Roles of PEG based Alternative Stimulant to Increase Latex Yield

and Renewable Bark Recovery of Clones PB 260 6 Years Old

Murni Sari Rahayu

1

, Nurhayati

1

, Yenni Asbur

1

and Radite Tistama

2

1

Lecturer on Department of Agrotechnology, Faculty of Agriculture, Islamic University of North Sumatera, Medan,

Indonesia

2

Rubber Research Institute, Sungai Putih, Deli Serdang, North Sumatra, Indonesia

Keywords: Stimulant, PEG, Clone PB 260.

Abstract: The research was aimed to obtain PEG based alternative stimulant formulation to increase Latex yield and

accelerate renewable bark recovery of clone PB 260. This research was conducted at PTPD Paya Pinang

Plantation, LauTador, in Tebing Tinggi, Regency of Deli Serdang, North Sumatera. The research site is at

25 m above sea level with Ultisol soil type. This research is to study the difference of observation variable

of g/p/s, bark thickness, number of latex vessels, plugging index. The results showed that stimulant had

significant effect on the production of g/p/s, and very significant effect on bark thickness, number of latex

vessels and plugging index. PEG applications increase production of g/p/s, bark skin, number of latex

vessels, plugging index. The combination of stimulant and PEG has very significant effect on the production

of g/p/s, bark thickness, plugging index.

1 INTRODUCTION

Rubber tree (HeveabrasiliensisMuell, Arg) is the

main source of natural rubber and large foreign

exchange income source. In the future, the prospect

of natural rubber is still good, as indicated by

increasing trend of natural rubber consumption

(Anwar, 2012; Boerhendhy, 2013).

Indonesia's opportunity to become the world's

largest producer of natural rubber is quite large due

to adequate resources to increase production.

Increased production can be achieved among others

by using superior clones and optimization of tapping

system. One of the optimization of tapping system is

the use of stimulants to increase rubber productivity

and business efficiency (Andriyanto and Darojat,

2016).

Stimulants can increase production by slowing

latex flow in latex vessels.

Stimulants applied to plant tissues can stabilize

lutoid which is the basic traction of latex and

contains many cautions. Lutoid stabilization is

crucial because if the lutoid ruptures, the cautions

will react with negative rubber particles and

resulting coagulation. Coagulation process causes

the latex to stop dripping (Krishnakumaret al, 2011).

Due to the reason, the purpose of stimulants

application is to delay coagulation of latex vessels

and latex mass flow is longer.

Acceleration of bark recovery is very important

particularly for superior clones of PB 260. Such

clone is Quick Starter which has some specific

properties such as high initial production, less

responsive to stimulants, thin renewable bark and

fast exploitation system. The economic life of clone

PB 260 is 17 years (Rahayu, 2017).

In addition,renewable bark recovery is essential

to support and at the same time create good

conditions for adjacent panels (panel BO-2)

(Sumarmadji, et al., 2012). This certainly can

prevent the occurrence of dry tapping grooves for

sufficient nutritional intake in panel BO-2 with rapid

bark recovery in panel BO-1.

PEG (Polyethylene glycol) is a compound that

can decrease osmotic potential through sub unit

ethylene oxide activity that increase water molecules

through hydrogen bond and potentially used as

stimulant material.

Rahayuet al (Rahayuet al,2016) was reported that

PEG application as stimulant can increase latex

production.Rahayuet al (Rahayuet al,2017) also

revealed that PEG can increase latex production and

increase bark thickness of 11 years old of clone PB

260.

The aim of this research is to study PEG as an

206

Rahayu, M., Nurhayati, ., Asbur, Y. and Tistama, R.

Roles of PEG based Alternative Stimulant to Increase Latex Yield and Renewable Bark Recovery of Clones PB 260 6 Years Old.

DOI: 10.5220/0008887502060211

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 206-211

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

alternative stimulant to increaselatex production and

accelerate renewable bark recovery and thickness in

6 years old of clone PB 260.

2 RESEARCH METHODS

This research was conducted at PTPD Paya Pinang

Plantation, LauTador, in Tebing Tinggi, Regency of

Deli Serdang, North Sumatera. The research site is

at 25 m above sea level with Ultisol soil type.

