Growth Conditions for Alpha-amylase-producing Bacterium PLS 75

Strain Isolated from a High Temperature and Saline Area

Teuku M. Iqbalsyah, Jasmin P. Nabila

and Febriani

Biomolecules Application Research Group, Chemistry Department, Faculty of Mathematics and Natural Sciences,

Universitas Syiah Kuala, Banda Aceh, Indonesia

Keywords: Thermophilic, halophilic, α-amylase, 16S rRNA

Abstract: Extreme habitat has been explored to find microorganisms that are capable of producing industrial enzymes

with better activity and stability. Four thermo-halophilic bacteria strains isolated from undersea fumaroles

were screened for their ability to produce extracellular hydrolytic enzymes. The most potent α-amylase

producer was PLS 75 strain. The strain was Gram-negative with uniform basil-chained shaped. Homology

analysis of the 16S rRNA gene fragments shows that the strain was closely related to an uncultured

bacterium isolate, supporting the fact that the strain was difficult to culture. Fermentation study shows that

PLS 75 produced the highest biomass (5.48 mg/ml) and α-amylase activity (4.43 U/ml) when incubated at

60 °C, pH 7 for 31 h. The results provided information on PLS 75 culture conditions that may be used to

produce the enzyme for the study of its attributes and catalytic activity.

1 INTRODUCTION

Microbiological research has shifted more attention

to extremophilic microorganisms. Their ability to

grow well in extreme conditions makes them unique.

Not only as of the source of distinct metabolites, but

they also a subject of adaption mechanism studies

(Elleuche et al., 2015). Extremophiles are

microorganisms inhabiting and living in extreme

conditions, such as high temperature (thermophile

and hyperthermophiles), high acidity (acidophiles),

high alkalinity (alkaliphiles), high pressure

(piezophiles), high radiation (radiophiles) and high

metal content (metalophiles). Habitats of

extremophiles widely diverse, from natural to

artificial environments. The former includes

hydrothermal and geothermal area, acid soil, soda

lake, high salt lake, deep ocean, while the latter

includes nuclear reactor and toxic chemical waste

(Dalmaso et al., 2015).

Enzymes produced by extremophiles are in-

demand biocatalysts due to their high activity and

stability in the harsh industrial process conditions.

Most enzymes are hampered due to high

temperature, pH and salinity requirement in the

process. Therefore, extremozymes are preferable for

their resistance to high temperature and chemical

denaturation (Souza et al., 2012).

Among the enzymes, thermostable hydrolases

are the most used enzymes in industries requiring

elevated temperature (Elleuche et al., 2014; Dalmaso

et al., 2015). Hydrolytic enzymes (carbohydrase,

protease, lipase) are accounted for about 80% of the

total enzyme market in the US, with a sales value

approaching USD 3 billion in 2019 (Grand View

Research, 2019).

α-Amylase (1,4-D-Glucan glucanohydrolase, EC

3.2.1.1) is a carbohydrase enzyme that catalyses the

hydrolysis of α-1,4-glycosidic bonds in starch to

produce simpler sugar molecules, such as dextrin,

maltose, and glucose (Reddy et al., 2003). The

enzyme has been widely used in food, textiles,

paper, detergents, bioethanol production and

pharmaceuticals industries (Souza and Magalhaes,

2010). α-amylases in starch industries are required to

remain active at high temperature, particularly those

involved in gelatinisation (100-110 °C) and

liquefaction (80-90 °C).

Our group has previously isolated some

microbial strains from shallow sea fumaroles

(Iqbalsyah et al., 2018; Iqbalsyah et al., 2019a). The

area provides extreme environments of high

temperature and salinity, which is an ideal habitat

for the extremophiles to produce enzymes with

368

Iqbalsyah, T., Nabila, J. and Febriani, .

Growth Conditions for Alpha-amylase-producing Bacterium PLS 75 Strain Isolated from a High Temperature and Saline Area.

DOI: 10.5220/0010182900002775

In Proceedings of the 1st Inter national MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 368-375

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

unique features. Therefore the objective of this study

was to screen the microbial strains, which were able

to produce hydrolytic enzymes, particularly α-

amylase. The potential strain was phenotypically and

genotypically identified. As it is essential to imitate

the conditions of the native sampling area for further

experiments in the laboratory, the optimum

fermentation time, temperature and pH for the

production of α-amylase by the strain was studied.

