Chemical Activation of Lignite by using a Combination of H

3

PO

4

-

NaHCO

3

Alwathan

1

, Muh. Irwan

1

, Panji Satrio Utomo

1

and Yuli Patmawati

1

1

Department of Chemical Engineering, Politeknik Negeri Samarinda

Jl.Dr.Cipto Mangunkusumo, Kampus Gn.Lipan Po.Box 1341 Samarinda, Kalimantan Timur - Indonesia

Keywords: Activated Carbon, Activation, Coal, Lignite, Low-Rank Coal.

Abstract: Coal is divided into four

classes: lignite, sub-bituminous, bituminous, and anthracite. Lignite is a low

rank coal. About 30% of Indonesia's coal reserves are included in the low rank category. The use of low-

rank coal is still limited for briquettes and as fuel for electricity generation. Improving the economic and

usage values of low-rank coal, processing low-rank coal into activated carbon should be done because coal

has a high carbon content.

The purpose of this study is to determine the effect of activation time on the

characteristics of the activated carbon produced by chemical activation process of lignite use a combination

of activator H

3

PO

4

- NaHCO

3

. Lignite has been prepared -100 +120 mesh is carbonized at 600

0

C for 3 h,

then after cold it was activated using 2.5 M concentration of H

3

PO

4

-NaHCO

3

for 2, 4, 6, 8 and 12 h.

Furthermore, proximate and iodine adsorption number analysis were used to

investigate the

characteristics of activated carbon produced refers to Indonesian National Standard (SNI 06-3730-1995)

including moisture content, ash content, volatile matter, fixed carbon and iodine absorption number. The

best results were obtained at 6 h of activation with the characteristics of activated carbon such as moisture

content, ash content, volatile matter, fixed carbon and iodine absorption number respectively as follows

3.5%, 14.91%, 9.81%, 71.78% and 505.1 mg/g. Activated carbon is a well known material that is used

extensively in industrial purification and

chemical recovery operations. It offers an attractive and

inexpensive option for removal of several

solutes from aqueous solutions.

1 INTRODUCTION

Coals are raw materials for many chemical syntheses

as well as cost-effective fuels for power plants due

to their low cost; however, some coals such as

low-rank coal (lignite) contain high amounts of

moisture (Karthikeyan and Mujumdar, 2009).

Activated carbon is a well known material that

is used extensively in industrial purification and

chemical recovery operations. It offers an attractive

and inexpensive option for removal of several

solutes from aqueous solutions.

Activated carbon

can be produced from different sources, such as

lignocellulosic materials, coal, baggase ash,

activated sludge and others (Shawabkeh and Al-

Ghamdi, 2014). Coal has the potential as a raw

material to produce activated carbon because it has a

high carbon content (Speight, 1994).

Activation processes are mainly categorized

into

two categories for the preparation of

activated carbon

i.e. physical and chemical

activation. Physical

activation usually involves the

carbonization of pre-cursor followed by the

gasification of the resulting char or direct

CO

2

/steam activation of the starting material.

Chemical activation involves the impregnation of

the given precursor with

activation agent such as

phosphoric acid (H

3

PO

4

), chloric acid ( H C l ) ,

nitrit acid ( H N

3

), zinc

chloride (ZnCl

2

), alkaline

metal compounds and salt.

The adsorption capacity of activated carbon is

very important because this property determines

how much of the substance can be absorbed per

gram of carbon. The activator type directly affects the

micropore structure,

specific surface area and pore

volume of the activated carbon, which makes its

adsorption capacity vary obviously (Bilal, 2016).

Activated carbon is sold at a high enough price if the

adsorption capacity is large. The quality

requirements for activated carbon refers to

Indonesian National Standard (SNI 06-3730-1995)

with max.15% moisture content, max.10% ash

182

Alwathan, ., Irwan, M., Satrio Utomo, P. and Patmawati, Y.

Chemical Activation of Lignite by using a Combination of H3PO4-NaHCO3.

DOI: 10.5220/0010025000002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 182-185

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

content, max.25% volatile matter, min.65% fixed

carbon and min. 750 mg/g iodine adsorption number

(Departemen Perindustrian dan Perdagangan, 2003).

Many studies regarding the change in

adsorption capacity of activated carbon as a

function of the type of chemicals and activating

conditions have been reported.

