Insurance as Efforts to Control Risk Disease Caused by Benzene for

Home Industry Shoes Workers

Abdul Rohim Tualeka, Heru Fahrudi, Siti Asiah

Department Occupational Health and Safety, Public Health Faculty, Universitas Airlangga, Mulyorejo, Surabaya,

Indonesia

{Abdul Rohim Tualeka, Heru Fahrudi, Siti Asiah} inzut.tualeka@gmail.com, herufahrudhi@gmail.com,

sitiasiah.skm2@gmail.com

Keywords: Benzene, Excess cancer risk, safe duration, Insurance.

Abstract: This study aimed to determine the risk characteristics of workers exposed to benzene and their insurance as

an effort to control the risk of occupational diseases in the shoe home industry in Surabaya. The research

method was a descriptive study by describing the risk control with insurance based on the characteristics of

the exposure to benzene. The sample size was 20 shoe home industry workers. The data analysis used was

descriptive. The results showed that the highest benzene concentration was 7.44 mg/m

3

, the average intake

of benzene was 0.00363 mg/kg/day, and that the Excess Cancer Risk of the 20 respondents >10

-5

means that

the exposure to benzene was not safe for their health. The safe duration for the workers between 0,03 - 3.53

years means that the workers have a high risk of suffering from leukemia due to their exposure to benzene.

Because it is high risk, the workers must be insured. However, based on the research results, 100% of the

workers had no insurance (BPJS Ketenagakerjaan); the home industry had no Pos Upaya Kesehatan Kerja.

From the results of the study, it has been concluded that the workers have a high risk of exposure to

benzene. The workers had no insurance (BPJS Ketenagakerjaan) and no Pos Upaya Kesehatan Kerja so

there was no protection for the workers.

1 INTRODUCTION

Benzene is in the working environment of

shoemakers. Therefore it is an absolute necessity to

know the level of risk of the exposed groups. This

study has measured 8 work sites to determine the

broader picture of benzene concentration.

One of the UKMs in Indonesia is the informal

industry of shoe craftsmen. In the early 1990s, the

footwear industry became a major contributor to

Indonesia's Gross National Product as the third

largest national income after the wood and textile

industry. About 40 percent of Indonesia's shoe

exports are shipped to the US market, while 33

percent are shipped to Europe. The rest are exported

to African, Middle Eastern and South American

countries.

The efforts of shoemakers to maintain the quality

and existence of their products are often not matched

by the protection from the occupational risks

associated with harmful equipment and materials.

The use of hazardous materials or chemicals in shoe

crafting includes using glue as a material for the

process of making shoes. The process consists of

several stages of work, starting with making the shoe

design, preparing the tops of the shoes (patterning,

pattern cutting, stripping, decorating, sewing and

insoles), preparing the bottom of the shoe (outer

soles, gluing, coat, sewing, nailing) finishing

(cleaning, smoothing) and packing for subsequent

delivery to the consumer/market in the production

process using a variety of equipment (Maryiantari,

2016).

Shoe work is a risky job. Long working hours not

supported by a safe and comfortable workplace,

uncomfortable body position, and harmful

equipment. Equipment used in the production

process includes electric heating/ fire (oven), nails

and hammer, raw materials made of fabric, synthetic

leather or plastic materials. For the process of

gluing, the workers use two types of glue; yellow

glue Pro ARDico Brand, glue LK and white glue

PU-Weber brand, DS-Bond DNS 818. Yellow glue

is used to connect the openings so it is usually used

in the surface and finishing, while white glue is

282

Tualeka, A., Fahrudi, H. and Asiah, S.

Insurance as Efforts to Control Risk Disease Caused by Benzene for Home Industry Shoes Workers.

In Proceedings of the 4th Annual Meeting of the Indonesian Health Economics Association (INAHEA 2017), pages 282-289

ISBN: 978-989-758-335-3

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

generally used to patch the soles because of the

much stronger adhesion force. In a normal situation

(normal day), within a month they can use 30-40 kg

of yellow glue and white glue by approximately 30

kg. The use of the glue means that it is poured in to

small containers such as bottles, drinks with open

positions or directly from a container of 3kg glue

size (Maryiantari, 2016). Based on the research

conducted by Hendra, it stated that there is an

organic solvent in the glue in the form of benzene by

about 1-2%.

