Mineralization

K

inetics of Hydroxyapatite/Chitosan Composite in a

Simulated Body Fluid

Liping Zeng

1

, Deliang He

1

and Xianglong Liu

2

1 Department of Building Engineering, Hunan Institute of Engineering, Xiangtan, Hunan 411104,China

2 College of Chemistry and Chemical Engineering, Hunan University, Changsha, 410082, PR China

Keywords: Hydroxyapatite; Chitosan; Mineralization; Electrochemical impedance spectroscopy

Abstract: This study offers provide real time and multidimensional information to the monitoring of biomaterial

mineralization process. In order to investigate on real time the mineralization process of

hydroxyapatite/chitosan (HAP/CS) composite in a simulated body fluid, the piezoelectric quartz crystal

impedance (PQCI) technique and electrochemical impedance spectroscopy (EIS) was used to reveal the

mineralization kinetics processes for bone tissue engineering. Various characterization techniques were

analyzed by Fourier transformed infrared (FT-IR), X-ray diffraction (XRD) and scanning electrode

microscopy (SEM). A decrease of the frequency (f) and an increase of the charge transfer resistance (R

ct

) at

the gold electrode/solution interface were observed due to the mineralization of HAP/CS composite.

According to the data of the frequency and static capacity (C

s

), the correlative kinetic equations and

parameters were obtained by nonlinear regression. The results show that the mineralization process of

HAP/CS is divided into two stages: the nucleation stage and the crystal growth stage, which paves the way

for applications of bone tissue engineering.

1 INTRODUCTION

Calcium phosphates that have a similar chemical

composite with the mineral phase of natural bone are

excellent candidates for bone repair and have been

used in bone tissue engineering for two

decades(Baker et al., 2006;Shadanbaz et al., 2012;

Chen et al., 2014). Hydroxyapatite

(Ca

10

(PO

4

)

6

(OH)

2

, (HAP) is one of the most

important and most widely used among calcium

phosphate bioceramics because of its excellent

osteoconductivity and bone replacement

abilities(Liu et al., 2015; Cengiz et al., 2008;

Balasundaram et al., 2006; Wang et al., 2007.

However, HAP use for reconstruction of a load

bearing bone is limited by its brittleness. To improve

the use of the HAP, hydroxyapatite/chitosan

(HAP/CS) composite polymer-ceramic has been

proposed and widely investigated (Petro et al., 2016;

Pangon et al., 2016; Zhao et al., 2011). In recent

years, significant research effort has been developed

for preparation and characterization of HAP/CS for

bone tissue engineering(Jiang et al., 2008; Zhang et

al., 2012). HAP/CS nanocomposite rods have been

prepared by in situ hybridization, and their

mechanical properties of bending and compressive

strength properties are enhanced(Bayrak etal., 2017;

Lei et al., 2017). HAP/CS composite in-vitro

investigations of biological mineralization are very

useful for correctly simulating in vivo conditions,

since the assays allow investigators not only to

predict the behavior of bioactive implant biomaterial

in the body but also to understand the physical-

chemical background of mineralization. One of the

most important characteristics of these bioactive

artificial bone materials is that there is bone-like

carbonate apatite, which is chemically and

structurally equivalent to the mineral phase in bone

and provides an interfacial bonding between

materials and tissues. This apatite layer can be

formed during mineralization process in a simulated

body fluid (SBF) solution(Ohtsuki et al., 2010;

Shahriarapanah et al., 2016; Li et al., 2010).