Research

conducted by Rahim and Indriyani using 5% NaOH

activator solution produced activated carbon

according to SII standard 0258-79 even though the

ash content was still above the standard (Rahim and

Indriyani, 2010). Another study was making of

activated carbon from sengon wood with chemical

activation using NH

4

HCO

3

activator solution of

concentration variation 0; 0.5; 1; 3; 5 and 10% by

weight, produce activated carbon with moisture

content of 6.39%, ash content of 9.15%, volatile

matter of 8.81%, fixed carbon of 82.04% and iodine

absorption number of 1154.4 mg/g. Meanwhile

research with chemical activation of bituminous coal

(Kusdarini and Ghafarunnisa, 2017) used a

combination of H

3

PO

4

- NH

4

HCO

3

activator solution

(concentration 2 M - 2.5 M) for 8 h followed by

physical activation to produce activated carbon with

a moisture content of 7.5%, ash content of 9%,

volatile matter of 43.3%, fixed carbon of 40.2% and

increased iodine absorption number to 1172.56 –

1238.544 mg/g (Kusdarini and Ghafarunnisa, 2017).

The purpose of this study is to determine the

effect of activation time on the characteristics of the

activated carbon produced by chemical activation

process of lignite use a combination of activator

H

3

PO

4

- NaHCO

3

.

2 METHODOLOGY

Lignite has been prepared -100 +120 mesh is

carbonized at 600

0

C for 3 h, then after cold it was

activated using 2.5 M concentration of H

3

PO

4

-

NaHCO

3

for 2, 4, 6, 8 and 12 h. Furthermore,

proximate and iodine absorption number analysis of

activated carbon refers to Indonesian National

Standard SNI 06-3730-1995 was carried out

including moisture content, ash content, volatile

matter and fixed carbon. Table 1 summerizes the

characterization of lignite before activation.

Table 1: Characteristics of Lignite.

Parameter Value

Moisture Content, % 37.86

Ash Content, % 5.53

Volatile Matter, % 25.06

Fixed Carbon, % 31.55

Iodine Number, mg/g 215.75

Caloric Value, cal/g 3665

3 RESULT AND DISCUSSION

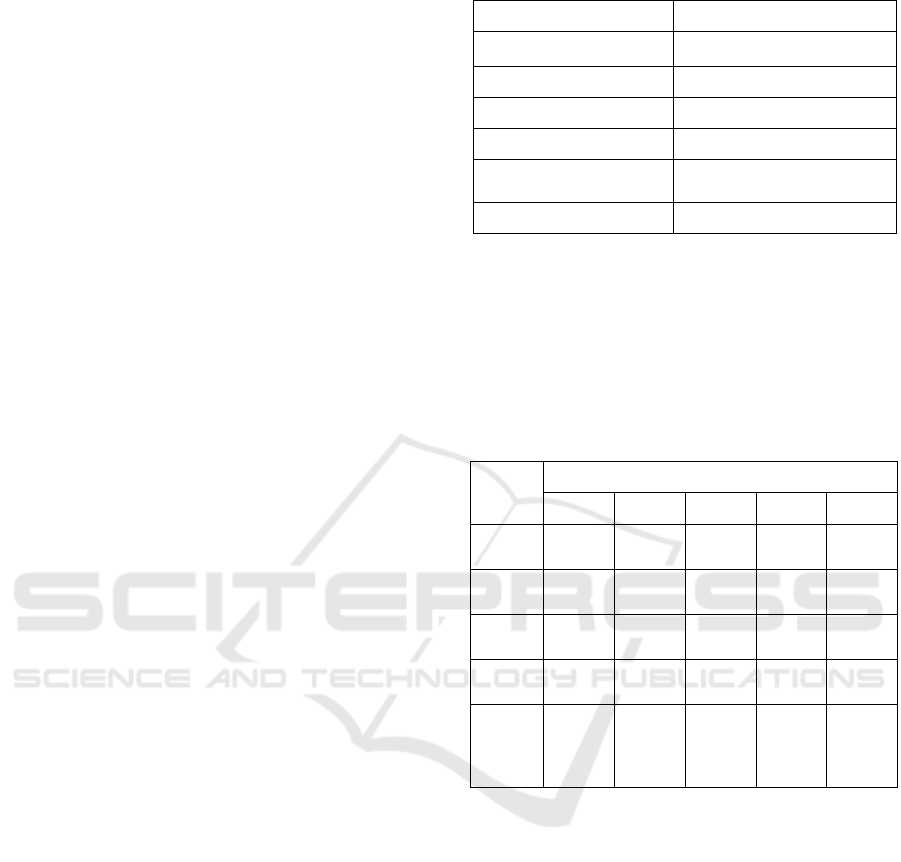

Table 2 summarizes the results of chemical

activation of lignite by using a combination of

H

3

PO

4

- NaHCO

3

activators.

Table 2: Characteristics of Activated Carbon.