The various equipment and materials used in the

shoe making process is one of the high risk hazards

involved. The use of chemicals can be detrimental to

the health of the shoemakers. One of them is the use

of glue. In the process, there is an organic solvent

vapor contained in the glue that is very likely to

have an impact on health if inhaled continuously for

long periods of time (Lu, 2006).

Benzene, when inhaled, can cause aplastic

anemia and leukemia. Research conducted in

Europe, America and Mexico has shown a

significant relationship between elevated levels of

benzene in the air and increased rates of cancer and

local leukemia. In other studies in the United States,

it has been shown that inhaling benzene even at the

threshold can cause chromosomal abnormalities in

sperm cells.

Indonesian National Standard in 2005 refers to

Permenaker No. 13 of 2011 which contains the time-

weighted avarage of workplace-treated chemical

substances, with the number of working hours of 8

hours per day or 40 hours per week. It states that

benzene is included in the A2 group (Chemical

substances estimated to be human carcinogens) and

has a NAB of 10 ppm or 32 mg/m

3

benzene in the

air (SNI 2005).

The occurrence of health problems due to

benzene exposure in shoe workshop workers is

reported to occur in China, which is the largest shoe

manufacturer in the world. A restrospective cohort

study of 75,000 workers exposed to benzene from

1987 to 1991 in 12 Chinese cities found that 43

groups of workers were exposed to benzene. This

study suggests that the workers exposed to benzene

are at a higher risk of dying from leukemia with a

relative risk of 2.3 compared with the workers not

exposed to benzene (Chen and Chan, 1999).

Risk control is a preventive method that is done

in such a way that the risk does not occur. One effort

to control the risk of disease in workers is with

insurance. Health insurance is an insurance product

that provides a finance security guarantee to the

policy holder at the time of health problems due to

illness or an accident (Tualeka, 2015). By insuring a

company's property when there is a big risk, it

transfers the impact of the risk to the insurer.

Insurance will not reduce the risk probability but it

will reduce the impact of those risks.

2 METHOD

This research was a descriptive and observasional

study conducted in the home industry of shoes

workers in Tambak Oso Wilangon, Surabaya. While

in terms of time, the type of approach used in this

study was a cross-sectional research design using a

risk analysis paradigm by taking one component,

namely the risk assessment/risk assessment (NRC,

1983). Risk assessment was used to calculate the

extent of cancer incidence, and if the duration of

work (Dt) was safe. Participation in relation to

insurance was done by interview.

This research was conducted at 8 locations of

work with the research subjects totalling 20

respondents. The measurement of benzene

concentration in the work environment was done by

using the NIOSH 1501 measurement method with an

active carbon absorbent pipe (choarcoal) by using

the Gas Chromatography (GC) technique by a

trained officer from UPTK3 Surabaya. To know the

ownership of insurance, we used the interview

method.

3 RESULT

Benzene in the working environment of shoemakers

makes it an absolute necessity to know the level of

risk of the exposed groups. This study measured 8

work sites to determine the picture of benzene

concentration.

Insurance as Efforts to Control Risk Disease Caused by Benzene for Home Industry Shoes Workers

