Mechanical Clinching Technology of the Lightweight Sheets

Yulin He

1

, Lianfa Yang

2

* and Kuang Yang

3

123

School of Mechanical & Electrical Engineering, Guilin University of Electronic Technology,

Guilin, Guangxi, China

Keywords: sheet joining, dieless clinching, hole clinching, flat clinching, roller clinching

Abstract: Aluminum alloy, magnesium alloy and other lightweight materials have been widely used in the lightweight

body. The mechanical clinching does not require additional parts and is a kind of green connection

technology, which has a broad development prospect in connecting lightweight materials. The scholars have

studied the process about this technology and have put forward some reliable connection methods. In this

paper, these methods are classified into two types according to the movement forms of the punch is vertical

or composite in the clinching process. The working principle and characteristics of the typical methods of

each type are mainly described in detail.

1 INTRODUCTION

In recent years, various kinds light materials (such as

aluminum alloy, magnesium alloy, composite

material and plastic) have been widely used in

automobile manufacturing with the development of

automobile light weight technology. There are many

ways to connect these different materials, such as

self-pierce riveting, mechanical clinching and

friction stir welding. The mechanical clinching

technology is very suitable for connection sheets of

dissimilar materials by the plastic deformation of the

sheet to create mechanical interlock to realize the

connection without pre-treatment, with high

production efficiency, simple operation and good

forming effect of the joints. It has broad

development prospects in the manufacture of

lightweight car body. For improving the strength and

quality of the joint, some researchers have carried

out correlative studies on this technology and many

connection methods are proposed.

These methods are classified into two types:

single-action clinching and multi-action clinching,

according to the movement forms of the punch

during the clinching process. The working principle

and characteristics of the typical connect methods of

each type are mainly described in detail.

2 SINGLE-ACTION CLINCHING

Single-action clinching is that the movement of

punch is single direction during the clinching

process, it mainly includes dieless clinching, flat

clinching, hole clinching etc.

