Ship’s Emission Standards on Fuel Changeover in ECAs (SECAs)

Feifei Li and Kun Dang

1

Department of Marine Engineering, Tianjin Maritime College, Tianjin, China

2

Marine Engineering College, Dalian Maritime University, Dalian, China

Email: lifeifei2835@sina.com

Keywords: Air pollution, Fuel changeover, ECAs.

Abstract: MARPOL 73/78 is the main convention covering prevention of pollution of the marine environment by

ships from operational or accidental causes. MARPOL Annex VI outlines international requirements for

vessel air emissions and pollution prevention. Under the terms of the convention, Undertaking Parties shall

require ships of their administration and foreign ships in their waters to comply with these international air

pollution prevention regulations. Upon entry into force of Annex VI to MARPOL on the 19 May 2005, the

sulphur oxide (SOx) emissions from ships are controlled by setting a limit of 3.5% on the sulphur content of

marine fuel oils. Furthermore, a limit of 1.0% on the sulphur content of marine fuel oil is apply in

designated SOx Emission Control Areas (SECAs) and Emission Control (i.e. NA-ECA).

1 INTRODUCTION

From January 1st, 2015, the maximum sulphur

content of fuel oil used within the MARPOL Annex

VI Emission Control Areas (ECAs) will be 0.10%,

unless using an approved alternative means for

controlling sulphur emissions. In most cases, the

fuel used will be low-sulphur distillate oil (LSDO).

Many ships operating both inside and outside ECAs

will changeover between LSDO and residual fuel oil

(RFO) when entering and exiting ECAs.

ECA means to unite Sulphur Emission Control

Areas (SECA) with incorporation of NOx emission

as requirements. So far Emission Control Area

means an area where the adoption of special

mandatory measures for emissions from ships is

required to prevent, reduce and control air pollution

from SOx, NOx, and particulate matter and its

attendant adverse impacts on human health and the

environment. Emission Control Areas includes those

listed in, or designated under regulations MARPOL

ANNEX VI Reg. 13 and 14. As of 2011 there were

four existing ECAs: the Baltic Sea, the North Sea,

the North American ECA, including most of US and

Canadian coast and the US Caribbean ECA. Other

areas may be added via protocol defined in Annex

VI as well. ECAs with nitrogen oxides thresholds

are denoted as Nitrogen Oxide.

