Design and Production of FRP Catamaran Boat for Better River

Transportation in Randuboto Village, Sedayu District, Gresik

Regency

Mohammad Sholikhan Arif, Sri Rejeki Wahyu Pribadi, Wing Hendro Prasetyo,

Dedi Budi Purwanto, Gita Marina Ahadyanti, Danu Utama and Rizky Chandra Ariesta

Department of Naval Architecture, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: FRP Catamaran, Randuboto Village.

Abstract: Gresik is one of the regencies in East Java which has become one of the important port cities of the archipelago

in the past, many of them use the river as a logistics route, At present, the crossing boat in Randuboto Village

have several limitations, namely safety issues, stability issues and wooden boat construction which have some

disadvantages. Catamaran boats have several advantages compared to single-hull boat like better cross-

stability, smaller resistance in the same Breadth. Limited wood supply causes the price of wood to soar and

difficult to obtain. The production of wooden boat is difficult to get raw materials so that the wooden boatyard

are not well developed. Alternative materials that can be used for shipbuilding are fiberglass. Fiberglass

material has several advantages including lightweight, easy to form and cheap. The methods of this research

is conducting a survey to existing wooden boat to get the main dimension of the boat. Secondly, do the design

process like design of linesplan, general arrangement and construction calculation. The result of this research

is catamaran boat that have main dimension L =12 meters, B =3,1 Meters T=0,5 meters H=1,2 meters.

Currently, boatbuilding process is still being carried out.

1 INTRODUCTION

Gresik Regency is a district in East Java Province,

Indonesia. Gresik Regency has an area of 1,191.25

km². The territory of Gresik Regency also includes

Bawean Island, which is 150 km off the coast of the

Java Sea. Gresik Regency borders Surabaya City and

Madura Strait in the east, Lamongan Regency in the

west, Java Sea in the north, Sidoarjo and Mojokerto

Regencies in the south. Gresik is a downstream area

of Bengawan Solo River, and several other rivers

such as Kalimas and Kali Lamong, so the use of

wooden boat transportation to cross from one area to

another (Muhatta and Soesanti, 2018).

The availability of wood in Indonesia as raw

material for boat is increasingly difficult to obtain,

because woods are shrinking every year. With these

conditions, the price of wood will be increasingly

expensive, causing the production costs of building

wooden boat increase. If this continues, the people's

shipyard in Indonesia can no longer meet the needs of

traditional boatbuilding because the capital used is

getting bigger. Therefore, alternative materials for

wood replacement are needed.

Lack of wood material is relatively expensive,

requires regular maintenance. As the age of the boat

increases, the aspect of boat maintenance costs

increases. The age of the vessel increases, it will

affect to cost of exploitation and maintaining the boat.

Thus the maintenance of wooden boat is one of

the problems of traditional fishermen. Maintenance of

wooden boat hull is carried out every 6 months, more

often than fiberglass boats, which is once every 1.5

years. Although the cost is more expensive, fiberglass

boat maintenance results is better and reduce the

frequency of treatment. The reduced frequency of this

treatment can lead to lower initial costs being spent.

The advantages of boat built from FRP are no

leaking in the hull wich continous piece of FRP with

no gap to allow water into hull. FRP does not shrink

or swell so leakage and re-caulking are avoided. FRP

is non-organic and will not rot. As a plastic it cannot

eaten by marine borers. FRP is inert, as a plastic it

will not corrode (Anmarkrud, 2009).

82

Arif, M., Pribadi, S., Prasetyo, W., Purwanto, D., Ahadyanti, G., Utama, D. and Ariesta, R.

Design and Production of FRP Catamaran Boat for Better River Transportation in Randuboto Village, Sedayu District, Gresik Regency.

DOI: 10.5220/0008375000820086

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 82-86

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The advantage of catamaran is that for the same

displacement the catamaran hull has been proven to

produce 20% less resistance compared to monohull

vessels. In addition, the broad deck allows for more

cargo transport (Coackley, 1991).

In this paper, the process of design and production

of FRP catamaran boat for river crossings in Gresik.

Boat design has the advantage of being safer and

more comfortable, better stability and can carry more

loads.

2 METHOD

Generally, catamaran boat design and construction

process uses spiral design method, with engineering

design to get more optimal design.

