Closed Contour Extraction based on Structural Models and Their

Likelihood Analysis

Jiayin Liu

1,2

and Yuan Wu

1,3

1

DeepSea Precision Tech (Shenzhen) Co., Ltd, B3-4A1 Merchants Guangming Science Park, Shenzhen, Guangdong, China

2

School of Electronics and Electrical Engineering, Pusan National University, Korea

3

Digital Media & Systems Research Institute, University of Bradford, U.K.

Keywords: Closed Contour Extraction, Structural Modelling, Likelihood Analysis, Image Processing.

Abstract: In this paper, we describe a new algorithm for extracting closed contours inside images by introducing three

basic structural models to describe all potentially closed contour candidates and their likelihood analysis to

eliminate pixels of non-closed contours. To further enhance the performance of its closed contour extraction,

a post processing method based on edge intensity analysis is also added to the proposed algorithm to reduce

the false positives. To illustrate its effectiveness and efficiency, we applied the proposed algorithm to the

casting defect detection problem and carried out extensive experiments organized in three phases. The

results support that the proposed algorithm outperforms the existing representative techniques in extracting

closed contours for a range of images, including artificial images, standard casting defect images from

ASTM (American Society for Testing and Materials) and real casting defect images collected directly from

industrial lines. Experimental results also illustrate that the proposed algorithm achieve certain level of

robustness in casting defect detection under noise environment.

1 INTRODUCTION

Closed contour detection, extraction and analysis

remains an important image processing tool for a

range of applications, such as object segmentation

(Wang et al., 2005; Felzenszwalb and McAllester,

2006), blob analysis (Kawulok, 2010; Diciotti et al.,

2010), and shape modelling (Sappa and Vintimilla,

2007; Zhu et al., 2007) etc. Over the past decades,

many different algorithms and techniques have been

proposed and reported in the published literature

within different contexts of applications. Even at

present, reliable closed contour extraction still

remains an unsolved problem yet its application has

significant impact for a number of high-level image

content analysis and processing tasks.

Representative existing work for closed contour

extraction can be summarized as follows.

The general principle for closed contour

extraction can be described by two essential steps: (i)

detecting all possible closed-contour pixels via edge

detection, filtering or any other gradient-based

image processing techniques; and (ii) post-

processing these detected potential pixels via a range

of criteria based approaches, such as modelling,

connection and cost measurement etc. to connect

them into closed contours. Wang et al exploits the

concept of saliency and encoded the Gestalt laws of

proximity and continuity to extract closed contours,

which achieved good results in extracting closed

boundaries for large objects (Wang et al., 2005). By

following the similar principle, Sappa and Vintimilla

adopted the cost minimization approach to connect

the open ended edge points into closed contours

(Sappa and Vintimilla, 2007). For small closed-

contours, such as blob-like objects and segmented

cells etc. filtering and texture analysis based

approaches could provide better performances

(Kawulok, 2010, Diciotti et al., 2010). Earlier work

on contour extraction is based on chain coding

technique and object-oriented approaches. These

include the algorithm (Pavlidis, 2012; Arbelaez et al.,

2011) for contour tracing in binary images, the other

similar versions (Ren et al., 2002; Martin et al., 2004)

and (Chang et al., 2004), as well as the contour

extraction algorithm (Nabout et al., 1995). The

inherent weakness of these methods can be

summarized as: (i) the need to select appropriate

starting points to ensure correct tracing; (ii) the need

to determine the appropriate searching direction

when the tracing encounters intersections; and (iii)

Liu J. and Wu Y.

Closed Contour Extraction based on Structural Models and Their Likelihood Analysis.

DOI: 10.5220/0006480700400049

In Proceedings of the 9th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (KDIR 2017), pages 40-49

ISBN: 978-989-758-271-4

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

limitations to large objects with traceable boundaries.

Active contour was developed in which a so

called “Snake” dynamic model is adopted to extract

closed contours in gray level images (Kass et al.,

1988). Developing flexible processing for different

stochastic shapes, a Gradient Vector Flow (GVF)

model was further developed which pushes the

‘Snake’ contour into concave regions and provides a

relatively free selection of the initial contour

position (Xu and Prince, 1998). The active contour

techniques work well on a single object with smooth

and salient contours in the image. With overlapping

of multiple small contours such as cells inside

medical images, however, it becomes difficult to get

clear, sharp and non-ambiguous contours. Other

weaknesses of this method include poor iteration

convergence and the need to define the initial

contour carefully.

Region growing is another image segmentation

method that is also called seed fill or flood-fill

method. It takes a set of seed points which are

planted within the image to form regions, and the

regions are iteratively grown by comparing all

unallocated neighbouring pixels to the regions. The

difference between the intensity of a pixel and the

mean of its region is used as a measure of similarity

between pixel and the corresponding region. The

pixel with the smallest difference value is allocated

to the respective region and it does not stop until all

pixels are allocated to the region. An example of

application is shown in (Dehmeshki et al., 2008)

which intended to extract the closed contours of

medical image segmentation. The limitation of this

method for practical applications is due to its need to

select the seed number and their initial locations, yet

such knowledge is often non-available in advance.

In addition, the determination of the criteria for the

similarity measurement between the seeds and their

surrounding regions are sensitive to lighting effect

and the variation of differences between the contour

region and backgrounds.

