Evaluation of Implementation of Occupational Health Safety

Management System (OHSMS) in PT. X, Magetan, East Java

Achmad Khoirur Rozi

1

1

Disaster Management Department of Post Graduate of Universitas Airlangga,

Airlangga Street No. 4-6 Surabaya, East Java Province of Indonesia

Keywords: OHSMS, evaluation, sugar industry.

Abstract: The implementation of health and safety management system (OHSMS) in Indonesia is mandatory as stated

in Government Regulation No. 50 of 2012 on the implementation of OHSMS as a form of occupational

health and safety (OHS). PT X as a company engaged in the field of sugar industry is required to apply

OHSMS because it meets the criteria as a company with the number of employees of more than 100 people

and having a high risk. This study aims to determine the value of implementation of OHSMS in PT X. This

research was conducted at PT X on Jl. Bhayangkara No.1, Kawedanan District, Magetan Regency, East

Java Province. This research used the qualitative method, while the data collection was done by interview

and OHSMS assessment form to the management representative and company employees. The analysis

used was descriptive analysis on the application of OHSMS with 12 elements described in 166 criteria. The

evaluation results for the value of the success rate of OHSMS application in PT X with the details of

development and assurance of the implementation of commitment (81%), development and documentation

of occupational health and safety plan (93%), design control and review (100%), document control (86%),

product purchasing and control (67%), security work based on OHSMS (83%), monitoring standard (76%),

reporting and repair deficiencies (100%), Material management and displacement (100%), data collection

and usage (100%), OHSMS audit (67%), and skill and ability development (93%). Thus, in total the

application of OHSMS belong to the satisfactory level of achievement with 86% of 85-100% needed to

achieve the level, which as per the definition deserves to be certified and to obtain the golden flag.

1 INTRODUCTION

Indonesia categorized as a rich country in term of

natural resources with a significant number of

industries. From a variety of industries in Indonesia,

there are industries that use complex technologies

and processes, such as the sugar industry. In line

with the complexity of the industry, there are

complete hazards and high risks attached, and

occupational health (OHS) for workers has always

existed.

From the data of the Social Security

Administering Agency (BPJS) of Employment, until

the end of 2015, there had been 105,182 cases of

occupational accidents which 2,375 cases resulted

death. Then from the beginning of January 2016 to

November 2016, there were 101,367 cases resulting

in 2,382 death cases

(www.bpjsketenagakerjaan.go.id). Based on the

data, it can be said that the number of occupational

accidents in Indonesia is still quite high.

To reduce the number of work accidents, the

company is required to be able to establish and

implement a health and safety management system

(OHSMS) in accordance with article 87 of Law No.

13 of 2003 on Employment. Meanwhile, the

implementation guide is contained in Government

Regulation No. 50 of 2012 on the implementation of

occupational safety and health management system

(Efendi, 2005). The purpose of the implementation

of OHSMS is to create an OHS system in the

workplace by involving the elements of

management, labor, conditions, and an integrated

work environment in order to prevent and reduce

occupational accidents and occupational diseases, as

well as the creation of safe, efficient, and effective

workplaces (Ramli, 2013).

PT X is a company engaged in the sugar

industry, which was established in 1890. In 2016, PT

550

Rozi, A.

Evaluation of Implementation of Occupational Health Safety Management System (OHSMS) in PT. X, Magetan, East Java.

DOI: 10.5220/0007546805500555

In Proceedings of the 2nd International Conference Postgraduate School (ICPS 2018), pages 550-555

ISBN: 978-989-758-348-3

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

X ground sugar cane on an area of 2,957,937 ha

(sugar cane itself comprised of 211,506 hectares and

community sugar cane comprised of 2,746,431 ha)

Meanwhile, for the year 2017 PT X grounded sugar

cane with an area of 3,500,000 Ha (500,000 Ha of

self-owned sugar cane, and 3,000,000 ha of

community sugar cane) with an average total

production of 365,668.2 tons annually. The PT X

sugar industry involves a total of 2000 workers in

every process of milling. The main process in the

production activity is a mechanical process using

automatic machining, while the side process is the

improvement process.