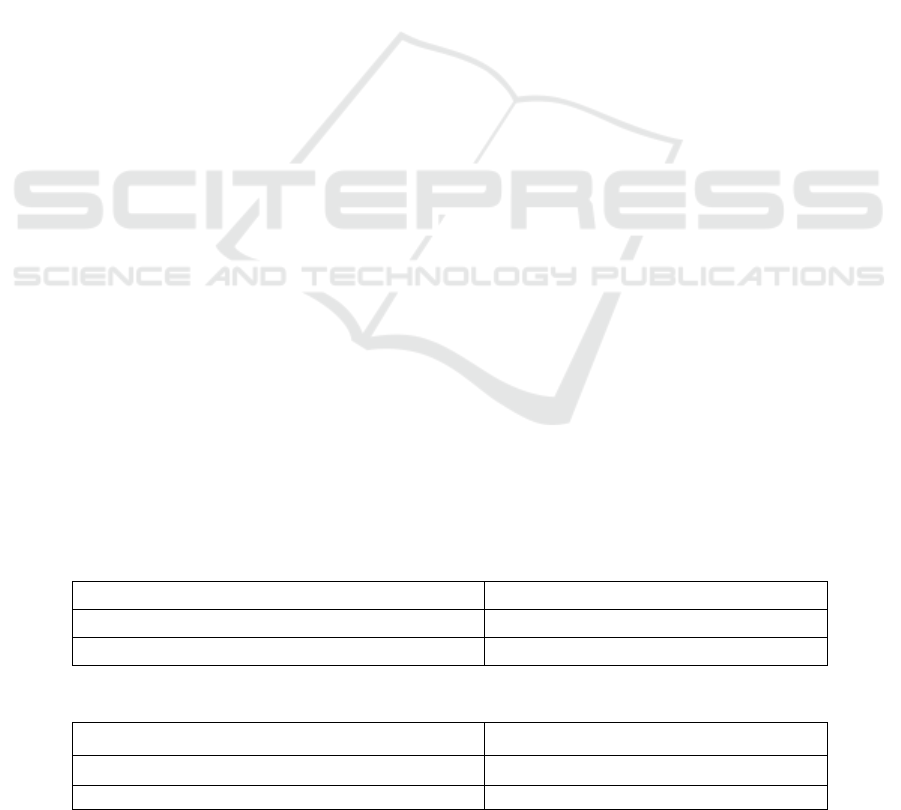

Two tables below show that sulphur limits for

fuel in SECA and other sea areas:

Table1. Sulphur Limits for Fuel in SECA.

before 1 July 2010 1.50% m/m

between 1 July 2010 and 1 January 2015 1.00% m/m

after 1 January 2015 0.10% m/m

Table2. Sulphur Limits in Other Sea Areas

before 1 January 2012 4.50% m/m

between 1 January 2012 and 1 January 2020 3.50% m/m

after 1 January 2020 0.50% m/m

Li, F. and Dang, K.

Ship’s Emission Standards on Fuel Changeover in ECAs (SECAs).

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 347-350

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

347

In addition, the volume of low sulphur fuel oils

in each tank as well as the date, time, and position of

the ship when any fuel oil change over operation is

completed prior to the entry into an ECA or

commenced after exit from such an area, shall be

recorded.

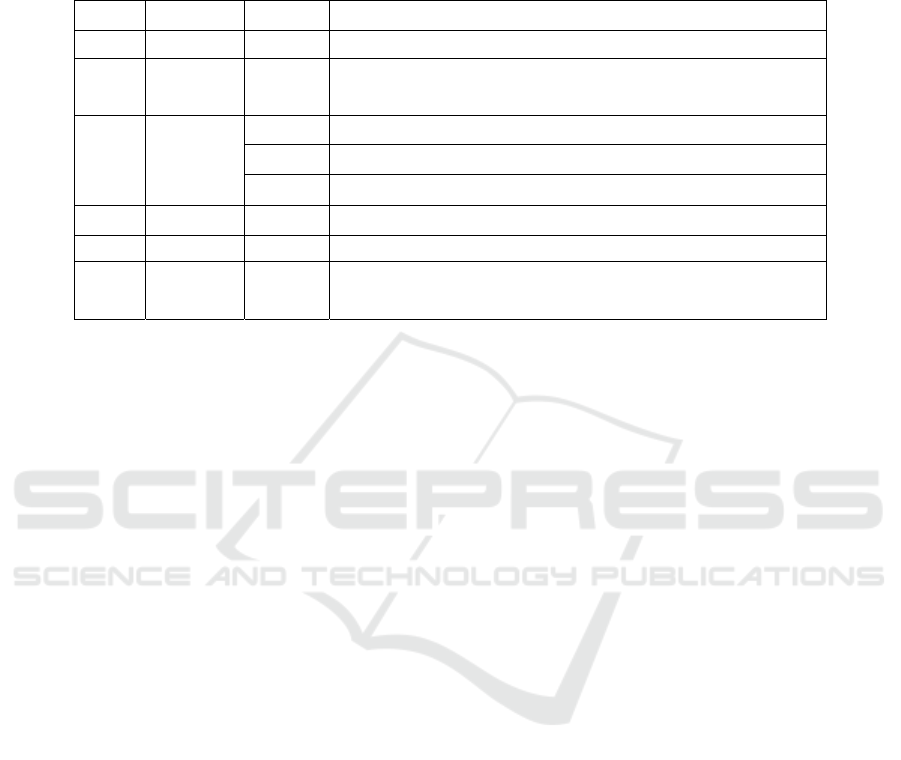

Table3. EU, CARB and Other Requirements for Changeover to MDO/MGO

2007 1st January CARB MDO Max 0.5% sulphur within 24 miles of California shore North