Manjubala et al. reported the mineralization process

of nano-hydroxyapatite-chitosan by double diffusion

technique and analyzed the phase purity of apatite

using X-ray diffraction (XRD) and Fourier

transformed infrared (FT-IR) analysis(Manjubala et

al., 2006; Meng et al., 2015). Furthermore, several

studies have made efforts to accelerate the

mineralization process using modified simulated

body fluid(Kong et al., 2006; Ying et al., 2011;

Barrere et al., 2002). The traditional mineralization

evaluation is mainly based on static characterization

by XRD, FT-IR and scanning electrode microscopy

(SEM). Few real-time kinetic investigations have

been reported in the literatures. The piezoelectric

quartz crystal impedance (PQCI) technique is a

useful tool not just for providing multidimensional

information reflecting some physical and chemical

properties of the investigated system (Muramatsu et

al., 1990; Zeng et al., 2009; Sauerbrey et al.,1959),

but also for on-line monitoring the mineralization

process of HAP/CS composite in a SBF solution.

This work focuses on the kinetic process of

mineralization of HAP/CS composite in a SBF

solution. In addition to PQCI that helped analyze the

kinetic process and mechanism, the cyclic

voltammetry (CV) and electrochemical impedance

spectroscopy (EIS) were used to characterize film

surface. Furthermore, to obtain a comprehensive

understanding of the nucleation and growth of HAP,

the crystal structure and morphology were examined

by FT-IR and SEM.

2 MATERIALS AND METHODS

2.1 Materials

CS (molecular weight 2.0×10

5

) was supplied by the

Sigma Company, and the degree of deacetylation

and purity of CS are 89% and 98%, respectively.

AT-cut 8MHz piezoelectric quartz crystal (PQC) of

approximately 15 mm diameter with gold electrodes

(8 mm in diameter) was obtained from 704

Company (Beijing China). Calcium nitrate

[Ca(NO

3

)

2

·4H

2

O], diammonium hydrogen phosphate

[(NH

4

)

2

HPO

4

], ammonia[NH

3

·H

2

O],

tris(hydroxymethyl)aminomethane [C

4

H

11

NO

3

], 2-

mercaptoacetic acid [SHCH

2

COOH], and all the

inorganic salts for SBF solution and phosphate-

buffered saline (PBS) were obtained from Shanghai

Chemical Reagents (Shanghai, China). All the

solutions were prepared with deionized water.

2.2 Preparation of HAP/CS Composite

CS was dissolved in a 1% acetic acid aqueous

solution until a 1% (wt %) CS solution was obtained.

Nano-HAP particles were prepared as previously

described(Wang et al., 2004). Briefly, precipitate

was performed by the slow addition of a 0.5 M

ammonium phosphate water solution into a 0.5 M

calcium nitrate anhydrous ethanol solution with

stirring at room temperature. The pH value of the

solution was adjusted to 11 by NH

3

·H

2

O. After the

addition of ammonium phosphate ended, the

reactants were stirred for another 2 h, and then the

suspension was left to settle for 24 h. The precipitate

was washed with deionized water and finally with

ethanol. According to our previous work(Xu et al.,

2009), HAP/CS composite with mass ratio of (6/4)

can be mineralizated well in SBF solution. In this

experiment, HAP was dissolved into CS of acetic

acid aqueous solution based on this ratio and

ultrasonic dissolution for 30 min. Then the prepared

HAP/CS composite solutions were kept in a

refrigerator.

2.3 Preparation of SBF Solution

The SBF solution was prepared by dissolving NaCl,

NaHCO

3

, KCl, K

2

HPO

4

·3H

2

O, MgCl

2

·6H

2

O CaCl

2

,

and Na

2

SO

4

into deionized water. The SBF solution

was adjusted to physiological pH (pH 7.4) with tris-

HCl buffer. The SBF concentrations were 142.5 mM

Na

+

, 2.6mM Ca

2+

, 1.5mM Mg

2+

, 5mM K

+

, 147.8mM

Cl

-

, 1.0mM HPO

4

2-

, 4.25mM HCO

3

-

and 0.5mM

SO

4

2-

.

