Fatigue Life Prediction Model of Pavement Cement Concrete

under Multi-field Coupling Condition

Shengbo Zhou

1

, Junlin Liang*

2

, Jianping Xiong

3

and Hao Wei

4

1

Guangxi XINFAZHAN Communications Group;Key Laboratory of Road Structure and Materials of Guangxi, Nanning

,

China

;

Research and Development Center on Technologies,Materials and Equipment of High Grade Highway

Construction and Maintenance Ministry of Transport,PRC;Guangxi Transportation Research Institute Ltd, Nanning

,

China

;

2

College of Civil Engineering and Architecture,Guangxi University, Nanning,China; *Corresponding author

3

Key Laboratory of Road Structure and Materials of Guangxi, Nanning

,

China

;

Research and Development Center on

Technologies,Materials and Equipment of High Grade Highway Construction and Maintenance Ministry of

Transport,PRC;Guangxi Transportation Research Institute Ltd, Nanning

,

China

;

4

Guangxi Transportation Research Institute Ltd, Nanning

,

China

;

Keywords: Road Engineering; Residual Flexural Strength;Fatigue Life; Loading-High Temperature- Wetting-Drying

Cycle; Pavement Concrete

Abstract: Research on the residual flexural strength and fatigue life of pavement cement concrete in Guang Xi region

under loading-high temperature-wetting-drying cycle condition to obtain the pavement concrete fatigue

strength damage and the residual life prediction model. Based on defining fatigue strength damage variable

and constructing residual flexural strength model, the nonlinear mathematical equation between residual

flexural strength and such parameters as number of loading, placing time in high temperature and wetting-

drying environment is established. Results showed that it can better reflect the decreasing process of

pavement cement concrete strength after fatigue damage. The S-N curvilinear equation and failure

probability were introduced to analyze the fatigue life of pavement cement concrete, results indicated that

the single logarithmic equation can be used to predict the fatigue life accurately with different probability,

and it accord with the Weibull distribution. the specific double parameters in Weibull distribution function

was given for pavement concrete fatigue life in this multi-field environment.

1 INTRODUCTION

Cement concrete pavement isa linear structure

exposed to traffic loading and atmospheric

environment. The performance variation of

pavement during used has important reference

significance for the pavement maintenance, and the

durability of concrete pavement under long term

fatigue is a problem that people pay close attention

to all the time, for example Baluch(2002) et

al.[1],Shi (1990)[2],Li(2002)[3]. The United States

has set up a special committee to study the problem

of concrete fatigue in 1947.Shortly thereafter, China

Academy of Railway Sciences Li and Che(1999)[4],

Harbin Institute of TechnologyJia(2009)[5], Dalian

University of TechnologyMeng(2006)[6] and other

units Pan and Qiu(2006)[7],Meng and

Song(2009)[8],JOAN and CESAR[9],Chen et

al.(2005)[10],Zheng et al.(2007)[11]also carried out

a series of experimental research on concrete

fatigue. In recent years, it has become a mature

method to study the evolution of fatigue damage of

concrete by using damage mechanics theory. On the

basis of the theory that the damage of concrete is

assumed to be the progressive accumulation of

damage, the damage variable is introduced to

quantify the damage degree of concrete.

Guangxi is located in the subtropical monsoon

climate zone, the cement concrete pavement is

subjected to the fatigue failure of the loading, high

temperature and wetting-drying cycle for a long

time. The study on fatigue performance of cement

concrete pavement in high temperature and humid

area under loading, high temperature and wetting-

drying cycle has not been reported. In this paper, the

fatigue performance of pavement cement concrete

under loading, high temperature and wetting-drying

cycle is studied. Based on continuum medium

damage mechanics theory, the damage degree of the

concrete is evaluated by defining damage variable.

The fatigue damage evolution model to reflect the

damage degree of concrete and the residual flexural

tensile strength, and the prediction model of fatigue

life of cement concrete pavement under three factors

are established. These models provide the basis for

evaluating the fatigue damage mechanism and

predicting the remaining life of concrete pavement.

2 EXPERIMENTAL RAW

MATERIALS AND CONCRETE

MIXTURE RATIO

2.1 Raw Material

The experimental raw materials are Qinling P.O

42.5R, YaozhouChangcheng S95 powder,

DatangHancheng first grade fly ash, Chuangqi

crushed stone which maximum nominal size is

19mm, Kaidi SDSP-1 high performance water

reducer (26% water reduction rate), municipal tap

water..

