Effects of Particle Agglomeration and Interphase on Nonacomposites

Jing Pan

1,a

, Li-chun Bian

1,b

and Ming Gao

1,c

1

Key Laboratory of Mechanical Reliability for Heavy Equipments and Large Structures of Hebei Province

Yanshan University, Qinhuangdao 066004, PR China

Keywords: Particle, agglomeration, interphase, Composite.

Abstract: In this paper, a simple approach is described to investigate the effects of particle content, presence of

interphase and agglomeration on the effective modulus of nanocomposites. A new micromechanical

agglomeration model and the Mori-Tanaka method are applied to account for these effects. In the process of

derivation, the composite is divided into two parts and the particles encapsulated by an interphaseare

regarded as a system. The main effects of nanoparticle radius and interphase thickness, as well as interphase

properties, on elastic modulus of nanocomposites are also discussed. The findings show that the

nanoparticle agglomeration significantly reduces the effective elastic modulus of composites.

1 INTRODUCTION

Particle-reinforced composites have been received

much attention due to their advantages over

conventional materials (Cheng et al., 2014; Odegard

et al., 2004; Pontefisso et al., 2013). The exceptional

properties of nanocompositesare related to small

particle size, which results in great

interfacialproperties between nanofiller and polymer

matrix.The properties of interphase in polymer

composites are often different from those of bulk

polymer matrix, which may include chemical,

physical, microstructural, and mechanical properties.

The nature of interphase is critical to the overall

properties and performance of polymer materials, in

particular in nanofiller reinforced composites (Xu et

al., 2016).The small size and high surface per unit

volume of nanoparticles leads to strong attractive

interaction between particles. So the nanoparticles

can be easily agglomerated when added to matrix

(Zare et al., 2017; Zare, 2016).

In recent years, several theoretical investigations

on particles agglomeration and interphaseproperties

have presented much information to attain desirable

properties in nanocomposites.Effect of inter-particle

interactions on the effective dielectricconstant was

calculated as a function of filler volume

fraction,packing density of particles inside

agglomerates and agglomerate size (Golbang et al.,

2017).Afinite element modelling is utilized to

investigate the effect of nanoparticle agglomeration

on the glass transition temperature of polymer

nanocomposites (Qiao et al., 2011). The Halpin-Tsai

micromechanical model is modified to account for

theeffect of interphase and filler agglomerates and

the model predictions for the effective modulus of

the composites arecompared to the experimental

data. The interphase width and modulus and

theagglomerate size were determined based

onatomic force microscopy (Karevan et al., 2010). A

straightforward analytical approach is presented to

estimate effective elastic properties of composites

comprising particles encapsulated by an interphase

of finite thickness and distinct elastic properties.

This explicit solution can treat nanocomposites that

comprise either physically isolated nanoparticles or

agglomerates of such nanoparticles (Deng and Van

Vliet, 2011).

2 AGGLOMERATION MODEL

Dispersion and agglomeration control the

macroscopic properties of nanocomposites, thus,

quantitative characterization of particle dispersion

and agglomeration is crucial. According to the

theoretical and experimental research, the particles

are easy to agglomerate in matrix. In order to study

the effect of particles agglomeration, we proposed

an agglomeration model as shown in Figure 1.

m

L ,

I

L and

p

L

are the stiffness tensor of matrix,

interphase and particle, respectively. The stiffness

tensor of composites and agglomerated particles are

denoted by

L

and

a

L . In the present model,the

particles encapsulated by an interphaseare

considered as a system. The entire composite is

divided into two parts: one part is the particle

agglomeration regions, the other part is randomly

dispersed particles in matrix.

Figure 1: The agglomeration model of nanoparticles.

2.1 Theory Formula

According to the above analysis, the volume

fractions of matrix, particle and interphase are

defined by

m

f

,

p

f

and

I

f

. So, we get:

1

pIm

fff++ =

(1)

The volume fraction of interphase is related to

that of particle, so, we have:

()

3

11

Ip

ff tr

⎡⎤

=+−

⎣⎦

(2)

Based on the present model, we introduce an

agglomeration parameter

ξ

to describe the

agglomerated degree of particles.

a

VV

ξ

=

(3)

here

a

V and

V

are the total volume of particles

agglomeration regions and representative volume

element, respectively. The volume ratio of particles

that are dispersed in agglomerated regions and the

total volume of the particles is denoted by

λ

.

p

a

p

VV

λ

=

(4)

Equations (1)-(4) correspond to Fig. 1 and they

will be applied in the following analysis.