283

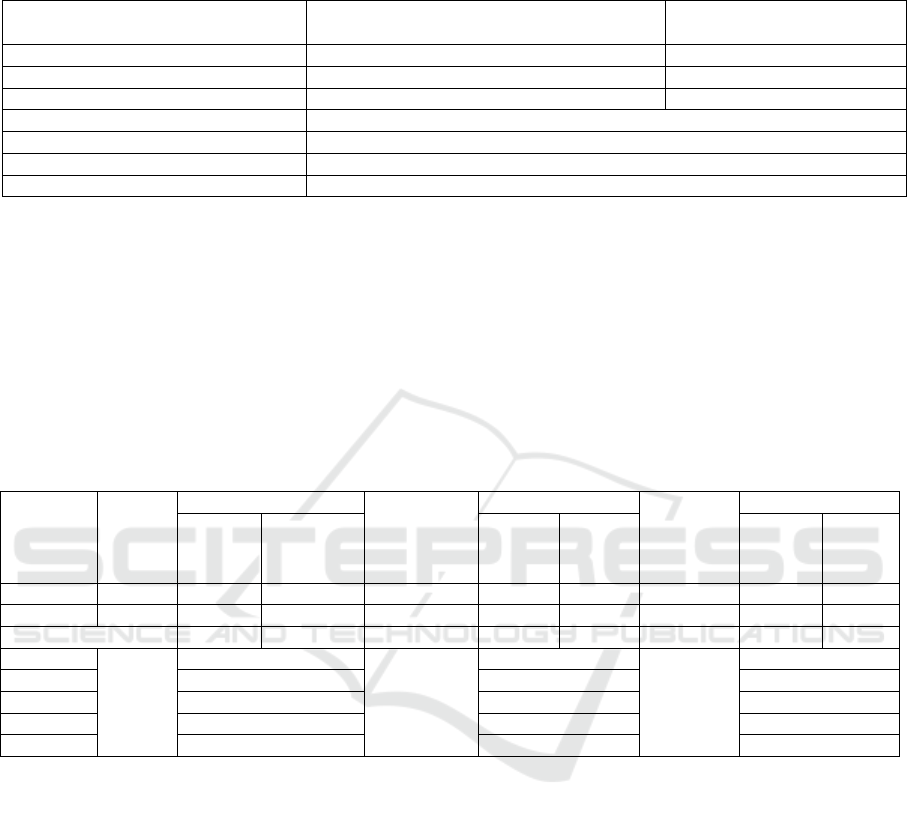

Table 1: Benzene Concentration Distribution in Working Environment of Shoemakers in Tambak OSO Vilagge Wilangun

Surabaya 2016

In Table 1, the concentration of benzene by as

much as 6 points (75%) is still below the

determined brick threshold value of 0.5 ppm or 1.6

mg/m

3

. The average benzene concentration is

1,6313 mg/m

3

. The lowest concentration level was

0.04 mg/m

3

and the highest concentration was 7.44

mg/m

3

.

The pattern of activities to be covered includes

exposure, frequency and the duration of exposure.

The working hours of each work location are not

the same. In addition to the working hours, other

variables that must be considered are the number

of working days and long working hours in the

home industry shoe of Tambak Oso Wilangun.

Table 2: Distribution of Descriptive Frequency of Pattern of Workers Activity of Shoemaker in Tambak Oso Vilagge

Wilangun Surabaya 2016

Info.

(tE)

Amount

(fE)

Amount

(Dt)

Amount

n % N %

N %

≤ 8 hours 1 5 ≤ 265 day - - ≤ 25 yea

r

10 50

>8 hours 19 95 > 265 da

y

20 100 > 25

y

ea

r

10 50

Total 20 100 20 100 20 100

Mean

hours

/day

10.55

day/year

346.75

year

24.93

Std. dev 3.086 30.680 10.957

Me

d

9.50 365 24.50

Min 6 260 3

Max 17 365 43

Table 2 illustrates the frequency distribution of

exposure time, exposure frequency, and the duration

of exposure. Exposure time (tE) is categorised into

two ie ≤ 8 hours / day and> 8 hours / day.

The result showed that 1 worker (5%) had an

exposure time of ≤ 8 hours / day and 19 workers

(95%) had an exposure time of > 8 hours/ day. The

average exposure time of 10.55 hours/ day shows

that each work location has a different exposure

time. The exposure frequency (fE) is categorised

into two, ie ≤ 265 days and> 265 days. The result of

the research is that all workers have an exposure

frequency > 265 days. The average worker in a year

works for 346.75 days. Exposure duration (Dt) is

categorised into two, i.e. ≤ 25 years and> 25 years.

The results showed a balanced result between the

two for each of 10 workers (50%). The average

duration of exposure was 24.93 years.

Based on the results of the interviews, it is

known that workers have worked for a long time

before, therefore this needs to be considered because

this can give the idea that they are always in an

environment that allows for exposure to benzene.

The result showed that one of respondents with

serial number 1 had a body weight of 51.4 kg (Wb).