2.2 Concrete Mixture Ratio

According to the design of the two kinds of traffic

grade pavement, the concrete with 28 day flexural

tensile strength of not less than 4.5 MPa and 5.0MPa

was prepared in this experiment. The concrete mix

ratio data through endurance performance

optimization is list in the Table1.

Table1: Optimum mix proportion of concrete based on durability.

Sample

number

Wat

er

binder

ratio

ceme

nt

Powd

er

fly

ash

water

coarse

aggregate

san

d

wate

r reducer

Kg/m

3

C1 0.34 315 63 42 0.8 1114 734 2.52

C2 0.34 285 57 38 129 1185 726 2.28

3 FATIGUE TEST METHOD

The test method based on “highway engineering

cement and cement concrete test code”.The flexural

tensile fatigue test was carried out for 90 days after

the standard maintenance of concrete specimens.

The fatigue testing machine is MTS-810 with a

maximum range of 10 tons, the loading fatigue level

is controlled to be 50% and 80% of the maximum

flexural strength, the loading scheme is a sine wave

three point loading, the loading frequency is set to

10HZ, the low stress ratio is 0.1, and the number of

fatigue cycle were 72 thousand times, 144 thousand

times and 216 thousand times respectively.

According to the climate zoning which is high

temperature and humidity in Guangxi. Select the

temperature difference is 32℃-40℃,the Humidity

difference is 60%-80%. The high temperature and

wetting-drying cycle corresponding to the fatigue

loading times were 1 months, 2 months and 3

months respectively. After the fatigue test, the static

tensile strength test was carried out on the universal

testing machine, and the fatigue damage evolution

model of the concrete was established based on the

residual flexural strength.

4 ANALYSIS OF RESEARCH

RESULTS

4.1 Definition Of Fatigue Damage

Variable

Fatigue damage of concrete is quantitatively

described by damage variable. In order to reflect the

fatigue damage evolution process of concrete

strength, the residual strength method is used to

define the damage variable, which is used to

characterize the residual bearing capacity of

concrete after fatigue. Under different conditions of

concrete application, Ravindrauses attenuation of

splitting strength of concrete under fatigue loading

to define damage variable, Lu et al.(2002)[12], Zhao

et al.(1999)[13] proposed static compressive residual

strength to define the damage variable, but the

control index of the mechanical properties of the

cement concrete pavement is the flexural tensile

strength. the results of the previous tests also

confirmed that the residual flexural tensile strength

of cement concrete pavement is decreasing under the

three factors of loading, high temperature and

wetting-drying cycle. Therefore, the residual flexural

strength of concrete is introduced as the damage

variable, and It is defined as the ratio of the concrete

flexural strength attenuation after a certain time to

the initial flexural strength of concrete. The formula

(1) is as follows:

0

0

f

ff

D

σ

σ

σ

−

=

(1)

