Simulation of Polymer Exchange Membrane Fuel Cell Utilizing

Empty Fruit Bunch Pyrolysis using Aspen Plus

Taufiq Bin Nur

1,2

, Zulkarnaen Pane

3

, Rulianda Purnomo Wibowo

4

and Nurhayati

5

1

Department of Mechanical Engineering, Faculty of Engineering, Universitas Sumatera Utara, Padang Bulan, Medan

20155, Indonesia

2

Sustainable Energy and Biomaterial Center of Excellence, Universitas Sumatera Utara, Padang Bulan, Medan 20155,

Indonesia

3

Department of Electrical Engineering, Faculty of Engineering, Universitas Sumatera Utara, Padang Bulan, Medan 20155,

Indonesia.

4

Department of Agribusiness, Faculty of Agriculture, Universitas Sumatera Utara, Padang Bulan, Medan 20155,

Indonesia

5

Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara, Padang Bulan, Medan 20155,

Indonesia.

Keywords: Polymer Exchange Membrane Fuel Cell, Empty Fruit Bunch, Pyrolysis, Aspen Plus, Biomass

Abstract: Indonesia has a large potential of biomass energy which can be used to increase electrification ratio of the

country. One the most important biomass resources to be considered as a promising option for fossil fuel

substitution and greenhouse effect reduction in the country is waste from palm oil mill plant (POM). This

study analysed the possible layout and performance of an integrated biomass pyrolysis with a polymer

electrolyte membrane fuel cell (PEMFC) as an alternative for energy system. The PEMFC is considered to be

one of a promising conversion technology for clean and efficient power generation in the current situation.

The biomass from empty fruit bunch (EFB) sent to pyrolysis unit to produce syngas which can be used as fuel

for PEMFC. A Purification processes consisting of a water gas shift reactor and a selective oxidation reactor

is necessary in order to reduce the impurity that can harmful fuel cell. It was found that, the PEMFC can

generate electricity around 512.5 kW (AC) at 0.22 A.cm

-2

with the system efficiency of 55.26% (HHV).

1 INTRODUCTION

Fuel cell is a device that converts chemical energy

into electrical energy with high efficiency through

electrochemical reaction (Guan, 2008). Fuel cell

systems have different variables such as type of the

electrolyte used in fuel cell, type of the reactants (e.g.

primary fuels and oxidants), operating temperature

and pressure, type of the exchanged ion through the

electrolyte, direct and indirect usage of the primary

fuels in fuel cell system. Based on the electrolyte

used, fuel cells can be classified into: (1) alkaline fuel

cells (AFC), (2) phosphoric acid fuel cells (PAFC),

(3) polymer electrolyte membrane fuel cell (PEMFC),

(4) molten carbonate fuel cells (MCFC), (5) solid

oxide fuel cells (SOFC) (Peighambardoust, 2010).

The polymer electrolyte membrane fuel cell

(PEMFC), with electrolyte is a solid polymer in

which protons are mobile, has received growing

attention as an efficient power generation unit due to

its low emissions, potentially high energy density,

compactness, modularity, light weight, fast start-up

and fast response to load changes (Chutichai, 2013;

Jo, 2017). The ideal fuel for PEMFC is hydrogen

which does not exist in nature and need to be

produced from other sources, such as natural gas,

water, and biomass. Due to the low temperature, the

PEMFC operates only with hydrogen of high purity,

and the concentration of carbon monoxide in the

gaseous flux should not exceed 10 ppm (Authayanun,

2013).

Biomass possesses a potential source for

renewable hydrogen production, and likely will give

the fuel cell a sustainable future. Biomass may be

divided into two groups according to its physical

characteristics: (1) liquid biomass mainly from

manure, agriculture and sludge from municipal

wastes and (2) solid biomass mainly as forest residues

Nur, T., Pane, Z., Wibowo, R. and Nurhayati, .

