Towards an Ontological Representation of Condition Monitoring

Knowledge in the Manufacturing Domain

Qiushi Cao

1

, Cecilia Zanni-Merk

1

and Christoph Reich

2

1

Normandie Universit

´

e, INSA Rouen, LITIS, 76000 Saint-

´

Etienne-du-Rouvray, France

2

Hochschule Furtwangen University, 78120 Furtwangen, Germany

Keywords:

Industry 4.0, Condition Monitoring, Preventive Maintenance, Ontology, Intelligent System.

Abstract:

In the manufacturing domain, machinery faults cause a company high costs. To avoid faulty conditions, the

discipline of condition monitoring contributes significantly. The objective of condition monitoring is to de-

termine the correctness of a machine, process or system. This is crucial for improving the productivity and

availability of production systems. In most situations, when the tendency of a fault emerges, highly experien-

ced and skilled professionals are capable of providing appropriate decisions about fault alarm launching and

maintenance plans. However, production systems are becoming more complicated, and it is more likely that

the professionals fail to respond to the faulty conditions timely and accurately.

In this paper, we present an ontological framework, that is used for developing an intelligent system, which

can provide decisions about alarm launching and maintenance plans in an intelligent and optimal manner. This

framework is based on an ontological representation of condition monitoring knowledge in the manufacturing

domain. The framework consists of an ontology structure which includes a core reference ontology for repre-

senting general condition monitoring concepts and relations, and several domain ontologies for formalizing

manufacturing domain-specific knowledge.

1 INTRODUCTION

Following the trend of Industry 4.0, managing in-

dustrial production systems become more and more

challenging. The competitive nature of today’s ma-

nufacturing industry forces manufacturers to respond

to the market timely and accurately. Increasing glo-

bal competition, fast technology evolution and custo-

mers’ perceptions of product quality trigger the de-

mand for future strategical plans and advanced manu-

facturing techniques (Rao, 1996). These challenges

have brought the issue to manufactures about how to

increase manufacturing productivity. In this context,

condition monitoring techniques have been accepted

as a significant solution to it.

By collecting sensor data from heterogeneous en-

vironments, the objective of condition monitoring is

to determine whether the condition of a machine, pro-

cess or system is correct or not. Performing condition

monitoring and its associated tasks such as fault pre-

diction and preventive maintenance have shown great

success in different subdomains in industry, such as

electrical motors (Nandi et al., 2005), wind turbines

(Papadopoulos and Cipcigan, 2009) and railway en-

gineering (Schwarzenbach et al., 2010). In the con-

text of Industry 4.0, condition monitoring tasks are

facilitated by the vision of cyber-physical systems

(CPS), within which information from various envi-

ronments are closely monitored and synchronized be-

tween the physical assets and the cyber-physical space

(Lee et al., 2015). As the data generated by sensors

and networked machines gets higher in volume, CPSs

are required to be more intelligent to handle a variety

of complicated situations (Lee et al., 2015). Thus, in-

telligent CPSs which can automatically perform con-

dition monitoring and related tasks are needed.

The development of such a system requires dom-

ain knowledge about system operation and mainte-

nance to be represented in a formal way, thus ma-

king this knowledge usable by the intelligent CPS. To

achieve this goal, ontologies have shown promising

results when formalizing knowledge about condition

monitoring tasks in various domains (Papadopoulos

and Cipcigan, 2009) (Schwarzenbach et al., 2010).

An ontology is a formal knowledge representation of

a domain, which captures domain knowledge and pro-

vides reusable conceptual resources about concepts

and relations. The existence of an ontology provides

312

Cao, Q., Zanni-Merk, C. and Reich, C.

Towards an Ontological Representation of Condition Monitoring Knowledge in the Manufacturing Domain.

DOI: 10.5220/0006957903120318

In Proceedings of the 10th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2018) - Volume 2: KEOD, pages 312-318

ISBN: 978-989-758-330-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

a common and controlled vocabulary of the domain,

which enables different actors and professionals share

the same understanding of domain knowledge, thus

ease the construction of an intelligent system.