σ f0: Flexural strength of concrete specimens in

initial state

σ f :Residual flexural strength of concrete

specimens subjected to damage

4.2 Residual Flexural Tensile Strength

Damage Model of Concrete Under

Loading ,High Temperature and

Wetting-Drying Cycle

4.2.1 Variation of Residual Flexural

Strength of Concrete Under Loading,

High Temperature and wetting-Drying

Cycle

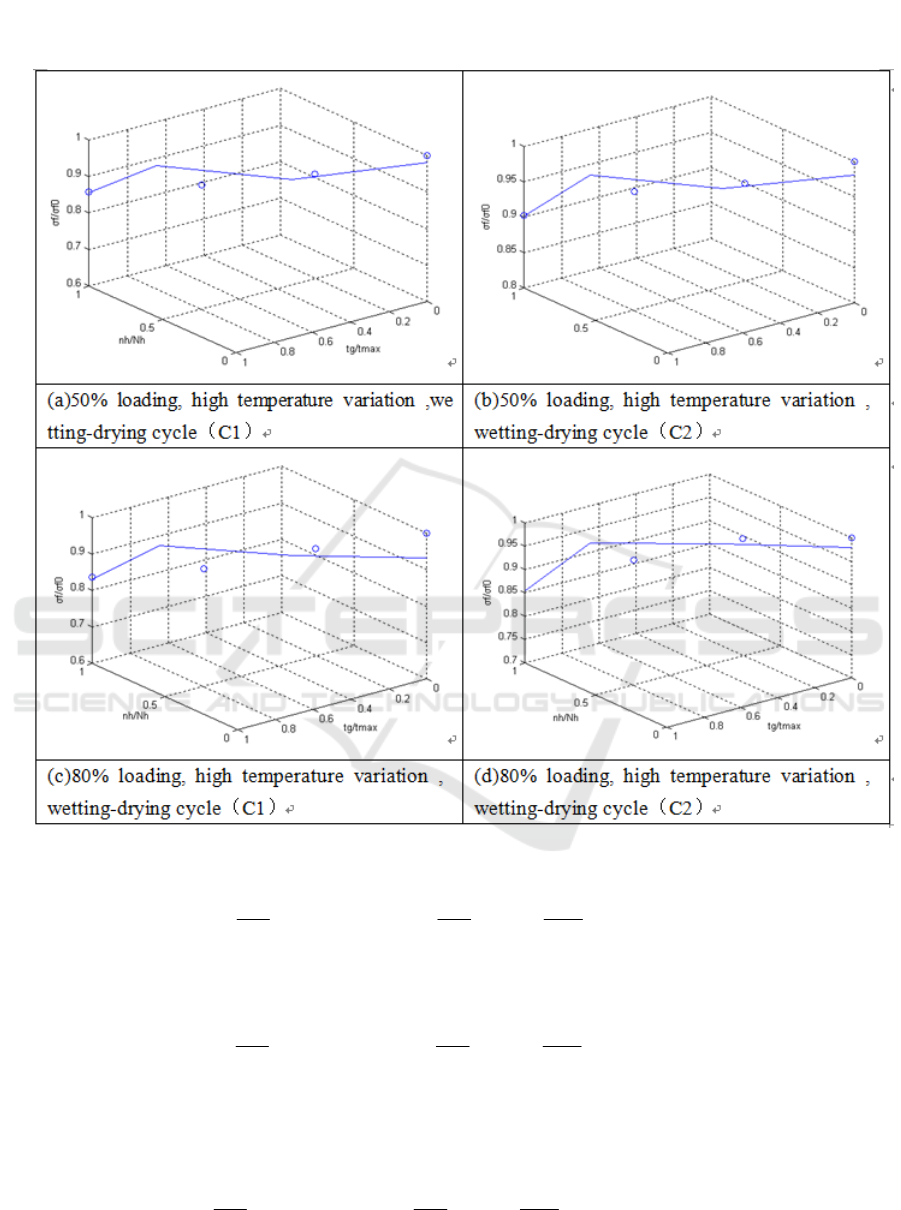

Scattered points distribution in Figure 1(a)-(d)

shows the variation law of the residual flexural

strength of C1 and C2 concrete under loading, high

temperature and wetting-drying cycle. Under this

condition, the flexural tensile strength of concrete

decreases with the increase of time, 80% stress level

significantly accelerated damage to concrete, the

lower the strength grade of concrete performance is

more significant. Under 50% and 80% stress level,

C1 concrete flexural strength decrease by 11.6% and

2.5% respectively, C2 concrete flexural strength by

10.4% and 4.8% respectively, compared with the

condition under loading of single factor. C1 concrete

flexural strength decrease by 33.4% and 3.4% lower

respectively, C2 concrete flexural strength by 31.9%

and 4.9% respectively, compared with the conditions

under loading and high temperature of double factor.

Compare the effects of the three factors, the order of

influence degree of concrete flexural tensile strength

is loading<high temperature<wetting-drying cycle.

When evaluating the mechanical properties value of

cement concrete pavement changing with time under

the condition of high temperature and wetting-

drying cycle,only consider the loading or consider

the effect of loading and temperature is not enough.

So it is necessary to introduce an influencing factor

to consider the humidity factor, and in the existing

two factors superimposed wetting-dryingcycle, will

produce a doubling damage effect.

4.2.2 Decreasing Model of Residual Flexural

Strength of Concrete Subjected to

Loading, High Temperature and

Wetting-Drying Cycle

Three variables of loading, high temperature and dry

wet cycle are needed in this model. Due to the

humidity and temperature have the characteristics of

adaptability and simultaneity,therefore, the residual

flexural tensile strength damage model of cement

concrete pavement is designed as two function

combinations: δ=F[f(nh), f(t)],n represents the

number of fatigue loading, t represents the time of

high temperature wetting-drying cycle.