The research is 2 factors Randomized Block

Design. The factor treatment is stimulant

concentration (S), consisted of 4 treatment levels

namely S

0

= no stimulant, S

1

= N

2

O

1

formulation, S

2

= Etephon 1.5% + N

2

O

1

formulation, S3 = 2.5%

etephon + N

2

O

1

formulation and PEG concentration

(P) consisted of 2 levels namely P

0

= no PEG, P

1

=

PEG 3%.

3 RESULTS AND DISCUSSION

3.1 Latex Yield (g/p/s)

Latex yield is measured by the volume of latex per

tree per tapping and then converted to dry

production in grams per tree per tap (g/p/s) after

multiplying by the Total Solid Content (TSC). The

results showed that application of Stimulant (S) has

significant effect on Latex production.

Application of PEG (P) also has significant

effect on Latex production. Combination of

Stimulant (S) and PEG (P) had very significant

effect on latex production (Table 1).

Table 1: Mean of Latex Production (g/p/s) on Treatment

of Stimulant and PEG at 6 years old of Clone PB 260.

Treatment

Latex

Production

(g/p/s)

Stimulant

S

0

(control)

S

1

(N

2

O

1

formulation)

S

2

(Etephon 1,5% + N

2

O

1

formulation)

S

3

(Etephon 2,5% + N

2

O

1

formulation)

PEG

P

0

(control)

P

1

(PEG 3%)

Interaction

30.47 d

35.79aA

31.43 c

33.12 b

26.85bB

38.55aA

S

0

P

0

S

0

P

1

S

1

P

0

S

1

P

1

S

2

P

0

S

2

P

1

S

3

P

0

S

3

P

1

29.00hH

37.23cC

27.33fF

44.26aA

29.88eE

32.98dD

26.49gG

39.74 Bb

Note: The numbers followed by the same letter on the

same row or column are not significantly

different at the 5% Duncan test level and 1%

(N

2

O

1

: NAA 100 ppm + kinetin 50 ppm +

palmitic acid 2%)

Table above shows that stimulant treatment has

significant effect on latex production. The highest

latex production is found at S

1

treatment namely

N

2

O

1

formulation at 35.79 g/p/s, while the lowest is

on S

0

treatment (control) at 30.47 g/p/s. In this case,

there is an increase in latex yield by 17.45% with

application of N

2

O

1

. PEG application also had

significant effect on latex yield that is an increase of

latex yield by 43.57%.

The combination of stimulants and PEG had

significant effect on latex yield. The highest latex

yield was found at S

1

P

1

treatment (N

2

O

1

and PEG

formulations), while the lowest was S

0

P

0

(control).

Increased latex yield by application of N

2

O

1

and

PEG formulations is 52.62%.

Interaction of stimulant S

1

treatment (N

2

O

1

formulation) and PEG show significantly increased

of production. This is because the formulation

material is containing palmitic acid (fatty acid). In

glycolysis process, such palmitic acid would be

converted into Acetyl Coenzym A. Such Coenzym

will form Tricarboxilie Acid (TCAs) which will

produce energy. The energy is used for vegetative

growth (stem cell enlargement) that is the addition

of brak thickness and the number of latex vessels.

Some of Acetyl Co A will produce terpenoid

compounds such as polyterpenes (latex). Therefore,

application of a stimulant containing palmitic acid

causes increasing the production of latex (Rahayuet

al, 2017).

In addition, PEG application will maintain the

osmotic potential stability and moisture content in

plant cells which will help to increase the turgor

pressure in the plant (Rouhi and Surki, 2011;

Rahayuet al., 2017). Availability of water in the cells

will help increase cell division followed by

increased bark thickness and number of latex

vessels.

Ariefet al (Ariefet al,2010) reported that

conditioning treatment with PEG 300 gl

-1

can

increase the growth of soybean. The maintained

Roles of PEG based Alternative Stimulant to Increase Latex Yield and Renewable Bark Recovery of Clones PB 260 6 Years Old

207

moisture content in the cells will increase turgor.