This paper presents an ontology-based framework

used for the development of an intelligent condi-

tion monitoring system, which aims to perform con-

dition monitoring and its associated tasks on pro-

duction systems in the manufacturing industry. The

framework is proposed based on an ontological re-

presentation of condition monitoring knowledge in

the manufacturing domain. We present the frame-

work by introducing an ontological structure which

includes a core reference ontology for representing

general condition monitoring concepts and relations,

and a set of domain ontologies for formalizing manu-

facturing and condition monitoring domain-specific

knowledge. The core reference ontology is aligned

with the UFO ontology (Unified Foundational Onto-

logy), which is an upper-level ontology providing ge-

neral concepts and relations at a high abstraction le-

vel (Guizzardi and Wagner, 2010). The domain on-

tologies specialize the core reference ontology into

the manufacturing and condition monitoring domains,

with representing domain-specific knowledge from

different aspects such as context, product, process,

and resources.

The rest of the paper is structured as follows. In

Section 2, we introduce the related work about exis-

ting ontologies that were developed for both condition

monitoring and manufacturing domains. In Section

3, we present the ontological framework with its de-

sign methodologies. Section 4 concludes the paper

and give future perspectives.

2 RELATED WORK

There exist several ontologies focusing on the ma-

nufacturing domain, but only a few of them capture

domain knowledge about condition monitoring and

maintenance. In this section, we introduce most re-

levant existing ontologies and discuss the suitability

of these ontologies for being reused for our purpose.

• The PSL (Process Specification Language) onto-

logy was designed to facilitate the sharing and

exchange of process information among manu-

facturing systems (Gruninger and Menzel, 2003).

These ontology models process-related know-

ledge such as process planning, process mo-

deling, production planning and project manage-

ment. The PSL ontology provides rich seman-

tics for process-related information in a general

point of view. However, it does not describe speci-

fic manufacturing processes, such as milling, dril-

ling, and cutting. Thus, to satisfy our needs, this

ontology needs to be specialized for having smal-

ler domain coverage.

• The Manufacturing Service Description Lan-

guage (MSDL) ontology was designed to provide

a common semantic model for describing manu-

facturing services (Ameri and Dutta, 2006). The

ontology formally represents key concepts that are

essential for describing manufacturing services,

such as Supplier, ManufacturingService, Manu-

facturingCapability and Process. This ontology

is suitable to be reused in our case since it provi-

des a rigorous conceptualization of manufacturing

processes.

• The P-PSO ontology (Politecnico di MilanoPro-

duction Systems Ontology) (Garetti and Fuma-

galli, 2012) address the manufacturing domain ac-

cording to four aspects: Product, Physical Aspect,

Technological Aspect and Control Aspect. The

ontology provides a comprehensive definition of

important concepts for describing the structure of

a manufacturing system.

Most of the ontologies listed above focus on the

manufacturing domain and provide representations of

manufacturing domain knowledge in a general point

of view. However, under the context of condition mo-

nitoring in manufacturing, they all lack some expres-

siveness concerning the representation of knowledge

about monitoring and maintenance activities.

There are only a few works address the deve-

lopment of ontologies for condition monitoring and

maintenance in manufacturing. Here we discuss two

notable examples.

• The ontology for Prognostics and Health Mana-

gement of Machines (Nu

˜

nez and Borsato, 2017)

was developed based on a set of international stan-

dards. The goal of this ontology is to provide stan-

dardization of concepts and terms that are relevant

to failure analysis in mechanical components. Ho-

wever, the ontology lacks representation of tem-

poral information. When the machinery faults and

failures propagate according to time, this ontology

is not capable of supporting temporal reasoning

about the propagation of them.