2.1 Dieless Clinching

The principle of dieless joining by forming

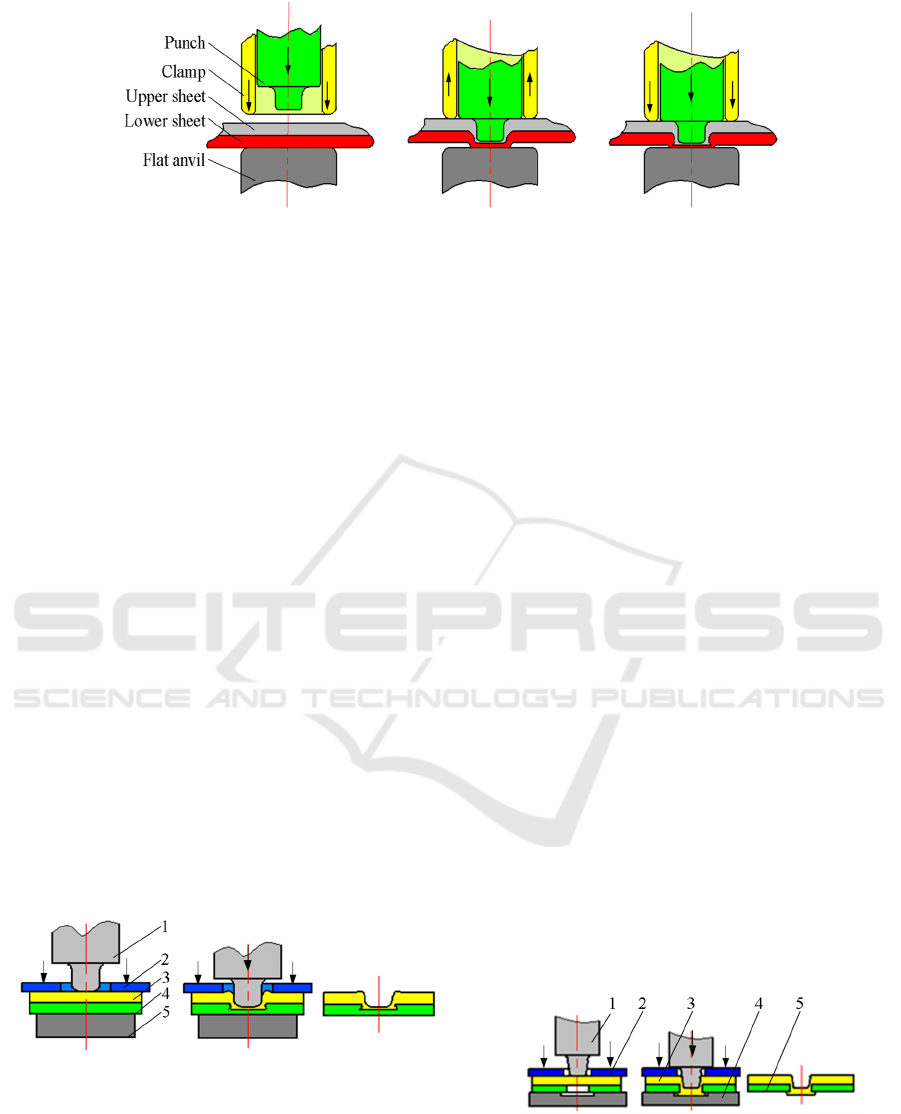

should be explained in detail in Figure 1 (

Neugebauer,

2007

). The components required for joining are the

punch, clamp, the upper sheet, the lower sheet and

the flat anvil. Firstly, these two sheets to be joined

are lying partially overlapped on the flat counter

tool. After that, for forming the clamp and the punch

move towards the sheets, the clamp gets into contact

to the upper sheet and a limited pressure is applied

without deforming. Then the punch is pressed into

the sheets with a high force. The material of the

sheets is displaced partially and flows in the

opposite direction to the movement of the punch,

thereby pushing the clamp upwards. Thus an

elevation is formed on the downside of the bottom

sheet. The size of this elevation is increasing the

further the punch is pressed into the sheets. As soon

as the material of the upper sheet has come into

contact with the shoulder of the punch, the material

flow against the movement of the punch is stopped.

Finally, when the punch is pressed even further, the

elevation at the downside of the bottom sheet is

flattened and the material displaced by the punch is

Figure 1: Principle of dieless clinching.

forced to flow in radial direction, thus forming an

interlock between the sheets. Compared to joining

by forming processes with a contoured die, dieless

joining has the following features (

Neugebauer, 2005

):

the wear of mold is low, the accuracy of the joining

equipment is less, and don’t require alignment, the

process reliability is high, but the joining force is

higher and the combined thickness of the connected

sheets is limited.

2.2 Flat Clinching

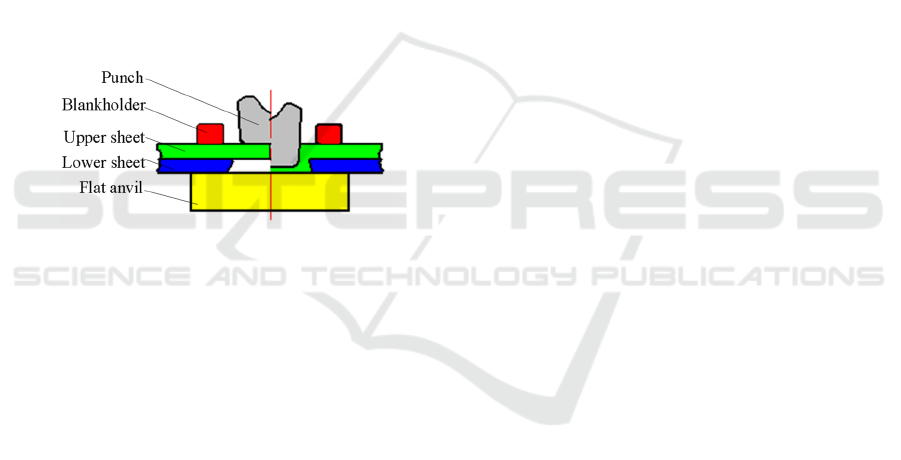

Figure 2 shows the process of flat clinching

(Neugebauer, 2007). The flat clinching is based on

the same principle as dieless clinching. The

components required for joining are the punch 1 ,

blank holder 2 , joint sheets 3and 4, the flat anvil 5.