2.2 The Effective Modulus of

Composites

The effective modulus of composites based on Mori-

Tanaka method is expressed as follow:

)

1

(1 )( )

ab

b

bab

KK

KK

KKK

ξ

αξ

⎡

⎤

−

=+

⎢

⎥

+− −

⎣

⎦

(

(5)

)

1

(1 )( )

ab

b

bab

GG

GG

GGG

ξ

βξ

⎡

⎤

−

=+

⎢

⎥

+− −

⎣

⎦

(

(6)

Here,

K

and

G

are bulk modulus and shear

modulus of composites.

α

and

β

are constants, and

related to the Poisson’s ratio of the materials.

In the same way, the bulk modulus

a

K and shear

modulus

a

G of agglomeration regions can be

derived.

1

2

()

1

()

Ipa m

am

mm Ipa m

cK K

KK

KcKK

α

⎧

⎫

−

⎪

⎪

=+

⎨

⎬

+−

⎪

⎪

⎩⎭

(7)

1

2

()

1

()

Ipa m

am

mm Ipam

cG G

GG

GcGG

β

⎧

⎫

−

⎪

⎪

=+

⎨

⎬

+−

⎪

⎪

⎩⎭

(8)

here,

1

()

pI

c

ff

λ

=+

()

2 pI

c

ff

ξλ

=− +

The bulk modulus

b

K and shear modulus

b

G of

random dispersed particles reinforced composite are

as follow:

3

4

()

1

()

Ipb m

bm

mm Ipb m

cK K

KK

KcKK

α

⎧

⎫

−

⎪

⎪

=+

⎨

⎬

+−

⎪

⎪

⎩⎭

(9)

3

4

()

1

()

Ipb m

bm

mm Ipbm

cG G

GG

GcGG

β

⎧

⎫

−

⎪

⎪

=+

⎨

⎬

+−

⎪

⎪

⎩⎭

(10)

here,

3

(1 ) (1 )

pI

cf f

λλ

=−+−

()

4

1(1)(1)

pI

cff

ξ

λλ

⎡

⎤

=− − − + −

⎣

⎦

The bulk modulus

Ipa

K

and shear

modulus

Ipa

G

of particle-interphase system in

agglomerated regions can be expressed.

5

6

()

1

)

pI

Ipa I

IIpI

cK K

KK

KcKK

α

⎧⎫

−

⎪⎪

=+

⎨⎬

+−

⎪⎪

⎩⎭

(11)

5

6

()

1

()

pI

Ipa I

II pI

cG G

GG

GcGG

β

⎧⎫

−

⎪⎪

=+

⎨⎬

+−

⎪⎪

⎩⎭

(12)

here,

5 p

c

f

λ

=

,

6 I

cf

λ

=

.

Similarly, the bulk modulus

Ipb

K

and shear

modulus

Ipb

G

of particle-interphase system randomly

dispersed in the original matrix.

7

8

()

1

()

pI

Ipb I

II p I

cK K

KK

KcKK

α

⎧⎫

−

⎪⎪

=+

⎨⎬

+−

⎪⎪

⎩⎭

(13)

7

8

()

1

()

pI

Ipb I

II pI

cG G

GG

GcGG

β

⎧⎫

−

⎪⎪

=+

⎨⎬

+−

⎪⎪

⎩⎭

(14)

here,

7

(1 )

p

cf

λ

=−

,

8

(1 )

I

cf

λ

=−

The effective elastic modulus of composite

consists of two parts have obtained. In the process of

analysis, the particles agglomerated state and radius,

as well as the interphase thickness and properties are

also considered.

3 RESULTS AND DISCUSSION

In this part, the effect of particles agglomeration on

the effective modulus of composites is predicted.

Moreover, the influences of particle radius and

interphase thickness are discussed. The materials

properties are from Cheng’s work (Cheng et al.,

2014).