The modeling idea is as follows: Query existing

literature, the concrete strength and the fatigue

loading approximate relation of power function.

Preliminary test indicates that there is a linear

relationship between the strength temperature,

humidity and the power exponent of time. Fatigue

damage formula under loading, high temperature

and wetting-drying cycle is as follows:(2)

(2)

δ/δf: The ratio of residual tensile strength to

maximum flexural tensile strength

nh/Nh: The ratio of loading times to fatigue life

t/tma: The ratio of the operating time and the

maximum test period under high temperature

wetting-drying cycle

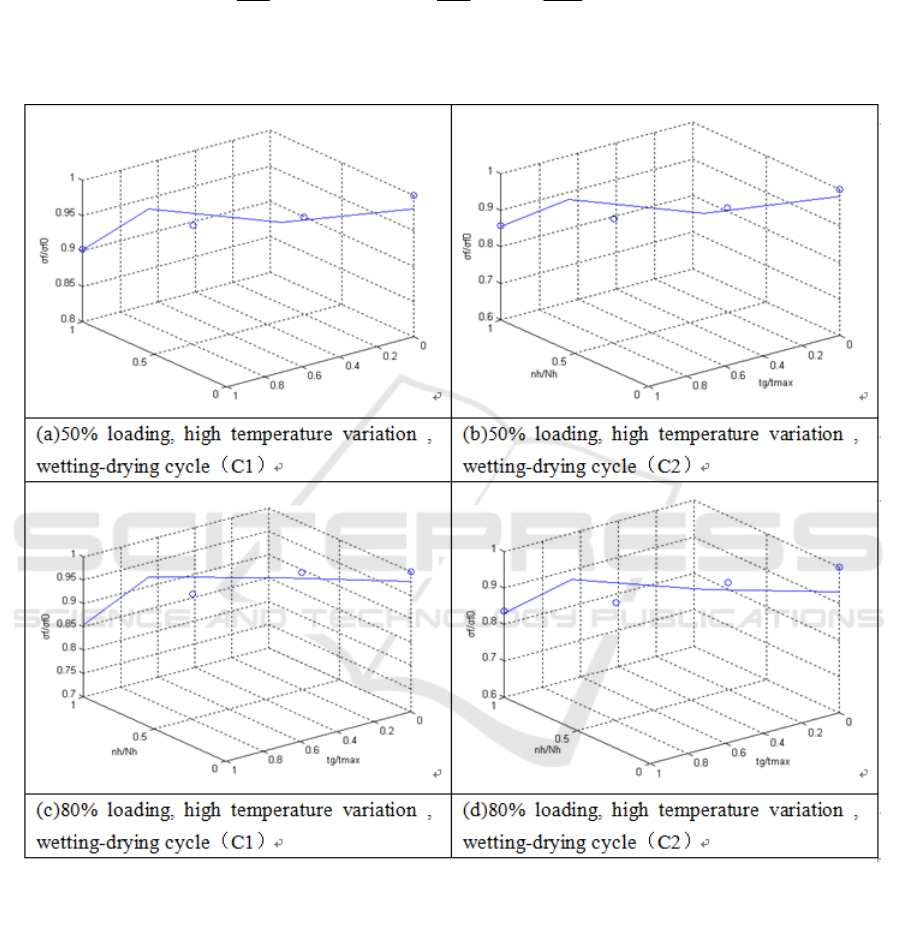

Multiple regression analysis (Formula 3-6) was

used to calculate the results, the complex correlation

coefficient is above 0.88. Table 2 shows the

comparison between the experimental values and the

predicted values using regression models, the results

show that the maximum prediction error is below

cb

h

h

f

t

t

N

n

aD )()1(1

max

•−•=−=

σ

σ

6.5%. It shows that the model has high prediction

accuracy. Figure 2 (a) - (d), the curve indicates the

change in the predicted value.

Fig. 1: Effect of loading, high temperature and wetting-drying cycle on the residual flexural tensile strength of concrete

(R

2

=0.935)

(C1 concrete under 50% loading high temperature difference wetting-drying environment)(3)

(R

2

=0.854)

(C2 concrete under 50% loading high temperature difference wetting-drying environment)(4)

(R

2

=0.944)

028.0

max

012.0

)()1(989.011

t

t

N

n

D

h

h

f

•−•−=−=

σ

σ

048.0

max

017.0

)()1(975.011

t

t

N

n

D

h

h

f

•−•−=−=

σ

σ

001.0

max

018.0

)()1(983.011

t

t

N

n

D

h

h

f

•−•−=−=

σ

σ

(C1 concrete under 80% loading high temperature difference wetting-drying environment)(5)

(R

2

=0.833)

(C2 concrete under 50% loading high temperature difference wetting-drying environment)(6)

Fig. 2: The residual flexural tensile strength prediction of concrete underthe loading, high temperature and wetting-drying

cycle environment.