• The sensing system ontology (Maleki et al., ) aims

to define the embedded sensing system for smart

Product-Service System. The ontology was deve-

loped based on the SSN ontology (Semantic Sen-

sor Network ontology) (Compton et al., 2012),

and it formally describes sensor knowledge that

is related to machine health monitoring service.

Towards an Ontological Representation of Condition Monitoring Knowledge in the Manufacturing Domain

313

This ontology was one of the modules that were

used to build the PSS-specific ontology.

However, after reviewing the existing ontologies

that are relevant to condition monitoring tasks, the

main conclusion is that most of them were only desig-

ned to represent a specific portion of knowledge about

condition monitoring in the manufacturing domain.

Thus, their coverage and scope are limited. In this

context, there is a need for an ontology which provi-

des a comprehensive representation of knowledge in

both condition monitoring and manufacturing dom-

ains. To this end, we introduce in the next section

a three-layer ontological framework which captures

condition monitoring and manufacturing domain kno-

wledge from different abstraction levels. The ontolo-

gical framework provides the formalization of kno-

wledge which is essential for the development of an

manufacturing condition monitoring ontology.

3 THE ONTOLOGICAL

FRAMEWORK FOR

REPRESENTING CONDITION

MONITORING KNOWLEDGE

IN MANUFACTURING

Formalizing knowledge is an essential phase for the

development of an intelligent system. The use of for-

mal models such as ontologies is a crucial step in the

development work. In this section, we present the on-

tological framework that will be used for constructing

an intelligent condition monitoring system. The fra-

mework is demonstrated with an ontological structure

which includes a core reference ontology for repre-

senting general condition monitoring concepts and re-

lations, and a set of domain ontologies for formalizing

domain-specific knowledge.

3.1 The Classification of Ontologies

The development of the ontological framework starts

with considering the choice of upper level ontologies.