Firstly, the two joined sheets are placed up on a flat

anvil. Afterwards, the blank holder moves down and

fixes the sheets in place. Subsequently, the punch

moves down and forms the material to establish the

characteristic interlocking within the total material

thickness.

Figure 2: Principle of flat clinching.

In contrast to other clinch connections, the

material flow is opposite to the punch movement

during the process, a one sided planar connection is

created that does not show the die-sided protrusion

reaching out of the material plane, so the flat

clinching can be used for the connection of metal

sheets to nonmetal sheets.

2.3 Hole Clinching

Schematic diagram of hole-clinching as shown in

Figure 3 (Chan-Joo, 2014), it is similar with the

process of flat clinching. The parts for the

connection are the punch 1, the holder 2, the upper

sheet 3, the lower sheet 4 and the die 5 with the

circular groove. In the hole-clinching process, the

ductile material is positioned uppermost and the

brittle material-into which a hole is formed is

positioned below that. At first, the holder presses the

upper sheet, and the upper sheet is squeezed into the

gap between the punch and the lower sheet. when

the upper sheet contacts the die bottom, it is

indented into a die cavity through the hole in the

lower sheet and spread out to fill the cavity in the die

to form geometrical interlocking.

Figure 3: Schematic diagram of hole-clinching process.

The hole-clinching is suitable for joining

different sheet in mechanical properties, but the

material with reduced formability on the die-side

must be pre-punched and the costs would increase;

there are protrusions at the joints and joints cannot

be created if the lower sheet is too thick.

2.4 Flat Hole-Clinching (FHC)

The principle of flat hole-clinching as shown in

Figure 4 (Tong, 2016). The flat is based on the same

principle as hole-clinching. It is different from the

hole-clinching, the hole of the flat hole-clinching is

stepped or inverted conical, there are not protrusions

at the joints too. This technique is fit for connecting

two layers of metallic sheets with dissimilar

materials and thicknesses by adding additional parts

to adjust the depth of the hole.

Figure 4: The principle of flat hole-clinching.

2.5 Injection Clinching

A detailed illustration of the injection clinching

process is shown in Figure 5 (Abibe, 2011). For the

material flowing during the process, there is a round

cavity at the bottom of the blank holder, a gap

between the hole and the stud that the lower plate

with a deformation element (normally a cylindrical

or cone stud). firstly, the joined sheets are assembled

together, inserted into the hole of the upper sheet,

the blank holder moves down and clamps the joined

plates with designed pressure; Afterwards, the punch

moves down to the plates and applies forming

pressure on the stud, to force it into the cavity in the

blank holder and the upper plate’s hole; then the

forming pressure is maintained to fully fill the round

cavity and gap; finally, the punch retracts and the

joint is formed.

In This technology creates a rivet by using part

of the structure itself, resulting in weight savings and

improved mechanical reliability. It is suitable for the

connection between metal to metal, metal to non-

metallic material (e.g. metal and thermoplastic

material).

2.6 Hydro-Clinching

Figure 6 shows the forming process of hydro-

clinching (Neugebauer, 2008), it is made up of the

punch 1, hydroforming tool 2, jointed sheet 3,

hydroformed sheet 4 and fluid 5. Firstly, the

hydroformed sheet and the jointed sheet are brought

in contact to the hydroforming tool by the fluid.