The results could be used to produce the enzyme for

the study of its attributes and catalytic activity.

2 MATERIALS AND METHOD

2.1 Microorganism

This study used four microbial strains, namely PLS

75, PLS 76, PLS 80 and PLS A, that were the stock

culture of the Biochemistry Laboratory, Faculty of

Mathematics and Natural Sciences Syiah Kuala

University. The strains were previously isolated

from the sea bead of fumaroles in Pria Laot and

initially cultivated from the sand sample on Thermus

medium.

2.2 Screening of Hydrolytic Enzymes

PLS 76, PLS 75, PLS 80 and PLS A was grown on

on separate agar plates to evaluate their ability to

produce protease, lipase, amylase and cellulase.

Media of ½ Thermus solid, containing 0.4%

peptone, 0.2% yeast extract, 1% NaCl, 0.25%

glucose, 3% bacto agar, was used. The medium was

added with 3% skim milk and 0.5% casein for

protease screening; 1% olive oil, 0.5% tween 80 and

200 µl of 0.001% of Rhodamine B for lipase

screening; 1% soluble starch for α-amylase

screening and 1% carboxymethylcellulose (CMC)

for cellulase screening. All media were incubated for

24 h at 70 °C.

Protease activity was indicated by a clear zone

around the colonies. Lipase activity was identified

by orange fluorescent around the colonies under UV

light. Strains with amylase activity showed by a

clear zone after staining with potassium iodium

iodate. Strains with cellulase activity were identified

by a clear zone formed after being washed by 1 M

sodium chloride.

2.3 Identification of Microorganism

The cells of the most potent strain in producing α-

amylase were centrifuged at 5000 ×g for 10 minutes.

The pellet was used for morphology identification

by Gram-staining and Scanning Electron

Microscope (SEM).

The strain genotype was analysed from the 16S

rRNA gene sequence. Genomic DNA was isolated

from the pellet by using a DNA isolation kit

(Genetika Science). It was then used as a template to

amplify the 16S rRNA gene fragments using a pair

of primers, i.e. Com 1F

5'-

CAGCAGCCGCGGTAATAC-3'

and Com-1R (5'-

CCGTCAATTCCTTTGAGTTT-3'

) (Schwieger

& Tebbe, 1998

). The amplification consisted of 30

cycles of denaturation at 95 °C for 5 minutes and

annealing at 55 °C for 1 minute, as well as an

extension at 72 °C for 2 minutes. The amplicons

were subjected to agarose electrophoresis. The 16S

rRNA gene was sequenced by direct sequencing

method and compared with GenBank entries by

BLAST search (www.ncbi.nml.nih.gov). Alignment

and phylogenetic analysis were done using ClustalW

and Mega 6 software (Tamura et al., 2013),

respectively.

2.4 Growth Curve Study

The most potent α-amylase-producing strain was

incubated in ½ T medium pH 7 (using 0.1M

phosphate buffer) enriched with 0.25% glucose and

1% soluble starch for 48 h at 70 °C and 150 rpm.

The media used in the experiments were diluted in

sterile seawater to maintain the native salt

conditions. The medium was inoculated with the

strain to a level of 1 x 10

6

cells/ml. The growth was

measured by cell dry weight.

The α-amylase activity was assayed by

measuring the amount of reducing sugar produced

from the starch hydrolysis by 3,5-dinitrosalicylic

acid (DNS) method (Miller, 1959), using a standard

curve of glucose (1–10 μg/mL) measured at 540 nm.

One enzyme unit (U) is defined as the amount of

enzyme required to produce 1 μmol of reducing

glucose per minute under the assay conditions. All

measurements were done in triplicates.

2.5 Effect of Temperature, pH and Salt

on Biomass and α-amylase

Production

The optimum temperature for growth and α-amylase

production was determined by inoculating the strain

in ½ T medium in 0.1 M buffer phosphate pH 7,

enriched with 0.25% glucose and 1% soluble starch.