According to (Roussey et al., 2011), ontologies can

be classified into four abstraction levels, depending

their domain coverage and scope. We modified this

classification methodology into a three-layer ontology

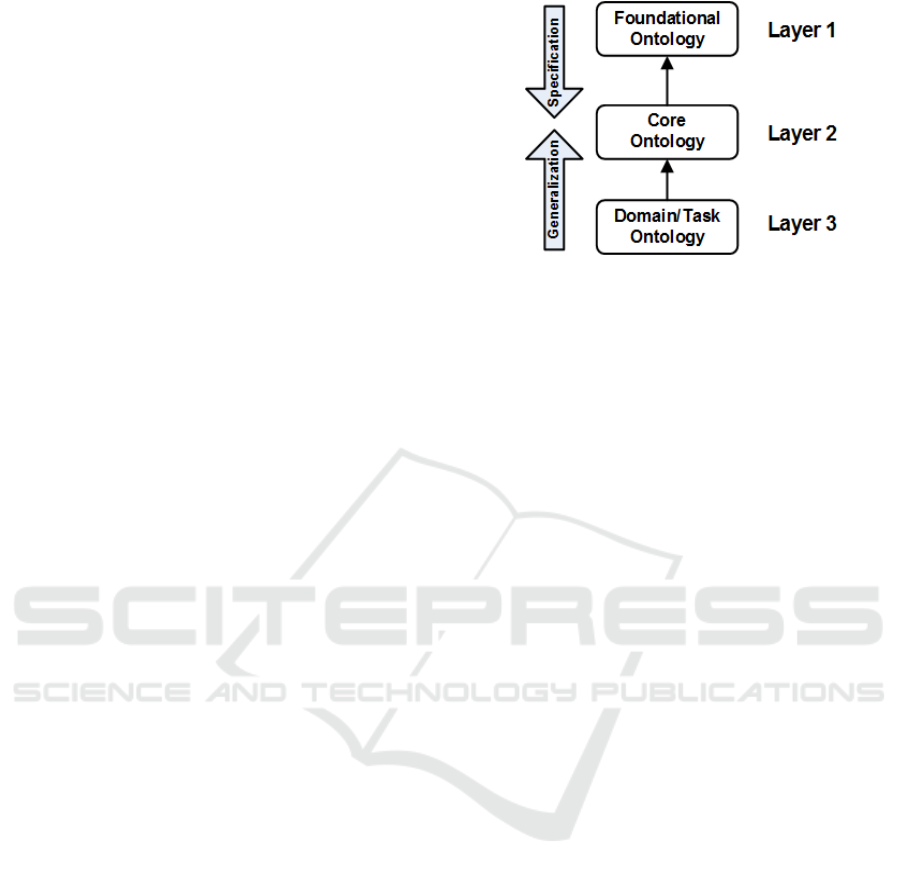

hierarchy, shown in Figure 1.

In Figure 1, the abstraction level of ontologies be-

comes more specific from top to bottom. The top level

or foundational ontologies define general and basic

notions across a wide range of domains. These no-

tions are widely applicable to various environments.

Figure 1: The ontology hierarchy according to domain co-

verage and scope, adapted from (El Ghosh et al., 2017).

Core reference ontologies are built within the scope

of a domain, and they integrate knowledge from dif-

ferent groups of actors and participants in the dom-

ain. Normally, a core reference ontology catches cen-

tral concepts and relations of a domain and is consi-

dered as an integration of several domain ontologies.

Domain ontologies and task ontologies only focus on

a specific domain. When the domain of interest chan-

ges, these two types of ontologies are not able to pro-

vide sufficient knowledge.

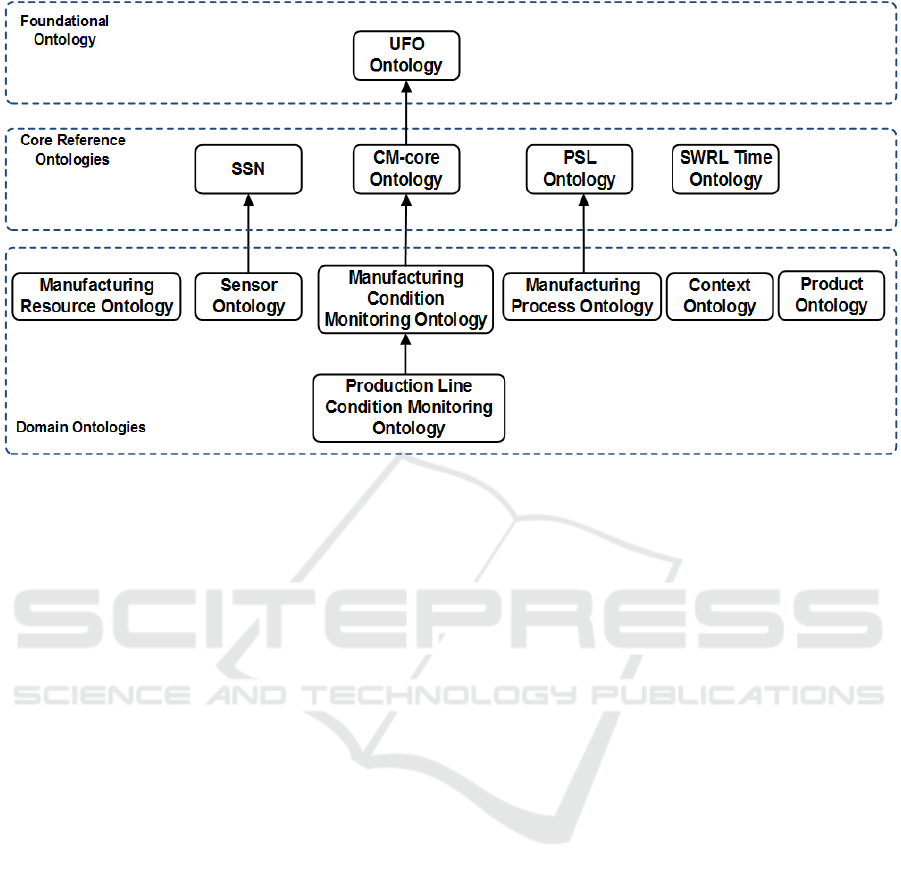

3.2 The Ontological Framework

This section introduces the ontological framework

we proposed. We developed our ontological frame-

work based on the ontology hierarchy in the prece-

ding section. Figure 2 shows all layers, that will be

desribed in the following sections.