During calibration the fluid works as a punch to

press the hydroformed sheet through a hole in the

jointed order to avoid bursting and to ensure a higher

forming level at the produced protrusion, the punch

is withdrawn. Subsequently, the punch is set towards

the high pressure fluid. Because the back forming is

prevented by the high pressure fluid, the material

that has been pressed through the hole is spread and

formed an interlock at the chamfering of the

connected sheet. During joining process, the punch

is not moving, the interlock forms automatically at

the hole chamfering of the joined sheet when the

hydroformed sheet is pushed through the hole.

The hydro-joining process decreases the number

of processing steps and can join in complex

hydroformed units and inaccessible places, but the

device needs to be sealed and higher pressure when

connecting thick sheets.

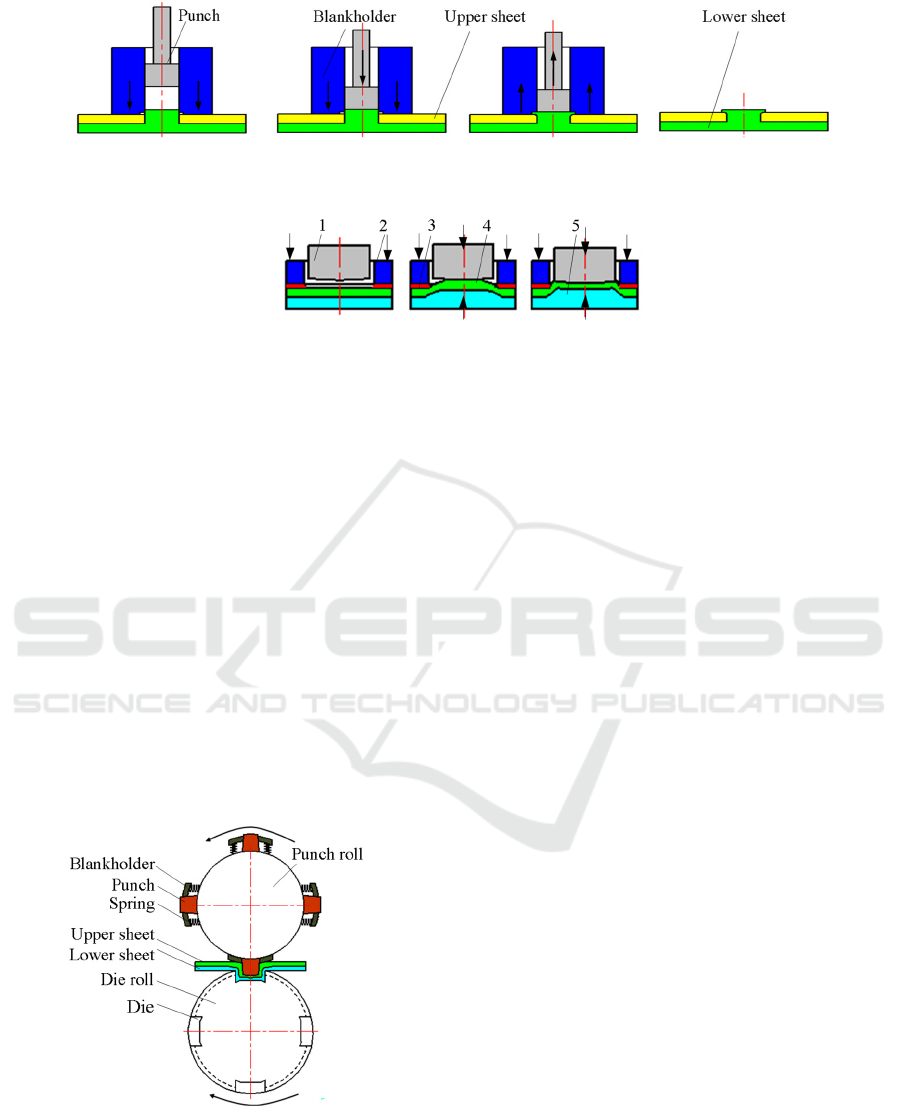

2.7 Roller Clinching

The schematic setup for rolling clinching is depicted

in Figure 7 (Daniel, 2014).