Simulation of Polymer Exchange Membrane Fuel Cell Utilizing Empty Fruit Bunch Pyrolysis using Aspen Plus.

DOI: 10.5220/0010079102370242

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

237-242

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

237

from the forest industry (Guan, 2015). Pyrolysis is

one of the most promising technologies of biomass

utilization, and it is also the first stage of biomass

thermochemical conversion, which converts biomass

resource to solid char, liquid oil, and hydrogen-rich

gas (Yang, 2006).

Palm oil has been one of the success stories of the

North Sumatera Province of Indonesian agricultural

sector. Following the palm oil extraction procedure,

palm oil wastes are obtained as empty fruit bunch

(EFB), palm kernel shell (PKS) and palm fibre.

Approximately 1 ton of EFB, 0.3 ton of PKS, and 0.7

ton of palm fibre are produced as palm oil mill (POM)

wastes from each ton of oil production (Nizamuddin,

2016). Annual production of palm oil in Indonesia

during 2016 reached 31.40 million tons which can be

used as renewable energy sources to generate

electricity (BPS, 2017). This paper presents the

thermodynamic analysis of PEMFC fuelled by syngas

from empty fruit bunch (EFB) pyrolysis to generate

electricity by using Aspen Plus simulation.

2 SYSTEM DESCRIPTION AND

MODELLING SIMULATION

The system configuration used in this analysis

consists of pyrolysis unit, fuel reforming unit, and

PEMFC unit. The process flow diagram (PFD) of

biomass pyrolysis unit is shown in Figure 1. The

biomass combustion will be simulated at near

atmospheric condition. The Aspen Plus block units

used to simulate biomass pyrolysis process are

RYield, RGibbs, and SSplit (Nur, 2018). The biomass

(1BIOMASS) was sent to RYield, labeled with

DECOMP, to predict the decomposition of the

biomass into the reference components such as C, H

2

,

S, O

2

, N

2

, etc. The RGibbs, labelled with PYROLYS,

used as pyrolysis reactor with the nitrogen as inert

gas.

Figure 1: The process flow diagram of biomass pyrolysis

unit.

The raw-syngas (stream 5) produced by pyrolysis

unit will go to the fuel reforming unit which

comprises syngas blower (named with BLOWE3) to

increase the pressure of raw-syngas, methane steam

reforming with water gas shift reactor

(REFORMER), heat exchanger (HEX-02), water

pump (WATER-P), and a selective oxidation reactor

(SELOX). Since the raw-syngas contains high CO

fraction, which will poison the PEMFC catalysts and

then degrade the PEMFC performance. Therefore, the

system equipped with a CO removal processes as

shown in Figure 2. The CH

4

is converted to H

2

, CO

and CO

2

, and the ratio of steam to carbon (S/C) is

3.4:1. The steam obtained by utilizing the heat energy

contained in the system during the process takes place

that is by using heat exchanger during the process of

reducing the syngas temperature to the working

temperature of PEMFC. The steam methane reaction

process in the reformer reactor is followed by a CO

removal process. There are two sub-steps included in

the CO removal process, e.g., water shift reactor, and

a selective oxidation reactor (SELOX). The involved

reactions for the production of hydrogen and CO

removal are shown in table 1. remember that all the

papers must be in English and without orthographic

errors.

Figure 2: The process flow diagram of fuel reforming unit.

Table 1: Reactions involved in the hydrogen production

process and CO removal (Guan, 2015).

