The Motion Response Analysis of Floating Jack-Up Rigs in the

Operating Condition

Asri Sawiji

Universitas Islam Negeri Sunan Ampel, Jl. A. Yani 117 Surabaya, Indonesia

Keywords: floating jack-up, motion, wave, six degree of freedom

Abstract: Natural gas reservoirs near the seabed (shallow gas) make drilling activities prone to blowout. Using a

modified jack-up in a floating state will facilitate evacuation to avoid gas explosion. The floating jack-up is a

misuse of the concept of jack-up structure design which must be operated in a fixed structural condition. This

issue requires further investigation regarding the feasibility of the drilling operation process. Motion response

of the floating structure is revealed in order to explore the feasibility of the operation of the jack-up. In this

study, the motion response of the floating bodies will be compared by varying the jack-up leg length immersed

in the water. The site reviewed in this analysis is in the Madura Strait, Indonesia. The floating jack-up was

modeled and analysed in the MOSES offshore platform design and simulation software. Results show that

the response amplitude operator of pitch motion has the most significant response in each variation. From

motion validation with rules it can be concluded that the heave motion of this structure exceeded criteria limits

for BOP and riser operations but is allowed for drilling activities. The obtained results show that a drilling

process in the Madura Strait site using a floating jack-up could possibly be operated by lowering the legs

until it reaches five meters above the seabed without running BOP and risers.

1 INTRODUCTION

Jack-up rigs are offshore drilling platforms with legs

that can be raised and lowered in the installation

process. The concept of designing a jack-up structure

is that it combines the advantages of fixed structure

buildings such as platform jacket legs and floating

platforms such as floating barges. The jack-up is a

self-elevating unit. The transportation and installation

phases are done during floating conditions, while the

spud cans will be jacked onto the seabed during the

operating or drilling phase (DNV, 1996).

Seabed sub-surface soil conditions containing

shallow gas where the trap of natural gas reservoirs

located near the seabed floor will cause the area to be

prone to blowout. The presence of shallow gas may

possibly cause blowout that will damage the jack-up

structure. The penetration of jack-up legs will make it

difficult to structure evacuation, because the jacking

process of the jack-up legs will take a long time. This

problem raises an idea: what if this offshore building

structure is operated under conditions where the legs

are not fixed on the sea floor or operated in floating

condition. Jack-up legs do not touch the sea floor,

meaning jack-ups will always be floating in the ocean

so evacuation procedures can run smoothly and

prevent damage to the structure. A jack-up structure

with hanging legs may prove to be the solution. In

accordance to the concept of jack-up design, the

floating structure of the jack-up clearly does not fulfil

the design rule. It may be questioned whether the

jack-up can remain stable in a state of operation

(drilling activities), how the structure moves, if it can

still withstand environmental loads such as wind,

currents and waves. With this analysis, we will find

out whether the floating jack-up can be operated in

drilling or operating conditions.

This research focuses on jack-up rigs of the three

independent leg type with K-braced truss legs. It

discusses how the motion response of the floating

jack-up was subjected to the environmental load. The

location of study of this simulation is in the Madura

Strait in Indonesia, which has a water depth of 57m.

This paper describes and compares the structural

motion analysis of six variations of immersed jack-up

legs which were subjected to environmental loads.

The behavior of motion response of each variation

was recorded.

Sawiji, A.

The Motion Response Analysis of Floating Jack-Up Rigs in the Operating Condition.