Increasing number of latex vessels and turgor

pressure will encourage production. Thus, PEG

application will increase latex production (Rahayuet

al., 2017; Rahayu, 2017; Rahayuet al., 2017).

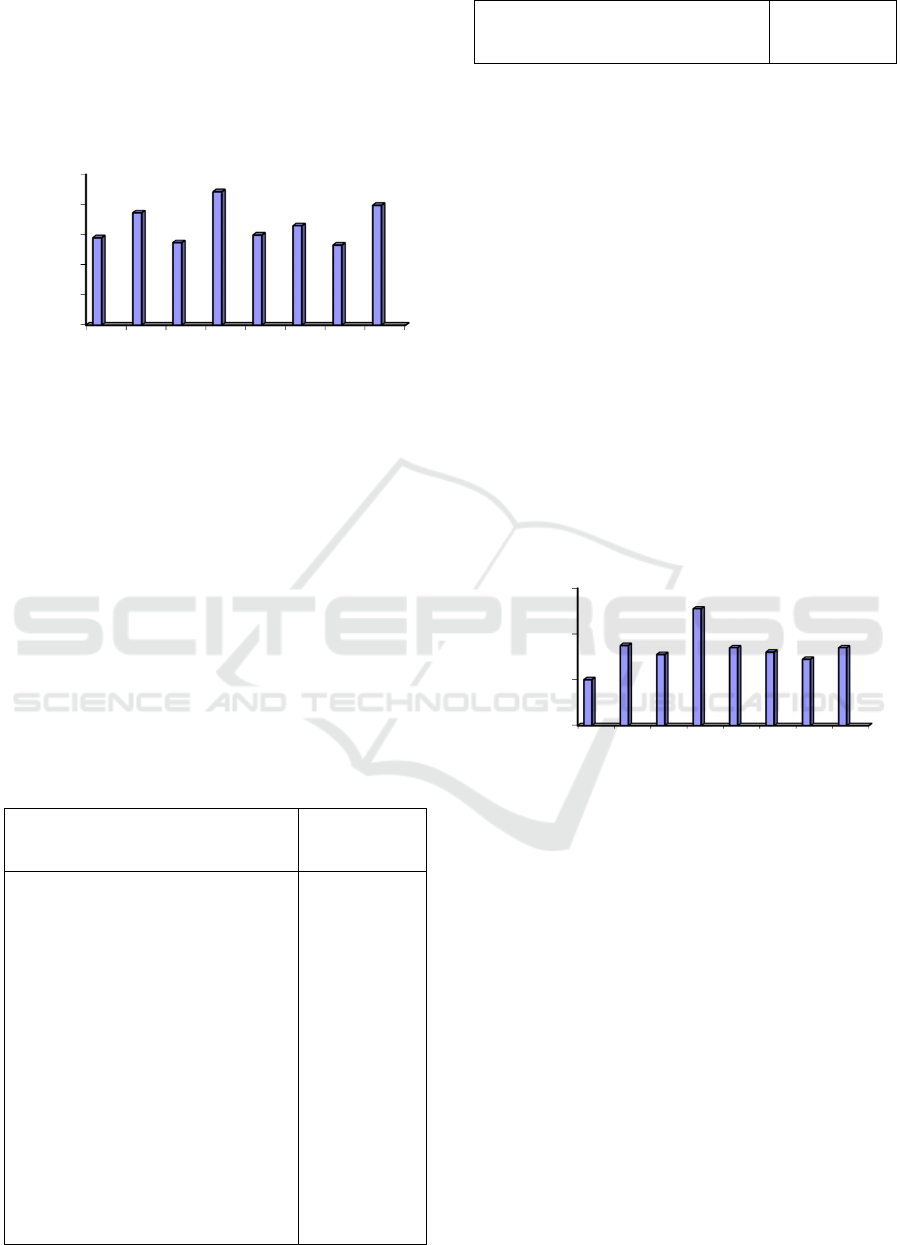

Figure 1: Histogram of Latex Production with

combination of Stimulant and PEG Treatment on 6 years

old of clone PB260.

3.2 Bark Thickness (mm)

Bark is the main capital of rubber cultivation.