In our recent research of developing closed

contour extraction algorithms for automatic

detection of casting defects on metal casting

industrial lines, we have tested all the above

representative techniques and found that none of

them could provide satisfactory performances. This

is primarily due to the fact that: (i) casting defects

have a wide range of different appearances, which

could either be isolated large closed contours or

overlapped multiple blob-like small closed contours;

(ii) when captured as images, the difference between

the defects areas and their normal background vary

significantly, and hence make their performances

non-stable without sufficient level of robustness. By

following the similar spirit of recent work on closed

contour detection in the principle of detecting edges

and then connect the selected open-ended edges into

closed contours, we have developed a new solution

for closed contour extraction, which proves working

well in the practical applications of detecting casting

defects from X-ray images. The new algorithm can

be described in terms of three components: (i)

extraction of potential contour points, i.e. detection

of all candidates for possible contours; (ii)

construction of the closed contours by eliminating

non-closed contour candidates, and (iii) further

reduction of false positives via a post-processing

technique based on edge intensity analysis. In

comparison with all the existing technologies, our

proposed algorithm makes the following

contributions: (i) corresponding to the problem of

varying appearances inside the casting defects, the

proposed algorithm detects the closed contours in

terms of structural models rather than individual

pixels through a likelihood analysis scheme; (ii)

corresponding to the problem of varying differences

between the defects and their background, the

proposed algorithm eliminates non-closed contours

rather than tracking the closed contours, which are

adopted by all the existing methods reported in the

literature. Our experimental results support that the

proposed algorithm achieves overwhelmingly better

performances in comparison with representative

existing techniques in terms of both robustness and

effectiveness for casting defect detection.

The rest of this paper is organized as follows.

Section II describes the proposed algorithm, which

includes introduction of basic structural models,

likelihood analysis, and the corresponding criteria as

well as other relevant strategies introduced. Section

III reports the experimental results, which are

organized in terms of four phases by running the

proposed algorithm on both standard defect images

and the real defect images collected from industrial

lines. Section IV provides concluding remarks.

2 THE PROPOSED ALGORITHM

While existing work on closed contour extraction

follows the principle of detecting potential contour

candidates via edge detection or other pixel based

processing techniques and then extract the closed

contours by further processing these candidates,

such as connection of open-ended edges etc. we

follow its opposite direction by focusing on

eliminating the non-contour candidates, in order to

overcome the problem of varying appearances inside

the casting defects. Consequently, our proposed

algorithm can be described in terms of three

operational elements, which include: (i) edge-based

detection of contour point candidates; (ii)

elimination of non-contour candidates via structural

modeling and likelihood analysis; and (iii) false

positive reduction via a strategy of dual-thresholding.

Details of all the three elements are described as

follows.

2.1 Edge-based Detection of Contour

Point Candidates

The LoG filter is widely used in a range of image

processing technologies (Howlader and Chaubey,

2010), in which its essential operation is to smooth

the input image with a Gaussian filter followed by a

Laplace operator. A Laplace operator, denoted by

,

is a 2

nd

derivatives filter which tries to locate the

edge points. Its basic idea is that the values of a

contour point’s neighbors are designated with

opposite signs.

Given the input imagewith its grey values for a

pixel located at the position

,

as represented by

.

, represents the Gaussian filtered image of by

the Gaussian filter with standard deviation σ. is

the LoG filtering output of , and can be worked out

as follows:

,

4

,

,

(1)

,

,

,

For the detection of the potential contour points or

pixels, we adopt a strategy such that: (i) the detected

contour points shall cover all the possible candidates

for closed contour extraction; (ii) the detected

contour points provide an effective and efficient

platform for achieving a high level of robustness in

detecting closed contours. Correspondingly, we

propose the following condition test:

,

1,

,

0∩

,

0∪

,

0∪

,

0∪

,

0

0,

(2)

Where

,

stands for the process of potential

contour point detection, and

,

1 designates

that the pixel

.

is a detected potential contour point

or pixel.

The condition test given in (2) is inspired by the

basic idea of zero crossing, which is adopted to

strengthen the potential contour point detection and

thus reduce the risk of the structural modeling at the

latter stage. In mathematical terms, a “zero-crossing”

is a point where the sign of a function changes (e.g.

from positive to negative), represented by a crossing

of the axis (zero value) in the graph of the function.

Following such contour point detection, a new

binary imagethat indicates the positions of those

detected potential contour points can be generated

by:

,

1,

,

1

0,

(3)

By designating that

,

1 indicates white color

and

,

0 black, all pixels inside the binary image

can be classified into contour pixels (white) and

non-contour pixels (black).

2.2 Structural Modeling

Given the generated binary image, all the detected

contour pixels do not necessarily formulate the

closed contours. If all pixels which do not belong to

any closed contour are removed, all the remaining

pixels can be associated with closed contours. This

is the essential principle that we adopted for

developing the proposed algorithm. Since most of

the images are so complicated that the pixels cannot

be handled as easily as we described above, we

propose to divide the binary image into three basic

structural models, and all these three basic models

have their own elimination rules, which follow the

same principle that the connectivity of the original

image should not be changed. In this way, the

process of closed contour extraction can be

implemented and operated in terms of these basic

structural models rather than individual pixels. In

other words, by using the proposed structural models,

the pixel-to-pixel approach adopted by the existing

research can be transformed into a structure-to-

structure technique, with which significant

advantage can be achieved in the sense that a

structure based model provides faster processing

speed and better robustness when operating in a

noisy environment, as encountered in automatic

casting defect detection.

(a) (b)

Figure 1: Illustration of skeleton images: (a) original

image I, and (b) the skeleton image S(I).