2008 1st January EU Max 0.1% sulphur for marine gas oils

2009 1st July CARB

Marine gas oil (DMA) at or below sulfur; or 1.5% Marine diesel oil

(DMB) at or below 0.5% sulphur

2010 1st January

EU Max 0.1% sulphur bunker fuel in use at EU berths

EU Max 0.1% sulphur in all EU inland waterways

CARB Max 0.1%sulphur within 24 miles of California shore (Delayed)

2012 1st January EU Ports Max 0.1% sulphur bunker fuel in use by Greek ferries at Greek

2012 1st August CARB Limit marine gas oil to 1% sulfur / MDO still remain at Max 0.5%

2014 1st January CARB

Max 0.1%sulphur marine gas oil (DMA) or diesel oil (DMB) within

24 miles of California shore

2 CHANGEOVER PROCEDURES

Change-over between heavy fuel oil grades is standard

practice and therefore is changed over from heavy fuel

oil to marine diesel oil in connection with e.g.

dry-dockings. Change-over from heavy fuel oil to

marine gas oil is however completely different and

clearly not common standard. If gas oil is mixed in

while the fuel temperature is still very high, there is

a high probability of gassing in the fuel oil service

system with subsequent loss of power. It should be

acknowledged that the frequency and timing of such

change-over may increase and become far more

essential upon entry into force of SECA’s. Additionally,

the time, ship’s positions at the start and completion

of change-over must be recorded in a logbook (e.g.

ER logbook), changeover operation, together with

details of the tanks involved and fuel used need to be

recorded as well. It can be anticipated that the same

will be applicable with respect to the EU proposal

upon entry into force. Description of procedures on

keeping set limits of sulphur with entrance in SECA(s)

ECA and CARB Areas are as follows.

2.1 Person In-Charge and Company’s

General Standards

The Person In-charge for the Fuel Changeover

operation shall be the 1st Asst. Engineer. He shall

assure that safety in the changeover operation is

observed to prevent any untoward incidents during

the changeover operations. Appointment of Person

In-charge shall be reflected to the Fuel Changeover

Operation Designation of In-charge Personnel.

Generally, the Company requires that planning for

changeover of fuel oil shall be made at least 7-days

prior to entry depending on the result of onboard

calculation. Please note that the higher the sulphur

content of both HSFO and LSFO, the longer the

changeover operation will take be attained. These

factors affecting the changeover process will be

explained as follows: (1) Sulphur content: The

higher the initial sulphur level, the longer the

change-over time will be. As well, the higher the

LSFO sulphur level, the longer the change-over time.

(2) Total fuel consumption rate: The higher the

consumption, the lower the changeover time will be.

The complexity is related to selecting the

appropriate consumption in the period the

change-over takes place (could involve port stay

where main engine consumption is negligible but

auxiliary engine and boiler consumption is high). In

some cases, boilers are fed by the settling tank, and

this contributes only to draining of the settling tank

and not to the direct reduction of the service tank

sulphur level. (3) Total volume in the fuel oil system:

The larger the total volume in the settling tank and

associated piping to be blended (diluted), the longer

the change-over time. The larger the total volume in

the service tank and associated piping to be blended

(diluted), the longer the change- over time. (4)

Separator(s) capacity: If the service tank is dropped

to 25% level, then the separator capacity is often

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

348

increased until the service tank is full (remembering

to take into consideration the water, cat fines, and

sediment levels in the LSFO to be treated). However,

when the service tank is full, it is recommended that

as far as practicable, the separator capacity is set

equivalent to the total consumption. One reason is

that a constant backflow to the service tank will

re-circulate fuel and increase the sulphur level in the

settling tank and subsequently the service tank. This

effect will be particularly evident when the LSFO

sulphur level approaches the target of 1.00%

maximum limit. (5) Fuel transfer pump(s) capacity:

Provided the piping arrangement facilitates stripping

of the service tank, the transfer pump capacity will

affect the time needed to drain it. Similarly, the

pump capacity will have impact on the time needed

to charge the settling tank after stripping.

2.2 Acceptable Methods of Fuel Oil

Changeover Operations

2.2.1 Natural Changeover Operation for

Entering ECA (SECA)

The number of days to start the changeover operation

mainly depends on the sulphur concentration of HSFO

in use and the sulphur concentration of LSFO

available onboard. It is comprehended that the time of

operation is expected to be quite long and required

LSFO to be consumed to replenish the fuel system is

considerably huge. The following Figure 1 show the

change-over time.

