Development of Intelligent Detector for Handheld Multifunctional

Power Equipment Based on Internet

Shisheng Liu

1

, Liang Chen

2

, Weizhang He

1

and Zuoshang Chen

1

1

Foshan Power Supply Bureau, Guangdong Power Grid Corporation, Foshan 528000;

2

Central Radio and Television Tower, Beijing 000001

Keywords: Power equipment, hand-held, multifunction and intelligent detection development.

Abstract: it is an important means to discover the hidden troubles of internal device by detecting infrared thermal

imaging and partial discharge testing in the running state of power equipment. However, it is difficult for

power enterprise to find out potential trouble of the equipment on the high-place (pole tower) in operation

condition at present. In order to make up for this trouble, this paper aims to develop a set of portable

integrated detector integrating image recognition, infrared thermal imaging partial discharge testing to

achieve multi-function integration and integration of charged high precise patrol as well as comprehensive

hidden trouble identification in deep level and charging device information excerption to avoid insufficient

hidden danger identification with strong concealment, which can not only enhance quality of line inspection

but also efficiency of operation and maintenance effectively. In addition, it reduces pole mounting work

falling risk for operator and maintainer and electric shock risk for live working so as to eliminate risk of

electric shock by employees in its tracks and realize essential safety.

1 INTRODUCTIONS

At present, for hidden danger identification

methods of power equipment on the high-place

(pole tower), most of power enterprises adopt

telescope observation method and power failure

pole mounting inspection method, and these two

conventional inspection methods mainly have

following limitations and hidden dangers:

1. Telescope observation methods are limited

by height and line sight, which is difficult to

observe and discover defects of high-place

equipment in all directions

Figure 1: Diagram of power system high-place power

equipment

2. Pole mounting inspection methods have

characteristics of working aloft, high risk and long

time-consuming, prone to falling, electric shock or

casualties in high altitude, which is difficult to find

equipment defects under operating conditions and

ensure reliability of power supply.

3. For charging transcription of power

equipment nameplate, there is a big security risk,

and more likely to occur accident of falling into

river in high altitude and electric shock casualties.

Figure 2: Notification for power system accidents and

events

Liu, S., Chen, L., He, W. and Chen, Z.

Development of Intelligent Detector for Handheld Multifunctional Power Equipment Based on Internet.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 27-32

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

27

4 Infrared thermal imager and partial discharge

tester are expensive, and inconvenient to carry,

leading to the application of great limitation in the

inspection and examination of distribution network

line equipment.

In order to make up for this trouble that is

difficult to find out potential trouble of the

equipment on the pole tower in operation

condition, this paper aims to develop a set of

portable integrated detector integrating image

recognition, infrared thermal imaging and partial

discharge testing to solve problem of equipment

hidden danger in the charging operation of

distribution network line, which reduces the risk of

pole mounting work in group and the risk of

electric shock in live working, improves the

reliability of power supplying network, and

extends the function of equipment data acquisition

and conversion.

2 TECHNICAL SCHEME

In this paper, an intelligent detection instrument

for handheld multi-function power equipment

based on Internet is developed. This instrument

combines main high-definition smart camera,

infrared thermal imager, partial discharge tester

and smart phone (or tablet PC) to achieve

comprehensive test integrating image recognition,

infrared thermal imaging and partial discharge test

in combination with wireless data transmission and

intelligent hardware and software.

