.

4.1 Functional Mock-up Interface

FMI is a tool independent standard developed within

the MODELISAR project (ITEA Office Association,

2015). It supports both model exchange and co-

simulation and exists as Version 1, released in 2010

and Version 2, released in 2014. It was developed to

improve exchange of simulation models between sup-

pliers and Original Equipment Manufacturers (OEM).

The standard describes how simulation units are to be

exchanged as ZIP archives called a Functional Mock-

up Unit (FMU) and how the model interface is de-

scribed in an XML file named modelDescription.xml.

The functional interface of the model is described as

a number of C functions that must be exported by the

library that implements the model inside the FMU.

Since the FMU only contains a binary implementa-

tion of the model it offers some level of intellectual

property protection. The focus of this work is on co-

simulation, where each FMU is capable of participat-

ing in a co-simulation without the need of an external

solver, i.e. each FMU includes the required solvers

needed for simulation.

4.2 The INTO-CPS Tool Chain

While individual tools and formalisms for the de-

velopment of controllers, including simulation, test-

ing and code generation, are very mature, the de-

sign workflow is only partially integrated. The Hori-

zon 2020 project INTO-CPS (Fitzgerald et al., 2015;

Fitzgerald et al., 2016) aims at closing this gap, by

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

78

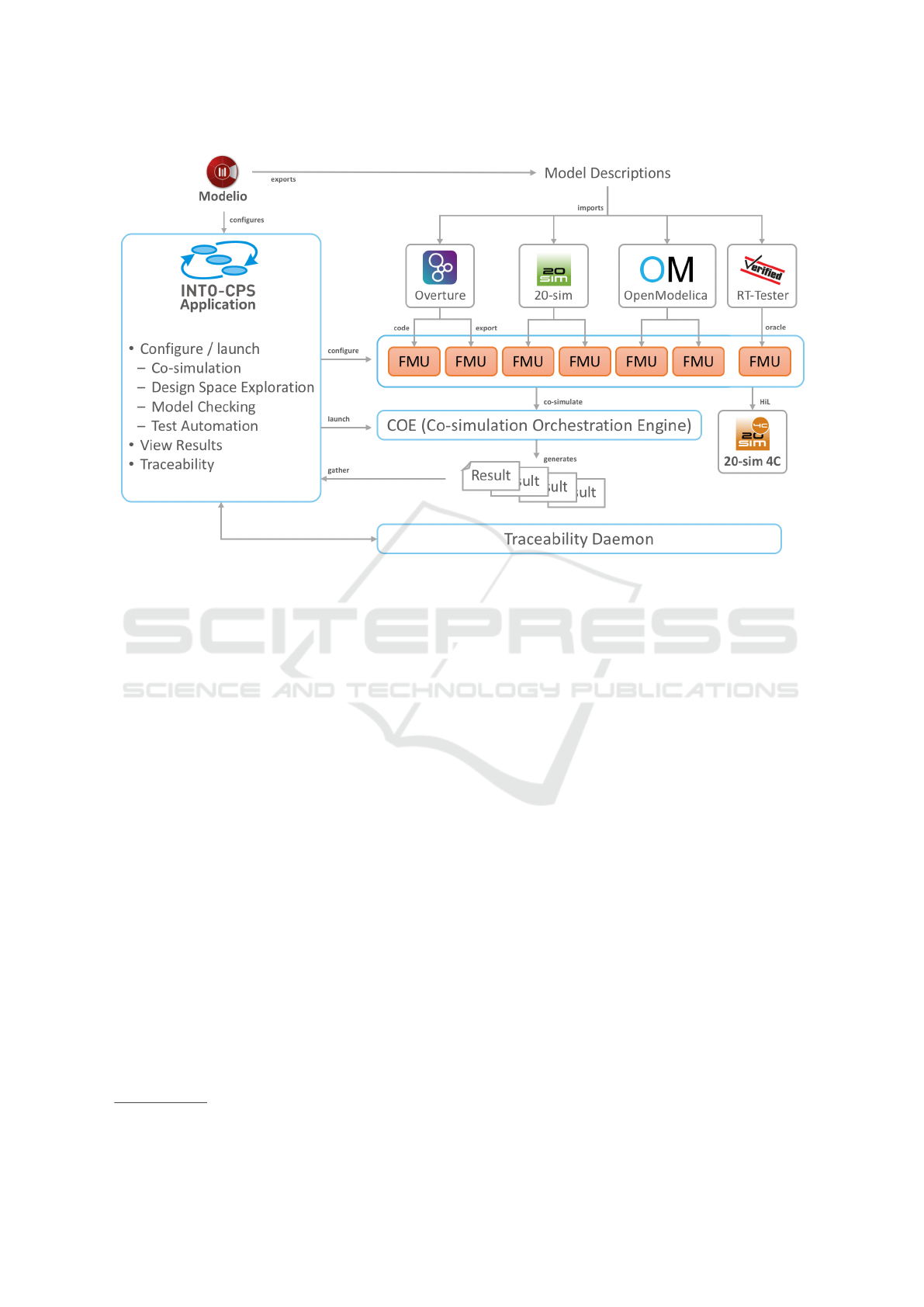

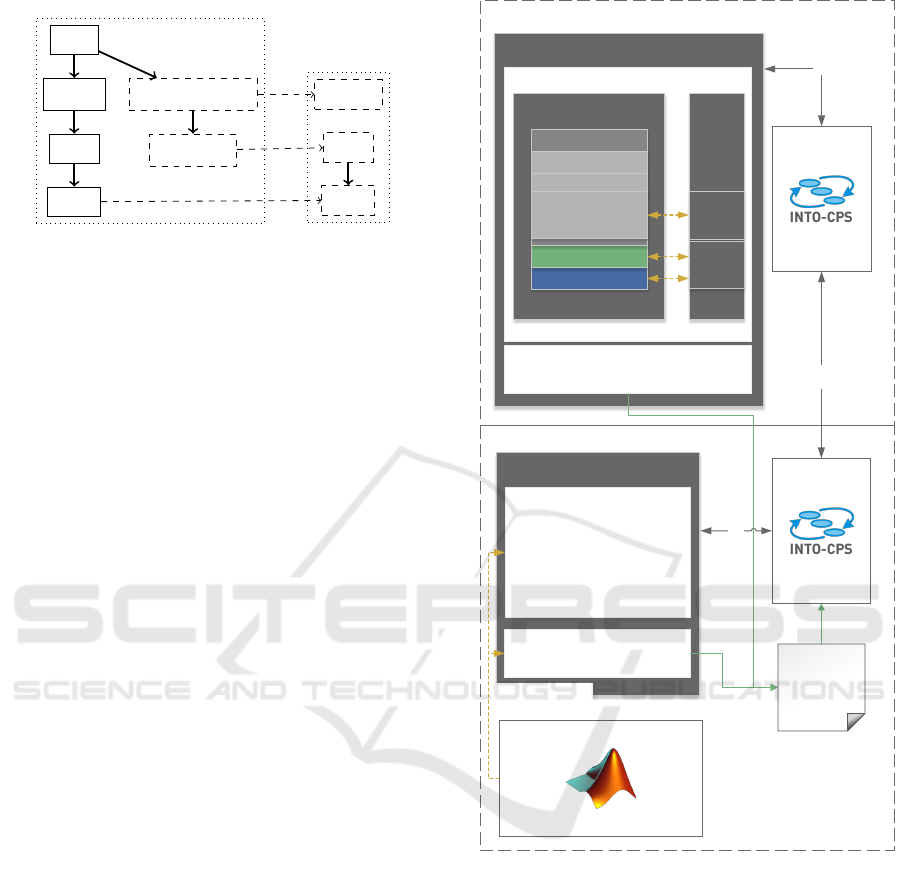

Figure 5: The INTO-CPS Tool Chain.

creating an Integrated Tool-chain for the model-based

design of Cyber-Physical Systems (Larsen et al.,

2016). The chain of tools are connected as illus-

trated in Figure 5, moving all the way from require-

ments to final realisations (Bandur et al., 2016). One

of the core tools of this chain is a newly developed

COE, which is a fully FMI 2.0 co-simulation com-

pliant Master supporting both fixed and variable step

size simulations. It was decided to use FMI as the in-

terface for the different simulation and testing tools,

since it is a mature standard

2

created in the MOD-

ELISAR project (ITEA Office Association, 2015)

with an active community.

The COE is developed in a combination of Java

and Scala, which makes it multi-platform and pro-

vides the simulation service through HTTP. Currently,

two methods for time-stepping are implemented; one

for fixed time steps, and one for variable time steps.