In order to handle complicated binary images,

the original image should be simplified without

changing its connectivity. The skeleton of an image

is the set of points whose distance from the nearest

image boundary is locally a maximum, and skeleton

operation can remove pixels on the contours of

objects without allowing objects to break apart.

From topology theory, it is known that an Euler

number is equal to the number of connected

components minus the number of holes. As the

skeleton operation preserves the Euler number, the

connectivity of the original image remains

unchanged (Lam et al., 1992). To derive such

skeletons, morphological operations can be adopted.

Following that, all skeletons extracted can be made

to be 1 pixel wide for all the contours, an example of

which is shown in Figure 1.

2.3 Basic Structural Models

Given the skeleton of the image , all the

directions from each pixel , to its neighbors can be

divided into two categories. One is along the x-axis

or y-axis, denoted as direction , and the other is the

direction that has an angle of 45 degrees to the axis,

denoted as direction . As

is a binary image

whose contour width is equal to 1, there are at most

three pixels ahead if tracking along the contour in

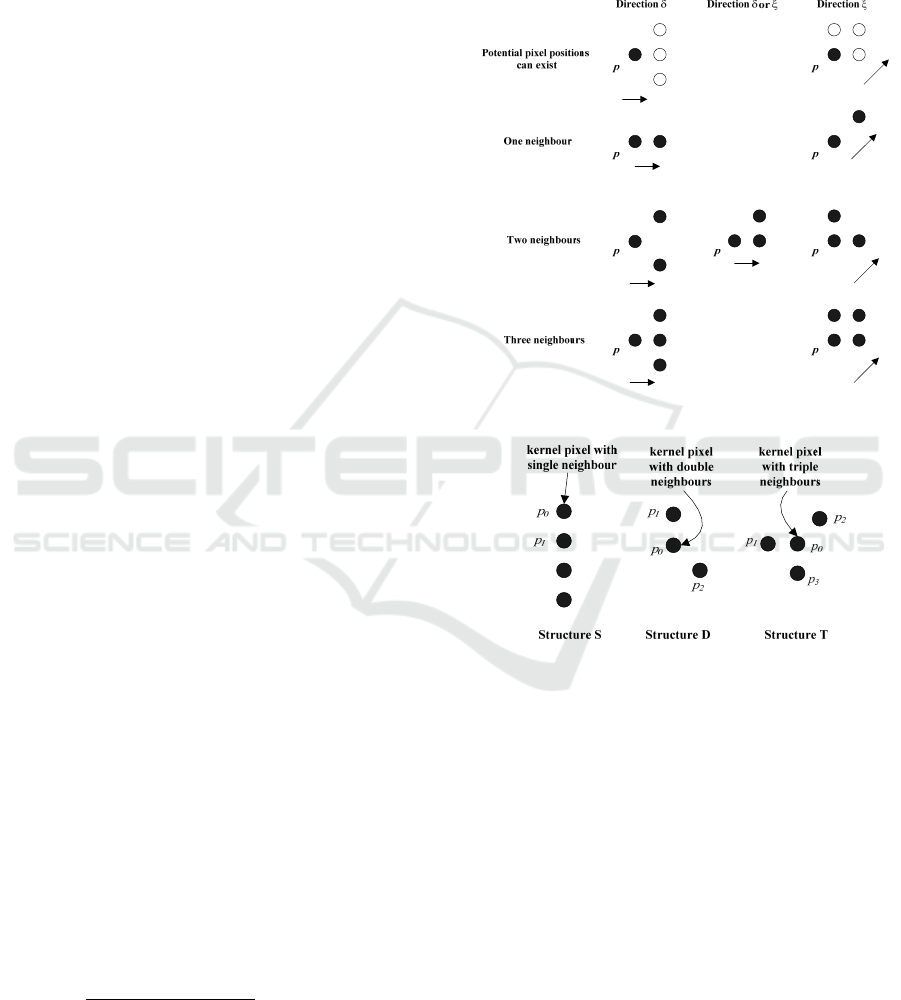

one direction. Figure 2 illustrates all the possible

situations, where, in the first row, the three blank

white circles around pixel indicate the potential

pixel positions that can exist, and in the second, third

and last row, there are all the possible situations

when has one, two and three neighbors

respectively. The arrows indicate a direction , or .

If is a pixel of, then is defined as a

set that contains all neighboring pixels of , and

|

|

is the number of neighboring pixels around .

Let , represent the chessboard distance

between pixels

,

and

,

, its definition

can be described as follows:

,

max

,

(4)

Definition 1: Compactness is a value that

indicates how compact in space distribution the

neighboring pixels of are. In general, the smaller

the value of compactness, the more compact the

elements in are, and thus we have:

∑

,

|

|

|

|

,

|

|

2

1,

|

|

1

(5)

When

|

2

|

,

,⋯,

|

|

∈,

|

|

is the

combinatorial number of selecting 2 items from

|

|

items. When

|

|

1, it means that has

only one neighbor, i.e., the most compact case, and

hence

1.

From the definitions, it can be worked out that:

1

,

2, and hence 12.

Figure 2: Construction of structural models.

Figure 3: A schematic drawing of the three basic

structures S, D, and T.

Definition 2: A Structure is a set of pixels that

consists of only one kernel pixel

and several shell

pixels

,

,⋯ which are all neighbors of

.

In the proposed algorithm, the principle adopted

for the elimination process is that we only remove

the kernel pixel

but leave the shell pixels, which

are required as evaluation pixels for detecting and

removing the kernel pixel.