Param

eter,%

Time, hours

2 4 6 8 12

Moist.

Cont.

5.15 3.89 3.05 3.83 3.62

Ash

Cont.

11.07 13.98 14.91 13.89 13.85

Vol.

Matter

10.36 9.71 9.81 12.03 10.08

Fixed

Crbon

73.42 72.42 71.78 70.25 72.45

Iodine

Numb

er,

mg/g

479.2 492.1 505.1 492.1 453.3

The effect of activation time on

characteristics

of activated carbon

is

represented in Figure 1 and

2.

In Figure 1 can be seen that the longer time of

activation, the moisture content has decreased from

37.86% to 3.5% at 6 h

of activation time

. This is

because water trapped into the cavity of activated

carbon will be more dehydrated by combination of

activator H

3

PO

4

- NaHCO

3

. The increase in moisture

content at 8 h and 12 h

of activation time

was due

to the hygroscopic characteristic of the activated

carbon so that in the cooling process water vapor in

the air is absorbed into the pores (Bilgen, 2016).

Chemical Activation of Lignite by using a Combination of H3PO4-NaHCO3

183

Figure 1: Characteristics of activated carbon versus time

of activation.

Ash content represents the bulk of the mineral

matter

in the coal after losing the volatile

components such as CO

2

, SO

2

, and H

2

O.

The

ash

content in Figure 1

was

measured to be 11.07%

; 13.98% ; 14.91% ; 13.89% and

13.85% at 2, 4, 6,

8 and 12 h

of activation time,

respectively.

The

increase in ash content until 6 h

of activation time

was due to the presence of alkali elements which are

absorbed in the low-rank coal pore during

immersion with an activator H

3

PO

4

- NaHCO

3

to

form a silicate from the alkali elements.

After

showing its highest value at 6 h activation time,

the ash content gradually decreased with

activation time and was 13.85% at 12 h of

activation.

Volatile matter show the portion of coal that is

released as gases and volatile liquids when heated

in the

absence of air at prescribed conditions. The

decrease in volatile matter from 25.06% until

10.36% at 2 h

of activation time

but the longer

time of activation (2 h – 6 h) of low- rank coal does

not have a significant effect on volatile matter. At 8

h activation, the volatile matter has increased

because the decomposition of H

2

CO

3

into H

2

O and

CO

2

. After 8 h activation, the volatile matter

decreased and was 10.08%

at 12 h of activation.

Fixed carbon is composed of carbon with

lesser amounts of H, N,

and S. It is generally

described as a coke-like residue. It

can be used to

give a forecast of heating value of the coal

(Speight, 2013a). Activation of lignite by using

combination of H

3

PO

4

- NaHCO

3

activators has

succeeded in increasing the fixed carbon from

31.55% to 70.25% -73.42%. This can be seen in

Figure 1. The increase in fixed carbon was due to

decrease in moisture content and volatile matter,

while the ash content does not contribute too much.