Government Regulation No. 50 of 2012 Article

4, paragraph 2, points a and b state that companies

are required to OHSMS government regulation

where the company is "a. employing a worker of at

least 100 (one hundred) persons; or b. has a high

potential hazard level". PT X is a company that is

required to implement OHSMS with a workforce of

more than 100 people and has a high risk of work

activities that are potentially causing fatal accidents

in the form of fire and explosion. PT X has

established and implemented OHSMS in all of its

activities. Therefore, the implementation

government regulation on OHSMS in PT X needs to

be evaluated as per the provisions of OHSMS

assessment in Government Regulation No. 50 of

2012, attachment 2, which is divided into 12

elements and 166 criteria. The percentage of

fulfillment of these criteria will describe the level of

achievement of OHSMS implementation in PT X.

Based on the description above, the problem of

this research is how high is the level of assessment

of the government regulation of OHSMS in PT X?

This research was conducted to evaluate the

implementation of OHSMS in PT X in reducing

work accidents in its operational activities, so the

level of government regulation of OHSMS

implementation based on Government Regulation

No. 50 of 2012 can be determined. The benefits

obtained in this research are:

1. Acting as an input for company management in

taking the results to improve the OHS program

2. Acting as a research material for further

researchers in the field of OHSMS

3. Acting as an input in the development of

Occupational Health and Safety (OHS) studies,

especially in the field of OHSMS.

2 METHOD

The research was conducted using the qualitative

method to understand the phenomenon by focusing

more on the complete picture of the phenomenon

studied in the hope of getting a deep understanding

about the phenomenon. The analysis of the research

was conducted descriptively.

The data was collected using observation and

interview to the management and OHS experts based

on OHSMS Government Regulation No. 50 of 2012

assessment form containing 166 questions. The data

processing from the OHSMS assessment form used

the calculation of the percentage of compliance of

criteria and achievement levels, which is divided

into 3 categories, namely poor, good, and

satisfactory. The calculation was done using the

formula of Hendri (2012) :

Table 1: Level of OHSMS implementation achievement

Company

Category

Level of Implementation

Achievement

0 – 59%

60% –

84%

85% –

100%

Early Level

(64 criteria)

Less

Good

Satisfy

Transition

Level

(122

criteria)

Less

Good

Satisfy

Advanced

Level

(166

criteria)

Less

Good

Satisfy

This research was conducted at PT X, which is

located at Jl. Bhayangkara No.1, Kawedanan

District, Magetan Regency, East Java Province. Data

retrieval was conducted for 2 days on March 15 -

March 16, 2017.