2.4 Preparation of PQC Sensor

In order to remove possible contamination, each of

the gold electrodes of PQC was cleaned in fresh

piranha solution (70% H

2

SO

4

, 30%H

2

O

2

) followed

by rinsing with deionized water. Then, self-

assembled monolayer was formed on the gold

electrode surface by immersing it into a solution of

0.01 M 2-mercaptoacetic acid for 12 h. Subsequently,

the HAP/CS composite was dropped on the surface

of gold electrode of PQC by a micro-syringe. The

electrode was put into an air oven to be dried at

60 ℃ for 24 h in order to remove all the acetic acid

and water, and then a rigid film was obtained.

2.5 PQCI Measurement

The mineralization process of HAP/CS composite

was monitored on-line using a piezoelectric

impedance analyzer (HP4192 LF, America). The

PQC sensor with modified (HAP/CS) electrode was

dipped in SBF solution at 37±0.5 ℃ . A user’s

program was developed using Visual Basic (VB) 5.0

to control the piezoelectric impedance analyzer,

which measures the resonant frequency (f) of the

PQCI simultaneously, and also fits the values of the

Butterworth-van Dyke (BVD) equivalent circuit

parameters by Gauss-Newton nonlinear least-

squares. In this work, the BVD equivalent circuit

parameters were obtained in 30 s intervals, including

motional resistance (R

m

), motional inductance (L

m

),

static capacitance (C

s

) and motional capacity (C

m

).

2.6 Electrochemical Measurements

The mineralization properties of the HAP/CS

composite were studied by electrochemical methods

using EIS and CV (CHI660B electrochemical

workstation, Instruments China CH). A conventional

three-electrode cell was utilized: a modified

electrode served as the working electrode, a

platinum plate served as the counter electrode, and a

saturated KCl calomel electrode served as the

reference electrode. All experiments were performed

at 37±0.5 ℃.

The variation of morphology and composition

for the corresponding stages of mineralization

products were characterized by FT-IR (Nicolet 5700,

Thermo), scanning electron microscopy (SEM, JSM-

6700F, Japan) and XRD (CO.. Ltd., Japan).

3 RESULTS AND DISCUSSION

3.1 PQCI Studies of Mineralization of

the HAP/CS Composite in SBF

Solution

The PQCI analysis technique is usually used to

study the on-line interface properties of surface-

modified electrodes. In piezoelectric analysis, the

frequency response change (Δf) of the sensor in

liquid depends on the mass and viscoelasticity

changes of the sensor surface, and the change in the

viscosity and density of the solution. Motional

resistance (R

m

) represents the loss in mechanical

energy mainly dissipated to the surrounding medium

and quartz interior. The change of motional

resistance (ΔR

m

) reflects the variation in the

viscoelasticity of the film and in the viscosity and

density of the contacting solution.