As a result, depending on the number of

neighbors surrounding

, we define the three basic

structural models as follows, which cover all the

situations illustrated in Figure 2. Corresponding to

each basic structure, we use a different rule to detect,

simplify or remove. A schematic drawing of the

three basic structures, S, D, and T, is given in Figure

3.

The definition of the structure S, i.e. the kernel

pixel with one single neighbor, can be given as

follows:

:

,

|

|

|

1,

∈

(6)

Where

is a kernel pixel, and

is a shell pixel.

A single pixel

can be treated as a special case

inside the Structure :

|

|

|

0

Structure D (a kernel pixel with double

neighbors) is defined as:

:

,

,

|

|

|

2,

,

∈

(7)

Where

is a kernel pixel,

and

are shell pixels.

Structure T (a kernel pixel with triple neighbors)

is defined as:

T:

,

,

,

|

|

|

3,

,

,

∈

(8)

Where

is a kernel pixel,

,

and

are shell

pixels.

Each basic structure is required to go through the

simplifying or removing process, which primarily

aims at removing the kernel pixel, i.e. the non-closed

contour candidates. Its removal is dependent on the

distribution of its shell pixels. In principle, a

structure with a compact distribution of shell pixels

means that it has a low probability of changing the

connectivity of the remaining shell pixels after the

kernel pixel is removed.

A likelihood based elimination scheme is

proposed to construct the rule for removing kernel

pixels, which is defined as:

2

⁄

1

(9)

Where is defined as the likelihood value of

pixel , which indicates a priority level that should

be removed as a non-closed contour pixel. The

smaller the compactness value is, the larger the

value of , and hence the higher the priority that

should be removed as a non-closed contour pixel.

According to the range of , we have 0

1, where

1 indicates that should

be removed definitely. Due to noise and other

unperceptive factors, not all pixels that should be

removed satisfy the condition

1 .

Correspondingly, we adopt the common principle

that, when

0.5, is removed, otherwise

stays. Details are described as follows.

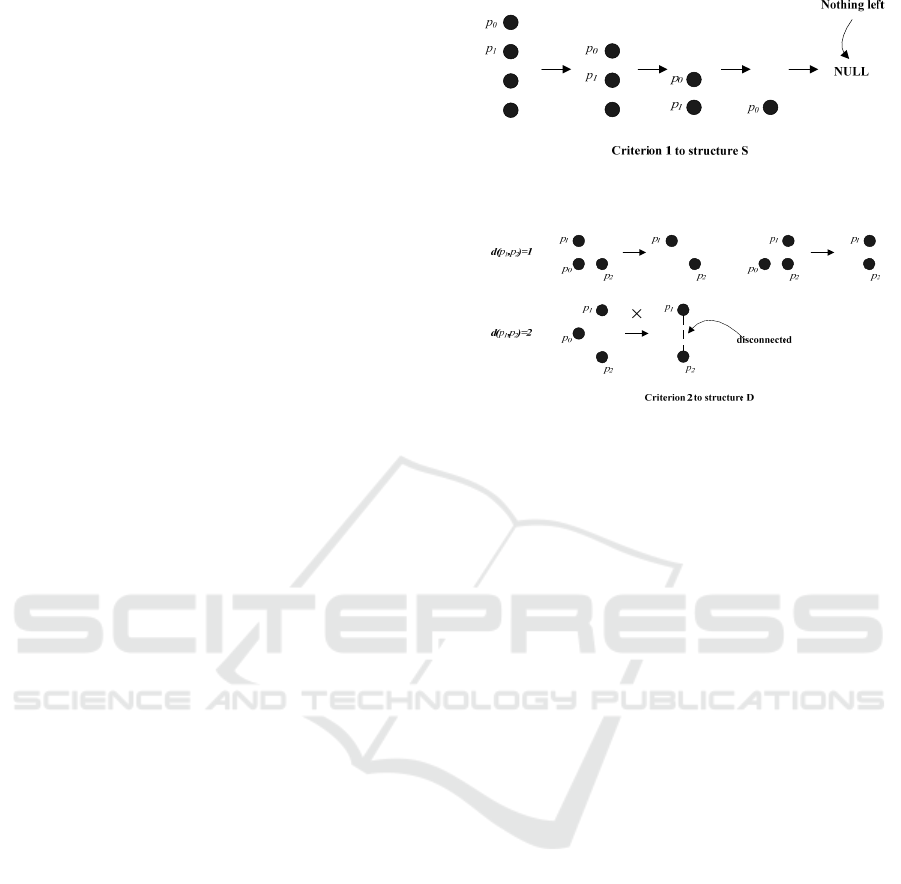

For S, we have:

2

⁄

11, and

hence

should be removed. This is repeated until

nothing is left, this process of which is illustrated in

Figure 4.

Figure 4: Illustration of a schematic elimination for

Structure S.

Figure 5: Schematic elimination for Structure D.

For D, we have:

∑

,

⁄

,

.

Therefore, removal of

is determined via the

likelihood value, which is depending on the value of

,

, as defined below:

2

⁄

1

1,

,

1

0,

,

2

(10)

The removal process is also illustrated in Figure 5,

where it is seen that, in the first row

when

,

1,

can be removed, while in the

second row when

,

2,

should stay.

For T, we have:

,

,

,

,

3

⁄

(11)

As the value of

is dependent on all three

distances, specific calculation of the priority level

can be derived as follows:

2

⁄

1

(12)

1,

,

,

,

1

0.5,

,

,

,

4

0.2,

,

,

,

5

0,

,

,

,

6

Similarly, the removal process is illustrated in

Figure 6, where, in the first row when

,

,

,

3 or

,

,

,

4,

can be removed,

while in the second row when

,

,

,

5 or

,

,

,

6 ,

should stay.