3 RESULTS

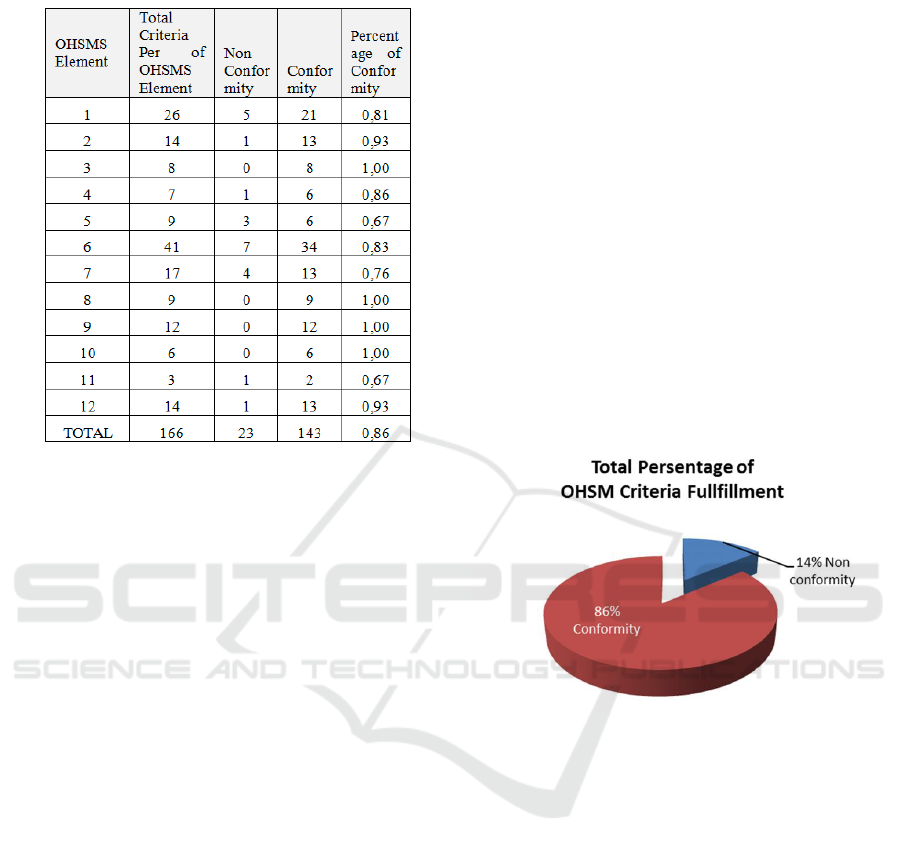

Based on the results of document review,

observation, and interview, the results of comparison

of the comparison with total criteria on each of the

OHSMS assessment elements are as follows:

Evaluation of Implementation of Occupational Health Safety Management System (OHSMS) in PT. X, Magetan, East Java

551

Table 2: Comparison of OHSMS Criteria Compliance.

Table 1 summarizes the overall OHSMS audit

results covering 166 criteria. From the table, it can

be seen that there is a percentage for each

compliance criteria.

Based on table 1 above, the following findings can

be described:

1. The development and guarantee of

commitment implementation were 81%

accomplished with 5 non-conforming criteria

and 21 conforming criteria from a total of 26

criteria.

2. The making and documenting of the OHS plan

was 93% accomplished with 1 non-conforming

criterion and 13 conforming criteria from a

total of 14 criteria.

3. Contract design and review was 100%

accomplished with 0 non-conforming criteria

and 8 conforming criteria from a total of 8

criteria.

4. Document control was 86% accomplished with

1 non-conforming criterion and 6 conforming

criteria from a total of 7 criteria.

5. Product purchasing and control was 67%

accomplished with 3 non-conforming criteria

and 6 suitabilities from a total of 9 criteria.

6. OHSMS-based working security was 83%

accomplished with 7 non-conforming criteria

and 34 conforming criteria from a total of 41

criteria.

7. Monitoring standard was 76% accomplished

with 4 non-conforming criteria and 13

suitability from a total of 17 criteria.

8. Deficiency reporting and repair was 100%

accomplished with 0 non-conforming criteria

and 9 conforming criteria from a total of 9

criteria.

9. The management and displacement of

materials was 100% accomplished with 0 non-

conforming criteria and 12 conforming criteria

from a total of 12 criteria.

10. The collection and use of data was 100%

accomplished with 0 non-conforming criteria

and 6 conforming criteria from a total of 6

criteria.

11. OHS examination was 67% accomplished with

1 non-conforming criterion and 2 conforming

criteria from a total of 3 criteria.

12. The development of skills and abilities was

93% accomplished with 1 non-conforming

criterion and 13 conforming criteria from a

total of 14 criteria.

The overall percentage of OHSMS assessment in

PT X can be seen in Figure 2 below:

Figure 1: Total Percentage of OHSMS Criteria Fulfillment

From Figure 1 above it can be seen that PT X has

fulfilled 143 criteria from a total of 166 criteria for

advanced level specified in OHSMS assessment

standards in Government Regulation Number 50

year 2012 with 86%, which amounts to a satisfactory

level of achievement.

4 DISCUSSION

Based on the research conducted, there were 23 non-

conforming criteria, namely:

1. Criteria 1.1.2

In the RDS/PK3/024 Procedure on Occupational

Health and Safety Policy, it is stated that the

establishment of OH&S policy is prepared through

consultation process with the representative of the

workforce. However, in the document search, the

process of establishing the OHS policy as intended

ICPS 2018 - 2nd International Conference Postgraduate School

552

has not been found. This is not in accordance with

the procedures for establishing OHS policies, which

must present the elements of the OHS Committee

(P2K3) in accordance with the Minister of

Manpower Regulation no. Per. 04/MEN/1987. There

should be a discussion on the preparation of OH&S

policy.