The incubation was conducted at 60, 65 and 70 °C

and 150 rpm until optimum incubation time.

Growth Conditions for Alpha-amylase-producing Bacterium PLS 75 Strain Isolated from a High Temperature and Saline Area

369

The optimum pH for α-amylase production was

determined by varying the pH of the media. The pH

was adjusted using 0.1M sodium acetate (pH 5),

0.1M dipotassium hydrogen phosphate (pH 7) and

0.1M glycine-NaOH (pH 9.0). The culture was

incubated at optimum incubation time and

temperature.

The effect of salt addition on α-amylase

production was determined by adjusting the ½ T

media to contain 1%, 2%, 3%, 4% sodium chloride.

The media was already dissolved in seawater, so the

final salt concentrations of the media were higher.

The culture was incubated at the optimum

incubation time, temperature and pH.

All experiments of temperature, pH and salt

variation were done in triplicates. Cell dry weight

and α-amylase activity were determined as described

in Section 2.4.

3 RESULTS AND DISCUSSION

3.1 Enzyme Assay

All strains produced α-amylase, with PLS 75

showed the most profound activity. Only PLS A was

able to produce protease. PLS 80 was the only strain

that showed a lipase activity. Meanwhile, PLS 75

exhibited better cellulase activity than PLS 80

(Table 1). PLS 75 was therefore selected for further

α-amylase production experiment.

Table 1: Screening results of the isolated strains for

hydrolytic enzymes activity.

Strain

Enzyme

Amylase Protease Lipase Cellulase

PLS A + ++ - -

PLS 75 +++ - - ++

PLS 76 + - - -

PLS 80 ++ - + +

3.2 Identification of PLS 75

Gram-staining result shows that PLS 75 was a

Gram-negative bacterium. The SEM image supports

the information that PLS has a uniform long rod-

chained shaped, with roughly 5-10 mm in length

(Figure 1).

The size of PLS 75 strain chromosomal DNA

was well over 10 kbp. The primers used in the

amplification of the 16S rRNA gene fragments

(Com 1F and Com 2R) were able to produce gene

fragments of nearly 500 bp (Figure 2).

Figure 1: a. Gram Staining result; b. SEM image of PLS

75 with 10000× magnifications.

The phylogenetic tree was constructed from

some homologous genes in the GenBank (Figure 3).

PLS 75 has the closest homology with Uncultured

bacterium clone YE-DC-B41 with sequence

similarity of 98%. Until the intact 16s rRNA gene

(1500 bp) is amplified and sequenced, the PLS 75

species is still indefinable.

Growing PLS 75 was indeed difficult. The ½

Thermus (½ T) medium needed enrichment with a

small amount of glucose to promote biomass

production. Thermus medium is designed for culture

Thermus genera. The use of ½ T medium in this

study was to isolate more robust microorganisms

that can survive in minimum nutrition supply. The

use of enriched media (for example LB or NB) was

avoided, as they would host common

microorganisms.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

370

Figure 2: a. Electrophoresis results of chromosomal DNA

of PLS 75; b. Electrophoresis results of 16S rRNA gene

fragments of PLS 75. M = DNA ladder, C = Chromosomal

DNA, S = 16S rDNA fragments.

3.3 Growth Curve of PLS 75

The growth curve study was conducted to determine

the optimum fermentation time for PLS 75 to

produce α-amylase. Fermentation was done at 70 °C

on ½ T medium containing starch. The starch

induced the production of the enzyme. Excreted α-

amylase then catalysed the starch digestion. The

products were further used for biomass and product

formation.