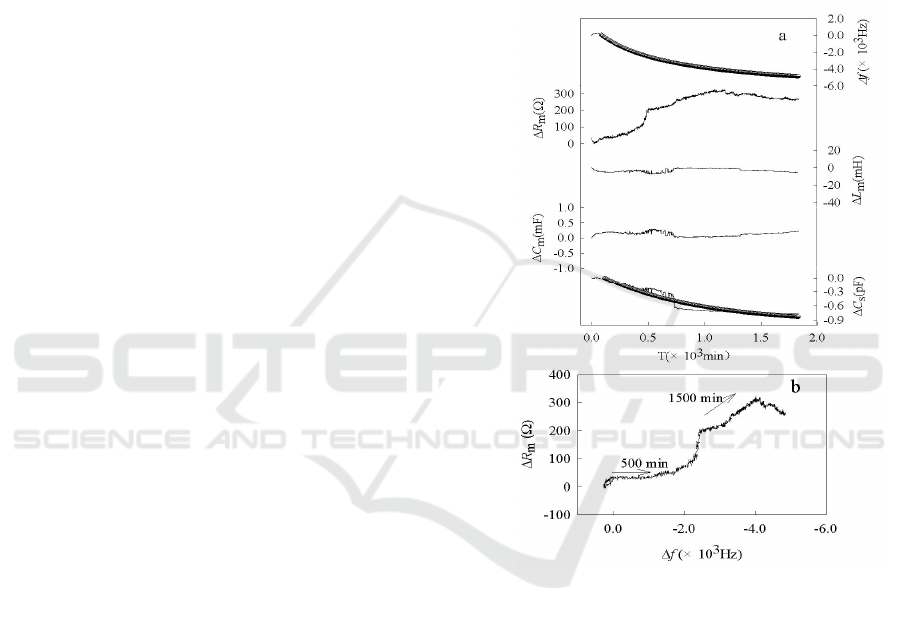

The typical PQCI response parameters (ΔR

m

, Δf,

ΔC

m

, ΔL

m

and ΔC

s

) during mineralization of the

HAP/CS composite in SBF solution are shown in

Fig. 1(a). It can be seen that as Δf and ΔC

s

decrease,

ΔR

m

increases, and ΔC

m

and ΔL

m

change modestly.

The decrease of Δf is due to the mineralization of the

HAP/CS composite in SBF solution; specifically

Ca

2+

and PO

4

3-

ions are coupled electrostatically

with carbonyl groups and amine groups of CS on the

electrode surface, thus increasing the mass of the

electrode surface film. In Fig. 1(b), the horizontal

line for the initial 500 min exhibits the mass binding

on the electrode surface(Marx et al., 2003). After

mineralization, HAP crystals gradually grow on the

surface of film, resulting in viscoelasticity change of

the film, which brings ΔR

m

increase and Δf decrease.

The slip of Δf versus ΔR

m

shows mass change and

energy dissipation properties.

Fig. 1. (a)Time course of simultaneous responeses of ΔR

m

,

Δf, ΔC

m

, ΔL

m

and ΔC

s

during the mineralization of the

HAP/CS composite in SBF solution; (b) Δf vs. ΔR

m

diagram for the mineralization of HAP/CS composite.

The static capacity, C

s

is related to the capacity

and structure of the electrical double layer at the

charge interface. ΔC

s

will provide the information

on the capacity and structure of the interface. In this

experiment, C

s

decreases gradually; this may be

caused by the mineralization of HAP/CS composite

that results in thicker film. Furthermore, the

deposited HAP covers the surface of HAP/CS

composite resulting in hydrophilicity decrease and

subsequent reduction in ion transfer. And, the

dielectric constant of the film also varies with HAP

formation. These factors combine to cause a

decrease of ΔC

s

.

The mineralization of HAP/CS composite in

SBF solution fits the two consecutive reactions

kinetic model. That is to say, the mineralization of

HAP/CS composite could be divided into

consecutive reaction steps. A conceptual model

advances carbonyl groups and amino groups of CS

as nucleation sites for HAP crystallization through

binding oppositely charged ions, calcium ion and

phosphate ion. Therefore, there is heterogenous

nucleation and growth of nano-HAP on the surface

of composite. Moreover, Ca

2+

ions enrich the

carbonyl groups and amino groups of CS in SBF

solution and PO

4

3-

enrich the amino groups of CS;

this enrichment may be attributed to electrostatic

interaction or/and polar interaction. Finally,

heterogeneous nucleation of HAP on the surface of

films forms crystals of HAP gradually. Due to OH

−

and CO

3

2-

doping in SBF solution, HAP crystalline

grew and formatted a biological active bone-like

carbonateapatite layer with mineralization times

increasing. The process of HAP crystal growth is

illustrated in Scheme 1.

Scheme 1. Schematic process of different steps involved

calcium phosphate crystals on HAP/CS composite.