037.0

max

020.0

)()1(968.011

t

t

N

n

D

h

h

f

•−•−=−=

σ

σ

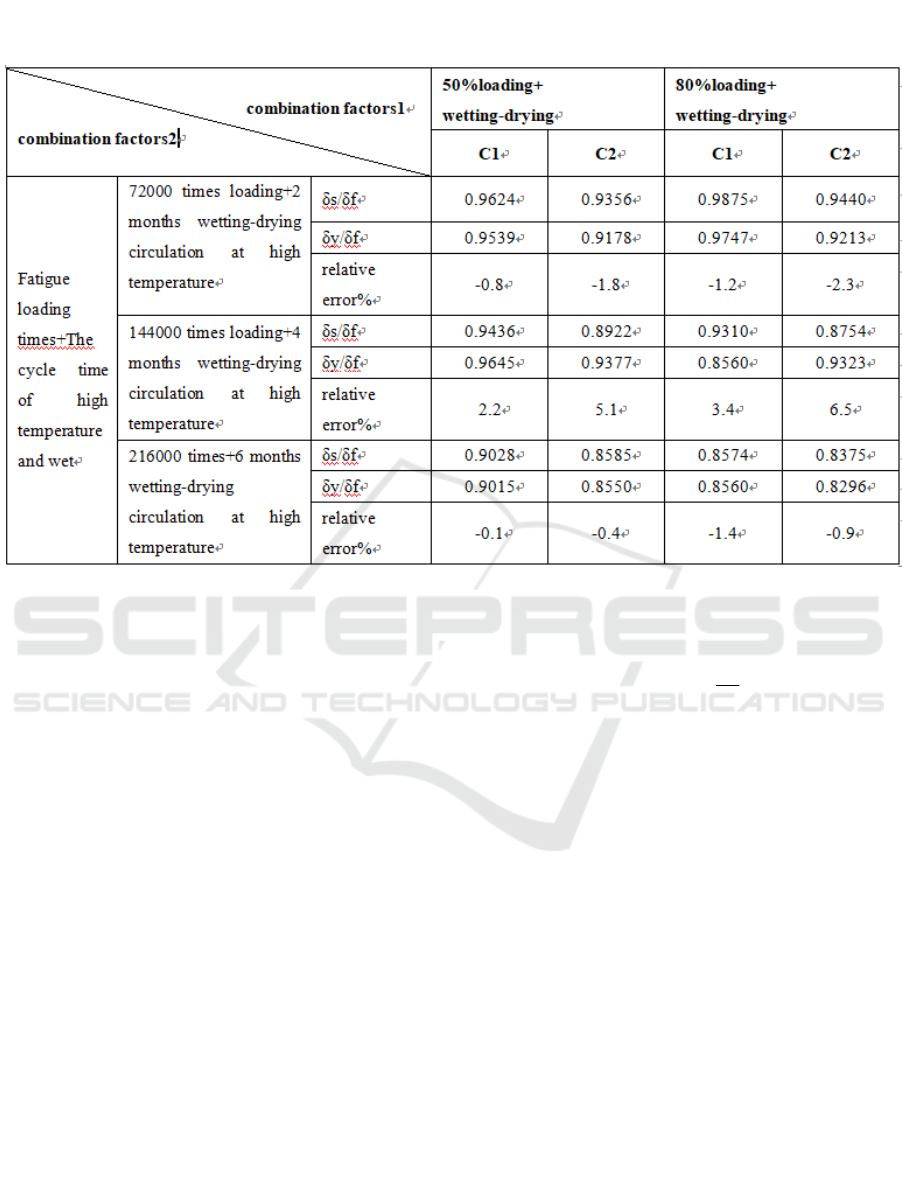

Table 2 Under the influence of three kinds of factors, such as loading, high temperature and wetting-drying cycle, the

predicted value of the damage model is compared with the experimental value.