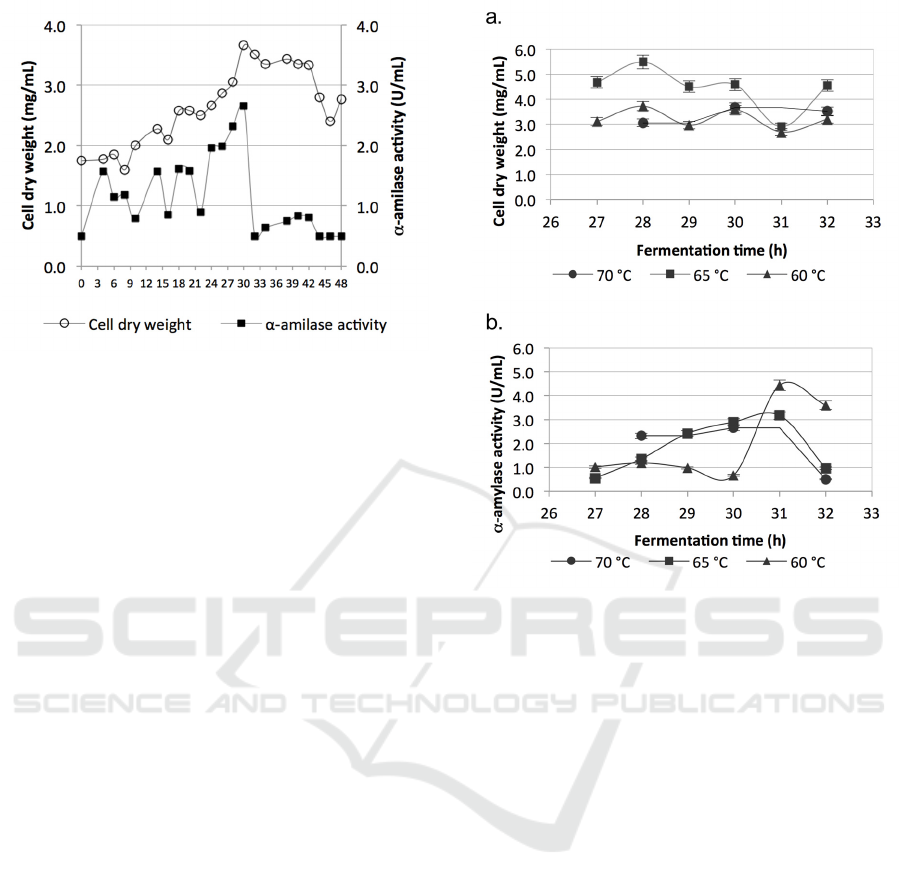

Figure 4 shows that the lag phase occurred up to

8 h, indicated by the relatively stagnant amount of

biomass. PLS 75 was in the exponential phase

between 8 to 30 h, marked by an increase in the

biomass. The highest amount of biomass produced

at 30 h (3.66 mg/ml). PLS 75 then entered the

stationary phase up to 42 h. The death phase

occurred afterwards.

Similar to biomass, the highest α-amylase

activity was also detected at the end of the

exponential phase (30 h). The activity then dropped

significantly. α-amylase production did not follow

the trend of biomass. There were fluctuations before

24 h of fermentation. Nevertheless, the enzyme was

still produced to utilise the starch in the medium.

The enzyme production declined when the biomass

decreased, implying the nutrition already exhausted.

The behaviour of microorganisms during

metabolites production depends on the strain, the

availability of the nutrients and the growth

conditions. Generally, α-amylase is optimally

produced at stationary phase (Malhotra et al., 2000;

Liu et al., 2008; Annamalai et al., 2011). However,

some are produced optimally in the exponential

phase (Moshfegh et al., 2013; Berekaa et al., 2007).

It has been suggested that the addition of glucose as

the carbon source in the media may lead to

catabolite repression that suppresses α-amylase

production (Berekaa et al., 2007). The same

suppression might also occur in this study, as a small

amount of glucose was added to the fermentation

medium.

Figure 3: Phylogenetic relationship of the 16S rRNA gene (480 bp) from PLS 75 with 17 most related gene sequence. The

phylogenetic tree was constructed using the neighbour-joining method of the Mega 6 software with 1000 bootstrap

replicates.

Growth Conditions for Alpha-amylase-producing Bacterium PLS 75 Strain Isolated from a High Temperature and Saline Area

371

Figure 4: Growth curve of PLS 75 in ½ T medium

enriched with 0.25% glucose. The incubation was

conducted at temperature 70 °C, pH 7 and 150 rpm. The

data was an average of triplicates ± SD.