DOI: 10.5220/0008908100002481

In Proceedings of the Built Environment, Science and Technology International Conference (BEST ICON 2018), pages 191-196

ISBN: 978-989-758-414-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

191

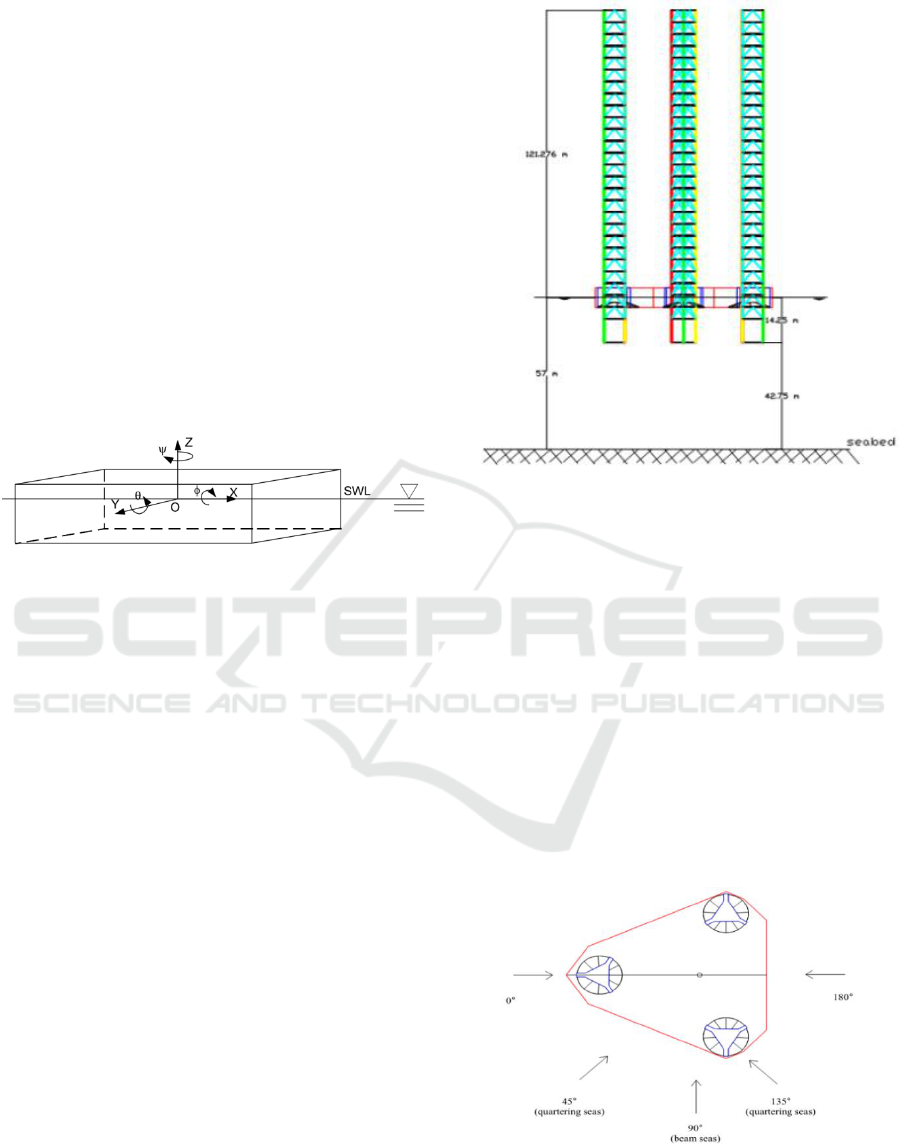

Figure 1: Outboard Profile and Plan Views

The principle particulars of the vessel are as indicated

below:

Length Moulded

64.643 m

Width of Hull

64.008 m

Depth of Hull

7.925 m

Leg length

140.208 m

Overall Length of Spud Legs

140.208 m

Longitudinal Leg Centres

40.915 m

Transverse Leg Centres

47.244 m

LCG Bow (Forward)Leg

10.622 m

Diameter of Spud Cans

7.315 m

Displacement at Load Line

23033.5 kips

The jack-up platform was normally designed to

function in several different operational modes, i.e.

the transit, installation, retrieval and operational

condition. Response of the jack-up in the floating

mode of operation is obviously far different from that

of the jack-up in the installed, elevated condition.