3.2.1 Layer 1: The Foundational Ontology

The development work starts with the choice of a

foundational ontology which can enable the integra-

tion of core reference and domain ontologies. For our

work, we adopted the UFO ontology, since it provi-

des rich descriptions of general concepts and relations

which form the foundation for conceptual modeling.

The UFO ontology adopts the Endurant/Perdurant di-

chotomy, in which an Endurant represents an entity

comprising spatial components that is not dependent

on any time frame of occurrence, while a Perdurant

stands for an entity containing temporal components,

and it presents only part of its temporal components

at different time points.

3.2.2 Layer 2: The Core Reference Ontology for

Condition Monitoring

After determining the foundational ontology, we de-

veloped our core reference ontology for condition

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

314

monitoring, named CM-core. The CM-core ontology

was developed with using the Middle-Out approach

for concept taxonomy construction (Roussey et al.,

2011). The idea of this approach is to construct an on-

tology through the combination of the Top-Down and

Bottom-Up approaches. To do this, we first identified

central concepts in the condition monitoring domain.

The central concepts were extracted from three sour-

ces: (i) ISO standards 13372 (ISO, 2012), 9000 (ISO,

2005) and 9001 (ISO, 2000); (ii) the domain ontolo-

gies relevant to condition monitoring; and (iii) rele-

vant research papers and textbooks, such as (Schrei-

ber, 2000) and (Kaposi and Myers, 2001). These cen-

tral concepts were then generalized to the upper level,

and the core reference ontology was aligned to the

UFO ontology. On the other hand, these central con-

cepts were specialized into different subdomains, for

building domain ontologies. In this step, the upper-

level concepts were specialized into lower-level ones.

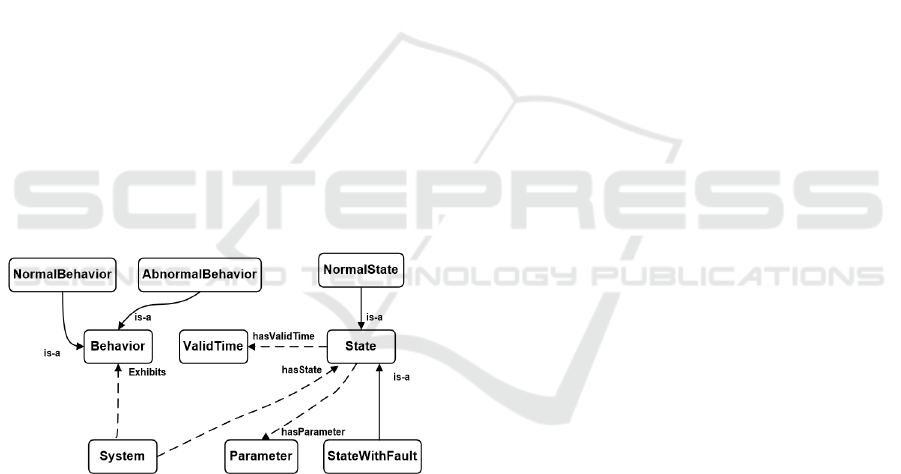

The CM-core ontology contains taxonomies of

core condition monitoring concepts such as system,

function, behavior, structure, process, state, failure

and fault, with their interrelationships. For clarity, we

only show a part of the whole ontology that is rele-

vant to our study. Figure 2 presents an excerpt of the

CM-core ontology. In the Figure, round boxes are on-

tology classes, dashed lines stand for object properties

among classes, and solid lines represent is-a or sub-

sumption relationships.

Figure 2: An excerpt of the CM-core ontology.