Otherwise

will be separated from

and

.

p

1

p

2

p

0

d(p

1

,p

2

)+d(p

1

,p

3

)+d(p

2

,p

3

)=3

p

1

p

2

p

0

Criterion 3 to structure T

p

3

p

1

p

3

p

2

d(p

1

,p

2

)+d(p

1

,p

3

)+d(p

2

,p

3

)=4

p

3

p

1

p

2

p

3

d(p

1

,p

2

)+d(p

1

,p

3

)+d(p

2

,p

3

)=5

d(p

1

,p

2

)+d(p

1

,p

3

)+d(p

2

,p

3

)=6

p

1

p

2

p

0

×

p

3

p

1

p

2

p

3

p

1

p

2

p

0

×

p

3

p

1

p

2

p

3

disconnected

disconnected

Figure 6: Schematic elimination for Structure T.

2.4 False Positive Reduction

To increase the robustness of the proposed scheme

in detecting closed-contour candidates, we further

propose a validation or post processing scheme to

reduce false positives by monitoring and analyzing

the differences between the LoG filtered pixels and

their surroundings.

Specifically, given an object pixel inside the

image,

,

, a value of MDV (Maximum Difference

Value) is introduced as follows:

,

max

,

,

,

,

,

,

,

,

,

,

,

(13)

Where represents the maximum value among

all the elements inside the bracket, and

,

represents the LoG filtered pixel.

Since a larger

,

indicates a higher

probability that the point

,

is a contour point, we

propose a two-step scheme to reduce the false

positives. In the first step, we use a threshold to

remove those points where their corresponding MDV

value is less than a threshold. This is defined below:

,

1,

,

0,

(14)

Where

,

represents the validation process, and

its value of unity indicates that

,

is a true positive.

Otherwise,

,

is false positive.

Following the validation process for individual

pixels, the second step of our proposed scheme

involves an examination of each contour candidate,

in which the number of pixels that are labeled as true

positives by the first step is counted. This process

can be described as follows.

,

1,

⁄

0,

(15)

Where

,

represents the validation of the

contour candidate inside the binary image

,

,

stands for the number of pixels labeled as true

positives by (14), and

stands for the total number

of pixels included in the contour candidate being

examined.

Determination of the two thresholds is mainly

via F-measure caculation approach on ground truth

database. The general principle is that the larger the

or

is, the more the false positives are removed.

Our extensive empirical studies reveal that

is not

particularly sensitive. With

, however, it is slightly

sensitive to the type of input image.

3 EXPERIMENTS

We formulate closed contour detection as a

classification problem of discriminating closed

contours from non-contour pixels and apply the

precision-recall evaluation framework to benchmark

the related algorithms. To evaluate the proposed

algorithm, we carried out extensive experiments

organized in three phases. The first phase

experiments carried out on the ASTM (American

Society for Testing and Materials) test data, the

second phase experiments carried out on the test

data sets with ground truth collected from industrial

lines and the final phase is dedicated to robustness

analysis, where Gaussian noise is added to the

casting defect images and the proposed algorithm is

evaluated to see if it can still produce acceptable

detection results. PR curve and F-measure are also

performed and evaluated, the optimal thresholds of

and

are obtained during the F-measure

caculation course.

3.1 Phase-1: Standard Casting Defect

Images

According to the suggestions made by ASTM

(American Society for Testing and Materials), all

standard casting defect images are divided into

seven categories in terms of the type of defects,

which include: air holes, foreign-object inclusions

(slag and sand), shrinkage cavities, cracks, wrinkles,

casting fins, and abnormal micro-fracture. Figure 7

illustrates samples of all seven categories.

In Li’s paper (Li et al., 2006), the algorithm is

only tested on ASTM standard images. It should be

noticed that the ASTM standard images are not

designed for quantity evaluation, thus our results

compared with Li’s do not give quantity evaluation

further. From the illustrated results in Figure 8, it is

cleared that our method outperforms Li’s especially

in details of the segmented defects. (To facilitate the

comparison with Li’s result, we inverted the gray

values of our result images.)

Figure 7: Representative samples of the seven categories

of casting defects.

Figure 8: Illustration of comparative experiments between

the proposed and Li’s work: from the leftmost to the

rightmost, the three columns are the original ASTM

standard images, our results, Li’s results.

While Li’s work did not report any of their testing

results on real defect images, the proposed algorithm

works well with processing real defect images as

reported in phase-2 of our experiments.

3.2 Phase-2: Real Defect Images and

Ground Truth

In this phase, we applied the proposed algorithm to a

range of real casting defect images collected from

industrial line and tested its usefulness in practical

applications and performance based on ground truth.

The ground truth datasets have two forms: the

contour form that can be tested by contour-based

methods, and the region form that will be used by

region-based methods such as thresholding

techniques. Basically, the two forms are equal: the

region form ground-truth is labelled by three

different professional examiners by hand-drawn, at

least two hints on one pixel will make this pixel

labelled as an object from the background in the

ground-truth; the contour form ground-truth is the

closed contours of the region form ground-truth. The

ground truth datasets contain 3080 positive samples

and 8600 negative samples.

A sample image and its detailed processing

results are illustrated in Figure 9.

Figure 9: Sample experimental results by the proposed: (a)

The original image captured from an industrial line, where

the defects are labeled in the circle; (b) illustration of the

defect via zooming-in of the original image; (c) Closed

contour extracted by the proposed; (d) Superimposed

contours with the defects on the original image.