2. Criteria 1.2.3

In the document review of the existing job

description, not all heads of work units within the

company are responsible for the performance of

OHS on the work unit. This criteria request that

every position from the highest to the lowest has a

responsibility for OHS performance on the unit it

leads. OHS in the workplace is the responsibility of

all people, so the duties and responsibilities of OHS

in the company must be comprehensive from the

highest position to the lowest (Ramli, 2013).

3. Criteria 1.2.5

In the RDS/PK3/036 Procedure on Emergency

Preparedness and Response, a responsible officer

has been assigned, but the officer has not received

the training and get the certificate. Every officer in

OHS field should have sufficient competence as

evidenced by certificate of competence.

4. Criteria 1.4.5

The government regulation of Occupational Safety

Expert as Secretary of P2K3 has been fulfilled as

intended. However, the relevant OHS Expert has not

reported its activities as regulated in Ministerial

Regulation No. 02/MEN/1992 (Tarigan, 2008).

According to the regulation, OHS Expert should

make a report every 3 months to the Ministry of

Manpower.

5. Criteria 1.4.8

In the field review, no meetings of P2K3 have been

disseminated in the workplace. As per the criteria

1.4.7 of Government Regulation No. 50 of 2012, the

structure of the P2K3 board must documented and

informed to the workforce through the company's

information boards provided in each area work or

other information media.

6. Criteria 2.3.1

In the RDS/PK3/026 Procedure on Access

Procedure, Identification, and Evaluation of

Compliance Regulation, procedures to obtain the

regulation have been established as intended.

However, in document search, no document has

been found. This was regarded as a mismatch

because what should be done according to the

procedure was not executed properly.

7. Criteria 4.1.1

In the Document Search, there are several

procedures written, or the title is not the same as

written in the Document List. This indicates that the

company has not been consistently in accordance

with the procedures they have agreed upon.

Therefore, this company must do re-checking of

each document created.

8. Criteria 5.1.1

Procedure RDS/PK3/014 on Procurement of Urgent

Local Goods has set out the technical specifications,

and the required OH & S requirements are listed at

the time of purchase request. However, from the

observation, the document of purchase as intended

has not been found. In this case, there are

inconsistencies in the implementation of OHS,

which are in the process of purchasing goods.

9. Criteria 5.1.3

The RDS/PK3/014 Procedure on the Procurement of

Local Goods PG Urgent has not set out the

mechanism on the OH & S requirements specified in

the purchase specification to be notified to the

employees who are using it. This criteria stresses

that what is done in criteria 5.1.1 should be informed

to the workforce.

10. Criteria 5.3.1

During the time of document review, it has not been

found the record of goods and services government

regulation by the customer which identified as

potential hazards and assess the risks. As stipulated

in OHSMS, any materials, equipment, or work

performed must be analyzed at risk to ensure OHS at

work.

11. Criteria 6.1.7

The RDS/PK3/032 Procedure on Government

Regulation has not yet set out the proper procedures,

selection, and use of Government Regulation

regarding the standards stated as eligible for use, as

in the Ministerial Regulation No. 08 of 2010 (using

SNI standards) (Ramli, 2013). This procedure needs

to be revised whereby PT X should set firmly in the

form of a document on the standards used in

determining the Personal Protective Equipment

(PPE) used in the workplace.

12. Criteria 6.4.4

At the time of field review, signs were found of

signing for fire extinguisher marking not in

accordance with standard and technical guidelines.

PT X should refer to the standard installation and

maintenance of fire extinguishers as described in

Ministerial Regulation No. 4 of 1980.

13. Criteria 6.5.1

In the document search, the Company does not have

document in the form of checklist/schedule of

maintenance/inspection of each production facilities

used in the workplace. This is an important note to

Evaluation of Implementation of Occupational Health Safety Management System (OHSMS) in PT. X, Magetan, East Java

553

measure the company's consistency in maintaining

the safety of production equipment.