With the aim of representing conceptual modeling

knowledge in a general point of view, the foundatio-

nal ontology UFO provides a formal structure for the

core reference CM-core ontology. Thus it is natural

to consider the alignment to the UFO ontology, which

can ensure the formalism of the CM-core ontology.

We give the descriptions of the ontology classes in

Figure 2, and their alignments to the UFO ontology:

• System: Set of interrelated elements that achieve a

given objective through the performance of a spe-

cified function (Stevens, 2016). The definition of

this class was adapted from OntoProg: System,

with slight alteration (Nu

˜

nez and Borsato, 2017).

The alignment of this class to the upper-level class

in the UFO ontology is

CM − core : System v UFO − A : Ob ject, (1)

in which the Object class (Endurant) in UFO

ontology represents entities that possess spatial-

temporal qualities, such as a person, a building, a

tree or a river. The System class in CM-core co-

vers different types of physical systems, and they

all own spatial-temporal qualities. Therefore, the

above alignment was proposed.

• Parameter: Variable representing some signifi-

cant measurable system characteristic. The value

of a Parameter is measured by sensors that are lo-

cated at different components of the System. The

definition and description of this class was adop-

ted from OntoProg: Parameter, with alteration.

This class was aligned with the Moment class in

UFO through the alignment

CM − core : Parameter v UFO − A : Moment,

(2)

in which the the Moment class (Endurant) is a set

of instances that are existentially dependent on the

instances of the Object class in UFO. The Para-

meter class in CM-core determines interesting Pa-

rameters whose values are relevant to abnormal

status of a System, and a Parameter can not exist

without the presence of a System. For this reason,

the alignment between these two classes was con-

structed.

• State: The condition of a System at a specific time.

The condition of a System is determined by the

values of a set of Parameters. The State class was

aligned to the UFO class Moment, by the align-

ment

CM − core : State v UFO − A : Moment. (3)

A State is also existentially dependent on an Ob-

ject such as a System, thus the State class is also

aligned with the UFO class Moment.

• ValidTime: This class represents the valid time en-

tities. It has two subclasses, named ValidInstant

and ValidInterval. The difination of this class was

adapted from the SWRL Temporal Ontology, with

slight adjustment (OConnor and Das, 2010). The

proposed alignment for this class is

CM − core : ValidTime v UFO − B : Time Point,

(4)

in which the Time Point class (Perdurant) is re-

presented as real numbers that provide temporal

information (Guizzardi and Wagner, 2010).

Towards an Ontological Representation of Condition Monitoring Knowledge in the Manufacturing Domain

315

• Behavior : The Behavior of a System is represen-

ted as a sequence of States and transitions among

them. The States together with transitions spe-

cify the evolution in the values of the Parame-

ters. For defining this class, we used the definition

introduced in (Goel et al., 2009), under the fra-

mework of the Structure, Behavior and Function

(SBF) model. In the SBF model, a complex Sy-

stem could be described by its Structure, Behavior

and Function, and the Behavior of a System is re-

flected by the States and States transitions. Based

on the definition, the alignment

CM −core : Behavior v UFO−B : Complex Event

(5)

was proposed, in which Complex Event in UFO is

a subclass of Event (Perdurant). An Event repre-

sents possible transformations from a portion of

reality to another, and it is categorized into Atomic

Event and Complex Event, where a Atomic Event

has no integral parts, and a Complex Event is com-

posed of at least two events. In CM-core, the Be-

havior of a System stands for a complex compo-

sition of events which happen at different times

points, and within different contexts. Thus, the

above alignment was proposed.

3.2.3 Layer 3: Domain Ontologies for Condition

Monitoring in Manufacturing

A domain ontology represents specific domain know-

ledge and is only applicable to a certain domain. In

this study, the CM-core ontology will be specialized

into domain ontologies using the Top-Down appro-

ach. Figure 3 shows the whole ontological frame-

work, in which the domain ontologies are presented

at the bottom level. In the figure, rectangles are diffe-

rent ontologies or conceptual models, solid lines are

subsumption relations, and rectangles with dashed li-

nes indicate different levels of domain scope.