Every day they worked 9 hours/day (tE) for 313

days (fE), and had worked for 34 years (Dt). With an

inhalation rate (R) of 0.6 m

3

/hr and the tavg for

carcinogenic substances was 10950 days. The result

of the benzene air measurement showed a

concentration of (C) 0.04 mg/m

3

, so the amount of

non-carsinogenic intake (intake) was:

Concentration Benzene

(NAB= 1,6 mg/m

3

)

N Percentage (%)

≤ 1.6 mg/

m

3

6 75

> 1.6 mg/

m

3

2 25

Total 8 100

Mean 1.3475

Median 0.6350

Std. Deviation 2.54762

Min-Max 0.04 - 7.44

INAHEA 2017 - 4th Annual Meeting of the Indonesian Health Economics Association

284

= 0,04 mg/m

3

x 0,6 m

3

/hours x 9 hours/day x 313

hours x 34 years

51.4 Kg x 10950 day

= 0,004084 mg/kg.day

The known benzene intake per day for the first

worker was 0.004084 mg/kg.day. As for the

calculation of the carcinogen intake using the

formula and value of the same variable, but using

the tavg for carcinogenic substances, the result was

25550 days. Here is the calculation of the

carcinogenic intake per day for the workers:

= 0,04 mg/m

3

x 0,6 m

3

/hours x 9 hours/day x 313 day x 34 year (1)

51.4 Kg x 25550 day

= 0,0018 mg/kg.day

The know benzene intake per day for the first

worker is 0,0018 mg/kg.day.

If ECR >10

-5

, then the concentration of

benzene exposure may cause a carcinogenic health

effect.

The risk characteristics for cancer effects can

be determined by multiplying the value of cancer-

causing substance intake with CSF values with the

following formula:

If ECR ≤10

-5

, then the concentration of

benzene exposure has not made the workers be at

risk of causing carcinogenic effects.

From the ECR calculation, it is known that the

ECR value for the current exposure is 5 years for the

30 workers with an ECR> 10

-5

. As many as 20

people (100%) are at risk of the health effects of

cancer.

After the risk assessment was done and got

results that are beyond the threshold value, the next

thing that was done was to conduct risk

management. This was done to minimise and even

eliminate the risk of danger posed by the hazard in

the workplace.