Steam reforming:

CH

4

+ H

2

O CO + 3H

2

∆𝐻

= 206 kJ mol

-1

CO water shift:

CO + H

2

O CO

2

+ H

2

∆𝐻

= -41 kJ mol

-1

SELOX:

2CO + O

2

2CO

2

∆𝐻

= -283 kJ mol

-1

Electrochemical:

𝐻

1/2𝑂

→𝐻

𝑂

DECOMP

PYROLYS

SLAG-REM

CALCULATO R

COMBUST

1BIOMASS

3

2

SLAG

HEATCOMB

Q-COMB

Q

4

INER T G AS

COMBUST

COMBUST

5

SYNBLO

W-SYNBLO

W

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

238

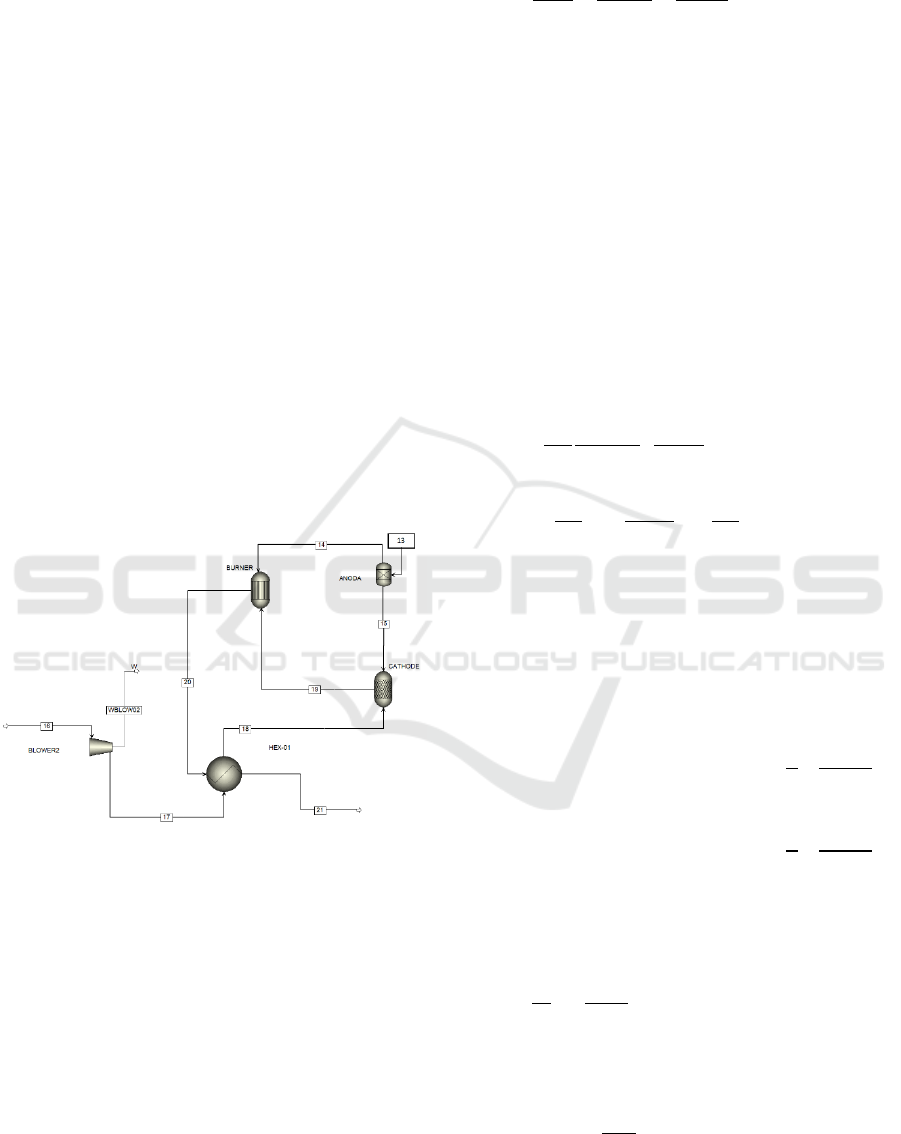

Syngas that are free from contaminants (stream

13) are fed into PEMFC, undergoing electrochemical

reactions while producing electrical energy and

thermal energy. Syngas out of the PMFC unit goes to

the burner sub unit where the remaining gases will be

burned completely. The Aspen Plus flowsheet of the

PEMFC unit is illustrated in Figure 3. The model is

based on the following assumptions: steady state

operation, pressure drops are neglected; chemical

reactions such as reforming and shift reactions reach

chemical equilibrium; the mobile ion cross over

through the electrolyte cannot modelled within Aspen

Plus, therefore the overall oxidation of H

2

was

considered instead of the cell half reaction.