3.2 SEM Characterization

Fig. 2 shows the SEM micrographs of HAP/CS at

12,000× after soaking in simulated body fluid for

various periods. In Fig. 2(a), porous structure is

observed before HAP/CS immersion. After

mineralizing for 500 min, white granules are found

in Fig. 2(b), which are HAP crystal consisting of

numerous tiny flake. It is considered that a single

layer of HAP particles start to deposit over the

surface. This microstructure corresponds to the

reported literature(Ramila et al., 2002; Zhu et al.,

2007). Then, at time of 1500 min in Fig. 2(c), the

surface is almost covered with calcium phosphate

particles accompanied by a secondary nucleation

over the initial layer. With increase of the immersion

time, the crystal grains congregate together and form

the porous HAP layer. Finally, the HAP crystal

grains fill in the porous HAP layer and grow a dense

structure in Fig. 2(d). Due to the HAP component of

the starting material, the HAP induced the new

nucleation and it grew vertically on the surface. This

microstructure corresponds to that deposited on a

bioactive glass or ceramics from SBF

solution(Oliveira et al., 2009; Davidenko et al.,

2010). To observe the typical HAP shape, it must be

at higher magnifications. Oliveira et al. reported that

it was possible a needle-like nanostructure for

characteristic of Ca-P coatings formed under the

present biomimetic conditions. Changes of

morphology and structure of various stages

demonstrate the nucleation and crystal growth.

Fig. 2. SEM images (12,000×) of HA/CS after soaking in

SBF solution at 0 min (a), 500 min (b), 1500 min (c), 2000

min (d).

3.3 Electrochemical Impedance

Investigation and Cyclic

Voltammetry Measurement

In order to clarify the difference among the

mineralization films of the HAP/CS composite,

electrochemical impedance spectroscopy and cyclic

voltammetry were carried out before and after

mineralization. Fig. 3 shows the electrochemical

impedance spectroscopy and cyclic voltammetry for

crystal modified with HAP/CS composite and the

crystal immersion in SBF for 12 h and 24 h,

respectively. The measurements were conducted in a

phosphate buffer solution (pH=7.4) containing 0.2

M NaCl, 1mM K

3

[Fe(CN)

6

] and 1mM K

4

[Fe(CN)

6

].

The semicircle region lying on the Z

re

axis included

in the electrochemical impedance spectroscopy

corresponds to the electron transfer limited process,

where the diameter corresponds to the electron

transfer resistance (R

et

) of the ferri-/ferrocyanide

probe at the gold electrode interface. Fig. 3(a)

illustrates that the electron-transfer resistance

increases with the mineralization process in the SBF

solution. For the crystal modified with HAP/CS

composite, the crystal after 12 h and 24 h of

immersion in the SBF solution, mineralization

introduces a barrier to interfacial electron transfer,

corresponding to the interfacial electron transfer

resistance Ret of about 323 Ω, 13300 Ω and 304700

Ω, respectively. This is mainly attributed to the

mineralization of HAP/CS in SBF solution, which

insulates the conductive support. As shown in the

Fig. 3b, K

3

Fe(CN)

6

/K4Fe(CN)

6

shows the reversible

behavior of HAP/CS coated electrode with a peak-

to-peak separation ⊿E

p

of 105 mV and a reduction

peak current I

p

of 32 μA. Peak currents decreased

sharply after HAP/CS composite was immerged into

the SBF solution for 12 h, and peak currents are

almost zero for 24 h. This is attributed to the film

thickening for mineralization of HAP/CS, which

results in the ferri-/ferrocyanide prode might be

blocked to the bare electrode.

Fig. 3. Electrochemical impedance spectra (a) for crystal

modified with HAP/CS composite, the crystal immersion

in SBF for 12 h and 24 h as well as Cyclic

voltammograms (b) for crystal modified with HAP/CS

composite, the crystal immersion in SBF for 12 h and for

24 h in a PBS solution (pH 7.4) containing 0.2 M NaCl,

1mM K

3

Fe(CN)

6

and 1mM K

4

Fe(CN)

6

. (a) 100 kHz~10

mHz, 10 mV rms, 0.17V versus SCE; (b) dE/dD=50 mV/s.