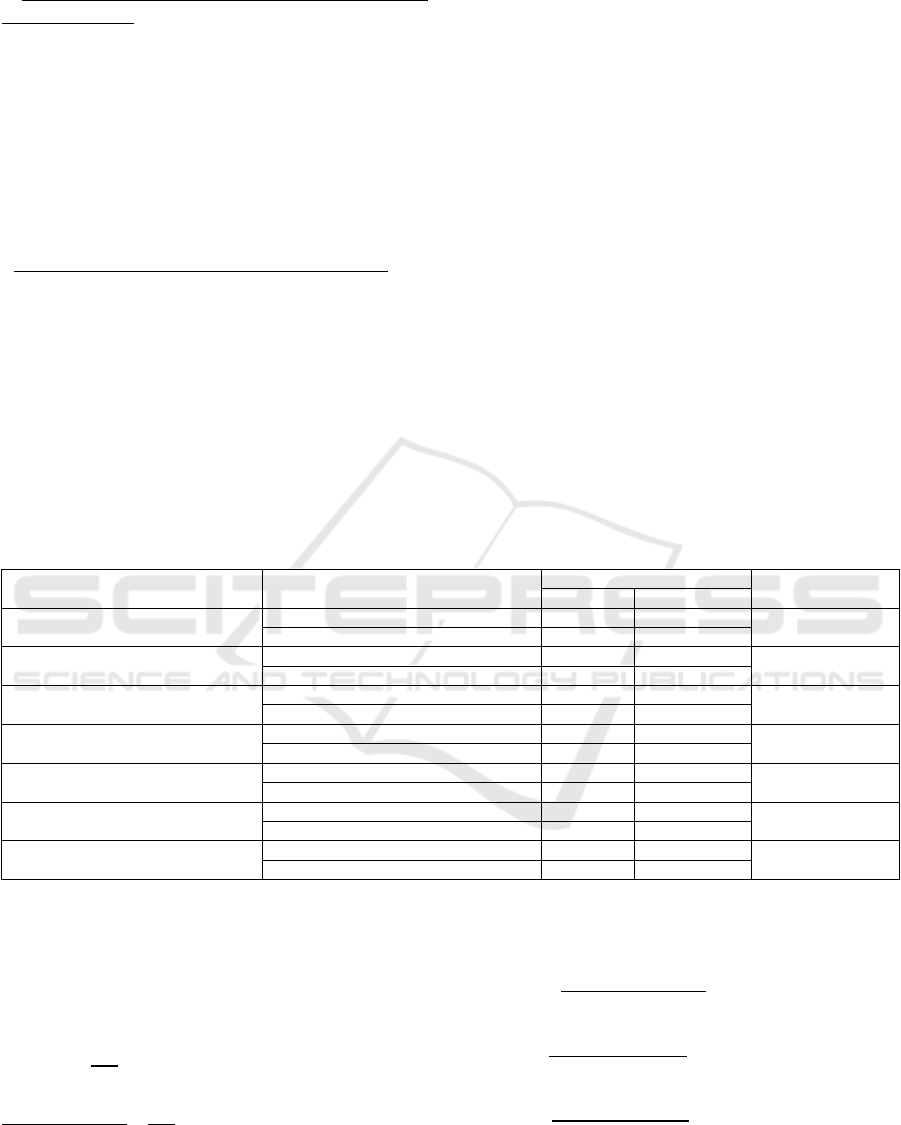

Table 3: Percentage of current Excess Cancer Risk (ECR) value, 5 th, 10 th, 15 th, 20 th, 25 th, and 30 th Shoemakers in

Tambak Oso Village Wilangun Surabaya 2016

.

Exposure ECR

Amoun

t

Total

N%

ECR

First

ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 5 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 10 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 15 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 20 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 25 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

ECR 30 th ECR ≤ 10

-5

00 20

ECR > 10

-5

20 100

In relation to carcinogens, the risk management

used is the value of ECR by applying the formula as

follows:

ECR = I

k

x CSF (3)

I

k

=

(4)

=

(5)

Based on the above calculation formula of

carcinogenic effect, it can be used to find the safe

value of C, t, and D safe as follows:

C safe =

(6)

tE safe =

(7)

Dt safe =

(8)

For the full calculation, the results can be seen

in the following table:

ECR=Intake Karsinogenik (I

k

) x CSF (2)

Insurance as Efforts to Control Risk Disease Caused by Benzene for Home Industry Shoes Workers

285

Table 4: The result of calculating the value of safe exposure of benzene carcinogenic health effect on benzene shoes worker

in Tambak Oso Village Wilangun Surabaya 2016

No. Worker

C

(mg/

m

3

)

C safe

(mg/

m

3

)

tE

(hours/day)

tE safe

(hours/day)

Dt

(year)

Dt safe

(year)

1 0,04 0.004 9 0.93 34 3.53

2 0,04 0.005 15 1.88 20 2.50

3 0,04 0.004 17 1.79 16 1.69

4 0.06 0.003 8 0.40 40 2.02

5 0.06 0.002 14 0.58 36 1.49

6 0.06 0.008 10 1.40 17 2.39

7 0.06 0.006 8 0.74 30 2.77

8 0.06 0.053 8 7.06 3 2.65

9 0,15 0.007 8 0.36 25 1.12

10 0,15 0.009 6 0.37 24 1.46

11 1,12 0.002 13 0.02 43 0.08

12 1,12 0.016 12 0.18 8 0.12

13 1,12 0.003 9 0.02 43 0.12

14 1,27 0.003 15 0.04 23 0.06

15 1,27 0.007 8 0.04 20 0.11

16 1,27 0.005 10 0.04 27 0.10

17 1,27 0.004 9 0.03 31 0.11

18 2,91 0.007 10 0.02 25 0.06

19 7,44 0.008 14 0.02 20 0.02

20 7,44 0.017 8 0.02 14 0.03

From the above data, the researchers took the

safe value by choosing the safe cancer risk from the

calculation data most likely applied by the workers

of shoe craftsman in Tambak Oso Village Wilangun,

Surabaya. Safe was 0,003 mg/m

3

, t

E

safe equals 7.06

hours/ day and Dt Safe is 3.53 years.