3 METHODOLOGY

3.1 PEMFC Stack

The output voltage of a single cell (V

cell

) can be

obtained by considering the ohmic, activation, and

concentration losses from the thermodynamic

equilibrium potential, V

Nernst

, as follow (Jo, 2017):

Figure 3: The process flow diagram of PEMFC unit.

𝑉

𝑉

𝑉

𝑉

𝑉

(1)

where V

ohm

, V

act

, and V

con

represent the ohmic,

activation, and concentration polarization,

respectively. The Nernst Potential, V

Nernst

, is given by

(Jo, 2017):

𝑉

𝑖

𝑅

𝑅

(3)

where the area specific resistance due to the proton

transport, R_(H^+ )was obtained by considering the

membrane and catalyst layer properties below (Jo,

2017):

𝑅

.

.

.

.

(4)

The 𝑣

and 𝑣

represent the volume fractions

of the electrolyte in the anode and cathode catalyst

layers, respectively. The number 0.5 appearing in the

numerator of Eq. (4) is due to the assumption that the

average proton transport path through the catalyst

layer is half of its thickness.

The activation polarization is the voltage over

potential required to overcome the activation energy

of the electrochemical reaction on the catalytic

surface. This type of losses dominates at low current

density. The activation polarization, 𝑉

, is

calculated using the Butler-Volmer equations for

hydrogen oxidation reaction in the anode (𝑉

,

) and

oxygen reduction reaction in the cathode (𝑉

,

), as

follows (Jo, 2017):

𝑉

,

,

,

/

(5)

𝑉

,

𝑙𝑛

,

/

.

(6)

where 𝐶

and 𝛼 represent the molar concentration and

transfer coefficient, respectively. The exchange

current density of hydrogen oxidation reaction, 𝑖

,

,

and exchange current density of oxygen reduction

reaction, 𝑖

.

, can be calculated by (Jo, 2017; Jiao,

2010):

𝑖

,

𝑇

𝑖

,

353.15 𝐾

.exp1400

1

𝑇

1

353.15

(7)

𝑖

,

𝑇

𝑖

,

353.15 𝐾

.exp7900

1

𝑇

1

353.15

(8)

The concentration polarization, 𝑉

, can be

calculated by following by (Jo, 2017; Jiao, 2010):

𝑉

𝑙𝑛

(9)

where the limiting current density, 𝑖

, determined

by:

𝑖

𝑣

.

𝐷

(10)

Simulation of Polymer Exchange Membrane Fuel Cell Utilizing Empty Fruit Bunch Pyrolysis using Aspen Plus

239

After calculating the voltage losses, the fuel cell

power output is the product of the cell voltage and the

current. The total current (I) and the direct current

(DC) output power of each cell can be calculated as

follows (Taufiq, 2015; Zhang, 2005):

𝐼

,

,

.

(11)

W

𝑉

𝑥 𝐼

(12)

The alternating current (AC) power of the cell

module can be specified using (Taufiq, 2015; Zhang,

2005):

W

W

𝑥 𝜂

(13)

where 𝜂

is the inversion efficiency of direct to

alternating current.

The performance of this system is defined by its

ability to convert the chemical energy contained in

biomass into electrical. The electrical efficiency of

the system is defined as follow (Chutichai, 2013):

𝜂

𝑁𝑒𝑡 𝑝𝑜𝑤𝑒𝑟𝑒𝑑 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑒𝑑 𝑘𝑊 𝑚

𝑥 𝐻𝐻𝑉

⁄

(14)

3.2 Input Data

EFB were selected as the main fuel in this study

because of its abundant availability in Indonesia,

especially the province of North Sumatera. The feed

composition of the EFB is specified as described in

table 2, while the main assumptions for analysis are

shown in table 3.