3.4 FT-IR Spectroscopy Characterization

In order to further characterize the mineralization

of HAP/CS composite in the SBF solution, FT-IR

spectrum analysis is performed and the spectra for

mineralized material are shown in Fig. 4. The peaks

at 1602 and 1484 cm

-1

are due to the amide Ι

carbonyl stretch of chitosan, which disappear

gradually with mineralization of HAP/CS composite

in the SBF solution. It is thought that there are

chemical interactions between the amide of the

chitosan and phosphates take place in the SBF

solution. On the other hand, the FT-IR spectrum of

three samples show that the typical peaks of

phosphate stretching vibration occur at 1027-1180

cm

-1

, and the peaks of bending vibrations of PO

4

3-

group are observed at 630 and 525 cm

-1

.

Furthermore, the adsorption peak displays greater

strength and acuity when the HAP/CS composite is

immerged in SBF solution for 24 h indicating

formation of crystal HAP with the mineralization.

Peaks for CO

3

2-

vibration mode appear at positions

740, 840, and 1458-1472 cm

-1

indicating that HAP

crystals are formed on the surface of composite

films; meanwhile, the PO

4

3-

sites of the nano-HAP

are partly substituted by CO

3

2-

groups. One may

deduce that there is formation of crystallized

carbonateapatite during mineralization of the /CS

composite in the SBF solution, which suggests that

the bioactivity of the HAP/CS composite can form a

biological active bone-like, carbonateapatite.

3.4 First Section

This section must be in one column.

2.2.1 Title

4. FT-IR spectrum of HAP/CS composite mineralized at

different time.

3.5 XRD Analysis

The XRD patterns of the HAP/CS after

mineralization in SBF and pure CS are shown in Fig.

5. The XRD pattern of pure CS showed two typical

peaks at 2θ = 11° and 20°, which corresponds to the

reported literature(Samuels 2010). After

mineralization in SBF solution, the HAP/CS

composite showed the characteristic peaks (26° and

32°) of hydroxyapatite, similar to that reported by

Kong et al(Kong et al., 2006). As the HAP peaks are

comparatively broader than a normal HAP

specimen, it is considered that the HAP crystals

were small crystallite size. Combined with the

results of FT-IR, it can be deduced that the induced

apatite was a carbonate HAP.

Fig. 5 X-ray diffraction patterns of HAP/CS composite

material mineralized at (a)500min, (b)1500min,

(c)2000min and (d)pure CS.

4 CONCLUSIONS

The mineralization kinetics of HAP/CS composite

were investigated by the piezoelectric quartz crystal

impedance combining with electrochemical

impedance spectroscopy and cyclic voltammetry, the

dynamically structural and morphological

characterization of mineralization products on

various stages by SEM, FT-IR and XRD. The

changes of PQCI parameters demonstrate the

changes of the physical and chemical properties

between the interfaces of the HAP/CS composite

and the SBF solution. Two parameters, Δf and ΔC

s

,

were used to simultaneously estimate the

mineralization process of HAP/CS composite in

SBF solution. Its process is comprised of nucleation

and growth of crystal of HAP, and their kinetics and

mechanism are analyzed. The results demonstrate

the validity of the proposed method for its ability to

provide real time multidimensional information

during the mineralization process; therefore the

present method will play an important role for

investigating biomaterial mineralization.

ACKNOWLEDGEMENTS

The present study was supported by Hunan

Provincial Natural Science Foundation of China

(2015JJ6025) and the Doctoral Scientific Fund

Project of Hunan Institute of Engineering (2014086).

REFERENCES

1. Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

2. Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

3. Baker K., Anderson M., Oehlke S., Astashkina A.,

2006, Growth, characterization and biocompatibility

of bone-like calcium phosphate layers biomimetically

deposited on metallic substrata, Materials Science

Engineering C 26,1351-1360.