Therefore efforts should be conducted to make

renewable bark can be recovered well so that can be

tapped again. The statistic analysis results showed

that Stimulant (S) and PEG (P) have significant

effect on bark thickness. Combination of Stimulant

(S) and PEG (P) application also has very significant

effect on bark thickness (Table 2).

Table2: Mean of Bark Thickness (mm) on Treatment of

Stimulant and PEG at 6 years old of Clone PB 260.

Treatment

Bark

Thickness

(mm)

Stimulant

S

0

(control)

S

1

(N

2

O

1

formulation)

S

2

(Etephon 1,5% + N

2

O

1

formulation)

S

3

(Etephon 2,5% + N

2

O

1

formulation)

PEG

P

0

(control)

P

1

(PEG 3%)

Interaction

S

0

P

0

S

0

P

1

S

1

P

0

S

1

P

1

S

2

P

0

2.27bB

2.41aA

2.33bB

2.32bB

2.28bB

2.38aA

2.20cC

2.35bB

2.31bB

2.51aA

2.34bB

S

2

P

1

S

3

P

0

S

3

P

1

2.32bB

2.29bB

2.34bB

Note: The numbers followed by the same letter on the

same row or column are not significantly

different at the 5% Duncan test level and

1%(N

2

O

1

: NAA 100 ppm + kinetin50 ppm +

palmitic acid 2%).

The table above shows that stimulant application

has very significant effect on renewable bark

thickness. The highest bark thickness found in S

1

treatment, namely application of N

2

O

1

at 2.41 mm.

The lowest is found at S

0

treatment (control) namely

2.27 mm, an increase by 6.17% with N

2

O

1

application. Application of PEG is also significantly

affect the thickness of renewable bark.

The combination of stimulant and PEG had

significant effect on the thickness of renewable bark.

The highest thickness of renewable bark was found

in S

1

P

1

treatment (N

2

O

1

formulations and PEG). The

lowest thickness of renewable bark was found in the

treatment of S

0

P

0

(control). Increased thickness of

renewable bark by application of N

2

O

1

formulation

and PEG is 14.09%.