A survey of existing vessels is carried out to

determine the current condition of the ship. The

survey method is to measure the dimensions of the

ship so that the length, width and loaded of the ship

are obtained. Another objective of surveying the

condition of the boat is to know the aspect of safety,

stability of the boat

Figure 1: Condition of Existing Wooden boat.

We can see in Figure 1, existing crossing river

boat made of wood, have one hull of the boat (less

stability) and no railings to protect passengers from

the danger of being plunged into the river. and there

are no lifejacket as important safety equipment for

passengers. From the survey results, then we design

safe crossing vessels, have good stability and

consider passenger safety aspects (Watson, 1998). the

results of the data obtained from the survey of the

condition of the existing vessels are as follows:

Table 1: Data obtained from Existing boat.

Dimension

Length : 12 meters

Breadth : 3 meters

Height : 0,9 meters

Draft : 0,49 meters

Speed : 10 knots

No. Amount of Motorcycle : 7

No. Amount of Passenger : 10 persons

Engine capacity : P

2.1 Lines Plan

Lines plan is the initial design of the crossing river

boat which consists of 3 main design namely body

plan (front rear view), sheer plan (side view) and Half

Breadth Plan (Ferry, 2013).

The lines plan design is based on the results of the

survey on existing crossing vessels and incorporates

other design parameters such as aspects of feasibility,

safety and design parameters of catamaran vessels

(Liu, 1998). The following figure is the linesplan

design that has been made using CAD software.

Figure 2: Lines plan of Catamaran Boat.

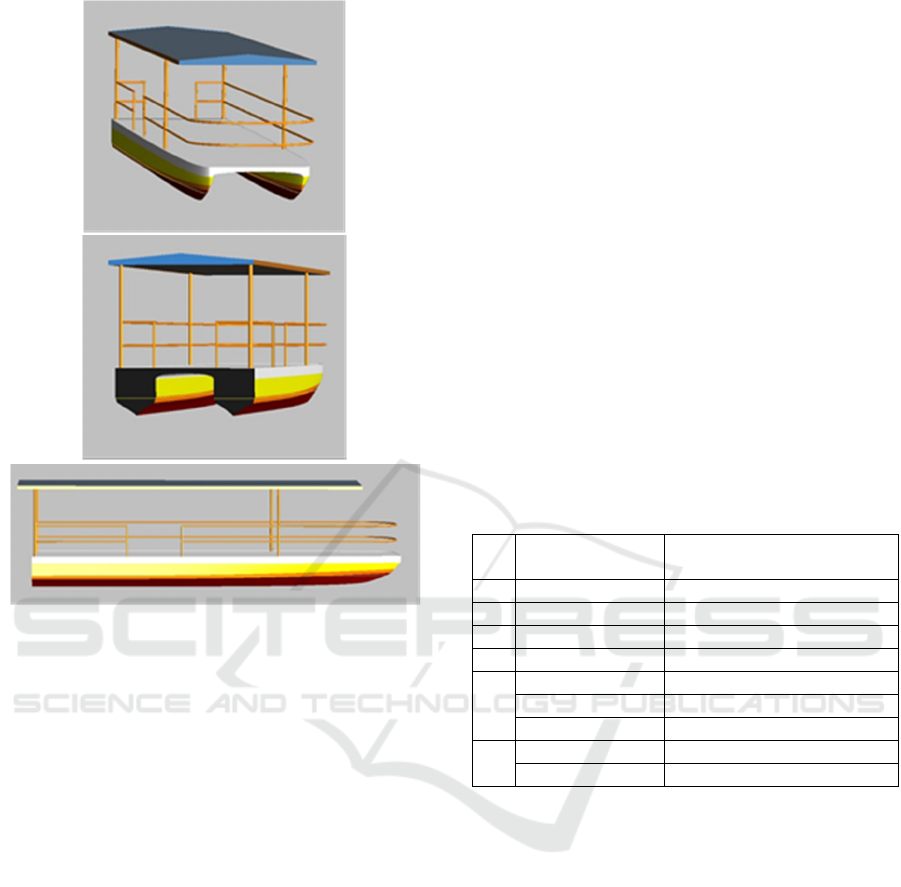

2.2 3D Conceptual Design

After the catamaran lines plan has been made, the

next step is to create a 3D / conceptual design of the

boat. The 3D design results from the catamaran ship

crossing the Bengawan Solo river are as follows:

Design and Production of FRP Catamaran Boat for Better River Transportation in Randuboto Village, Sedayu District, Gresik Regency

83

Figure 3: 3D Conceptual Design.