14. Criteria 6.5.7

In the RDS/PK3/035 Procedure on Lock Out & Tag

Out, the Locking and Laminating procedure for

energy isolation has been set up. However, in the

aforementioned procedures, procedures on marking

for equipment that is no longer safe for use or that

has not been used has not been set.

15. Criteria 6.7.4

In the RDS/PK3/036 Procedure on Emergency

Preparedness and Response, the Emergency of

Organization has been established. However, the

procedure regarding the procedure of informing the

emergency handling officer to all people in the

workplace has not been set.

16. Criteria 6.8.1

The company has evaluated the first aid tool, but

from the field review the condition of the contents of

the first aid box is not guided by the Minister of

Manpower Regulation no. 15 of 2008 on First Aid in

an Accident at Work.

17. Criteria 6.9.1

In the RDS/PK3/037 Procedure on Recovery the

condition has not yet been set up for recovery

procedures, especially for traumatized workers after

accidents and occupational diseases.

18. Criteria 7.1.1

In the RDS/PK3/038 Procedure on Occupational

Safety and Health Inspection the regular work

procedure has been established. However, in the

document search, the procedure was not working as

intended.

19. Criteria 7.2.2

In the RDS/PK3/039 Procedure on OHS Monitoring

and Examination, its implementation is conducted

once in 3 years, not guided by Ministerial Decree

No.187/MEN/1999, which stipulates that the

measurement of Work Environment of Chemical

Factor should be done once a year.

20. Criteria 7.4.3

Employee Health Check that has been done has not

been reported per period as in the Ministerial

Regulation no. 02 of 1980.

21. Criteria 7.4.5

In the review of documents on employee health

checks in the government regulation, the results of

the health examination have not been subjected

analysis and evaluation as monitoring materials in

accordance with the provisions.

22. Criteria 11.1.3

In the document search, there was no publication of

the results of internal audits that have been done to

employers or other officers and officials concerned

and monitored to ensure corrective action.

23. Criteria 12.1.1

The company has not set up a Training Need

Analysis (TNA) covering the needs of OHS training

(the relationship between OHS competence and

OHS training that needs to be planned).

All the 23 non-conforming as discussed above are

classified as minor findings. The findings were

obtained because the company was inconsistent in

meeting the requirements of legislation and other

requirements. Thus, it can be concluded that the

implementation of OHSMS in PT X met 143 criteria

from 166 criteria, amounting to 86% compliance,

which is within to the satisfactory level of

achievement of 85-100%, which by definition

deserves certification and the golden flag.

5 CONCLUSIONS

From the results of research and discussion above, it

can be concluded that PT X has implemented

OHSMS based on Government Regulation No. 50 of

2012, which were assessed based on advanced

criteria containing 166 items. Of the 166 criteria,

there are 23 non-conforming findings classified as

minor findings, so in this case PT X has met 143

criteria with the percentage of OHSMS assessment

being 86%, which belongs to the satisfactory level of

achievement of 85-100%, which by definition

deserves to be certified and obtain the golden flag.

REFERENCES

BPJS. The number of work accidents in Indonesia is

still high.

http://www.bpjsketenagakerjaan.go.id/berita/576

9/Jumlah-kecepatan-kerja-di-Indonesiamasih-

tinggi.html. Assessed October 14, 2017.

Efendi, Y. The regulatory framework of

occupational health and safety version 01.

Jakarta: Portal OHS; 2005.

Hendri. Analytical Level of Management System of

Occupational Safety and Health Management of

GOKPL Company in sugovernment

regulationressing accident rate in oil and gas

exploration activity. Thesis. Depok. Faculty of

Public Health University of Indonesia; 2012.p 2-

8.

ICPS 2018 - 2nd International Conference Postgraduate School

554

Ramli, S. Effective OHSMS Agovernment

regulationlication Guide. Jakarta: PT Dian

Rakyat; 2013. p 39-335.

Tarigan Z. Analysis of Occupational Safety and

Health Management System at Oil Palm Plant

(PKS) Tanjung Medan PTPN V Riau Province.

Thesis. Riau. Graduate School of Universitas

Sumatera Utara; 2008. P 47-48.

Evaluation of Implementation of Occupational Health Safety Management System (OHSMS) in PT. X, Magetan, East Java

555