Both of these modes are critical to the safe operating

of a jack-up unit as each mode of operation may

impose its own limiting design criteria on certain

parts of the structure (DNV, 1996). In the

transportation phase, the jack-up is towed towards the

drilling point location with the leg lifted above the

hull. Arriving at the drilling point, the jack-up legs are

lowered down onto the seabed then jacked until the

bearing capacity is sufficient to hold the sea current.

The installation phase is the phase where the jack-up

leg is self-elevating upward and downward in the sea

water, which is commonly called the jacking process.

The operation phase is the phase where the jack-up

performs its function.

This paper considered the operation phase as the

focus of analysis. Six cases were chosen to analyse

the motion response of the jack-up platform to

explore the possibilities of this structure when

operated in a floating condition. The cases are

described in the table below.

Table 1: Motion response analyses of case studies.

Case

Immersed Leg

Length (m)

Remarks

1

0

Towing

2

14.25

¼ of Water Depth

3

28.5

½ of Water Depth

4

42.75

¾ of Water Depth

5

52

5 meters above seabed

6

57

Jacked

2 METHOD

The jack-up rig of this model was simulated on the

MOSES 7.0 software with the aim of discovering the

motion response of the structure. The jack up was

designed in three dimensions and was only

considered on the operating condition. The WSD

method was generally used in this analysis. The hull

and leg structure was modelled as subjected to

horizontal load (wind, wave, current load) for all

cases. The structural load implied on this model is the

self-weight of the jack-up, distributed load on the hull

and the derrick load. The Metocean data used in this

analysis was one year of the return period. Based on

environmental data, the heading direction was

dominantly from the west. The wind speed used in

this analysis was 3 seconds gusting condition or

50.268 knots, the significant wave height was 3.24

meters, with a wave period of 9.01 seconds. The

current speed was 0.62 m/s on the mean sea level and

0.49 m/s on the seabed.

The floating jack-up is identified as a mobile

offshore drilling unit (MODU). The designing of a

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

192

MODU needs to consider the variation of

environmental load, minimize riser vibration and

interference between risers and structure in order to

anticipate the structural failure and blow out. To

understand which cases can be applied on the drilling

operation condition based on the analysis of criteria

such as motion response, drilling and tripping,

running and setting casing, running and landing

BOP/Riser, transferring equipment, they were

verified based on the book Floating Drilling:

Equipment and Its Use by Riley Sheffield, 1980.

The motion of floating was considered in order to

find out the behaviour of the structure. The behaviour

of the floating structure is the freedom of movement

or oscillation. This oscillation consists of six

movements, which consist of three lateral movements

and three rotational movements in three direction

axes, as shown on Figure 2.

Figure 2: Six degrees of freedom

These types of movements are:

a. Surging: Movement of lateral oscillations on the x-

axis.

b. Swaying: Movement of lateral oscillations on the -

y axis.

c. Heaving: Movement of lateral oscillations on the -

z axis.

d. Rolling: Movement of rotational oscillations on the

x-axis.

e. Pitching: Rotational oscillation movement against

the -y axis.

f. Yawing: Rotational oscillation movement against

the -z axis.

However, the scope of work of this paper only

considered the heave, roll and pitch motions. These

three motion responses were analysed on the MOSES

software with the output of Response Amplitude

Operator. The Response Amplitude Operator was

used to assess the frequency-domain linear wave

body response of the floating platform during the

design process. RAO is defined as the response

amplitude per unit wave height (Chakrabarti, 1987).

𝑅𝑒𝑠𝑝𝑜𝑛𝑠𝑒

(

𝜔

)

= 𝑅𝐴𝑂

(𝜔) (1)

Where: = Wave amplitude (m, ft)

Figure 3: Jack-up modelling on MOSES 7.0 (case 2)

3. RESULT AND DISCUSSION

Sawiji (2015) stated that the stability of a floating

jack-up with the leg length of 140.208m and water

depth 57m is classified as a stable structure with an

area ratio above 1.4 and a tilted angle more than

28(American Bureau of Shipping, 2005). In

structure response analysis, cases are exposed to

waves, winds and currents in five different directions,

i.e. in the heading direction of 0°, 45°, 90°, 135°,

180°. In the MOSES software, the angle direction is

read in a clockwise direction. The five heading

directions were the approaching wave and wind

direction.