We formulate closed contour detection as a

classification problem of discriminating closed

contours from non-contour pixels and apply the

precision-recall evaluation framework to benchmark

the related algorithms, including Mery’s (Mery and

Filbert, 2002), Li’s (Li et al., 2006), Canny (Canny,

1986), and some recently published works to the

best of our knowledge (Zhao et al., 2014; Zhao et

al., 2015; Ramírez and Allende, 2013). The ground

truth data set contains 5,000 X-ray images collected

from the real industrial environment. Mery’s

performed better than others. We will perform

comparative tests between Mery’s and our method

thoroughly.

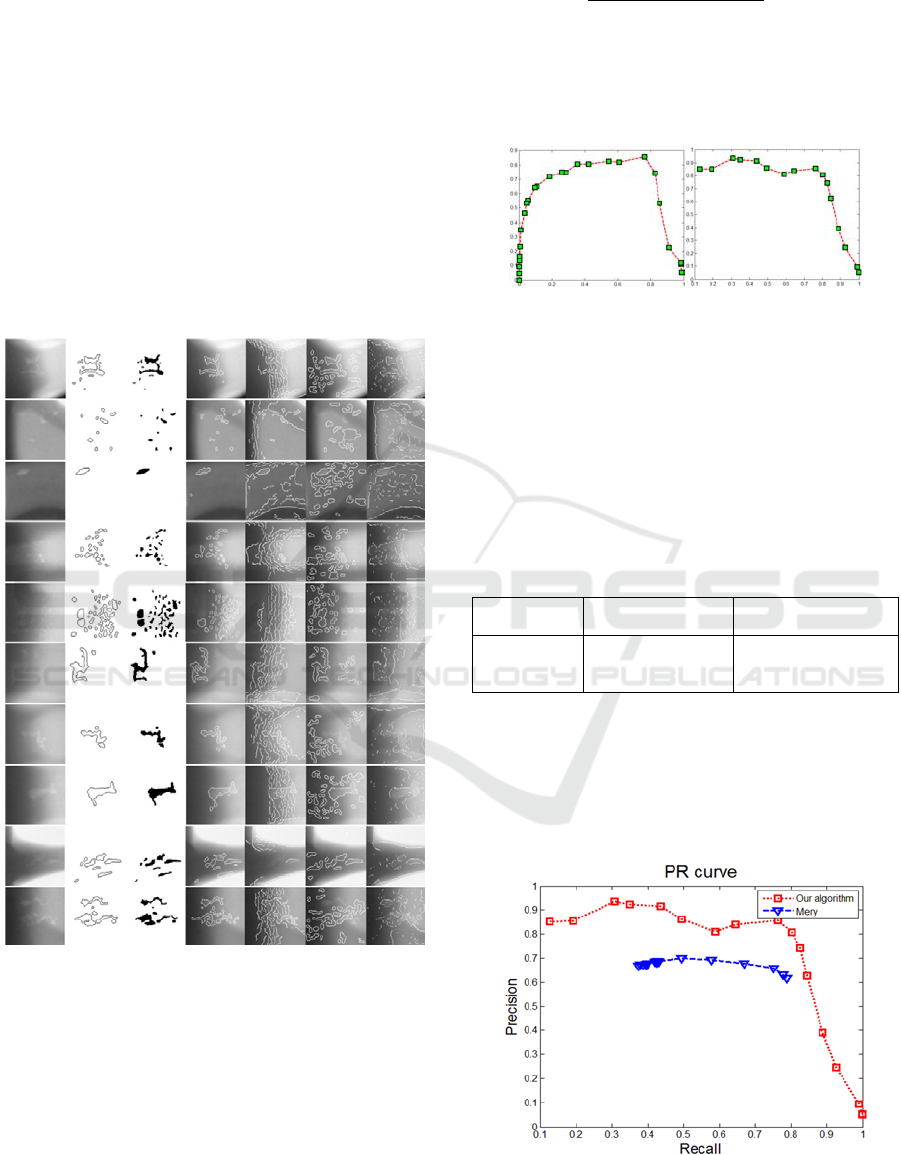

Some samples from the ground truth and their

corresponding results are presented in Figure 10:

from the leftmost column to the rightmost, they are

the original images, contour form ground truth,

region form ground truth, our results, Canny’s

results, Mery’s results (Mery and _Filbert, 2002),

Elder’s (Elder and Zucker, 1998).

The preferred evaluation measure the precision

recall (PR) framework can capture the trade-off

between accuracy and noise while the algorithm

threshold varies. Using the PR evaluation is a

standard evaluation technique in information

retrieval, precision is the fraction of retrieved

instances that are relevant,

⁄

,while recall is the fraction of relevant

instances that are retrieved,

⁄

.

Receiver operating characteristic (ROC) curves are

considered not appropriate for quantifying boundary

or contour detection in classification tasks (Martin et

al., 2004). In our work, the precision is the number

of true positives (i.e. the number of pixels correctly

labelled as belonging to the positive class) divided

by the total number of pixels labelled as belonging

to the positive class (i.e. the sum of true positives

and false positives), and recall is defined as the

number of true positives divided by the total number

of elements that actually belong to the positive class

(i.e. the sum of true positives and false negatives).

Figure 10: Illustration of ground truth and their

corresponding results: From the leftmost column to the

rightmost, they are original images, contour form ground

truth, region form ground truth, our results, Canny’s,

Mery’s and Elder’s results.

