Infrared Microscopic Imaging Analysis

Anselmo Jara, Guillermo Machuca, Sergio Torres and Pablo Gutiérrez

Departamento de Ingeniería Eléctrica, Universidad de Concepción, Casilla 160-C, Concepción, Chile

Keywords: Image Formation, Acquisition Devices and Sensors, Image Enhancement and Restoration.

Abstract: In this paper, we present imaging processing advances and applications of mid-wavelength infrared

(MWIR) microscopy imaging. Practical issues related to imaging acquisition, image nonuniformity

correction, infrared image quality assessment, and even the MWIR microscope optical Point Spread

Function experimental estimation are discussed. The built-up MWIR microscope imaging system allows us

to analyse thermal features near to the system diffraction limit, up to 200 frames per second and to focus on

less than 2 mm

2

area. On basis of this technology, our group has been focused efforts in exothermal

biological processes, achieving the results exposed in this paper.

1 INTRODUCTION

Infrared (IR) imaging systems enable users to

determine the thermal spatial distribution of a target

object in a non-invasive manner, and furthermore,

without requiring any physical contact between the

target and the imaging system. IR imaging sensors

are based on the Infrared Focal Plane Array (IRFPA)

technology that consists of a mosaic of independent

photo-detectors placed at the focal plane of an

imaging system (D. A. Scribner et al., 1991).

Every image acquisition system can be

considered as a cascade formed set-up, which is

mainly composed by a physic interface and an

electronic interface. The physic interface is used to

focus the irradiance on the IRFPA, even more, in

such unit, the image is magnified by an array of

lenses. The electronic interface collects the

irradiance by means of an IRFPA located exactly in

the Focal Plane, to filter and digitalize the electric

data as a raw image output data.

Nevertheless, the detectors in the array has

unequal responses under a homogeneous stimulus,

which leads to the presence of a Fixed Pattern Noise

(FPN) noise, well known as Non-uniformity (NU)

noise, on the resulting images. Furthermore the lens

aberrations effect causes a spatial degradation

namely blurring (V. N.Mahajan., 1998). Thus, NU

noise and blurring degrade image quality and lead to

major difficulties in MWIR microscopic imaging

analysis for all kinds of applications.

In the literature, scene-based techniques perform

the NU correction (NUC), using only the video

sequences that are being imaged, not requiring any

kind of laboratory calibration technique (P. M.

Narendra., 1980, S. N. Torres and M. M. Hayat,

2003, E. Vera et al., 2011). However in blurring

correction, the problem needs to characterize the

optical array in order to inversely solve the image

degradation. Several deconvolutive methods have

been developed to allow the best image restoration

(N. Wiener, 1949, W. H. Richardson, 1972, L B.

Lucy, 1974).

Our research group is currently working: in

MWIR microscopic imaging applications (mainly to

exothermal biological processes). Particularly, on

MWIR video signal analysis (NUC and de-blurred

algorithms and IR imaging performance metrics),

and on MWIR microscopic parameters (Diffraction

Limit, Instantaneous Field Of View, point spread

function (PSF)). Here we present, some of our most

recently results.

This paper is structured as follows. In Section 2,

we describe the microscopy instrumentation and IR

microscopy imaging features are exposed. In Section

3 an experimental PSF estimation method from the

IR microscope system is sumarized. In Section 4, we

tested an algorithm to correct simultaneously the NU

noise and blurring artifacts. To evaluate the

technique performance, a novel metric is computed

in Section 5. Finally, in Section 6 we present the

conclusions and future research.

Jara, A., Machuca, G., Torres, S. and Gutiérrez, P.

Infrared Microscopic Imaging Analysis.

DOI: 10.5220/0006716702130218

In Proceedings of the 13th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2018) - Volume 4: VISAPP, pages

213-218

ISBN: 978-989-758-290-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

213

2 IR MICROSCOPY

PARAMETERS AND IMAGING

SYSTEM FEATURES

2.1 IR Microscopy Parameters

The built-in IR microscope unit is composed of a

MWIR camera (Sofradir model EC-IRE 320M)

shown in Figure 1, with a HgCdTe FPA transducer

that has a spectral response between 3.7 and 4.8

micrometers. The FPA is composed by an array of

320x256 IR detectors, with a 14-bit analog/digital

converter with a noise-equivalent temperature

difference (NETD) of 10 mK. The FPA can operate

up to 320 frames per second. The optical system (IR

objective) is integrated by an array of lenses from

Janos Technology, allowing a 4X magnification.

Figure 1: Mid-wave infrared microscope system utilized to

acquire microscopic thermal maps.

2.2 System Characterization

The first work was to find the optical system IFoV.