Table 5: Have Known about JKK (Jaminan Kecelakaan

Kerja)

ECR Have Known about JK

K

Amount

Respondens Yes No

> 10

-5

5 15 20

(

25,00%

)

(

75,00%

)

(

100,00%

)

≤ 10

-5

0 0 0

(0,00%) (0,00%) (0,00%)

In Table 5 above, the respondents who are ECR>

10

-5

or are not carcinogenically safe 75,0% do not

know about JKK and 25,0% 25,0% have known

about JKK.

Table 6: Have Known about JKM (Jaminan Kematian)

ECR Have Known about JKK

Amount

Respondens Yes No

> 10

-5

5 15 20

(25,00%) (75,00%) (100,00%)

≤ 10

-5

0 0 0

(

0,00%

)

(

0,00%

)

(

0,00%

)

In Table 8 above, for the respondents who are

ECR> 10

-5

or are not carcinogenically safe 75,0% do

not know about JKM and 25,0% 25,0% have known

about JKM.

Table 7: Workers Insurance (BPJS Employment)

ECR Have BPJS

Amount

Res

p

ondens Yes No

> 10

-5

0 20

20 (100,0%)

(0,00%) (100,00%)

≤ 10

-5

00 0

(0,00%) (0,00%) (0,00%)

In Table 7 above, for the respondents who are

ECR> 10

-5

or who are not carcinogenically safe,

100% have no insurance with BPJS Employment.

Table 8: Pos Upaya Kesehatan Kerja (Pos UKK) / Post

Work Healt Effort

ECR

Responden

Has Pos Upaya Kesehatan

Kerja (Pos UKK)

Amount

Yes No

> 10

-5

0 20 20

0,00% (100,00%) (100,00%)

≤ 10

-5

00 0

(

0,00%

)

(

0,00%

)

(

0,00%

)

INAHEA 2017 - 4th Annual Meeting of the Indonesian Health Economics Association

286

In Table 8 above, for the respondents who are

ECR> 10

-5

or are not 100% carcinogenic in the

home industry of shoes in Romokalisari Surabaya do

not have Pos Upaya Kesehatan Kerja (Pos UKK) or

Post Work Health Effort.

Table 9: Why not have BPJS Ketenagakerjaan?

Why not have

BPJS

ketena

g

ake

j

aan

Respondens

Amou

nt

Yes No

No information

5 75 20

(100,0

%)

(0,00%) (100,00%)

No socialitation

20 0 20

(100,0

%)

(100,00%) (0,00%)

No enough

money

20 0 20

(100,00%) (0,00%)

(0,00

%)

In Table 9, for the 20 respondents, 100,0% said

that they had never been given information about

BPJS but 100,0% also said that they had never been

socialited by BPJS and had no enough money.

4 DISCUSSION

The measurement of benzene concentration was

done at 8 sampling points at the location of

shoemaker workers. Kelurahan Tambak Oso

Wilangun in Surabaya showed the highest

concentration of 2,333 ppm equal to 7.44 mg/m

3

and

the lowest was 0,0129 ppm equal to 0,04 mg/m

3

.

The measured benzene concentration at each point

was different. The high-measured benzene

concentration is due to several things including the

production of the shows and the glue used which

also follows the amount of shoes produced.

The exposure time describes the number of hours

worked per day in the work environment. The results

of the study showed that the lowest worker worked

at work for 6 hours per day, and the highest work for

17 hours per day. The results of the study above

show that the threshold value of normal working

hours the standard as 7 hours of work a day or 6

days a week, or 8 hours of work a day or 5 days a

week. The highest working time is 17 hours a day

due to high orders and fast production deadlines so

that the workers strive to meet the target order.

The frequency of exposure indicates the time that

the workers spend working in the shoe-making

industry within the space of 1 year. The results

indicate that the workers spend the least time or 260

days/year and the highest 365 days/year.

The calculation of the risk level of individual

cancers at the current time is that for up to 30 years,

as many as 20 people (100%) have the results of the

ECR calculation of > 10

-5

. The results explain that at

the present time, exposure of up to 30 years are all at

risk of cancer health and are in unsafe conditions

against benzene exposure.