Figure 5: The stages of the injection clinching process.

Figure 6: The forming process of hydro-clinching.

The movement of punch is only rolling. Punches and

dies are mounted on contrariwise rotating rolls.

During clinching, the punch roll and die roll rotate

contrariwise, with the angular velocity and the sheet

is continuously fed through the rollers. A spring-

suspended blank holder prevents the material from

an extrusion out of the die cavity. It ensures a proper

separation of the obtained clinching point from the

tools. This process can be divided into four distinct

phases: initial contact, drawing phase, forming the

undercut and retraction.

The rolling radius have significant influence on

the joint formation and therefore on the joint’s

mechanical properties for the employed material

combinations, and the variation of the rolling radius

will result in an symmetry of the neck or the

undercut.

Figure 7: The schematic setup for roller clinching.

3 MULTI-ACTION CLINCHING

The multi-action clinching is that the movement of

punch is multy during the clinching, there are

rotational motion and vertical motion and so on. It

mainly cludes friction clinching and spinning

clinching.

3.1 Friction Clinching

The friction clinching is that the punch rotates at a

given speed and plunges the material (under load

control) up to reaching a given depth; then, the

punch is retracted up to the initial position to finish

the clinching, as shown in the Figure 8 (Lambiase,

2017). Due to the rotation of the punch, so the

friction between the punch and the connected sheet

material is produced, that the connecting plate is

heated and the join-ability is greatly improved.

The friction clinching can be used on highly

reflective materials (such as aluminum and copper

alloys), the heating is confined in the joint position

so the plunging force is dramatically reduced, and

the development of cracks in the aluminum alloy

was delayed or even avoided.