For this, images of the USAF Target, were acquired,

as shown in Figure 2. The 6th element of 1 group

bars was chosen. The length of the bars is known, so

that IFoV can be found by dividing the length of

said bar by the number of pixels that occupy this

object in the image. The second method described in

this work is about how to find the diffraction limit.

For this purpose, the USAF Target was also used

using the Rayleigh criterion (Hecht. 2002) to find

the smallest element that can be solved by the

Microscope. According to our experiments, such a

microscope permits to integrate IR exothermal

process with images contained in a 1.99x1.49 mm

scene area, with an approximate diffraction limit of

12, 4[µm].

Finally, next performed work corresponds to the

determination of a radiometric response curve

(temperature). For this, several procedures were

employed, giving the best result, the method in

which the microscope was located directly in front

of the black body. Video sequences of 10 frames

from the black body were taken at different

temperatures, from 0 to 100 [

o

C] with intervals of 5

[

o

C] at a controlled ambient temperature of 17 [

o

C].

The results are shown in the Figure 3.

Figure 2: USAF 1951 Target used for the diffraction limit

determination. 6th group and 1st element are indicated,

last to be solved.

Figure 3: Radiometric response curve using different

methods.

3 POINT SPREAD FUNCTION

In this work the applied mathematical foundation for

the MWIR microscope PSF estimation, is based on

the experimental method proposed in (K.

Rossmann., 1969). Where it is assumed that the

optical system PSF is isotropic and separable, so it

can be computed from the combination of the

estimated line PSFs in the x and y axes separately,

and

, respectively. Each line PSF can be

estimated as the derivative of a sharp transition step

function in the desired direction of the scene as

follow

VISAPP 2018 - International Conference on Computer Vision Theory and Applications

214

(1)

where is the intensity value of the scene

background and

,

are the step’s derivative

with respect to and direction respectively. These

results are obtained by also assuming that the

acquisition setup is a linear and shift-invariant

system.

Figure 4: Images of the heat target to produce the desired

step functions in the x and y direction.

Finally, and assuming that the PSF varies

smoothly in all the other directions, the IR

microscope

is completed by a 2D Gaussian fit

using both components, and enforcing the values of

to

.

To produce the needed spatial thermal step, a

metal target was cooled down to 5°C and the

blackbody radiator source, located at a distance of

20 cm from the microscope optical system, was

adjusted to emit at 90 °C. Then, the metal target was

positioned at the microscope focal length (2.5 cm) in

vertical and horizontal arrangements. Perpendicular

linear vectors were extracted from both the x axis

(columns) direction and y axis (rows) directions, as

depicted in the Figure 4. The estimated PSF can be

seen in Figure 5.

Figure 5: Experimental estimated Point Spread Function,

1.6 standard deviation estimated. a) 2-D image

representation. b) 3-D graph representation.

Figure 6 depicts the target images to be used to

test the PSF in the de-blurred process. The PSF

estimation was applied to a simulated target, for the

blur correction using a blind method and non-blind

deconvolution. The blind deconvolution method

Deconvblind uses an ones-matrix to operate in

recursive iterations, estimating a progressive

deconvoluted image, regardless the use of the

infrared microscope PSF.

Figure 6: Deconvolution methods no-PSF and using the

PSF estimation. (a) Target used for measure the focus

level. (b) Blurred target. (c) Target using deconvolution

method with use of PSF. And (d) is the target using blind

deconvolution method (without uses of PSF).

Figure 7 shows a row-by-row improvement in the

RMSE value for the corrected image with the

convolution method, using the estimated PSF, in

comparison to deconvolution method that do not use

the estimated PSF.

Figure 7: RMSE curves, along the image rows. RMSE for

the blurred target (blue), RMSE for the deconvolution

with PSF target (black), and RMSE for the deconvolution

with PSF target (red).

4 IMAGE DEGRADATION

FEATURES ON INFRARED

MICROSCOPY

Considering the image acquisition as a cascade

Infrared Microscopic Imaging Analysis

215

model, where the latent image is degraded, mainly

by two stages: The optic stage and the digitalization

circuitry. This is, after both steps a MWIR

microscopic image suffer a Signal to Noise Ratio

(SNR) lower than one, which is mainly produce by

two major artefacts blur and NU.

In order to jointly diminish the optical blurring

and NU noise on IR microscopic images, we tested

here a Joint NU/blur Correction (JNBC) method (A.

Jara et al.).