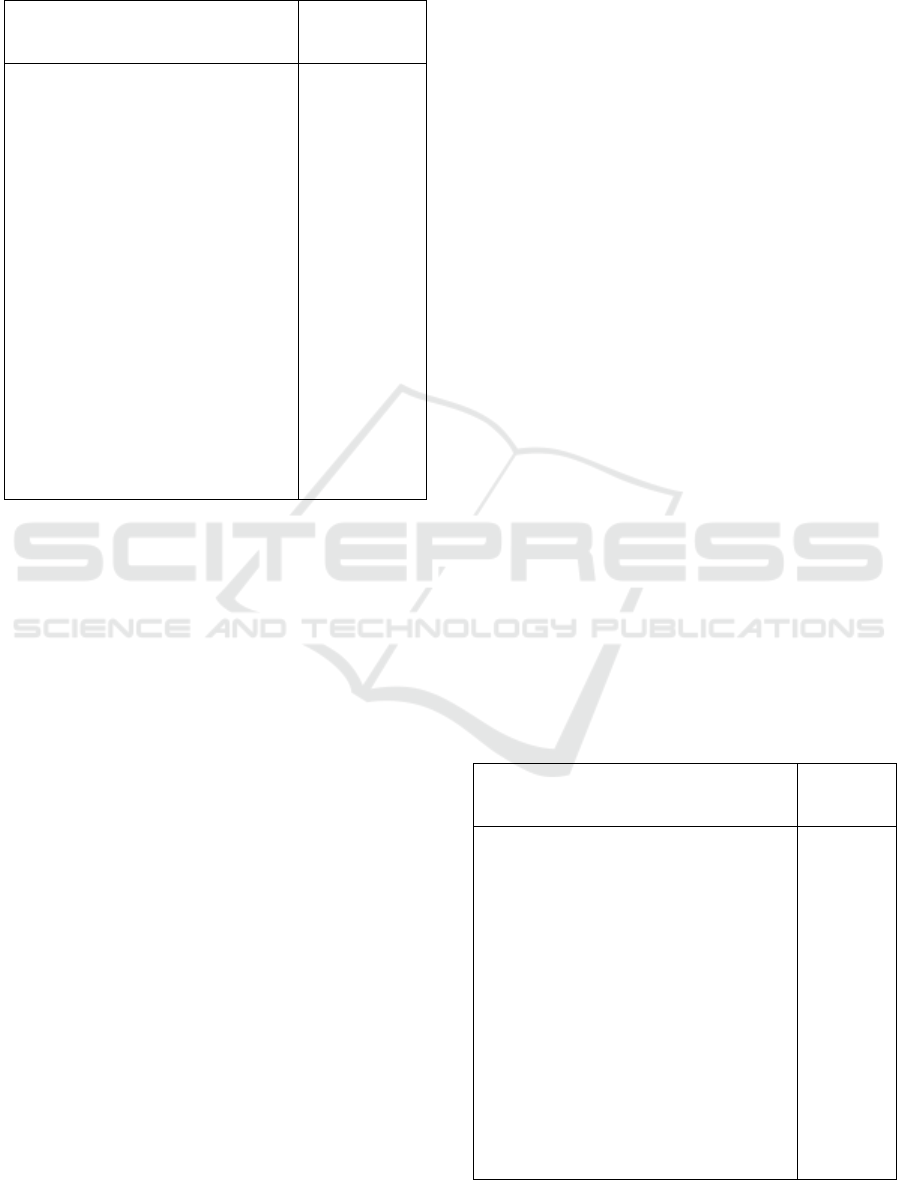

Figure 2: Histogram of Renewable Bark Thicknesswith

combination of Stimulant and PEG Treatment on 6 years

old of clone PB 260.

3.3 Number of Latex Vessel

The results showed that stimulant and PEG

treatment have very significant effect on the number

of latex vessels. The combination also has very

significant effect on the number of latex vessels

(Table 3).

2.00

2.20

2.40

2.60

S0P0 S0P1 S1P0 S1P1 S2P0 S2P1 S3P0 S3P1

Bark Thickness (mm)

Giving Stimulants dan PEG

0.00

10.00

20.00

30.00

40.00

50.00

S0P0 S0P1 S1P0 S1P1 S2P0 S2P1 S3P0 S3P1

Latex Production (g/p/s)

Giving Stimulants and PEG

ICMR 2018 - International Conference on Multidisciplinary Research

208

Table 3: Means of the Number of Latex Vessels on

Stimulant and PEG Treatment at 6 years old of Clone PB

260.

Treatment

Number of

Latex

Vessel

Stimulant

S

0

(control)

S

1

(N

2

O

1

formulation)

S

2

(Etephon 1,5% + N

2

O

1

formulation)

S

3

(Etephon 2,5% + N

2

O

1

formulation)

PEG

P

0

(control)

P

1

(PEG 3%)

Interaction

S

0

P

0

S

0

P

1

S

1

P

0

S

1

P

1

S

2

P

0

S

2

P

1

S

3

P

0

S

3

P

1

10.58bB

11.74aA

11.41abAB

10.96bB

10.44bB

11.91aA

9.80

11.35

10.80

12.69

10.91

11.91

10.24

11.69

Note:The numbers followed by the same letter on the

same row or column are not significantly different

at the 5% Duncan test level and 1%(N

2

O

1

: NAA

100 ppm + kinetin50 ppm + palmitic acid 2%).

The table above shows that stimulant application

has very significant effect on the number of latex

vessels. The highest number of latex vessels was

found in S

1

treatment (N

2

O

1

formulation) namely

11.74,while lowest found at S

0

(control) namely

10.58. Increasing the number of latex vessels by

N

2

O

1

is10,96%. PEG application also has very

significant effect on the number of latex vessels that

is an increase by 14.08%.

The combination of stimulant and PEG did not

significantly affect the number of latex vessels.

However, there is a tendency for the largest number

of latex vessels to be found in S

1

P

1

treatment (N

2

O

1

and PEG 10%), while the lowest number is found in

the S

0

P

0

treatment (control). Increasing number of

latex vessels by stimulant (control) and PEG is

29,49%.