Table 2: Composition of EFB (Wijono, 2014).

Proximate analysis (wt.%)

Fixed carbon 9.94

Volatile matter 42.20

Moisture content 44.60

Ash content 3.26

Ultimate analysis (wt.%)

Ash content 3.26

Carbon 26.94

Hydrogen 3.22

Sulphur 0.05

Nitrogen 0.35

Oxygen 21.58

Heating values (MJ/kg)

Higher heating value (HHV) 10.29

Table 3: Main operational conditions and

assumptions for plant calculation.

EFB feed pyrolysis reactor (kg hr

-1

) 250

Nitrogen feed pyrolysis reactor (kg

hr

-1

)

25

Pyrolysis working temperature (C) 650

Pyrolysis working pressure (bar) 1.013

Environment temperature (C) 25

PEMFC operating temperature (C) 120

Anode/Cathode inlet pressure (bar) 1.20

Thickness of anode/cathode GDLs,

CLs, 𝛿

, 𝛿

(mm) (Jo, 2017)

0.35;

0.015

Thickness of anode/cathode

membrane, 𝛿

(mm) (Jo, 2017)

0.07

Reference H

2

/O

2

molar

concentration, 𝐶

,

/𝐶

,

(mol/m

3

) (Jo, 2017)

40.88

Anode/cathode transfer coefficient

(Jo, 2017)

0.5; 0.65

Reference exchange current density

in anode/cathode, 𝑖

,

, 𝑖

,

(A/m

2

)

(Jo, 2017)

1.0 x 10

9

;

1.0 x 10

4

Porosity of GDL, CL (Jo, 2017) 0.6; 0.4

Volume fraction of ionomers in CL

(Jo, 2017)

0.3

Electronic conductivity in CL (S m

-

1

) (Jo, 2017)

300

DC to AC inverter efficiency (%) 95

Electric generator efficiency (%) 98.7

Miscellaneous BOP, % input HHV 13.3

4 RESULTS AND DISCUSSION

The main raw synthesis gas mass and composition

leaving the pyrolysis unit (stream 4) are 264.20

kg.hr

-1

and 13.74% H

2

O, 42.92% H

2

, 6.68% N

2

,

0.04% S, 19.61% CO, 12.88% CO

2

, 4.13% CH

4

,

respectively. This raw synthesis gas from the

pyrolysis process is treated to reduce the quantity of

CO it contains to an acceptable level for PEMFC

operation. The main raw syngas composition leaving

the reformer and CO removing are 21.8% H

2

O, 1.4

O

2

, 31.8% H

2

, 24.8% N

2

, 0.0143% S, 19.7% CO

2

,

0.4394% CH

4

. Then, this clean syngas goes to the

PEMFC unit.

The performance of the PEMFC is evaluated

using a polarization curve showing the relationship

between current density, cell potential and power

density. The cell potential decreases with increasing

current density due to large voltage losses are

observed at higher current density as shown in figure

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

240

4. It can be seen that the activation polarization is

much higher than the other polarizations.

The maximum power density that PEMFC unit

can generate in this study is around 0.829 W.cm

-2

at

current density of 1.42 A.cm

-2

as shown in figure 5.

With the total current is 502,932.72 A, the PEMFC

unit can produce power of 512.5 kW (AC) at 0.22

A.cm

-2

.

Based on the analysis, it was observed also the

requirement of power during processes within the

system and system electrical efficiency. Those

internal power consumed are listed in table 4. The

system electrical efficiency when PEMFC generate

power of 512.5 kW (AC) at 0.22 A.cm

-2

is 55.26%

(HHV).

Figure 4: PEMFC voltage characteristics versus current

density.