The COE is capable of switching on stability check-

ing as well as using parallelism (Thule and Larsen,

2016). In addition to the baseline tools incorpo-

rated inside the tool chain, a number of other mod-

elling and simulation tools have been tested with the

COE. This includes both commercial tools such as

Dymola, Modelon, SimulationX and Unity as well as

additional open source tools such as 4Diac. While

the COE is multi-platform it does not directly sup-

port mixed-architecture (combinations of 32bit and

2

http://fmi-standard.org

64bit architectures) or mixed-platform (combinations

of e.g. Windows and Linux) simulations as required

for the WHS system as discussed next in section 5.

5 WHS CO-SIMULATION

To co-simulate the WHS from section 3 using FMI, it

is required that both constituent models must support

FMI, and that a suitable orchestration engine that sup-

ports FMI and the required platform and architecture

combination is available. Since no such simulator is

available an extension to the COE is described in sec-

tion 5.1. To enable FMI for the constituent models,

an extension was developed for the MDT software

application framework which has been published in

(Pedersen et al., 2016; Pedersen et al., 2015). The

model of the WHS is exported from MATLAB to

an FMU using the Modelon FMI Toolbox for MAT-

LAB/Simulink (Modelon, 2015). The complete co-

simulation model is shown in section 5.2, and evalu-

ated in section 5.3.

5.1 Distributed COE Extension

To enable multi-architecture co-simulation, the chal-

lenge of mixing 32bit and 64bit code needs to be ad-

dressed. Essentially, two processes with inter-process

Distributed Co-Simulation of Embedded Control Software with Exhaust Gas Recirculation Water Handling System using INTO-CPS

79

COE

Factory

FMU

*.fmu

Distributed Factory

Proxy FMU

Host 1

Daemon

FMU

*.fmu

Host 2

Transferred

Figure 6: Distributed Extension Overview.

communication are required by the host system to re-

alize this, where one of them acts as the simulation

master. A similar challenge arises when different plat-

forms need to interact in a co-simulation.

An extension to the COE was developed that is

capable of both simulating across architectures and

platforms. The solution chosen was to utilize an ex-

tension point in the COE that allows a custom factory

to be used for FMU instantiation. An overview of the

extension is realized and shown in in Figure 6. The

COE uses the distributed factory to instantiate FMUs

that require execution with a different host configura-

tion, either architecture or platform deviation.

The extension is realized using Java-Remote

Method Invocation (JAVA-RMI) to provide cross-

platform communication (JavaRMI, 2004). It consists

of a distribution factory and an FMU proxy that is

plugged into the COE. It uses a daemon that must run

on the remote host to provide a service that enables

the COE to remotely load and control FMUs. The

COE configuration is also extended to specify which

remote daemon a specific FMU should be executed

by. When a co-simulation is started the COE will

communicate with the specified remote daemons to

configure the co-simulation by first pushing FMUs to

the remote daemons that then in turn load and setup a

communication channel for the loaded FMUs. These

will then be connected to the FMU proxy in the COE,

which is responsible for handling remote communi-

cation.

5.2 Co-Simulation Setup

The co-simulation setup is illustrated in Figure 7. The

master COE is running on the Windows host, and the

COE-deamon on the Linux host. A JSON configura-

tion file describes the co-simulation setup to the COE.

The configuration file tells the COE where the FMU-

archives are located and on which host-ip they should

be executed. The configuration file also contains in-

formation about connections between the inputs and

outputs of the FMUs, parameters and simulation al-

Windows Host

Linux Host

FMU

Distributed

COE

Daemon

FMI Wrapper

Shared Library Linux 32-bit

EGRCU

(EGR Control Unit)

Share Library (.SO)

BSP (x86)

RTOS (x86)

Application

Component X

Component Y

WHS Control

FMI API

Data

Exchange

Simulation

Execution

ModelDescription.xml

FMU

ModelDescription.xml

Code Generation

(Modelon FMI-Toolbox)

WHS Physics Model

Dynamic-link library Win 64-bit

WHS Physics Model

MATLAB

COE

Master

FMI

FMI

JAVA

RMI

Config.json

Figure 7: Co-Simulation Configuration.

gorithm: variable/fixed time step.

The WHS MATLAB model is code generated into

an FMU using the Modelon FMI toolbox for MAT-

LAB/simulink. The toolbox compiles the MATLAB

model to a 64-bit DLL including the FMI-API and

auto-generates the model description XML defining

the interface to the FMU. The control system FMU

has been created by wrapping the FMI Application

Programming Interface (API) around the SIL simula-

tion and compiling it to a Linux 32-bit shared library.