The concentration of benzene exposure towards

the shoemaker workers in Tambak Oso Wilangun of

Surabaya is influenced by the air condition at the

worker's location as well as the materials in the form

of shoe glue which is used in the shoe production

process. From the calculation of the value of health

risk, control of non-cancer effects and the effects of

cancer on safe exposure of benzene to sharecropper

workers in Kelurahan Tambak Oso Wilangun in

Surabaya 2016 obtained a safe value of (C) of 0,003

mg/ m

3

, safe snack time (tE) of 7,06 hours/day,

exposure frequency (fE) of 322 days/year and an

exposure duration (Dt) of 3.53 years.

Based on the research results, 100% of the

respondents have no insurance.This can not protect

workers from exposure to benzene-causing cancer

because the ECR is greater than 10

-5

which means a

high risk with major consequences. In the United

States, ECR 10

-5

is established as a carcinogenic

limit for workers. In Shingga, workers working in

industries with an ECR larger than 10

-5

should be

protected, among others, by having medical

insurance.

According to Presidential Regulation of the

Republic of Indonesia No. 12 2013 on Health

Insurance, health insurance is a guarantee of health

protection for the participants so they can benefit

from health care and have protection in meeting

their basic health needs. A participant is any person,

including foreigners, who work for a minimum

period of 6 (six) months in Indonesia, and who have

paid the contribution. From the observation, it is

known that 100% of the workers do not guaranteed

Health Insurance. The workers exposed to benzene

have a high risk of leukemia because there is no

protection against their health.

According to Kountur 2008, in Tualeka, A.R.

(2016), the high risk control is because the

consequences are carried out with the transfer of

risk, among others, by the insurance. Thus, there is

the need to control the risk of exposure to benzene

workers such as insurance with BPJS Employment.

In addition, in the area, there must also be Post

Work Health Efforts. With insurance, it will not

reduce the probability of the occurrence of the risk

Insurance as Efforts to Control Risk Disease Caused by Benzene for Home Industry Shoes Workers

287

but it will transfer the risk of the impact of benzene

exposure from the workers to the insurer. Thus, the

workers are not harmed by the losses borne by the

insurer. According to the Ministry Menpower

Regulation RI No.1 2006 about Insurance for

Manpower in the informal sector who must have

insurance.

More of the manpower in the informal sector

have no BPJS insurance because the company has

never done any solicitation in the home industry, and

they have no money. Information about BPJS for the

manpower in the informal sector is important to

increase the knowledge about BPJS and to change

the behaviour so then the workforce become

members of BPJS.

5 CONCLUSION

Workers in the insecure home shoe industry are not

encountering enough carcinogenic ingredients to

encounter the high consequences of cancer. 100% of

the shoe industry workers do not have insurance so

they do not get protection due to their exposure to

benzene, which is a cause of cancer.

The lowest benzene concentrations were present

at work site 1 of 0.04 mg/m

3

and the highest

concentration was found at work site 8 of 7.44 mg

/m

3

.

For the calculation of the cancer risk rate (ECR),

most workers have an ECR value > 10

-5

, meaning

that at the time of the study, there were workers in

unsafe conditions due to benzene exposure. The safe

limits for the workers are as follows: safe

concentration (C) 0.003 mg/m

3

, safe travel time (tE)

7.06 hours/day, exposure frequency (fE) 322

days/year and exposure duration (Dt) 3.53 years.

The workers have a high risk of cancer because

the benzene safe exposure time of only 7.06

hours/day and the duration of safe work is only 3.53

years.

REFERENCES

ATSDR., 2007. ToxGuide for Benzena.

(http://www.atsdr.cdc.gov/toxguides/index.asp).

Accessed 2016 March 27.

Chen,M., Chan, A., 1999. “China’s “Market Economics in

command” Footwear Workers Health in Jeopardy”,

International Journal of Health Services, Volume 29,

Number 4, Pages 793–811, 1999.

(http://footwearsinfolinethree.tripod.com). Accessed

2016 April 15.

George D, Clayton., Florence D, Clayton., 1994. Patty’s

Industrial Hygiene & Toxicology. 4th edisi vol. 11

Part B. A Willey_Interscience Publication. John

Willey And Sons Inc.