2.1 Main components

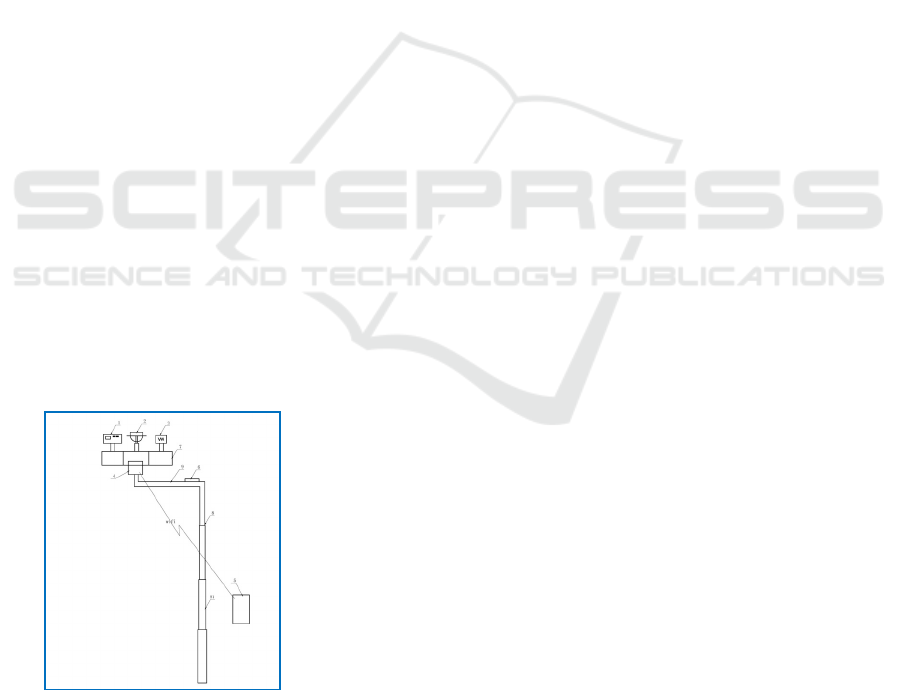

Figure 3: Structure diagram of power equipment

intelligent detector

Among them: 1.Partial discharge detector

2.Camera 3.Infrared thermal imager 4. Master

controller 5. Mobile terminal 6. Battery 7. Bracket

8. Extendable rod 81. Insulating tube 9. Support

rod.

2.1.1 Partial discharge detector, camera and

infrared thermal imager are installed in the bracket

at the same time, and connected with main

controller electrically;

2.1.2 Bracket is fixed at one end of the support rod,

and the other end of the support rod is expandable

Rod;

2.1.3 The internal support bar is equipped with

local discharge detector, camera and infrared

thermal imager and battery electrically connected

to main controller.

2.1.4 Signals collected by camera, partial discharge

detector, infrared thermal imager are transmitted to

mobile terminal by the wireless network through

host controller, and reflected in a chart or video.

2.1.5 Mobile terminals are mainly mobile phones,

laptops and other commonly used mobile devices

with popularizing rate.

2.1.6 Expansion rod is composed of multi-section

flexible tube, including 1 to 2 insulation tube.

2.2 Enforcement mode

In order to explain this device clearly, the

following content is described further in

combination of Figure 3 and specific

implementation mode

The first enforcement mode: signals collected

by partial discharge detector1, camera 2 and

infrared thermal imager 3 are transmitted to mobile

terminal 5 by the wireless network through host

controller 4, reflecting in a chart or video.

The second enforcement mode: the difference

from the first one is that users can separately check

detection information transmitted by partial

discharge detector 1, camera 2 or infrared thermal

imager 3 according to the need:

Signals collected by partial discharge detector1,

camera 2, infrared thermal imager 3 are

transmitted to mobile terminal 5 by the wireless

network through host controller 4.

Specific operation flow: in the actual power

inspection application, firstly pull extendable rod 8

and move it to detection position according to

detection position; then open mobile phones,

computers and other mobile terminals 5 and open

public wireless network, log in corresponding

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

28

display and control software, observe detection

information transmitted by partial discharge

detector 1, camera 2 or infrared thermal imager 3

through mobile terminal 5 according to the need at

the same time, or observe it respectively.

3 PRINCIPLE DESCRIPTION

3.1 Preliminary conceptions

Aiming at limitations and potential risks in the

telescope observation method and power failure

pole mounting inspection method, operators of

power enterprises have developed a set of

distribution network equipment device - mine

sweeper which is the prototype of power

equipment detector (Figure 4) with safe and easy

operation and maintenanceaccording to the initial

ideas: install high definition smart camera in the

insulating rod so as to achieve visual observation

of charging equipment in close range and hidden

danger of charged equipment in all directions in

combination with tablet PCs, APP applications and

wireless real-time transmission technology.

Figure 4: Prototype of power equipment intelligent

detector

The use of “mine sweeper” has realized

close-range hidden danger identification for

360-degree of all-weather, safe and charging

power equipment in high-altitude without hidden

corners, and discovered equipment hidden dangers

that cannot be found by routine inspection, which

reduced ascent work greatly, improved operation

and maintenance quality and efficiency, relieved

pressure on owner of equipment operation and

maintenance, and won general consent of teams

and groups.