Note:δsrepresents the flexural tensile strength of test, δy represents the predicted flexural tensile strength, δf represents the

ultimate flexural tensile strength

4.3 Fatigue Life Prediction Model of

Pavement Cement Concrete Under

Loading High Temperature and

Wetting-Drying Cycle.

In the 1850s, the German scholar Whǒler put

forward the concept of fatigue limit and characterize

the s-n curve equation of the fatigue life,. At present,

there are two expressions of concrete fatigue

equation (7) and (8), and the physical meaning of

each parameter is clear, so it is widely used.

However, due to the heterogeneity of concrete, the

fatigue life of discrete data is very large. In order to

model can better reflect the project objective

uncertainty, Weibull, a Swedish scholar, proposed a

two-parameter Weibull distribution function(9) with

a probabilistic physical quantity in 1939.Take

double logarithm of either side of the equation, if the

linear rule is satisfied, the test data are in accordance

with the Weibull distribution.

NbaS lg−=

(7)

NbaS lglg −=

(8)

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−−=

α

u

N

NP exp1)( (9)

N represents fatigue life, s represents Stress

level, a represents Height of fatigue curve (The

higher the value, the better the fatigue performance

of concrete), b represents the fatigue curve of the

speed of change (The higher the value, the more

sensitive to the stress level), P (N) Failure

probability, α is the slope of the Weibull function at

the stress level S, u presents dimension parameters.

In this paper in order to better compare the

advantages and disadvantages of the model,

regression analysis was performed for each model.

At the same time, in order to improve the accuracy

of the equation, the experimental test of the three

factors condition is added when the level is 0.7,

And each condition choose five samples for fatigue

test, The formula for calculating the failure

probability is P=i/(k+1)(I is the ith failure sample

ordinal, K is the total number of samples).