The simulation can access the RTOS for scheduling

and a hook to the clock in the BSP, all described in

(Pedersen et al., 2016). Accessing the variables of the

WHS control is done through a proxy interface that

provides pointers to internal variables to be manipu-

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

80

lated. Furthermore, the proxy interface introduces a

conversion layer between internal types such as FIX-

POINT16 and FMI-types. The SIL simulation only

includes the EGRCU controller, which contains the

WHS control. The ESU controller, containing the

DSE models, has been replaced with the MATLAB

model in the co-simulation.

The simulation is initiated through the COE and

results delivered in Comma-Separated Values (CSV)

format on the Windows host.

5.3 Co-Simulation Evaluation

Figure 8 shows the simulation results with the pro-

posed Co-Simulation setup, where the DSE physical

model has been replaced with the more detailed MAT-

LAB model. Being able to anticipate the behaviour

of the accumulated water in the Water Mist Catcher,

it is now possible to address it and to modify the state

machine accordingly to control the components in a

more appropriate way during WHS shutdown. The

first 600 seconds show the same response as in Fig-

ure 1. However, the new state machine now ensures

Figure 8: WHS Control results.

that the WMC is drained before shutting down RTLV

control. This prevents the water level in the PWRT

from overflowing, but instead stabilize at a desired

level of approximately 20-25%.

6 CONCLUDING REMARKS

This paper shows how the control development pro-

cess at MAN Diesel & Turbo could benefit from in-

troducing co-simulation. The conventional approach,

where control algorithms and strategy are formulated

using simplified models of the physical dynamics, is

not always able to properly represent the complex-

ity of the system. Importantly, with this approach,

defects are typically not found before moving to the

expensive engine test bench. With the co-simulation

approach proposed in this paper, higher-fidelity con-

stituent models of physical dynamics, formulated in

dedicated tools, can be simulated together with a SIL

simulation of the control software, at an earlier stage

of development. In the example presented, the ac-

cumulation of water in a water mist catcher was ne-

glected in the initial model, essentially resulting in

a water tank overflow during shutdown. With the

co-simulation, a more detailed model, formulated in

MATLAB, could be used for developing a working

control strategy. Had the co-simulation been used for

initial control development, the issues seen on the test

engine would likely have been discovered at an earlier

stage, saving money and time.

The main challenge enabling co-simulation at

MDT was the deviation in both OS platform and hard-

ware architecture of the simulation tools used. The

SIL simulation of the control software is constrained

to a 32-bit Linux platform and the MATLAB environ-

ment was required to run on a 64-bit Windows plat-

form due to change management concerns. In coop-

eration with the INTO-CPS-project, the INTO-CPS

Co-simulation Orchestration Engine for executing co-

simulations complying with the Functional Mock-up

Interface standard was adapted to enable distributed

co-simulation. With the distributed COE it was possi-

ble to conduct the co-simulation despite the platform

and architecture deviation.

Besides the promising results shown in this paper,

additional benefits form the INTO-CPS co-simulation

tool chain are anticipated. The extensions developed

to the MDT frameworks and development processes

enable not only co-simulation of the EGR system, but

also of any other system to be developed in the future

by MDT, with minimal effort. In the future it will

be explored when it makes sense to also make use of

more capabilities from the INTO-CPS tool chain.

Distributed Co-Simulation of Embedded Control Software with Exhaust Gas Recirculation Water Handling System using INTO-CPS

81

In the EGR Water Handling System presented

here, a subsystem called Water Treatment System is

delivered by an MDT OEM and neither modelled nor

controlled by MDT. One of the main advantages of

the Functional Mock-up Interface standard used by

INTO-CPS is that models are exchanged on a binary

level offering protection of intellectual property. One

of the future ambitions is to be able to share models

with OEMs so systems like the WHS and WTS can be

simulated together, improving both companies prod-

ucts. Part of the high-fidelity models developed at

MDT are very complex and require time to simulate,

especially if co-simulated with several other models.

One of the additional advantages of the distributed co-

simulation is that the simulation process can be par-

allelized and perhaps distributed to centralized high-

performance hardware. This could potentially speed

up simulation execution times and enable more ad-

vanced system investigations, previously deemed too

time consuming. Initial work on using the COE in

a cloud setting has already been initiated, in particu-

lar in relation to design space exploration in situations

where there is large room for different alternative so-

lutions.