Table 2 and 3 show that N

2

O

1

application of

increases bark thickness and number of latex

vessels. This is because N

2

O

1

formulation is

containing auxin (NAA) and cytokinin (kinetin)

along with palmitic acid. The synergism of both

hormones can lead to cell division, enlargement, and

cell differentiation, especially in the rubber stems

which resulted in the thickening of the bark and the

number of latex vessels. Rahayuet al (Rahayuet

al,2016) reported that the application of NAA +

kinetin can increase the bark thickness and the

number of latex vessels. Koryati (Koryati,2016)

also found that the administration of auxin hormone

(IAA) and kinetin may affect the bark thickness and

the number of latex vessels in various clones.

In other hand, the palmitic acid in the

formulation will be converted to Acetyl Co A as

important precursor in primary and secondary

metabolism. In primary metabolism, Acetyl CoA

will enter to Tricarboxilyc Acid (TCA) cycle that

will produce energy (ATP) where the energy (ATP)

will be used by plants for vegetative growth such as

increases the bark thickness and the number of latex

vessels (Rahayuet al, 2016; 2017).

PEG application is capable to maintain osmotic

potential and water content in plant cells

(RouhiandSurki, 2011, Rahayu, 2017). In addition,

PEG works optimally in the process of entering

water into cells and thus will increase and spur cell

division followed by the addition of cell number and

size (cells enlargement) (Sufinoris, 2009;Susanti,

2014). Thus the provision of PEG here can help

increase the bark thickness and the number of latex

vessels.

3.4 Pluging Index (IP)

The result of statistic analysis showed that stimulant

and PEG treatment have very significant affect on

plugging index. The treatment combination also has

significant affect on the plugging index (Table 4).

Table 4: Mean of Plugging Index on Stimulant and PEG

Treatment at 6 years old of Clone PB 260.

Treatment

Pluging

Index

(IP)

Stimulant

S

0

(control)

S

1

(N

2

O

1

formulation)

S

2

(Etephon 1,5% + N

2

O

1

formulation)

S

3

(Etephon 2,5% + N

2

O

1

formulation)

PEG

P

0

(control)

P

1

(PEG 3%)

Interaction

S

0

P

0

S

0

P

1

S

1

P

0

S

1

P

1

S

2

P

0

S

2

P

1

7.15 bB

6.12 dD

7.53 aA

7.08 cC

7.29 aA

6.60 bB

8.04 a

6.27 e

6.43 d

5.61 f

7.62 b

7.44 b

Roles of PEG based Alternative Stimulant to Increase Latex Yield and Renewable Bark Recovery of Clones PB 260 6 Years Old

209

S

3

P

0

S

3

P

1

7.10 c

7.07 c

Note: The numbers followed by the same letter on the

same row or column are not significantly

different at the 5% Duncan test level and

1%(N

2

O

1

: NAA 100 ppm + kinetin 50 ppm +

palmitic acid 2%)

The table shows that stimulant application (S)

has very significant effect on the plugging index

(IP). The lowest plugging index was found in S

1

treatment with application of N

2

O

1

formulation, and

the highest on S

2

treatment with etephon 1.5% +

N

2

O

1

formulation. The decrease in the plugging

index by application of N

2

O

1

formulation compared

with control (S

0

) is 23,04%. PEG application has

very significant effect on the 23,04 index that is

lowering the 23,04index by 10.45%.

The combination of stimulant and PEG has

significant effect on the plugging index. The lowest

plugging index was found in S

1

P

1

treatment (N

2

O

1

formulation and PEG), while the highest found in

S

2

P

1

treatment. The decrease in the block index by

application of N

2

O

1

and PEG formulation compared

with the controls is 43,32%.