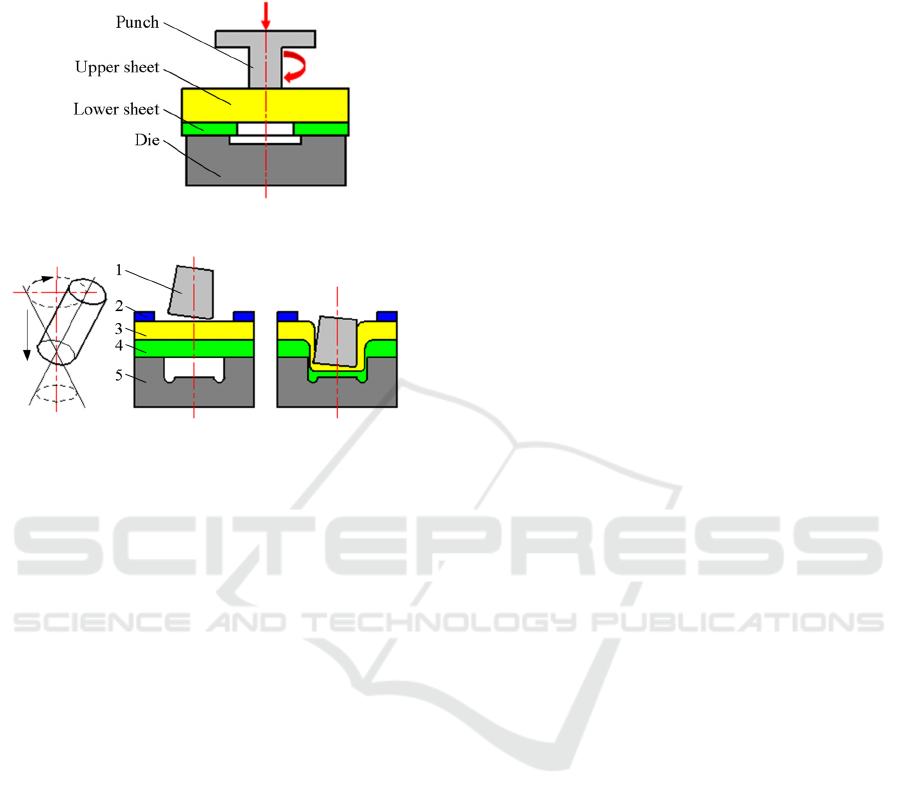

3.2 Spinning Clinching

The principle of spinning clinching is shown in

Figure 9 (Zhi-chao, 2011). It is composed of the

punch 1, blankholder 2, upper sheet 3, lower sheet 4

and die 5. The punch turns around the axis in an

acute angle continuously and vertically downward to

exert pressure on the sheet to form interlock during

the clinching process. Compared with the ordinary

clinching, the spinning clinching has the advantages

of larger interlock value, smaller forming load and

higher efficiency, but the joint exists an asymmetry.

Figure 8: The principle of friction clinching.

Figure 9: The principle of spinning clinching.

4 CONCLUSIONS

In addition to the above the mechanical clinching

technology of the sheet, there are some other

auxiliary connection technology, such as ultrasonic

assisted clinching , laser clinching, vibration assisted

clinching, etc. The main purpose of these methods

are to increase the strength of joint, to improve the

connection quality and decrease the forming force

and to join the different sheets. No matter what kind

of methods, the strength of joint has a great

relationship with the geometry of clinched joint,

while the technological parameters, geometric

parameters and material flow have important effects

on the joint shape and size, therefore, it is necessary

to find some new connection methods to further

research by using numerical simulation calculation

and experimental method.

ACKNOWLEDGMENT

The authors would like to acknowledge the support

of Guangxi Natural Science Foundation

(2015GXNSFBA139223) and Guangxi university

student innovation and entrepreneurship training

program (201610595088).

REFERENCES

1. Neugebauer R., Reimund Neugebauer, Dietrich S.,

Kraus C., 2007. Dieless clinching and dieless rivet-

clinching of magnesium. Key Engineering Materials.

2. Neugebauer R., Mauermann R., Dietrich S., 2005.

Chances and challenges in joining by forming with flat

a counter tool. Advanced Materials Research.

3. Neugebauer R., Reimund Neugebauer, Dietrich S.,

Kraus C., 2007. Joining by Forming With a Flat

Counter Tool – a New Way of Joining Magnesium

Components. Materials Science Forum.

4. Chan-Joo L., Jung-Min L., Ho-Yeon R., et al, 2014.

Design of hole-clinching process for joining of

dissimilar materials Al6061-T4 alloy with DP780 steel,

hot-pressed 22MnB5 steel, and carbon fiber reinforced

plastic. Journal of Materials Processing Technology.

5. Tong W., Qian H., Qing L., et.al, 2016. Joining

different metallic sheets without protrusion by flat

hole clinching process.Internationa Journal Advanced

Manuf acutoryTechnology.

6. Abibe AB, Amancio-Filho ST, Dos Santos JF, et al,

2011. Development and analysis of a new joining

method for polymer-metal hybrid structures. Journal

Thermoplast Composite Mater.

7. Neugebauer R., Mauermann R., Grützner R., 2008.

Hydrojoining. International Journal of Material

Forming.

8. Lambiase F., Paoletti A., Di Ilio A., 2017. Advances in

Mechanical Clinching Employment of a rotating tool.

SHEMET17, 17th International Conference on Sheet

Metal, Procedia Engineering.

9. Zhi-chao H., Zu-feng Q., Lian-hong P., Jia-mei L.,

2011. Comparison of Numerical Simulations Between

Spin Clinching and Ordinary Clinching. Coal Mine

Machinery. (In Chinese)

10. Daniel R., Maria W., Hartmut H., 2014. Simulation

Assisted Analysis of Material Flow in Roller Clinched

Joints. Advanced Materials Research.