Figure 5: Effect of current density of voltage and power

density.

Table 4. Energy consumption during processes

Energy consumed by blower to supply

air for SELOX reactor (BLOWER3)

1.72 kW

Energy consumed by syngas blower

(

SYNBLO

)

7.04 kW

Energy consumed by air blower for

cathode section (BLOWER2)

12.33 kW

Energy consumed by water pump

(WATER-P)

0.0035 kW

Miscellaneous BOP 96.47 kW

5 CONCLUSIONS

In this study, the system consists of a biomass

pyrolysis to produce syngas as fuel and PEMFC to

generate electricity was analysed by using Aspen Plus

simulation. It was found that EFB is a potential fuel

for PEMFC unit. When this biomass pyrolysis unit

operated at 650 C and atmospheric pressure, it can

produce raw syngas which composition of H

2

is

42.92%. Based on the analysis, the PEMFC can

generate electricity around 512.5 kW (AC) at 0.22

A.cm

-2

while the system efficiency can reach up to

55.26% (HHV). More details calculation doing

modelling simulation and experimental are needed to

improve this analysis.

ACKNOWLEDGEMENTS

This work has been fully supported by Directorate of

Research and Community Service, Directorate

General Strengthening Research and Development

Ministry of Research, Technology and Higher

Education Republic of Indonesia, in accordance with

the funding agreement and community service for

fiscal year 2018.

REFERENCES

Authayanun S, Mamlouk M, Scott K, Arpornwichanop A

2013 Applied Energy 109 pp 192-201

BPS Statistics Indonesia 2017 Indonesian Oil Palm

Statistics 2016

Chutichai B, Authayanun S, Assabumrungrat S,

Arpornwichanop A 2013 Energy 55 pp 98-106

Guan T, Alvfors P 2015 Energy Procedia 75 pp 2003-2008

Guan T, Chutichai B, Alvfors P, Arpornwichanop A 2015

Energy Conversion and Management 106 pp 1183-

1191

Jiao K, Li X 2010 Fuel Cells 10 pp 351-362

0,00

0,20

0,40

0,60

0,80

1,00

1,20

0,00 0,20 0,40 0,60 0,80 1,00 1,20 1,40 1,60 1,80

CellVoltage(V)

CurrentDensity(A/cm

2

)

OhmicPolarization

ActivationPolarization

ConcentrationPolarization

CellVoltage

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

1,00

1,10

1,20

1,30

0,0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8

PowerDensity(Watt/cm

2

)

CellVoltage(Volt)

CurrentDensity(A/cm

2

)

Simulation of Polymer Exchange Membrane Fuel Cell Utilizing Empty Fruit Bunch Pyrolysis using Aspen Plus

241

Jo A, Oh K, Lee J, Han D, Kim D, Kim J, Kim B, Kim J,

Park D, Kim M, Sohn Y J, Kim D, Kim H, Ju 2017

International Journal of Hydrogen Energy 42 pp 1698-

1714

Nizamuddin S, Shrestha S, Athar S, Ali B S, Siddiqui M A

2016 Rev Chem Eng 32 pp 489-505

Nur T B, Syahputra A W 2018 IOP Conf. Series: Materials

Science and Engineering 308

Peighambardoust S J, Rowshanzamir S, Amjadi M 2010

International Journal of Hydrogen Energy 35 pp 9349-

9384

Taufiq B N, Kikuchi Y, Ishimoto T, Honda K, Koyama

2015 Applied Energy 147 pp 486-499

Wijono A 2014 Proceeding Simposium Nasional RAPI

XIII-2014 FT UMS (Indonesian Version).

Yang H, Yan R, Chen H, Lee D H, Liang D T, Zheng C

2006 Energy & Fuels 20 pp 1321-1328

Zhang W, Croiset E, Douglas P L, Fowler M W, Entchev E

2005 Energy Conv Manag 46 pp181–96

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

242