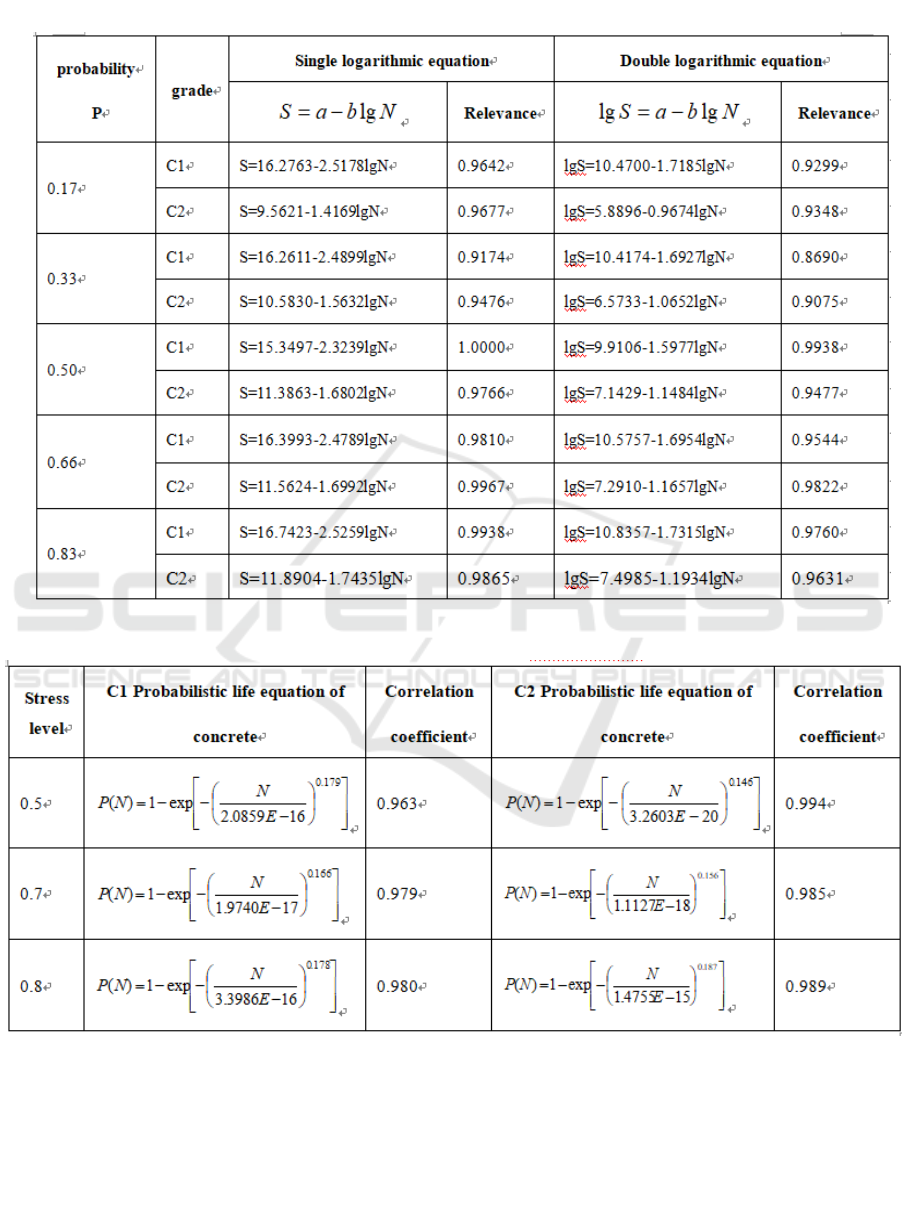

Table 3 fatigue life equation of concrete under loading high temperature and wetting-drying cycle.

Table4. Concrete probabilistic fatigue equation under loading hightemperature and wetting-drying cycle

Under the three conditions of loading, high

temperature and wetting-drying cycle and based on

the least square method,the fatigue life equation of

concrete is obtained to calculate the failure

probability of concrete. The correlation coefficient is

between 0.8690-1.0000 shown in Table 3, which has

high prediction accuracy and Using single

logarithmic equation has higher precision of

prediction. Therefore, in this paper, the single log

equation is recommended to predict the fatigue life

of cement concrete pavement under the condition of

loading, high temperature and wetting-drying cycle.

By using the Weibull distribution function for

data regression analysis. The mathematical equation

between the probability and the fatigue life under

different stress levels is shown in Table 4.The linear

correlation coefficient is above 0.963. It can be seen

that the fatigue life of pavement cement concrete is

more consistent with the Weibull distribution

function under the conditions of loading, high

temperature,

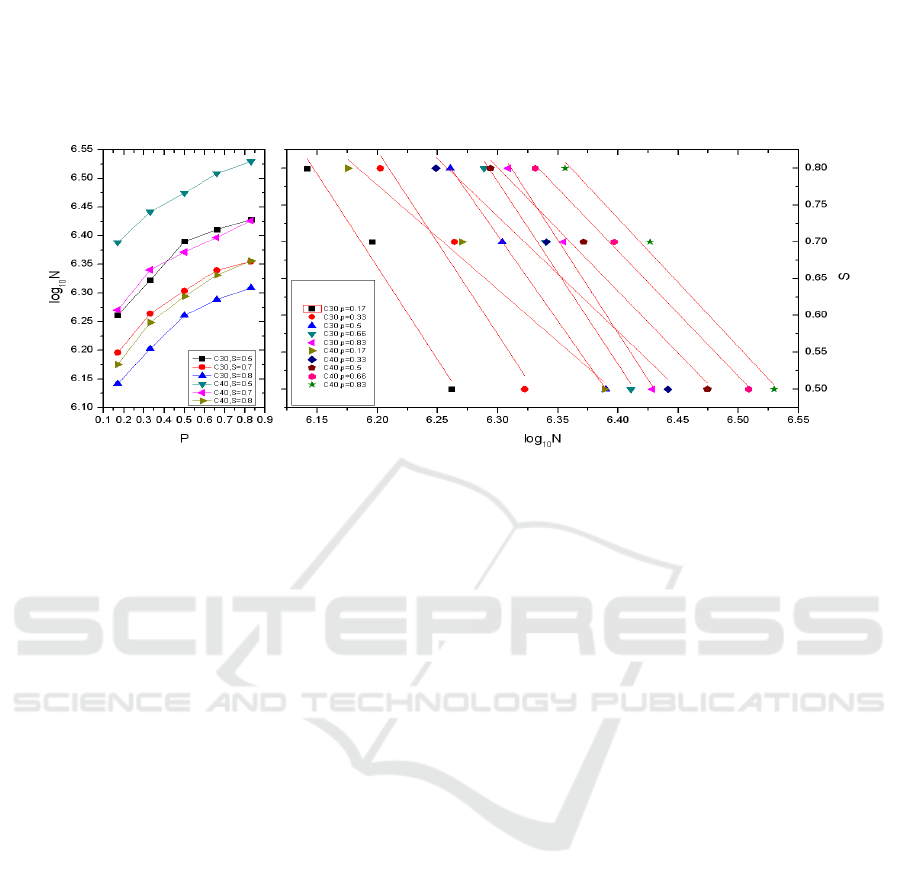

dry - wet cycle. In order to evaluate the stress level

and fatigue life of concrete under the conditions of

loading, high temperature, dry-wet cycle and

different failure probability, the drawing of the S-N-

P curve is shown in Figure 3.