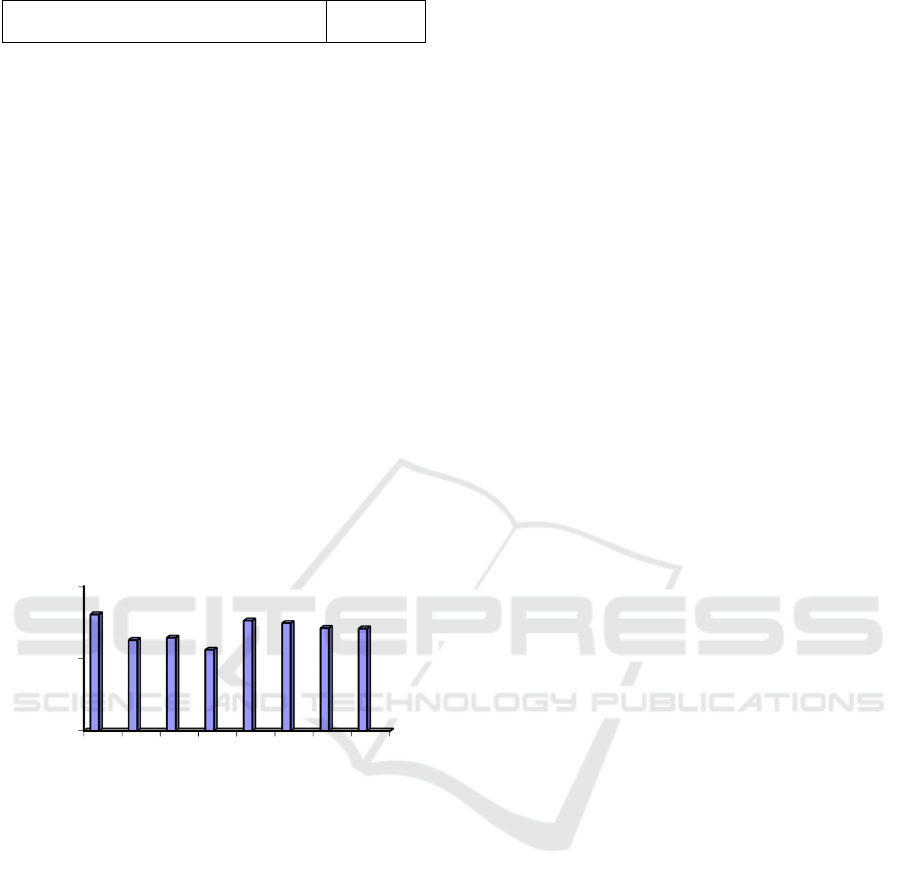

Figure 3: Histogram of Plugging Indexwith combination

of Stimulant and PEG Treatment on 6 years old of clone

PB 260.

The decrease in plugging index with N

2

O

1

formulation is caused by increased energy from the

palmitic acid contained in the formulation. Such acid

will produce ATP (energy) derived from

Tricarboxylic acid (Respiration). ATP will be used

as a source of energy for the formation of Iso

Pentenyl Pyrofospat (IPP) which will produce

isoprene (latex) (Rahayuet al, 2017; Rahayuet al,

2017).

Accordingly, Zulhilmiet al (Zulhilmiet al,2012)

confirm that photosynthesis activity will increase

with the provision of PEG so that NADH-oxidase is

also increases. Increased NADH-oxidase is followed

by increased Super Oxide Dismutase (SOD)

enzymes that play a role in stabilizing lutoid. Stable

lutoid will decrease the plugging index so latex will

flow and latex production becomes increased

(Rahayuet al, 2017; Rahayu, 2017).

Accordingly, Sumarmadji (Sumarmadji,1999)

states that if the production increases the plugging

index will decrease, in other words plugging index is

negatively correlated with production.

4 CONCLUSION

1. Stimulant application is significantly lead to

increased production; reduce plugging index,

increase bark thickness and number of latex

vessels.

2. PEG application also encourage increased

production (g/p/s), bark thickness, number of

latex vessels and decreasing the plugging

index

3. The combination of stimulant and PEG

increase latex production, bark thickness and

the number of latex vessels, and decreasing

the plugging index.

REFERENCES

Andriyanto, M dan Darojat, M.R. 2016. Potensi

Polyethylen Glycol (PEG) sebagai Stimulan Lateks

pada Tanaman Karet (Heveabrasiliensis Muel.Arg).

Agrovigor 9(1).

Anwar, C. 2012. Prospek Karet Masih Bagus. Media

Perkebunan Edisi 106. November 2012, 68-69.