We can see in the figure 3 above, the catamaran

boat conceptual design that has been made has several

advantages: it has railing to protect passengers from

danger of falling into the river, there is a roof that

protects passengers from the sun's heat and rainy

weather. Catamaran boats provide better stability than

one hull boat. with the same width, catamaran boat

have a smaller resistance compared to one hull boat.

2.3 FRP Construction Calculation

In building a ship, the applicable regulations in the

area of the ship will be used. The purpose of using

rules is to ensure that the construction of the ship that

has been built meets the standards and seaworthy.

In Indonesia, rules that are commonly used are

rules issued by the Bureau Indonesian Classification

(BKI). Rules of the Indonesian Classification Bureau

regarding fiberglass construction vessels include

(Biro Klasifikasi Indonesia, 2015, 2016):

• Rules for FRP and Wooden Fishing Vessel up to

24 m, 2015 edition

• Rules for Fiberglass Reinforced Plastic Ships,

2016 edition

• Rules for Non-Metallic Materials, 2014 edition

In the BKI rules mentioned above, the required

construction measures are specified, the strength

standards of fiberglass materials and material testing

standards

Under the rules of BKI Fiberglass Reinforced

Plastic 2016, results from FRP testing

which is composed of chopped strand mats and

woven roving must not be less than what has been

determined as follows (Biro Klasifikasi Indonesia,

2015, 2016):

1. Tensile Strength: 98 N / mm2

2. Modulus of Tensile Elasticity: 6.86 x 103 N /

mm2

3. Bending Strength: 150 N / mm2

4. Modulus of Bending Elasticity : 6.86 x 103 N /

mm2

The results of construction calculations carried out,

obtained fiberglass laminate arrangement of

catamaran boat. The laminate structure of FRP

catamaran boat construction is as follows:

Table 2: Lamination Schedule of FRP Catamaran Boat.

No.

Construction of

ship

FRP Laminate Arrangement

1 Bottom Plating G+2M300+4M450+4WR800

2 Side Shell G+2M300+2M450+3WR800

3 Deck Plating 4M450+Ply 9 mn

4 Frames

Transver frames 3M450+2WR800

Side longitudinal 3M450+3WR800

Center girder 3M450+2WR800

5

Deck Transverse 3M450+2WR800

Deck Longitudinal 3M450+2WR800

3 FRP CATAMARAN BOAT

BUILDING

After designing lines plan, general arrangement and

calculation of boat construction, the next step is FRP

catamaran boat building; . the steps in boat building

of FRP catamaran boat are mold making, gel coating,

hand lay up, Unplugging from molding, framing and

stiffening section, and Finishing.

3.1 Mold Making

FRP boat molds are composed of wooden frames, 6

mm plywood and melamine plywood. Wooden

frames are used to strengthen the mold, the body of

the ship on the mold is formed using triplex and

melamine plywood. Triplex joints on the mold are

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

84

caulked to flatten the surface of the mold in order to

smooth the hull.

Figure 4: Mold making Process and mold result.

To produce this catamaran boat, only one mold is

needed due to symmetrical catamaran hull. Ready

mold need to clean and mash before lay-up, but not

enough to just be cleaned and mashed. Repair any

holes with appropriate filler. To repair a hole in

corner of plywood, apply a fiberglass patch measured

and cut to fit the hole and apply resin. For the best

results, sand the surface of the mold.

3.2 Gel Coating

The mold surface is waxed as much as 5-7 times for

new molds. The last process in making the mold is the

provision of PVA (Polyvinyl Acrylate) membrane,

this is so that the boat does not stick to the mold. The

process of FRP boat lamination begins with the

provision of Gelcoat layer (the outer layer as a

protective hull) on the mold, this layer is given 2

times so that the resulting FRP catamaran boat is

thicker in color.

Figure 5: Gel Coating Process.