Figure 3 S-N-P curve of pavement cement concrete under loading, high temperature and wetting-drying cycle

5 CONCLUSIONS

Research and analysis of residual fatigue strength

model and fatigue life prediction model of cement

concrete pavement under under the conditions of

loading, high temperature, wetting-drying cycle, the

main conclusions are as follows.

(1)It is feasible to use the residual bending

strength as a fatigue damage variable to characterize

the mechanical properties of pavement cement

concrete.The maximum prediction error is less than

6.5% when using the nonlinear equation of fatigue

damage of concrete subjected to loading, high

temperature and dry wet cycles to predict the

residual flexural strength of concrete under fatigue

loading. It can better reflect the attenuation law of

fatigue strength of cement concrete pavement.

(2)The single-logarithmic S-N curve equation

has higher prediction accuracy when calculate the

fatigue life of pavement cement concrete under the

conditions of loading, high temperature and dry-wet

cycle.

(3)The fatigue life of pavement cement concrete

under the conditions of loading, high temperature

and dry-wet cycle conforms to Weibull distribution.

The correlation coefficient of failure probability and

fatigue life of concrete under different stress levels

is above 0.945.

ACKNOWLEDGEMENTS

This research was supported by Guangxi Natural

Science Foundation under Grant No. GUIKE

AB17292032,GUIKE AC16380109 and National

Nature Science Foundation of China(51278059).

REFERENCES

1. Baluch M H, Al Gadhib A H . Khan A R . et

a1.CDM model for residual strength of concrete

under cyclic compression [].Cement and Concrete

Composites,2002,25(12):503-512

2. Shi Xiao-ping. Study on flexural fatigue behavior of

cement concrete[J]. China Civil Engineering

Journal,1990,23(3):11-22.

3. Li Zhao-xia. Damage mechanics and its

application[M]. Beijing: Science Press. 2002:12-41

4. Li Yong-qiang,CheHui-min. Study on concrete fatigue

performance under constant amplitude repeated

stress[J].Journal of the China Railway

Society,1999,21(2):76-79

5. Jia Shao-wen. Continuum damage mechanics-based

fatigue damage model for concrete[D]. Harbin: Harbin

Institute of Technology,2009.

6. Meng Xian-hong. Experimental and theoretical

research on residual strength of concrete under fatigue

loadinging[D]. Dalian: Dalian University of

Technology, 2006.

7. Pan Hua, Qiu Hong-xing. Fatigue model of concrete

based on continuum damage mechanics[J]. Journal of

Southeast University(Natural Science Edition),

2006,36(4):605-608

8. Meng Xian-hong,,Song Yu-pu. Damage model for the

residua strength of concrete under compression fatigue

loadinging[J]. Journal of Harbin Institute of

Technology(New Series),2009,25(1):12-16.

9. JOAN R C.CESAR C M.Probabilistie response of

prestressed concrete bridges to fatigue[J]. Engineering

Structure,1998,20(11):940-947.

10. Chen Shuan-fa, Zheng Mu-lian, Wang Bing-gang.

Formulation and application of fatigue equation for

porous cement concrete[J], Journal of the Chinese

ceramic society, 2005,33(7):827-831

11. Zheng Mu-lian, Sun Jia-wei, Wang Bing-gang. Study

on formulation and application of fatigue equation for

lean concrete[J]. Journal of Xi’an University of

Architecture &Technology(Natural Science Edition),

2007,39(1):92-97.

12. LU Jing-zhou,LINGao,WANGZhe,XIAO Shi-yun. On

the reduction of strength of concrete and supersonic

inspection due to triaxial compressive loading

history[J].Engineering Mechanics.2002,19(5):52-57

13. Yong-li ZHAO,WeiSUN.Establishment of fatigue

damage equation of concrete materials[J].Journal of

Chongqing Jiaotong University,1999,18(1):17-22.