ACKNOWLEDGEMENTS

The work presented here is partially supported by the

INTOCPS project funded by the European Commis-

sion’s Horizon 2020 programme under grant agree-

ment number 664047. In addition we would like to

thank Victor Bandur for inout on an earlier draft of

this article.

REFERENCES

Bandur, V., Larsen, P. G., Lausdahl, K., Thule, C.,

Terkelsen, A. F., Gamble, C., Pop, A., Brosse, E.,

Brauer, J., Lapschies, F., Groothuis, M., Kleijn, C.,

and Couto, L. D. (2016). INTO-CPS Tool Chain User

Manual. Technical report, INTO-CPS Deliverable,

D4.2a.

Fitzgerald, J., Gamble, C., Larsen, P. G., Pierce, K., and

Woodcock, J. (2015). Cyber-Physical Systems de-

sign: Formal Foundations, Methods and Integrated

Tool Chains. In FormaliSE: FME Workshop on For-

mal Methods in Software Engineering, Florence, Italy.

ICSE 2015.

Fitzgerald, J., Gamble, C., Payne, R., Larsen, P. G.,

Basagiannis, S., and Mady, A. E.-D. (2016). Collab-

orative Model-based Systems Engineering for Cyber-

Physical Systems – a Case Study in Building Automa-

tion. In INCOSE 2016, Edinburgh, Scotland.

Fitzgerald, J., Larsen, P. G., and Verhoef, M., editors

(2014). Collaborative Design for Embedded Systems

– Co-modelling and Co-simulation. Springer.

Gomes, C., Thule, C., Broman, D., Larsen, P. G., and

Vangheluwe, H. (2017). Co-simulation: State of the

art. Technical report.

IMO, I. M. O. (2015). MARPOL ANNEX VI and NTC

2008 with Guidelines for Implementation - Supple-

ment. Technical Report September 2015.

ITEA Office Association (2015). Itea 3 project 07006

modelisar. https://itea3.org/project/modelisar.html.

(Visited on 12/06/2015).

JavaRMI (2004). Java remotemethodinvocation specifica-

tion 1.5.0. http://java.sun.com/j2se/1.5/pdf/rmi-spec-

1.5.0.pdf.

Kleijn, C. (2006). Modelling and Simulation of Fluid Power

Systems with 20-sim. Intl. Journal of Fluid Power,

7(3).

Larsen, P. G., Fitzgerald, J., Woodcock, J., Fritzson, P.,

Brauer, J., Kleijn, C., Lecomte, T., Pfeil, M., Green,

O., Basagiannis, S., and Sadovykh, A. (2016). Inte-

grated Tool Chain for Model-based Design of Cyber-

Physical Systems: The INTO-CPS Project. In CPS

Data Workshop, Vienna, Austria.

MAN Diesel & Turbo (2016). Emission Project Guide,

MAN BW Two-stroke Marine Engines. Technical re-

port, MAN Diesel & Turbo.

MathWorks (2011). http://www.mathworks.com. Matlab

official website.

Modelon (2015). http://www.modelon.com/products/fmi-

tools/fmi-toolbox-for-matlabsimulink/. Modelon FMI

Toolbox for MATLAB/Simulink official website.

Pedersen, N., Bojsen, T., Madsen, J., and Vejlgaard-

Laursen, M. (2016). FMI for Co-Simulation of Em-

bedded Control Software. In Link

¨

oping Electronic

Conference Proceedings, number 124, pages 70–77.

Pedersen, N., Madsen, J., and Vejlgaard-Laursen, M.

(2015). Co-Simulation of Distributed Engine Control

System and Network Model using FMI and SCNSL.

10th IFAC Conference on Manoeuvring and Control

of Marine Craft MCMC 2015, 48(16):261–266.

SYST

`

EMES, D. (2017). https://www.3ds.com/products-

services/catia/products/dymola. 3ds official website.

Thule, C. and Larsen, P. G. (2016). Investigating con-

currency in the co-simulation orchestration engine

for into-cps. In Alexander S. Kamkin, A. K. P.

and Terekhov, A. N., editors, Preliminary Proceed-

ings of the 10th Anniversary Spring/Summer Young

Researchers’ Colloquium on Software Engineering

(SYRCoSE 2016), Krasnovidovo, Russia, May 30-

June 1, 2016), pages 223–228. ISP RAS.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

82