4. Shadanbaz S., Dias C., 2012, Calcium phosphate

coatings on magnesium alloys for biomedical

applications: a review, Acta Biomaterials 8,20-30

5. chen F., Zhu Y., 2014, Multifunctional calcium

phosphate nanostructured materials and biomedical

applications, Current Nanoscience 10,465-485

6. Liu B., Zhang X., Xiao G., Lu Y., 2015, Phosphate

chemical conversion coatings on metallic substrates

for biomedical application: A review, Materials

Science and Engineering C 47,97-104

7. Cengiz B., Gokce Y., Yildiz N., Aktas Z., Calimli A.,

2008,Synthesis and characterization of hydroxyapatite

nanoparticles, Colloids Surface A 322,9-25.

8. Balasundaram G., Sato M., Webster T., 2006, Using

hydroxyapatite nanoparticles and decreased

crystallinity to promote osteoblast adhesion similar to

functionalizing with RGD, Biomaterials 27,2798-2805.

9. Wang H., Li Y., Zuo Y., Li J., Ma S., Cheng L., 2007,

Biocompatibility and ostegenesis of biomimetic nano-

hydroxyapatite/polyamide composite scaffolds for

bone tissue engineering, Biomaterials 28,3338-3348.

10. Petro I., Kalinkevich O., Pogorielov Ma., Kalinkevich

A., Stanislavov A., et al., 2016, Dielectric and electric

properties of new chitosan-hydroxyapatite materials

for biomedical application: Dielectric spectroscopy

and corona treatment, Carbohydrate polymers

151,770-778

11. Pangon A., Saesoo S., Saengkrit N., Ruktanonchai U.,

Intasanta V., 2016, Hydroxyapatite-hybridized

chitosan/chitin whisker bionanocomposite fibers for

bone tissue engineering applications, Carbohydrate

Polymers 144, 419-427.

12. Zhao Y., Jiang Z., Xiao L., Xu T., Qiao S., Wu H.,

2011,Chitosan membranes filled with biomimetic

mineralized hydroxyapatite for enhanced proton

conductivity, Solid State Ionic. 187,33-38

13. Jiang L., Li Y., Wang X., Zhang L., Wen J., Gong M.,

2008, Preparation and properties of nano-

hydroxyapatite/chitosan/carboxymethyl cellulose

composite scaffold, Carbohydr Polym 74,680-684.

14. Zhang J., Liu G., Wu Q, Zuo J., Qin Y., Wang J.,2012,

Novel mesoporous hydroxyapatite/chitosan composite

for bone repair, Journal of Bionic Engineering 9,243-

251 .

15. Bayrak G., Demirtaş T., Gümüşderelioğlu D.,

2017,Microwave-induced biomimetric approach for

hydroxyapatite coatings of chitosan scaffolds,

Carbohydrate Polymers. 157,803-813

16. Lei Y., Xu Z., Ke Q., Yin W., Chen Y., Zhang C., Guo

Y.,2017, Strontium hydroxyapatite/chitosan

nanohybrid scaffolds with enhanced osteoinductivity

for bone tissue engineering, Materials Science and

Engineering C 72,134-142.

17. Ohtsuki C., Kamitahara M., Miyazaki T.,2007,

Coating bone-like apatite onto organic substrates using

solutions mimicking body fuild, Journal of Tissue

Engineering Regenerative Medicine. 1,33-38

18. Shahriarpanah S., Nourmohammadi J., Amoabediny

G., 2016, Fabrication and characterization of

carboxylated starch-chitosan bioactive scaffold for

bone regeneration, International Journal of Biological

Macromolecules. 93,1069-1078

19. Li J., Zhu D., Yin J., Liu Y., Yao F., Yao K., 2010,

Formation of nano-hydroxyapatite crystal in situ in

chitosan-pectin polyelectrolyte complex network,

Materials Science and Engineering C 30, 795-803

20. Manjubala I., Scheler S., Bossert J., Jandt K., 2006,

Mineralisation of chitosan scaffolds with nano-apatite

formation by double diffusion technique, Acta

Biomaterials 2,75-84.