Figure 1: Graph of Change-over Time for natural changeover method.

2.2.2 Forced Changeover Operation for

Entering ECA (SECA)

Before passing borderline of SECA / ECA, Settling

Tank should be drained in one of F.O. Storage Tanks

available using either the shifter pump or by draining

it manually to the FO Overflow tank. However, the

number of hours required to changeover the fuel oil

prior to entering SECA/ECA also depends on the

sulphur content of HSFO and LSFO to be used during

the changeover. This operation is initiated by draining

the HSFO inside the FO Settling tank and then refilled

Ship’s Emission Standards on Fuel Changeover in ECAs (SECAs)

349

with LSFO. The starting point of fuel changeover shall

be decided once the FO purifier has been put into

operation to shift the LSFO from FO Settling Tank

into FO Service Tank. It is therefore essential that the

“time required for draining the FO Settling Tank” and

the “most minimum quantity of HSFO that can be

attained” shall be comprehended in advance. These

factors depend on piping arrangements of each ship. If

vessel is fitted with large drain line connecting the FO

Settling tank going to FO overflow (or FO storage

tank), use this to expedite the draining of HSFO. For

the draining of FO Service tank, please take care to

keep a quantity equivalent to operating the M/E for

8hrs at 85%MCR.

Date, time and position of the ship on

commencement of changeover, completion of

changeover and at the point of entry into ECA/SECA,

remaining quantity from FO Settling Tank, FO

Service Tank, and all LSFO Storage Tanks onboard

shall be recorded in the log book. In ECR make sure

that all tank indicators for designated LSFO and

HSFO to be marked accordingly to avoid mistakes in

the changeover operation. Furthermore, all HSFO

Tank valves to be closed completely and locked when

the changeover operation is completed to avoid

contamination of fuel oil while ship is operating

within SECA/ECA. All relevant valves shall be

marked accordingly in the ECR for guidance during

changeover during entry and upon exit from emission

controlled area.

After leaving the SECA / ECA area the fuel

system can be switched back to normal HSFO but

particular attention shall be paid to the ship’s

position when changing over to HSFO to ensure that

changeover took place when vessel is already

outside the borderline of emission controlled area.

3 CONCLUSION

Air pollution caused by ships is severe in recent years

in accordance with IMO GPG Study of 2014. SOx

and NOx emissions account for 15% and 13%

respectively which are caused by global shipping

industry from 2007 to 2012. It indicates that the

shipping pollution is a serious problem and needs to

take necessary measures to improve it. Port’s air

quality will be affected due to the ships’ air

pollution, therefore, MPEC that belongs to IMO set

up four ECAs. The North American ECA has had

obvious improvement through various measures,

including taking samples frequently for checking,

imposing punishment for the disqualified check,

supervising the fuel’s quality, efficient

division-cooperation system and so on. So far China

has set up ECA to fight against air pollution and

achieved the preliminary effects. However, there

are a series of problems, e.g. inadequate supervision,

while carrying out specific measures. China can

draw lessons from the North American ECA which

can further improve our air pollution and protect

human beings’ health and accelerate shipping

technology.

REFERENCES

Air Pollution and Greenhouse Gas Emissions,

International Maritime Organization (IMO), 2014a,

retrieved 4 May 2014.

New rules to reduce emissions from ships enter into force,

Briefing 23, International Maritime Organization, 18

May 2005, retrieved 4 May 2014.

Sulphur Oxides, International Maritime Organization,

2014, retrieved 4 May 2014.

Emission StandardsInternational: IMO Marine Engine

Regulations: Background, Diesel Net, September

2011, retrieved 4 May2014.

Air pollution.http://www.imo.org. Retrieved 2017-04-08.

Nitrogen oxides (NOx) – Regulation 13. www.imo.org.

Retrieved2017-04-08.

Designation of North American Emission Control Area to

emissions from ships. Washington D.C.: EPA,2010.

California SECA Regulations Upheld by Supreme Court,

Marine Link, 20 July 2012, retrieved4 May2014.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

350