Usually, precision and recall scores are not

discussed in isolation. Instead, either value for one

measure is compared for a fixed level at the other

measure. A measure that combines precision and

recall is the harmonic mean of precision and recall,

the traditional F-measure:

2∙∙

(16)

This is also known as the

measure, because recall

and precision are evenly weighted. PR curves based

on threshold

and

are illustrated in Figure 11, in

which we alter

from 0 to 0.6, and

from 0 to 0.8.

(a) (b)

Figure 11: PR curves based on threshold

and

, in

which the horizontal axis is recall, and the vertical axis is

precision, left:

from 0 to 0.6, right:

from 0 to 0.8.

The location of the maximum F-measure along

the PR curve provides the optimal algorithm

threshold. In table 1, we could see the optimal

thresholds (

0.16 and

0.35) are obtained

during the F-measure caculation course.

Table 1: The optimal thresholds obtained based on F-

measure.

Method

Our algorithm

(

)

Our algorithm

(

)

F-measure

@parameter

0.78@

0.14

0.79@

.

0.68@

0.18

0.797@

.

0.793@

0.4

0.75@

0.45

We carried out further experiments for

performance comparison between Mery’s and ours,

the PR curve is presented in Figure 12. From the

illustrations in Figure 10 and the PR curve

performance in Figure 12, it shows that the proposed

method performs better.

Figure 12: The proposed algorithm and Mery’s

performance are evaluated with PR curves.

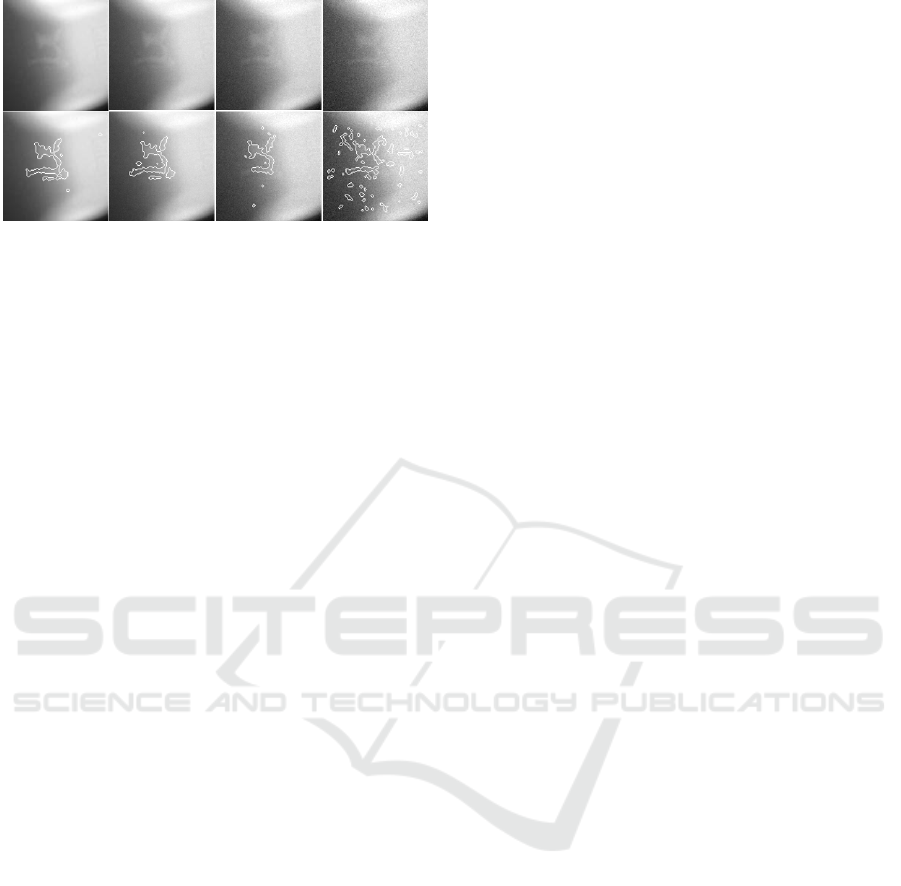

Figure 13: Experimental results to test the robustness of

the proposed algorithm, the top row, from left to right: The

original image, corrupted images with additive Gaussian

noise of variances 1, 2, 3 respectively, the bottom row,

from left to right: The corresponding results,

superimposed closed contours with the real defects inside

the original images.

3.3 Phase-3: Robustness Test and

Computing Burden

To test the robustness of the proposed algorithm, we

added Gaussian noise to the X-ray images with three

levels of variance and repeated the experiments.

Figure 13 illustrates a sample of such test results, in

which the original image and its corrupted versions

with variances of 1, 2 and 3 are shown from left to

right on the top row, and the results are shown in the

bottom rows. As seen, the proposed algorithm is

able to produce acceptable detection results with a

noisy environment until the variance level is

increased to 3. This result illustrates a high level of

robustness achieved by the proposed algorithm,

although, for the case of noisy environment with

variance of 3, the proposed algorithm failed to

achieve right detection of the closed contours. This

is reasonable due to the fact that, under this

circumstance, it is difficult to see the real defect

even with our naked eyes as shown in the right-most

column. It should also be noted that, during the

entire experiments, no extra de-noise technique has

been applied to the proposed algorithm.

On a PC with Intel Core i7-2600 3.4GHz CPU

and 8GB RAM, the average processing time of our

method in MATLAB implementation is around 0.45

seconds per image. The image resolution is 140*140

pixels.

4 CONCLUSIONS

In this paper, we described a structural model based

approach for closed contour detection, which is

prompted by our recent research on developing

image-based algorithms for casting defect detection.