(2)

Where

is a NU-noise-free image, but still

degraded by the distortion of the aggregated PSF,

is the noisy and blurred imagery,

and

are the global mean and standard deviation,

respectively, of the input irradiance, which are

known due to the assumption that X follows a

Uniform distribution. The quantities

and

are the mean and standard deviation,

respectively, computed with the digital numbers

measured from the (i,j)-th detector within the array

and using the information available up to the n-th

video frame. Normally the mean and standard

deviation of the noisy image Y is estimated

recursively, which is the approach we adopt here.

(3)

where

is the discrete Fourier

Transform (DFT) of the estimated PSF and

is

the flipped PSF. As in the numerical implementation

of the Richardson Lucy algorithm we enforce the

denominator in Eq. (3) to have values different from

zero. Now, we simply apply inverse filtering over

to estimate, namely

(4)

In Figure 8 can be appreciated a raw MWIR

microscopic image highly corrupted by both NU

noise and blur. The JNBC method is able to

simultaneously compensate for both as shown in

Figure 8(b). Significant improvement, in spite of the

severity of the NU noise and blur, can be observed

with only a naked-eyes evaluation. Moreover, note

that as expected, the dead and saturated pixels

shown in Figure 8(a) are compensated in the scene

by the JNBC method.

Figure 8: Estimated images using IR Microscopy samples

affected by both real NU noise and blur. (a) Raw frame

and (b) corrected frame using proposed method. The

improved quality of the corrected image can be easily

noted at naked eye.

5 INFRARED IMAGE QUALITY

ASSESSMENT

We, also here like to test a metric with ability of

evaluate jointly blur and NU noise for IR imaging

systems. This metric works in the spatial domain

applying discrete filtering in order to quantify the

edges amount from distinct frequency basis (A. Jara

et al.).

The Roughness Laplacian Pattern (RLP) metric

quantifies simultaneously the roughness (NU noise)

and the spatial blur on an IR image. It works by

combining two measures: the Laplacian (

2

) of the

image, in order to quantify the NU noise, and the

norm of the discrete Laplacian of a Gaussian (LoG)

of the image, in order to quantify image edges and

details (i.e., measuring the sharpness of the

sequence).

(5)

where parameter can be used to tune the RLP to

evaluate IR images with low blurring distortion, e.g.,

macroscopic IR images ( closer to one), or IR

images with high blurring distortion, e.g.,

microscopic IR images ( closer zero). The RLP

approaches to zero as the NU noise and/or the image

blur is reduced.

The RLP metric was evaluated using images

with different degradation caused by NU noise and

blur, which are shown in the Figures 9 and 11. In

Figure 9, each of the simulate images has a fixed

level of NU and increases the level of blur, being

Figure 9(a) and 9(d) degraded with minor and

greater blur, respectively. As can observed in some

the structures, e.g. the clock, the edges are not

clearly distinguished due to degradation. A different

case is perceived in Figure 11, where each simulated

images has a fixed level of blur and increases the

level of NU noise, this degradation effect can be

VISAPP 2018 - International Conference on Computer Vision Theory and Applications

216

better observed when comparing Figure 11 (a) and

Figure 11 (d).