3.2 Ultimate technical principles

In the popularization and application process of

“mine sweeper”, it was found that some power

equipment not only needed to inspect

image recognition for discover of equipment

hidden danger in high altitude, but also test

infrared thermal imaging and partial discharge in

high altitude so as to further determine online

health state of running equipment, and other

extension functions of “mine sweeper” shall be

dug deeply.

What is more, due to slim and long insulation

rod, it is difficult to for operators to operate and

control, and insulation rod should be improved

further. Therefore, a set of portable integrated

detector integrating image recognition, infrared

thermal imaging and partial discharge testing shall

be developed in combination with wireless data

transmission and intelligent hardware and

software. Technical principles include the

following aspects:

(1) Partial discharge detector, camera and

infrared thermal imager are installed in the bracket

at the same time, and connected with main

controller electrically; bracket is fixed at one end

of the support rod, the other end of the support rod

is expandable rod; the internal support bar is

equipped with local discharge detector, camera and

infrared thermal imager and battery electrically

connected to main controller.

(2) Signals collected by three instruments are

transmitted to mobile terminal by the wireless

network through host controller, and reflected in a

chart or video.

(3) Expansion rod is composed of multi-section

flexible tube, including 1 to 2 insulation tube.

(4) Mobile terminals are mainly mobile phones,

laptops and other commonly used mobile devices

with popularizing rate.

Steps: in the actual power inspection

application, firstly pull extendable rod and move it

Development of Intelligent Detector for Handheld Multifunctional Power Equipment Based on Internet

29

to detection position according to detection

position; open mobile terminals and public

wireless network, log in corresponding display and

control software, observe detection information

transmitted by three instruments through mobile

terminal according to the need at the same time, or

observe it respectively.

4 IMPLEMENTATION EFFECT

The instrument is applied in the field of smart grid

detection equipment technology, using mutual

interoperability of high definition smart camera,

infrared thermal imager, PD tester and smart

handheld devices to achieve 360-degree high

definition video inspection in all directions in the

operation condition of pole tower, and

simultaneously realize running equipment

temperature measurement, partial discharge and

internal defect hidden dangers in accordance with

the health status of running equipment, which

improves the operation and maintenance quality

and operation and efficiency greatly and has great

economic and social benefits:

4.1 Economic benefits

It can be seen that intelligent detector of power

equipment improves operation and maintenance

efficiency obviously through power equipment

intelligent detector and conventional methods to

carry out hidden danger identification for power

equipment.

Table 1: Comparison of hidden danger identification

efficiency for power equipment intelligent detectors and

conventional methods

Equip

ment

checkin

g

Conventional

checking time

Checking

time of

intelligent

detecto

r

Saving

time

Transfo

rmer

body

Close

observation

power failure

pole mounting

(totaling power

failure, electrical

power and

grounding time)

takes more than

60 minutes.

Full angle

observatio

n takes 10

minutes.

More

than 50

minutes

Drop-o

ut fuse

Close

observation

power failure

pole mounting

(totaling

p

ower

Full angle

observatio

n takes 5

minutes

More

than 55

minutes

failure, electrical

power and

grounding time)

takes more than

60 minutes.

Drop-o

ut

lightnin

g

arrester

Close

observation

power failure

pole mounting

(totaling power

failure, electrical

power and

grounding time)

takes more than

50 minutes.

Full angle

observatio

n takes 5

minutes

More

than 55

minutes

Switch

body

Close

observation

power failure

pole mounting

(totaling power

failure, electrical

power and

grounding time)

takes more than

50 minutes.

Full angle

observatio

n takes 10

minutes

More

than 40

minutes

Switch

PT

Close

observation

power failure

pole mounting

(totaling power

failure, electrical

power and

grounding time)

takes more than

50 minutes.

Full angle

observatio

n takes 8

minutes

More

than 42

minutes

Through the calculation, it took an average of

more than 60 minutes to check the equipment by

pole mounting in the last. At present, by using

portable integrated detector for checking hidden

danger, it took about 10 minutes on average. In

comparison with the past, about 50 minutes can be

saved. There are about 89, 444 switchgear

transformers and switch gears on pole in Foshan

Power Supply Bureau. With a monthly inspection

of 30 %, it can save 22,361 hours per month, with

an average hour of 11 Yuan for one person per

month, which can save 491, 900 million per

month.