In the ontological framework, the Manufacturing

Condition Monitoring Ontology plays the central role

among all the domain ontologies. This ontology ma-

kes use of elements from other domain ontologies and

represents knowledge from both manufacturing and

condition monitoring domains. The other domain on-

tologies are included in the framework development

phase, but we do not introduce them in details in this

paper. We shortly discuss their main usage here: the

Product Ontology aims to provide a comprehensive

representation of manufacturing products and product

components. The Manufacturing Process Ontology

gives a formal representation of manufacturing pro-

cesses, such as cutting, drilling, milling, and casting.

The Manufacturing Resource Ontology provides kno-

wledge about manufacturing resources which are phy-

sical objects used for executing a range of operations

during different manufacturing processes. The Sensor

Ontology structures knowledge about sensors. This

ontology is specialized from the core reference on-

tology SSN. The Context Ontology contains the re-

presentations of contextual knowledge, including the

formal definitions of context entities such as person,

activity, location and time.

The CM-core ontology consists of 42 classes and

15 object properties. In the context of smart fac-

tories, the ontological framework was evaluated by

domain experts for its expressiveness and quality. It

paves the way for the development of an intelligent

system, which aims to perform condition monitoring

and maintenance tasks automatically.

4 CONCLUSIONS AND FUTURE

PERSPECTIVES

This paper presents an ontological framework which

is the basis for the development of an intelligent con-

dition monitoring system in manufacturing. The onto-

logical framework was developed using a Middle-Out

approach. It includes the CM-core ontology, which

is a core reference ontology for representing gene-

ral condition monitoring concepts and relations, and a

set of domain ontologies for gathering and structuring

knowledge in both condition monitoring and manu-

facturing domains. The CM-core ontology was alig-

ned with the foundational ontology UFO, for obtai-

ning a rigorous conceptualization. Also, the CM-core

ontology will be specialized into domain ontologies,

for integrating and representing domain-specific kno-

wledge.

Currently, we are in the process of developing the

domain ontologies that are at the bottom level of the

ontological framework. These domain ontologies can

be categorized into two types: (i) the ontologies for

structuring knowledge in the manufacturing domain;

and (ii) the ontologies for structuring knowledge in

the condition monitoring domain. The first category

of ontologies will provide the formalization of key

concepts in manufacturing, such as Product, Process,

Manufacturing Resource and Context. The second ca-

tegory of ontologies will focus on the representation

of concepts that are relevant to machinery prognos-

tics and health management (PHM), especially on the

conceptualization of Fault, Error and Failure. Future

perspectives include the integration of these domain

ontologies with the CM-core ontology, to provide se-

mantic capabilities for an intelligent condition moni-

toring system. On the other hand, a rule base will be

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

316

Figure 3: The ontological framework.

constructed to enable reasoning about future fault and

failure occurrences. The rule base consists of logical

rules that are extracted from the mining of sensor data

and from experts’ knowledge, and it will be integra-

ted with the ontological framework for developing the

intelligent condition monitoring system.

ACKNOWLEDGEMENTS

This work has received funding from INTER-

REG Upper Rhine (European Regional Development

Fund) and the Ministries for Research of Baden-

Wrttemberg, Rheinland-Pfalz (Germany) and from

the Grand Est French Region in the framework of the

Science Offensive Upper Rhine HALFBACK project.

REFERENCES

Ameri, F. and Dutta, D. (2006). An upper ontology for

manufacturing service description. In ASME 2006 in-

ternational design engineering technical conferences

and computers and information in engineering confe-

rence, pages 651–661. American Society of Mechani-

cal Engineers.