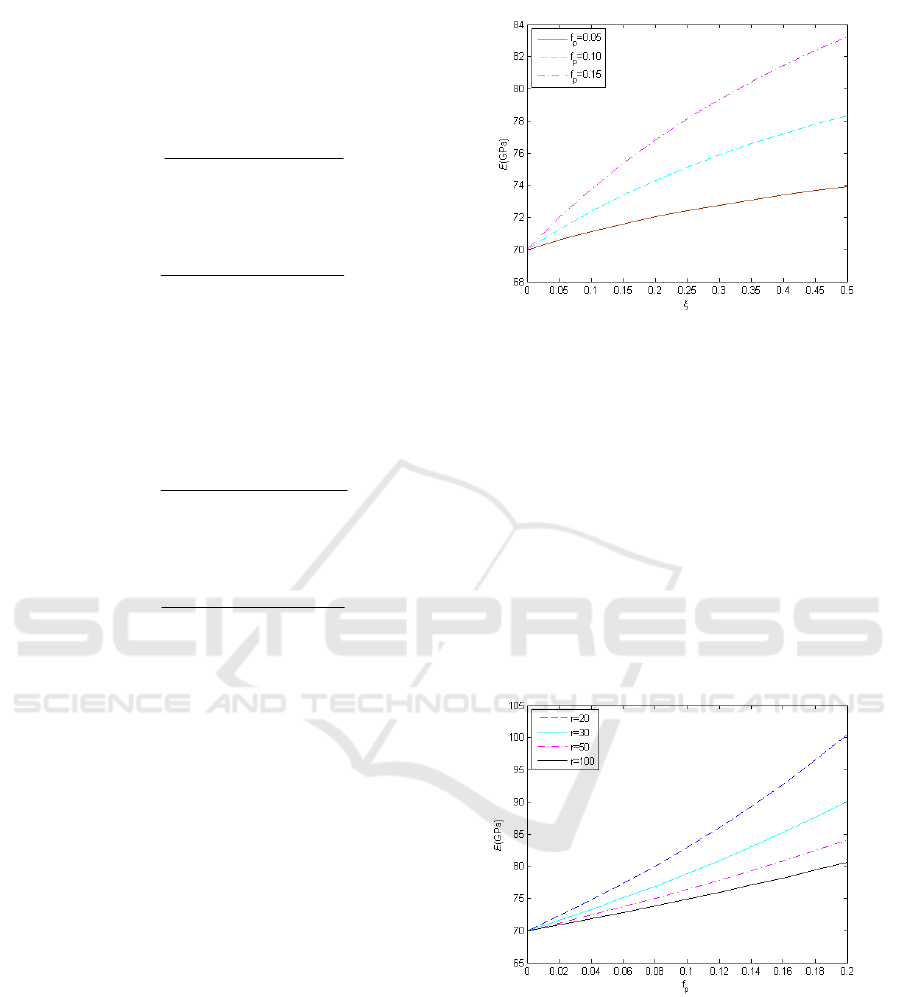

Figure 2: The variation of effective modulus of composites

with agglomeration parameter

ξ

.

Figure 2 presents the variation of effective

modulus of composites with agglomeration

parameter

ξ

. It can be seen that the effective

modulus of composites monotonically increases with

the increase of agglomeration parameter

ξ

. The

reason could be that the particles agglomeration

more loosely with increasing parameter

ξ

. With

increasing the volume fractions of particles, the

effective modulus of composites increases. So, the

increase of particles volume fraction apply to a

reinforcing effect for the composites.

Figure 3: The variation of elastic modulus of composites

with particles radius at different particles volume fraction.

The effect of particle radius on the elastic

modulus of composites is depicted in Figure 3. The

elastic modulus of composites decreases with the

increase of particles radius as shown in Figure 3.

Therefore, the increase of particle radius reduces the

effective elastic modulus of composites. But, the

increase of particles volume fraction increases the

effective elastic modulus of composites.