3.3 Hand Lay Up

The next step after gelcoating is hand laying up,

installation of the first layer with MAT 300 fiber

material, so that the coating can attach well to the

complicated parts of the ship (corners, etc.). The

second layer is fiber MAT 450 material (thicker than

MAT 300), then we give WR 800 layer, the next layer

uses MAT 450 and so on to the last layer according

to the lamination schedule.

Figure 6: FRP Lamination Process.

The first coat is called seal coat, Using a roller to

apply on the suface of boat and firm pressure and

directional strokes to spread the resin as evenly as

possible. Cut fiberglass cloth to the shape needed and

attach the fiberglass cloth to the hull using tape, tacks

or staples. The second coat is called the bond coat.

Before this coat applied working from one end of the

hull to the other, apply the bond coat over the

fiberglass. Remove the material attach to fiberglass

cloth to the boat before the bond coat sets up

completely and repeat. The finish coat should be

smooth and even, but should also be thick enough to

allow sand the hull evenly without damaging the

cloth. Give the final coat enough time to dry,

preferably overnight.

Releasing is the FRP Hull release process, which

has been finished laminated and in a curing condition,

from the ship's mold.

3.4 Framing and Stiffening Sections

Frames serves as a reinforcement for the boat. Boat

frame is made of a mixture between CSM and WR

which is molded to "U" form profile. Fiberglass boat

frame consists of several types of construction,

including: Web Frame, Girder, Stiffener, Side Girder,

Center Girder and Side Stringer.

Design and Production of FRP Catamaran Boat for Better River Transportation in Randuboto Village, Sedayu District, Gresik Regency

85

Figure 7: Frame installation result.

Figure 8: Catamaran Boat has been finished.

4 SUMMARY

This article analyzed design and production of

catamaran boat using Fiberglass Reinforced Plastic

as the material with crossing route in Bengawan solo

river in Gresik. Technical analysis conducted with

preliminary design. Using parent base design

methods, the main dimensions of FRP Catamaran

Boat as follows: L (length) = 12 [m] B (Width) = 3.1

[m] H (High) = 1.2 [m] T (Loaded) = 0.5 [m]. From

the results of technical analysis obtained design of

lines plan, general arrangement and boat construction

of Catamaran boat made of fiberglass reinforced

Plastic. catamaran boat conceptual design that has

been made has several advantages: it has railing to

protect passengers from danger of falling into the

river, it has a roof that protects passengers from the

sun's heat and rainy weather. Catamaran boats

provide better stability than one hull boat. with the

same width, catamaran boat have a smaller resistance

compared to existing boat.

The Boatbuilding process of FRP Catamaran Boat

has been carried out, consist of mold making process,

polishing, Gel coating, hand laying up, releasing and

Finishing

ACKNOWLEDGEMENT

This research project was financially supported by

Institut Teknologi Sepuluh Nopember under the

grant: Pengabdian Masyarakat Berbasis Penelitian

2018. This boat using FRP Product from PT. Justus

Kimiaraya.

REFERENCES

Anmarkrud, Thomas, 2009. Fishing boat construction: 4.

Building an undecked fibreglass reinforced plastic boat.

FAO Fisheries and Aquaculture Technical Paper 507.

Biro Klasifikasi Indonesia. 2015. Guidance for FRP and

Wooden Fishing Vessel Up To 24m. Jakarta: BKI.

Biro Klasifikasi Indonesia. 2016. Rules for Fiberglass

Reinforced Plastic. Jakarta: BKI.

Coackley, 1991. Ned. Fishing Boat Construction, 2:

Building a Fiberglass Fishing Boat. No. 321. Food &

Agriculture Org.

Ferry, M. 2013. Comparative Study Of Hybrid Catamaran

Versus Diesel Monohull Boat As Ferry For Short

Distance Routes. The Indonesian Journal of Naval

Architecture 1.1.

Liu, Qian, et al. 1998. Effects of Principal Dimensions,

Moulded Lines and Parameters of Channel on Speed

and Powering of Catamaran Planins Boat. Shipbuilding

of China 3: 001.

Muhatta, Z., and N. Soesanti, 2018. The toponymy of the

ancient port city of Gresik in the northern coastal area

of Java, Cultural Dynamics in a Globalized World.

Watson D, 1998. Practical Ship Design, Butterworth

Heinemann, Oxford.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

86