Arif, M., Tariq, M., Khan, M.U and Munir, I. 2010. Effect

of Seed Prinning on Growht Parameter of Soybean. J

Bot. 43(4). 2803-2812.

Boerhendhy, I. 2013. Penggunaan Stimulan Sejak Awal

Penyadapan untuk Meningkatkan Produksi Klon IRR

39. Jurnal Penelitian Karet, 2013, 31(2):117-126.

Koryati, T. 2016. Upaya Mempercepat Matang Sadap dan

Karakter Produksi Lateks Beberapa Klon Karet

melalui Penggunaan Zat Pengatur Tumbuh. Disertasi

Program Doktor Ilmu Pertanian. Pascasarjana Fakultas

Pertanian Universitas Sumatera Utara.

Krishnakumar, R., R.L. Helen., P.K. Ambily dan J. Jacob.

2011. A Modified Stimulation Method in

Heveabrasiliensis for Reducing Oxidative Stress.

IRRDB International Rubber Conference Thailand,

15-16 Dec 2011.

Rahayu, M.S., Siregar. L.A.M., Purba, E., Tistama, R.

2016. Pengaruh Waktu Aplikasi dan Pemberian PEG

TerhadapProduksiKaret (HeveabrasilliensisMuel.Arg)

pada Klon PB 260. Prosiding Seminar Nasional

PERAGI. Bogor.

0.00

5.00

10.00

S0P0 S0P1 S1P0 S1P1 S2P0 S2P1 S3P0 S3P1

Plugging Index (%)

Giving Stimulants dan PEG

ICMR 2018 - International Conference on Multidisciplinary Research

210

Rahayu, M.S. 2017. Peran Zat Pengatur Tumbuh,

Oleokimia dan PEG dalam Meningkatkan Produksi

dan Mempercepat Pemulihan Kulit Tanaman Karet

Klon PB 260. Disertasi, Program Doktor Ilmu-Ilmu

Pertanian Pascasarjana Fakultas Pertanian Universitas

Sumatera Utara Medan.

Rahayu, M.S., Siregar. L.A.M., Purba, E., Tistama, R.

2017. Pengaruh Stimulan Berbahan Pemulih Kulit dan

PEG (Polyetilen Glikol) Terhadap Pertumbuhan Kulit

Pulihan dan Produksi Tanaman Karet

(HeveabrasilliensisMuel.Arg) Klon PB 260.

International Journal of Science and Research

Methodology.

Rahayu, M.S., Nurhayati., Tistama, R., Asbur, Y. 2017.

The Role of PEG Based Stimulant Application on The

Production and Physiology Character of Clone PB

260. International Journal of Sciences: Basic and

Applied Research.

Rouhi, H.R. and Surki, A.A. 2011. Study of Different

Priming Treatments on Germination Traith of Soybean

Lots Biol Sci. 3(1). 101-108.

Sufinoris. 2009. PeningkatanViabilitas (Priming) Benih

Kapas (Gossypium hircatum L.) dengan Polyethylene

Glycol (PEG) 6000. Skripsi diterbitkan. Malang: UIN

Maliki Malang.

Sumarmadji. 1999. Respon Karakter Fisiologi dan

Produksi Lateks Beberapa Klon Tanaman Karet

Terhadap Stimulan Etilen. Balai Penelitian Sungei

Putih dan Badan Penelitian dan Pengembangan

Pertanian.

Susanti, E. 2014. Pengaruh Osmoconditioning dengan

PEG (Polyethylene Glycol) 6000 Terhadap Viabilitas

Benih Kenaf (Hibiscus cannabisius L.). Fakultas Sains

dan Teknologi. Universitas Islam Negeri Maulana

Malik Ibrahim, Malang.

Zulhilmi; Suwirmen; Surya, W.N. 2012. Pertumbuhan dan

Uji Kualitatif Kandungan Metabolit Sekunder Kalus

Batang (SpilanthesacmellaMurr.) dengan Penambahan

PEG untuk menginduksi Cekaman Kekeringan. Jurnal

Biologi, Universitas Andalas. September 2012:1-8.

Roles of PEG based Alternative Stimulant to Increase Latex Yield and Renewable Bark Recovery of Clones PB 260 6 Years Old

211