3.4 Effect of Incubation Temperature

on Biomass and α-amylase

Production

The effect of temperature on biomass and α-amylase

production was studied at 60 °C, 65 °C, and 70 °C in

a narrow time window (27 – 32 h). Figure 5a shows

that the biomass, measured as cells dry weight, was

best produced at 60 °C. The highest biomass

concentration (5.5 mg/ml) was observed at 60 °C

and 28 h. The biomass at 70 °C was roughly half of

that at 60 °C. Optimum α-amylase activities of all

temperature were observed at a slightly delayed

time. The highest activity (4.43 U/ml) was achieved

at 60 °C and 31 h. The optimum time was also

applicable to all other temperature (Figure 5b).

The number of cells and enzyme activity is

generally interrelated. On the one hand, the increase

in cells mass will produce more enzymes. On the

other hand, biomass formation is catalysed by

enzymes. Enzyme production increases with

increasing temperature until a certain level. A

temperature above the optimum causes a decrease in

enzyme activity. It gives adverse impacts on

metabolic activity, which reduce growth and product

formation (Sundarram and Murthy, 2014). High

temperature affects enzyme activity in two ways, i.e.

changing the reaction rate constant and causing

thermal denaturation of the enzyme (Demirkan et al.,

2017). However, cells formation and α-amylase

production are controlled by different regulatory

mechanisms (Baysal et al., 2003).

Figure 5: Effect of fermentation temperature on; a.

Biomass production; b. α-amylase activity. The incubation

was conducted at pH 7 and 150 rpm. The data was an

average of triplicates ± SD.

The results are in agreement with several studies

employing thermophilic bacteria. Devi et al. (2010)

reported that the optimum incubation temperature

for two of Bacillus spp. strains to acquire high α-

amylase activity was in the range 60-80 °C. The

enzyme is already produced in the exponential phase

and reaches a maximum at the stationary phase.

Meanwhile, a thermo-halophilic Bacillus sp.

NRC22017 produces optimum α-amylase at 45 °C.

A 10 °C increase in the temperature reduces the

enzyme activity by two-third (Elmansy et al., 2018).

3.5 Effect of pH of Medium on Biomass

and α-amylase Production

The effect of pH on biomass and α-amylase

production was studied at pH 5, 7 and 9. The

biomass at pH 5 and 7 was about twice as much as

that at pH 9 (Figure 6a). The highest biomass (3.57

mg/ml) was observed at pH 7 and 30 h. The highest

α-amylase activity (4.4 U/ml) was also produced at

pH 7 and 31 h. The enzyme activity at acidic and

alkaline pH was low (Figure 6b).

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

372

Figure 6: Effect of pH of the medium on; a. Biomass

production; b. α-amylase activity. The incubation was

conducted at temperature 60 °C and 150 rpm. The data

was an average of triplicates ± SD.

We have previously reported that the highest

activity of the purified amylase from PLS 75 strain

was at pH 5 (Iqbalsyah et al., 2018). Other

molecules might have affected the activity as the

enzyme was still in the crude form. Most microbial

α-amylases perform the best catalytic activity at low

pH (Zhang et al., 2017). However, some may work

across a wide range of pH (Ghorbel et al., 2009).

3.6 Effect of Salt Addition on Biomass

and α-amylase Production

On the top of the available salts in the medium, as it

was dissolved in seawater, various concentrations of

sodium chloride were added to the media to contain

an additional 1%, 2%, 3% and 4% to study the

halophilic character of PLS 75 strain. The highest

biomass concentration (5.40 mg/mL) was observed

with the addition of 4% salt (Figure 7a). The highest

α-amylase activity (2.38 U/mL) was also observed at

the same salt concentration, although the difference

was inconsequential (Figure 7b).

Figure 7: Effect of NaCl addition on; a. Biomass

production; b. α-amylase activity. The salt addition was

made to a final concentration of the media. The incubation

was conducted at temperature 60 °C, pH 7 and 150 rpm.

The data was an average of triplicates ± SD.

The results suggest that the α-amylase from PLS

75 strain was an extreme halophilic enzyme as it was

still active in the presence of 2.5–5.2M NaCl. This

result is in agreement with our previous report of

PLS A strain isolated from the same area in

producing protease (Iqbalsyah et al., 2019a). This

result suggests that the enzyme may be able to

escape denaturation in high salt concentrations. It

can thus be useful to catalyse reactions in non-

aqueous solution (Moreno et al., 2013).