4.2 Social benefit

4.2.1 Based on Internet, through common mobile

terminals, relying on relevant software, detection

information is directly to mobile terminal; achieve

function of image contrast and preliminary

analysis to make it more adaptable to requirements

for site.

4.2.2 With multi-functional integration, achieve

partial discharge performance, images or video,

thermal performance of corresponding detection

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

30

position, can be reflected in a picture or video

centrally, and provide more intuitive data for

scientific decision-making; achieve purpose of

equipment data acquisition and conversion,

portable temperature measurement and partial

discharge.

4.2.3 Low price; adapt to requirements for smart

grid application of a large number of intelligent

testing

equipment; there are no separate external test outer

parts and displayed long-distance detection settings

due to electrical safety. In particular, there is no

need to configure a dedicated monitor, which can

display detection information directly by using

mobile terminals such as personal mobile phones

and computers with low cost.

4.2.4 The combination of intelligent power

detector and insulation rod can shoot clear picture

of equipment in high altitude and observe

equipment health status in 360-degree and all

directions, carry out temperature measurement and

partial discharge work for necessary equipment,

complete it without pole mounting, and reduce

work risk effectively.

5 RANGE OF APPLICATION

Portable integrated detector can be promoted

widely in power industry. It is mainly used in

various equipment hidden danger identification,

equipment rated plaet information collection,

project constructional acceptance of common

distribution transformer, 10kv outdoor switch body

and feeder automation switch PT, drop-out fuse,

dis-lodging arrester in the operating condition.