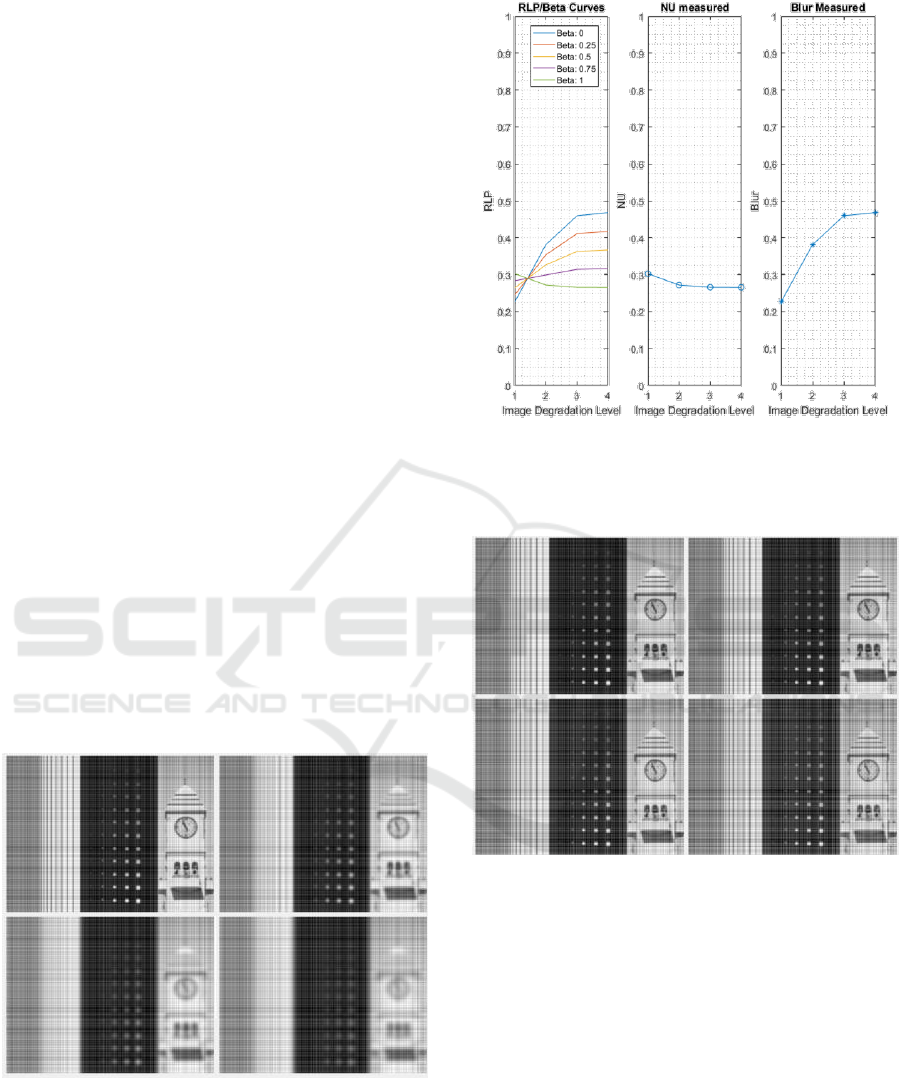

Figure 10 shows the results obtained using RLP

on the images with fixed NU noise and variable blur.

On the left, RLP curves are observed with different

sensitivity parameters allowing a change in the value

obtained by the metric on the degraded images. In

the middle and on the right, the high frequency and

low frequency components (NU noise and blur),

respectively, are quantified for each image simulated

using the terms that compose the proposed metric

independently. When we focus on the NU noise, we

observe an almost constant trend in the values

obtained, which is precisely the effect that we

wanted to achieve. On the other hand, the blurring

curves increases its values allowing seeing the effect

of degradation of blurring on the simulated images.

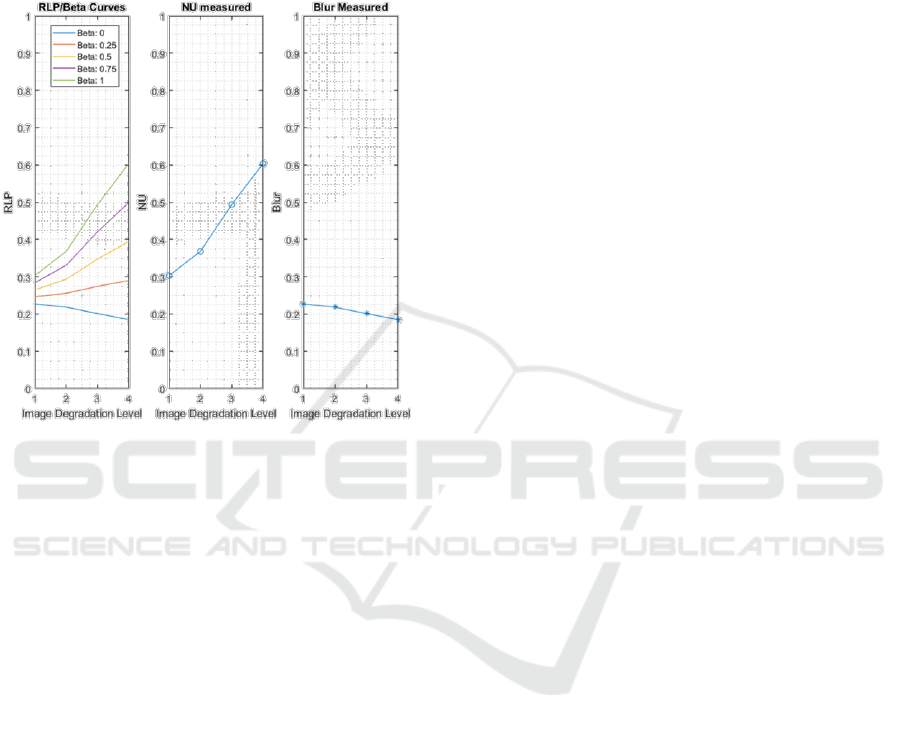

RLP Curves and independent components of NU

noise and blur for different image degradation levels

are shows in Figure 12. On the left, we can see that

as the sensitivity parameter varies, the RLP obtains

other values due to the weight that is granted to each

degradation effect. On the other hand, it is seen that

the quantized blur effect has very small variations

when comparing each value obtained for each case

of the degraded images, as shown on the right in

Figure 12. This behaviour is totally opposite when

we look at the measurement of the NU noise in the

center of Figure. Overall, the metric manages to

quantify both special effects, separately and mixed,

and give a corresponding weight considering the

degradation observed.