Figure 4: Heading Direction

The following figure displays some of the results

of the structural response from several cases. The

chart shows that the heave motion at heading 90 was

The Motion Response Analysis of Floating Jack-Up Rigs in the Operating Condition

193

relatively higher than the other heading directions in

all cases. The maximum heave motion in these cases

was 1.491m on 90° direction on case 1. Based on

(Sheffield, 1980), the heave RAO should be under 10

ft or 3.048 m. It shows that the vertical oscillation for

the six cases has fulfilled the criteria.

Figure 5: Heave motion of six cases

Table 2: The results of heave motion by considering

the floating jack-up as a vessel with/without pipe

handling equipment.

After considering the response amplitude operator

as a criteria of mobile offshore drilling unit operation,

it should also be reviewed and simulated when all

activities are running. To determine whether it fulfils

the drilling criteria, as mentioned in the book Floating

Drilling: equipment and its use, Sheffield 1980,

where the heaving movement limit criteria for drilling

and tripping activity must be below 7 ft, in this study

it can be concluded that all activities can still run,

except the activity of running BOP and installation of

risers. The running of the blow out preventer requires

the maximum allowable heaving motion of 0.822m,

whereas the result measured out of the criteria.

Different to the heave motion, the roll motion

graphs show that the structural movements tend to be

high in the direction of loading 45° and 135°, and tend

to be low in headings 0°, 90 ° and 180 °. The highest

motion roll was 1.65, heading 45°, on case variation

one.

Figure 6: Roll motion of six cases

Table 3: The results of roll motion by considering the

floating jack-up as a vessel with pipe handling

equipment

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

194

As for roll motion, the maximum allowable roll

motion was 7 degrees. The rolling movements that

occurred in the structure were feasible for drilling

activities for all cases. Moreover, from the Pitch

Motion graphs we can see that the pitching motion of

the structure is very high in headings 0° and 180°,

with the maximum value of 4.117 degrees in the first

variation in heading 0°.

Figure 7: Pitch motion of six cases

Regarding pitch motion, the maximum

allowable pitch movement for drilling and tripping

activities is 7 degrees. In the case of pitch motion, the

running BOP and riser installation activities in cases

5 and 6 were accepted.

Table 4. The results of pitch motion considering the

floating jack-up as a vessel with pipe handling

equipment

4 CONCLUSION

The results show that the response amplitude operator

of pitch motion had the most significant response in

each variation. From the motion validation with rules,

it can be concluded that the heave motion of this

structure exceeded criteria limits for BOP and riser

operations, but is still allowed for drilling activities.

The obtained results show that drilling processes in

the Madura Strait site using the floating jack-up could

possibly be operated by at least lowering the legs until

it is 5 meters above the seabed without running BOP

and risers.

REFERENCES

American Bureau of Shipping. 2005. Commentary on

the ABS Rules for Building and Classing

Mobile Offshore Drilling Units, 2001 Part 3-

Hull Construction & Equipment, January, 53.

Chakrabarti, S. K. ed 1987. Fluid Structure

Interaction in Offshore Engineering,

Southampton: Computational Me-chanics

Publications.

DNV. 1996. Guidelines for Offshore Structural

Reliability - Application to Jackup Structures.

The Motion Response Analysis of Floating Jack-Up Rigs in the Operating Condition

195

Sawiji, A. 2015. Analisis Stabilitas Jack-Up

Terapung pada Kondisi Operasi di Selat

Madura. Marjan, 0101, 37–41.

Sheffield, Riley. 1980. Floating Drilling: Equipment

and its Use.Practical Drilling Technology,

Vol.2, Gulf Publishing Company, Houston,

TX,.

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

196