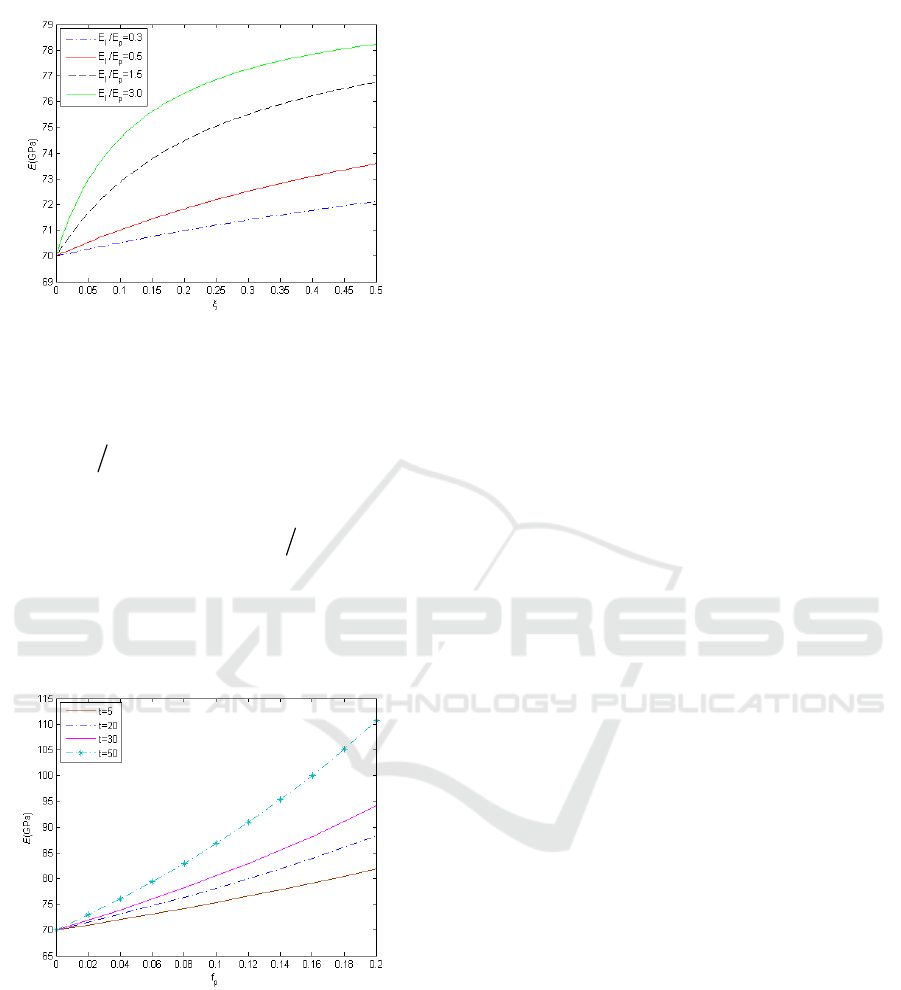

Figure 4: The effect of interphase properties on the elastic

modulus of composites.

Figure 4 depicts results of elastic modulus of

composites versus relative interphase

stiffness

Ip

E

E

based on the present approach. It is

found from Figure 4 that the effective modulus

increases with the increase of both the

relativeinterphase stiffness

Ip

E

E

and the

agglomeration parameter

ξ

. That is, for a given

particle stiffness

427GPa

p

E =

, an increase in

interphase stiffness increases the elastic modulus of

composites.

Figure 5: The effect of interphase thickness on the

effective elastic modulus of composites.

The effect of interphase thickness on the

effective elastic modulus of composites is shown in

Figure 5. The effective elastic modulus of

composites increases with the increase of both

interphase thickness and particles volume fraction.

The increase of interphase thickness and particles

volume fractions play an important role in

improving the effective properties of composites.

4 CONCLUSIONS

In this article, a new particle agglomeration model is

proposed to study the influences of particle radius

and interphase thickness on the effective modulus of

composites. In the process of derivation, an

agglomeration parameter is introduced to denote the

agglomerated degree of particles. The calculated

results show that the agglomerated particles and

interphase properties have a significant effect on the

composites. The nonuniform dispersion of particles

in the matrix reduces the overall stiffness of

composites.

ACKNOWLEDGEMENTS

This research was supported by the Science

Research Foundation of Hebei Advanced Institutes

(ZD2017075) and Graduate Innovation Research

Assistant Support Project of Yanshan University

(CXZS201708).

REFERENCES

1. Cheng Y, Bian L, Wang Y, et al., 2014. Influences of

reinforcing particle and interface bonding strength on

material properties of Mg/nano-particle composites.

International Journal of Solids & Structures,

51(18):3168-3176.

2. Odegard G M, Clancy T C, Gates T S., 2005.Modeling

of the mechanical properties of nanoparticle/polymer

composites. Polymer, 46(2):553-562.

3. Pontefisso A, Zappalorto M, Quaresimin M., 2013.

Influence of interphase and filler distribution on the

elastic properties of nanoparticle filled polymers.

Mechanics Research Communications, 52(4):92-94.

4. Xu W, Zeng Q H, Yu A B, et al., 2017.Determination

of Interphase Thickness and Mechanical Properties of

Effective Nanofillers in Polymer Nanocomposites by

Molecular Dynamic Simulation. Materials Science

Forum, 654-656:1654-1657.

5. Zare Y, Rhee K Y, Hui D., 2017. Influences of

nanoparticles aggregation/agglomeration on the

interfacial/interphase and tensile properties of

nanocomposites. Composites Part B Engineering,

122:41-46.

6. Zare Y., 2016. Study of nanoparticles

aggregation/agglomeration in polymer particulate

nanocomposites by mechanical properties.

Composites. Part A Applied Science &

Manufacturing, 84:158-164.

7. Golbang A, Famili M H N, Shirvan M MM., 2017. A

method for quantitative characterization of

agglomeration degree in nanocomposites. Composites

Science & Technology, 145:181-186.

8. Qiao R, Deng H, Putz K W, et al., 2011. Effect of

particle agglomeration and interphase on the glass

transition temperature of polymer nanocomposites.

Journal of Polymer Science Part B Polymer Physics,

49(10):740-748.

9. Karevan M, Pucha R V, Bhuiyan M A, et al., 2010.

Effect of Interphase Modulus and Nanofiller

Agglomeration on the Tensile Modulus of Graphite

Nanoplatelets and Carbon Nanotube Reinforced

Polypropylene Nanocomposites. Carbon Lett,

11(4):325-331.

10. Deng F, Van Vliet K J., 2011.Prediction of elastic

properties for polymer-particle nanocomposites

exhibiting an interphase. Nanotechnology,

22(16):165703.