21. Meng D., Dong L., Wen Y., Xie Q., 2015, Effects of

adding resorbable chitosan microspheres to calcium

phosphate cements for bone regeneration, Materials

Science and Engineering C 47,266-272

22. Kong L., Gao Y., Lu G., Gong Y., Zhao N., Zhang X.,

2006, A study on the bioactivity of chitosan/nano-

hydroxyapaptite composite scaffolds for bone tissue

engineering, European Polymer Journal 42,3171-3179.

23. Yin N., Chen S., Yang Y., Tang L., Yang J., Wang H.,

2011, Biomimetic mineralization synthesis of

hydroxyapatite bacterial cellulose nanocomposites,

Progress in Natural Science: Materials International

21,472-477

24. Barrere F., Blitterswijk C., Groot K., Layrolle P., 2002,

Influence of ionic strength and carbonate on the Ca-P

coating formation from SBF×5 solution, Biomaterials

23,1921-1940.

25. Muramatsu H., Suda M., Ataka T., Seki A., Tamiya E.,

karube I., 1990, Piezoelectric resonator as a chemical

and biochemical sensing device, Sensors Actuators A

Physical 21,362-368.

26. Muramatsu H., Tamiya E., Suzuki M., Karube I., 1988,

Viscosity monitoring with a piezoelectric quartz

crystal and its application to determination of

endotoxin by gelation of limulus amebocyte lysate,

Analytical Chimica Acta 215,91-99.

27. Sauerbrey G., 1959, The use of quartz oscillators for

weighting thin layers and for microweighing, Z.

Physical 155,206-222.

28. Wang Q.L., Ge S., Zhu H., 2004, Studies on the

synthesis and structure of nanosized hydroxyapatite

crystals at normal temperature and atmospheric press,

China University Mining Technology 33,533-536. (in

chinese).

29. Xu C., He D., Zeng L., Luo S., 2009,

Biomineralization of hydroxyapatite-chitosan

composite in a simulated body fluid using

piezoelectric quartz crystal impedance, Journal of

Central South University (Science and Technology)

40,334-339. (in chinese)

30. Muramatsu H., Tamiya E., Karube I., 1988,

Computation of equivalent circuit parameters of quartz

crystals in contact with liquids and study of liquid

properties, Analytical Chemistry 60,2142–2146.

31. Marx K., 2003, Quartz crystal microbalance: A useful

tool for studying thin polymer films and complex

biomolecular systems at the solution-surface interface,

Biomacromolecules 4,1099-1120.

32. Rámila A., Padilla S., Muñoz B., Vallet-Regí M., 2002,

A new hydroxyapatite/glass biphasic Material: In vitro

bioactivity, Chemistry Materials 14, 2439-2433.

33. Zhu Z., Tong H., Jiang T., Shen X., Wan P., Hu J.,

2006, Studies on induction of L-aspartic acid modified

chitosan to crystal growth of the calcium phosphate in

supersaturated calcification solution by quartz crystal

microbalance, Biosensors Bioelectronics 22,291-297.

34. Oliveira A., Costa S., Sousa R., Reis R., 2009,

Nucleation and growth of biominetic apatite layers on

3D plotted biodegradable polymeric scaffolds: Effect

of static and dynamic coating conditions, Acta

Biomaterialia 5, 1626-1638.

35. Davidenko N., Carrodeguas R., Peniche C., Solís Y.,

Cameron R, 2010, Chitosan/apatite composite beads

prepared by in situ generation of apatite or Si-apatite

nanocrystals, Acta Biomaterialia 6, 466-14.

36. Samuels R., 1981, Solid state characterization of the

structure of chitosan film, Journal Polymer Science:

Polymer Physics Edition 19,1081-1105.