In comparison with the existing techniques, the

proposed algorithm has the following features: (i)

closed contour detection and extraction is carried out

in terms of structural models rather than individual

pixels; (ii) removal of non-closed contour candidates

is guided via likelihood analysis. Extensive

experiments were carried out to evaluate the

proposed algorithm, and all the results show that the

proposed algorithm is capable of achieving excellent

results for closed contour detections, providing a

robust tool for casting defect detection in practical

applications.

REFERENCES

Wang, S., Kubota, T., Siskind, J. M., & Wang, J. 2005.

Salient closed boundary extraction with ratio

contour. IEEE transactions on pattern analysis and

machine intelligence, 27(4), 546-561.

Kawulok, M. 2010. Energy-based blob analysis for

improving precision of skin segmentation. Multimedia

Tools and Applications, 49(3), 463-481.

Diciotti, S., Lombardo, S., Coppini, G., Grassi, L.,

Falchini, M., & Mascalchi, M. 2010. The LoG

Characteristic Scale: A Consistent Measurement of

Lung Nodule Size in CT Imaging. IEEE transactions

on medical imaging, 29(2), 397-409.

Sappa, A. D., & Vintimilla, B. X. 2007. Cost-based

closed-contour representations. Journal of Electronic

Imaging, 16(2), 023009-023009.

Pavlidis, T. 2012. Algorithms for graphics and image

processing. Springer Science & Business Media.

Ren, M., Yang, J., & Sun, H. 2002. Tracing boundary

contours in a binary image. Image and vision

computing, 20(2), 125-131.

Chang, F., Chen, C. J., & Lu, C. J. 2004. A linear-time

component-labeling algorithm using contour tracing

technique. Computer Vision and Image

Understanding, 93(2), 206-220.

Nabout, A., Su, B., & Eldin, H. 1995. A novel closed

contour extractor, principle and algorithm. In Circuits

and Systems, 1995. ISCAS'95., 1995 IEEE

International Symposium on (Vol. 1, pp. 445-448).

IEEE.

Kass, M., Witkin, A., & Terzopoulos, D. 1988. Snakes:

Active contour models. International journal of

computer vision, 1(4), 321-331.

Xu, C., & Prince, J. L. 1998. Snakes, shapes, and gradient

vector flow. IEEE Transactions on image

processing, 7(3), 359-369.

Elder, J. H., & Zucker, S. W. 1998. Local scale control for

edge detection and blur estimation. IEEE Transactions

on Pattern Analysis and machine intelligence, 20(7),

699-716.

Dehmeshki, J., Amin, H., Valdivieso, M., & Ye, X. 2008.

Segmentation of pulmonary nodules in thoracic CT

scans: a region growing approach. IEEE transactions

on medical imaging, 27(4), 467-480.

Howlader, T., & Chaubey, Y. P. 2010. Noise reduction of

cDNA microarray images using complex

wavelets. IEEE transactions on Image

Processing, 19(8), 1953-1967.

Lam, L., Lee, S. W., & Suen, C. Y. 1992. Thinning

methodologies-a comprehensive survey. IEEE

Transactions on pattern analysis and machine

intelligence, 14(9), 869-885.

Mery, D., & Filbert, D. 2002. Automated flaw detection in

aluminum castings based on the tracking of potential

defects in a radioscopic image sequence. IEEE

Transactions on Robotics and Automation, 18(6), 890-

901.

Mery, D., da Silva, R. R., Calôba, L. P., & Rebello, J. M.

2003. Pattern recognition in the automatic inspection

of aluminium castings. Insight-Non-Destructive

Testing and Condition Monitoring, 45(7), 475-483.

Li, X., Tso, S. K., Guan, X. P., & Huang, Q. 2006.

Improving automatic detection of defects in castings

by applying wavelet technique. IEEE Transactions on

Industrial Electronics, 53(6), 1927-1934.

Canny, J. 1986. A computational approach to edge

detection. IEEE Transactions on pattern analysis and

machine intelligence, (6), 679-698.

Felzenszwalb, P., & McAllester, D. 2006. A min-cover

approach for finding salient curves. In Computer

Vision and Pattern Recognition Workshop, 2006.

CVPRW'06. Conference on (pp. 185-185). IEEE.

Zhu, Q., Song, G., & Shi, J. 2007. Untangling cycles for

contour grouping. In Computer Vision, 2007. ICCV

2007. IEEE 11th International Conference on (pp. 1-

8). IEEE.

Martin, D. R., Fowlkes, C. C., & Malik, J. 2004. Learning

to detect natural image boundaries using local

brightness, color, and texture cues. IEEE transactions

on pattern analysis and machine intelligence, 26(5),

530-549.

Arbelaez, P., Maire, M., Fowlkes, C., & Malik, J. 2011.

Contour detection and hierarchical image

segmentation. IEEE transactions on pattern analysis

and machine intelligence, 33(5), 898-916.

Zhao, X., He, Z., & Zhang, S. 2014. Defect detection of

castings in radiography images using a robust

statistical feature. JOSA A, 31(1), 196-205.

Ramírez, F., & Allende, H. 2013. Detection of flaws in

aluminium castings: a comparative study between

generative and discriminant approaches. Insight-Non-

Destructive Testing and Condition Monitoring, 55(7),

366-371.

Zhao, X., He, Z., Zhang, S., & Liang, D. 2015. A sparse-

representation-based robust inspection system for

hidden defects classification in casting components.

Neurocomputing, 153, 1-10.