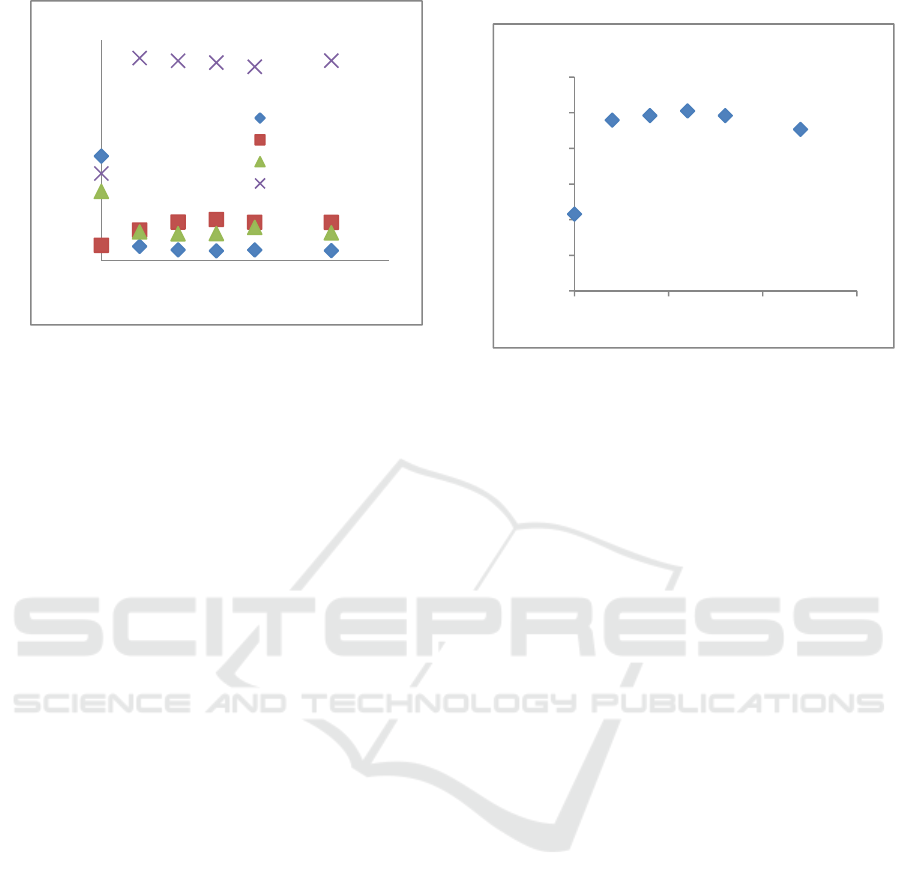

Figure 2: Iodine absorption number of activated carbon

versus time of activation.

The iodine adsorption number reflected the adsorption

per-formance of activated carbon, as shown in

Figure 2. It tends to increase from 215.75 mg/g to

505.1 mg/g at 6 h of activation time. Furthermore at

8 and 12 h of activation time there was decrease

until finally obtained an iodine absorption number of

453.3 mg/g. I

n general, the iodine

absorption

number

of activated carbon, which represents

its adsorption

capacity. When activation was

carried out longer than 6 h the decrease in

iodine

absorption number

probably

due to higher

ash content so that inorganic substances left on the

activated carbon cover the pores of the activated

carbon.

4 CONCLUSION

1.

Chemical activation of lignite by

using

a

combination of H

3

PO

4

- NaHCO

3

activators

was evaluated taking activation

time as the major influential parameters

were obtained the best condition at 6 h of

activation time with the characteristics of

activated carbon such as moisture content,

ash content, volatile matter, fixed carbon

and iodine absorption number respectively

as follows 3.5%, 14.91%, 9.81%, 71.78%

and 505.1 mg/g.

2.

Ash content and iodine absorption number

was still below the standards referred to

Indonesian National Standard (SNI 06-

3730-1995).

0

10

20

30

40

50

60

70

80

0 5 10 15

Percentage, %

Time, hours

Moisture Content

Ash Content

Volatile Matter

Fixed Carbon

0

100

200

300

400

500

600

0 5 10 15

Iodine Adsorption Number, mg/g

Time, hours

ASAIS 2019 - Annual Southeast Asian International Seminar

184

REFERENCES

Bilal Khalid et.al., 2016. Effects of KOH Activation on

Surface Area, Porosity and Desalination

Performance

of Coconut Carbon Electrodes. Desalination and

Water Treatment Journal

57. pp. 2195–2202.

Bilgen, S., 2016. The effects of Chemical Characteristics of

Coal on Coal-Based Industry. Energy Sources, Part A:

Recovery, Utilization and Environmental Effects.

38:22.

pp.

3324-3331.

Departemen Perindustrian dan Perdagangan, 2003. Syarat

Mutu dan Uji Arang Aktif SNI No. 06-3730-1995.

Balai Perindustrian dan Perdagangan.

Karthikeyan, M., Zhonghua, W. and Mujumdar, S.Arun,

2009.

Low-Rank Coal Drying Technologies—

Current Status and New Developments.

Drying

Technology: An International Journal.

Kusdarini, E., Budianto, A. and Ghafarunnisa, 2017.

Produksi Karbon Aktif dari Batubara Bituminus

dengan Aktivasi Tunggal H

3

PO

4

, Kombinasi H

3

PO

4

-

NH

4

HCO

3

, dan Termal. Jurnal Reaktor. UNDIP.

Rahim, M. and Indriyani, O., 2010. Pembuatan Karbon

Aktif dari Batubara Peringkat Rendah. Jurnal

Teknologi Media Perspektif. Politeknik Negeri

Samarinda.

Shawabkeh, R.A., Al-Harthi and Al-Ghamdi, 2014. The

Synthesis and Characterization of Microporous,

High

Surface Area Activated Carbon from Palm Seeds.

Energy Sources, Part A. 36:93–103.

Speight, J.G., 1994. The Chemistry and Technology of

Coal. Marcel Dekker. Inc. New York.

Speight, J. G., 2013a. Coal-Fired Power Generation

Handbook. Beverly, USA. Scrivener Publishing.

Chemical Activation of Lignite by using a Combination of H3PO4-NaHCO3

185