Compton, M., Barnaghi, P., Bermudez, L., Garc

´

ıA-Castro,

R., Corcho, O., Cox, S., Graybeal, J., Hauswirth, M.,

Henson, C., Herzog, A., et al. (2012). The ssn on-

tology of the w3c semantic sensor network incubator

group. Web semantics: science, services and agents

on the World Wide Web, 17:25–32.

El Ghosh, M., Naja, H., Abdulrab, H., and Khalil, M.

(2017). Using the unified foundational ontology (ufo)

for grounding legal domain ontologies. In 9th Inter-

national Conference on Knowledge Engineering and

Ontology Development.

Garetti, M. and Fumagalli, L. (2012). P-pso ontology for

manufacturing systems. IFAC Proceedings Volumes,

45(6):449–456.

Goel, A. K., Rugaber, S., and Vattam, S. (2009). Struc-

ture, behavior, and function of complex systems: The

structure, behavior, and function modeling language.

Ai Edam, 23(1):23–35.

Gruninger, M. and Menzel, C. (2003). The process spe-

cification language (psl) theory and applications. AI

magazine, 24(3):63.

Guizzardi, G. and Wagner, G. (2010). Using the unified

foundational ontology (ufo) as a foundation for gene-

ral conceptual modeling languages. In Theory and Ap-

plications of Ontology: Computer Applications, pages

175–196. Springer.

ISO (2012). Condition monitoring and diagnostics of

machines–vocabulary.

ISO, B. (2000). 9001: 2008 quality management systems.

requirements. International Organization for Stan-

dardization.

ISO, E. (2005). 9000: 2005. Quality management systems-

Fundamentals and vocabulary (ISO 9000: 2005),

page 1.

Kaposi, A. and Myers, M. (2001). Systems for all. World

Scientific Publishing Company.

Lee, J., Bagheri, B., and Kao, H.-A. (2015). A cyber-

physical systems architecture for industry 4.0-based

manufacturing systems. Manufacturing Letters, 3:18–

23.

Maleki, E., Belkadi, F., Boli, N., van der Zwaag, B. J.,

Towards an Ontological Representation of Condition Monitoring Knowledge in the Manufacturing Domain

317

Alexopoulos, K., Koukas, S., Marin-Perianu, M., Ber-

nard, A., and Mourtzis, D. Ontology-based framework

enabling smart product-service systems: Application

of sensing systems for machine health monitoring.

Nandi, S., Toliyat, H. A., and Li, X. (2005). Condi-

tion monitoring and fault diagnosis of electrical mo-

torsa review. IEEE transactions on energy conversion,

20(4):719–729.

Nu

˜

nez, D. L. and Borsato, M. (2017). An ontology-based

model for prognostics and health management of ma-

chines. Journal of Industrial Information Integration,

6:33–46.

OConnor, M. J. and Das, A. K. (2010). A method for re-

presenting and querying temporal information in owl.

In International Joint Conference on Biomedical En-

gineering Systems and Technologies, pages 97–110.

Springer.

Papadopoulos, P. and Cipcigan, L. (2009). Wind turbi-

nes’ condition monitoring: an ontology model. In

Sustainable power generation and supply, 2009. SU-

PERGEN’09. International conference on, pages 1–4.

IEEE.

Rao, B. (1996). Handbook of condition monitoring. Else-

vier.

Roussey, C., Pinet, F., Kang, M. A., and Corcho, O. (2011).

An introduction to ontologies and ontology engineer-

ing. In Ontologies in Urban Development Projects,

pages 9–38. Springer.

Schreiber, G. (2000). Knowledge engineering and manage-

ment: the CommonKADS methodology. MIT press.

Schwarzenbach, J., Wilkinson, L., West, M., and Pilling,

M. (2010). Mapping the remote condition monitoring

architecture. Research Programme. Rail Safety and

Standards Boards (RSSB) LTD. RSSB Core Report.

Stevens, R. (2016). Engineering mega-systems: The chal-

lenge of systems engineering in the information age.

CRC Press.

KEOD 2018 - 10th International Conference on Knowledge Engineering and Ontology Development

318