5.1 Achieve hidden danger

identification for 360-degree of

all-weather, safe and charging power

equipment in high-altitude; implement 360-degree

high definition video inspection in all directions in

the operation condition of pole tower; realize

running equipment temperature measurement,

partial discharge and internal defect hidden

dangers simultaneously; solve equipment hidden

dangers that cannot be found by routine inspection

basically

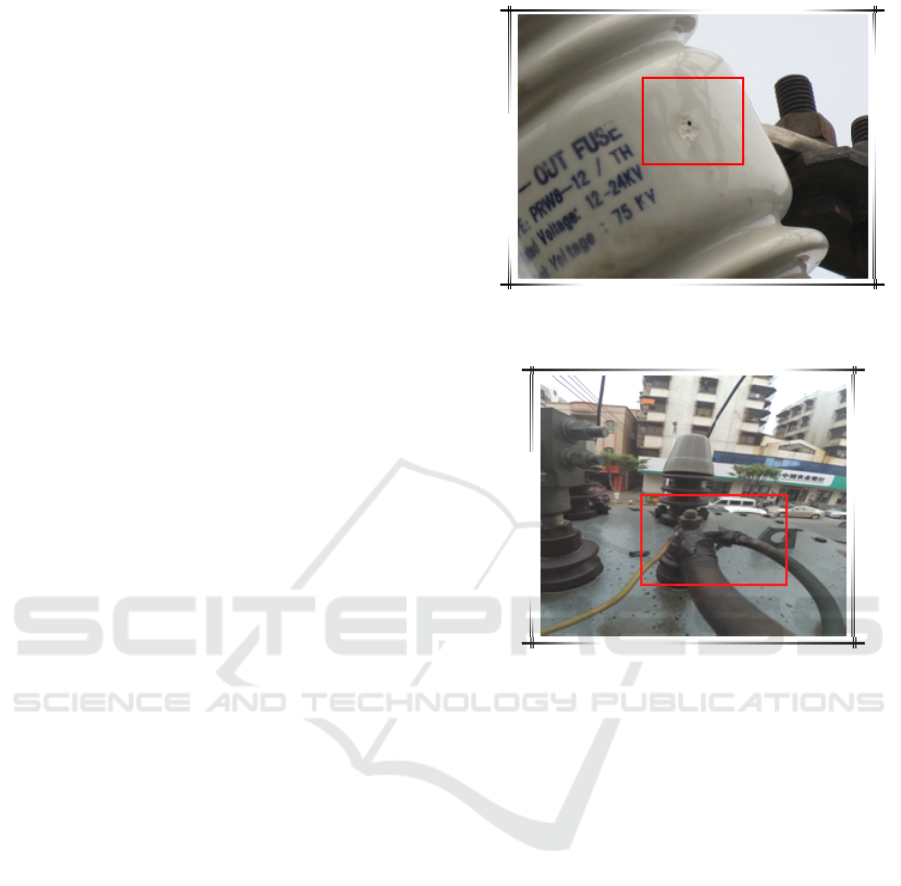

Figure 5: Practice effect of power equipment intelligent

detector 1

Figure 6: Practice effect of power equipment intelligent

detector 2

5.2 Achieve charging transcripts and

data conversion of equipment

information, do not contact with adjacent

charging equipment, no risk of electric shock, and

eliminate electric shock risk of copy information

for staff. The organic combination of instrument

and insulated expandable rod and realization of

safe operation of operation and maintenance and

charged equipment without using pole mounting

can reduce risk of high-altitude falling and electric

shock effectively, and solve personal safety

problems of power operator and maintainer during

inspection operation basically.

5.3 Accurate image video analysis;

reducing the gap between staff experience;

scientific and accurate equipment hidden danger

analysis.

Development of Intelligent Detector for Handheld Multifunctional Power Equipment Based on Internet

31

5.4 Enhance level of equipment

operation and maintenance, improve

quality and efficiency of operation and

maintenance, reduce the user’s power failure time

indirectly, and improve reliability of power supply

essentially.

5.5 Reduce pole mounting operation

quantity of operator and maintainer in

an all-round way, realize risk pre-control of

pole mounting operations, solve risk of pole

mounting effectively during equipment inspection,

reduce pressure on operator and maintainer, and

improve operation and maintenance efficiency.

6 CONCLUSION

The development and use of portable integrated

detector can solve technical problems of

equipment hidden danger in the charging operation

of distribution network line, on one hand, it can

implement data acquisition of distribution network

equipment in all weather, high precision operation

and maintenance, troubleshooting analysis,

inspection of distribution network line equipment

and other daily operations and maintenances, on

the other hand, it can achieve safety isolation of

operation and maintenance work and charging

equipment in all weather, which reduces pole

mounting work falling risk for operator and

maintainer and electric shock risk for live working

efficiently without using pole mounting and solves

safety issue for power operator and maintainer in

the inspection operation and work safety accident

caused by insufficient potential safety hazard

checking and controlling for power equipment in

high altitude.

REFERENCES

Bai Taili, He Ling, Wang Caiyun, Deng Tieliu et al.

Multifunctional intelligent detector based on

vibrating wire sensor [J] .Sensor Technology, 2004,

03: 60-65.

Sun Zuo; Wang Nianchun; Xu Weibing et al. Design of

intelligent detector with multi-function power

parameter based on DSP and μC / OS-Ⅱ [J]. China

Instrumentation, 2006, 12: 58-61.

Yuan Weizhong; Su Mei; Yu Weimin, et al. Design of

intelligent power parameter monitoring instrument

with self-calibration function [J]. China

Instrumentation, 2006, 01: 44-47.

Zhang Huiyi; Tao Tao; Zhou Xiuli et al.. Detection

technology of power parameters based on embedded

processor [J]. Electrical measurement and

instrumentation, 2006, 08: 64-68.

Zhu Hong; Han Jianghong; Zhang Yongli et al. Research

and implementation of power parameter

measurement in industrial digital platform [J]

.Journal of Hefei University of Technology (Natural

Science Edition), 2006, 06: 703-706.

Liu Fangliang, Jiang Dalin, Xu Pengxiang, et al.

Research and implementation of intelligent power

parameter integrated measuring instrument [J].

Chinese Journal of Scientific Instrument, 2006, S1:

206-208.

Wang Xiuyan; Li Zongshuai et al.design of

multifunctional intelligent detection node based on

DeviceNet [J]. Machinery and Electronics, 2009, 07:

49-51.

Xu Pengxiang; Jiang Dalin; Liu Fangliang et al.

Algorithm implementation based on AD73360 power

parameter measurement [J]. Chinese Journal of

Scientific Instrument, 2006, S1: 20-22.

Li Zhenmei, Yang Aijun, Gu Xiaona et al. Software

design of power quality monitoring and analysis

based on virtual instrument [J] .Journal of Shandong

University of Technology (Natural Science Edition),

2004, 05: 8-12.

Hu Wenjun, Li Zhenmei, Rao Mingzhong, et al. Study

on phase difference measurement of power network

signal based on virtual instrument [J] .Journal of

Shandong University of Technology (Natural Science

Edition), 2003, 02: 90-93.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

32