Figure 9: Simulated target image with fixed level of NU

(

) and increasing level of Blur (). (a) NU

,

, (b) NU

, , (c) NU

,

, (d) NU

, .

Figure 10: RLP Curves and independent components NU

and Blur curves for different image degradation levels.

Curves obtained to the simulated target image assessment

with fixed level of NU and increasing level of Blur.

Figure 11: Simulated target image with fixed level of Blur

() and increasing level of NU (

). (a) , NU

, (b) , NU

, (c) , NU

, (d) , NU

.

The proposed RLP index is calculated for the in

Figure 8 mentioned real IR data sets, showing an

improvement from 0.87 to 0.69.

6 CONCLUSIONS

In this paper, advances in mid-wavelength infrared

microscopy referred to acquisition, spatial domain

infrared image correction, Point Spread Function

experimental estimation and image quality

(a) (b)

(c) (d)

(a) (b)

(c) (d)

Infrared Microscopic Imaging Analysis

217

assessment are presented. The key of the PSF

estimations is through using deconvolution in a

blurred IR-simulated target image showing an

improvement when comparison with a blind-

deconvolution (no-PSF) method, this is better

appreciated in the global RMSE parameter.

Figure 12: RLP Curves and independent components NU

and Blur curves for different image degradation levels.

Curves obtained to the simulated target image assessment

with fixed level of Blur and increasing level of NU.

The tested JNBC method combines a well-

known NUC algorithm based on constant range

statistics and Fourier-based deconvolution method in

a single step. Thus, the method has the ability to

simultaneously compensating the blurriness and the

NU noise from degraded IR image sequences,

generating an estimation of the true irradiance in

scene-based. The assessment of the method has

demonstrated that it successfully reduces the

NU/blur. The performance of the JNBC method is

tested in a biological exothermal processes raw

datasets with NU/blur evidencing an improved

image restoration. The proposed RLP index is

calculated for the mentioned real IR data sets,

showing an improvement from 0.87 to 0.69. The

improvement on the thermal spatial gradients and

resolution of the MWIR microscopic images of the

show datasets are quantitatively demonstrated and

qualitatively noticeable with naked eyes.

ACKNOWLEDGEMENTS

This research work was partially supported by the

Chilean CONICYT doctoral scholarship program

and by FONDECYT grant #1160613.

REFERENCES

D. A. Scribner, M. R. Kruer, J. M. Killiany,, 1991.

Infrared focal plane array technology, Proceedings of

the IEEE, 79, 66-85. doi:10.1109/5.64383.

V. N. Mahajan., 1998. Optical Imaging and Aberrations,

Vol. 45.

P. M. Narendra., 1980. Reference-free nonuniformity

compensation for ir imaging arrays.

doi:10.1117/12.959478.

S. N. Torres and M. M. Hayat, 2003.Kalman Filtering for

adaptive nonuniformity correction in infrared focal-

plane arrays, J. Opt. Soc. Am. A, 20, 470-480.

E. Vera, P. Meza, and S. Torres, 2011. Total variation

approach for adaptive nonuniformity correction in

focal-plane arrays, Opt. Lett. 36, (2) ,172-174.

doi:10.1364/OL.36.000172.

N. Wiener, 1949. Extrapolation, interpolation, and

smoothing of stationary time series, Vol. 7, MIT press

Cambridge, MA.

W. H. Richardson, 1972. Bayesian-based iterative method

of image restoration, 325 JOSA 62 (1), 55-59.

L B. Lucy, 1974. An iterative technique for the

rectification of observed distributions, The

astronomical journal 79, 745.

Hecht., 2002. Optics. Editorial Addison-Wesley.

K. Rossmann., 1969. Point spread-function, line spread-

function, and modulation transfer function: tools for

the study of imaging systems, Radiology 93, (2), 257-

272.

A. Jara, S. Torres, G. Machuca, W. Ramírez, P. A.

Gutiérrez, L. A. Viafora, S. E. Godoy, E. Vera,

Submited to Infrared Physics & Technology, Elsevier.

A. Jara, S. N. Torres, G. Machuca, S. E. Godoy, A non-

reference metric for non-uniformity and blurring

artifacts on infrared imaging, Unpublished results.

VISAPP 2018 - International Conference on Computer Vision Theory and Applications

218