(http://www.kemenperin.go.id/artikel/9745/Kemenperi

n Terus Dorong Pengembangan Industri Alas Kaki

Nasional). Accessed 2016 April 14.

ILO., 2008 Menuju Tempat Kerja yang Lebih Produktif

dan Aman: Petunjuk Praktis untuk Tempat kerja

dengan Pekerja Usia 15-17 tahun, Jakarta.

ILO., 2004. Pekerja Anak Di Industri Sepatu Informal di

Jawa Barat (Sebuah Kajian Cepat), Jakarta.

Kementrian Perindustrian., 2017. Kementrian Dorong

Pengembangan Industri Alas Kaki Nasional.

(http://www.kemenperin.go.id/artikel/9745/Kemenperi

nterusDorongPengembanganIndustriAlasKakiNasiona

l). Accessed 2017 January 17.

Krogholm, KS., 2010. Free fruit at workplace invention

increases total fruit intake: a validation study using

24h dietary recall and urinary flavonoid excretion.

European Journal of Clinical Nutrition, 64: 1222-

1228.

Lu, F. C., 2006. Toksikologi Dasar. Asas, Organ Sasaran,

dan penilaian Risiko, Penerbit Universitas Indonesia,

page 371-376. Jakarta, 2

nd

edition.

Maryiantari, Ellyza S., 2016. Thesis. Risk Assessment

Pajanan Toluena Pada Pekerja Pengrajin Sepatu Di

Kelurahan tambak Oso Wilangun Surabaya Tahun

2016. Departmen Kesehatan Dan Keselamatan Kerja,

Fakultas Kesehatan Masyarakat, Surabaya.

National Occupational Health and Safety Commision.,

1990. Industrial Organic Solvents Australian

Government Publishing Service Canberra.

NRC., 1983. Risk Assessment in the federal government

health. February 1992, Volume 63, issue 6, pp 377-

381.

Perpres., 2013. Peraturan Presiden Republik Indonesia No.

12 Tahun 2013 Tentang Jaminan Kesehatan.

Permenaker, 2004. Peraturan Menteri Tenaga Kerja Dan

Transmigrasi RI No. Kep 102/MEN/2004 Tentang

Waktu Kerja Lembur Dan Upah Kerja Lembur.

Permenaker, 2011. Perturan Menteri tenaga Kerja Dan

Transmigrasi Republik Indonesia Nomor

PER.13/MEN/X/2011 Tentang Nilai Ambang Batas

Faktor Fisika dan Faktor Kimia di Tempat Kerja.

2011.

(http://webcache.googleusercontent.com/search?q=cac

he:mf5eV-

HihLEJ:www.djpp.kemenkumham.go.id/arsip/bn/201

1/bn684-2011.pdf+&cd=2&hl=en&ct=clnk&gl=id).

Accessed 2017 March 27.

SNI., 2005. Nilai Ambang Batas (NAB) Zat Kimia di

Udara Tempat Kerja. 2005.

(http://webcache.googleusercontent.com/search?q=cac

he:DJzRvmd3u3gJ:web.ipb.ac.id/~tml_atsp/test/SNI%

252019-0232-

2005.pdf+&cd=1&hl=en&ct=clnk&gl=id). Accessed

2016 March 27.

Sugiharto, Eram T.P., 2009. Hubungan antara Perilaku

Penggunaan Insektisida Dalam Pengendalian Hama

INAHEA 2017 - 4th Annual Meeting of the Indonesian Health Economics Association

288

Ulat Bawang (Spodoptera Exigua Hbn) Dengan

Tingkat Keracunan Petani Penyemprot Bawang Merah

Di Desa Bangsal Rejo, Kec. Wedari Jaksa, Kab. Pati.

Jurnal Kemas, 4 (2): 132-139.

Susilowati, B., 2011. Skripsi. Risiko Kesehatan Terhadap

Panajan Benzena Pada Pekerja Industri Sepatu Kulit

Di PIK Pulogadung Tahun 2011. Departmen

Kesehatan Lingkungan Fakultas Kesehatan

Masyarakat. Depok

Tualeka, A.R., 2015. Analisis Risiko, CV. Bumi Lestari,

Surabaya.

Insurance as Efforts to Control Risk Disease Caused by Benzene for Home Industry Shoes Workers

289