The fumaroles from which the PLS 75 strain was

isolated had an onset temperature around 80-100 °C,

a neutral pH and a salt concentration of around 3.5

M. Magnesium, chloride, iron, lead and copper ions

are much higher than those in typical seawater

(Iqbalsyah et al., 2019b). The different chemical

composition than the typical seawater implies

unique physiology of PLS 75 strain.

Growth Conditions for Alpha-amylase-producing Bacterium PLS 75 Strain Isolated from a High Temperature and Saline Area

373

4 CONCLUSION

Four poly-extremophilic strains isolated from

undersea fumaroles in Pria Laot Sabang were able to

secrete extracellular hydrolytic enzymes. PLS 75

was the most potent strain to produce thermostable

α-amylase and cellulase. The strain had a close

relationship with uncultured microorganism after

16s rRNA gene sequence analysis. The results of

growth condition experiments show that PLS 75

optimally produced thermostable α-amylase at 60°C

and pH 5 for 30 h incubation. It resisted high salt

concentration. This study provided preliminary

information on PLS 75 cultivation conditions. may

The results may be used for scaling-up of the

enzyme production for various uses.

ACKNOWLEDGMENT

This work was financed by the Fundamental

Research Grant Number 383/UN11/A.01/

APBNP2T/13 from Universitas Syiah Kuala.

REFERENCES

Annamalai, N., Thavasi, R. and Vijayalakshmi, S. and

Balasubramanian, T. 2011, 'Extraction, purification

and characterisation of thermostable, alkaline tolerant

α-amylase from Bacillus cereus', Indian Journal of

Microbiology 51 (4), 424–429.

Baysal, Z., Uyar, F. and Aytekin, C. 2003, 'Production of

α-amylase by thermotolerant Bacillus subtilis in the

presence of some carbon, nitrogen-containing

compounds and surfactants', Annals of Microbiology

53 (3), 323–328.

Berekaa, M. M., Soliman, N. A. and Abdel-Fattah, Y. R.

2007, 'Partial characterisation and cloning of

thermostable α-amylase of a thermophile Geobacillus

thermoleovorans YN', Biotechnology 6, 175–183.

Dalmaso, G. Z. L., Ferreira, D. and Vermelho, A. B. 2015,

'Marine extremophiles a source of hydrolases for

biotechnological applications', Marine Drugs 13 (4),

1925–1965.

Demirkan, E., Sevgi, T. and Başkurt, M. 2017,

'Optimisation of physical factors affecting the

production of the α-amylase from a newly isolated

Bacillus sp. M10 strain’, Karaelmas Fen ve

Mühendislik Dergisi 7 (1), 23–30.

Devi, L. S., Khaund, P. and Joshi, S. R. 2010,

Thermostable α -amylase from natural variants of

Bacillus sp. prevalent in Eastern Himalayan range.

African Journal of Microbiology Research 4 (23),

2534-2542.

Elleuche, S., Schafers, C., Blank, S., Schroder, C. and

Antranikian, G. 2015, 'Exploration of extremophiles

for high-temperature biotechnological processes',

Current Opinion in Microbiology 25, 113–119.

Elmansy, E. A., Asker, M. S., El-Kady, E. M., Hassanein,

S. M and El-Beih F. M. 2018, 'Production and

optimisation of α-amylase from thermo-halophilic

bacteria isolated from different local marine

environments', Bulletin of the National Research

Center 42: 31.

Ghorbel, R. E. Maktouf, S., Massoud, E. B., Bejar, S., and

Chaabouni, S. E. 2009, 'Thermostable amylase from

Bacillus cohnii US147 with broad pH applicability',

Applied Biochemistry and Biotechnology 157, 50–60.

Grand View Research 2019, Enzymes market size, share

and trends analysis report by product (carboydrases,

proteases, lipases), by application (industrial,

specialty), by end use, by region, and segment

forecasts, 2019 - 2025. [online] Available at:

https://www.grandviewresearch.com/industry-

analysis/enzymes-industry [Accessed 26 August

2019].

Iqbalsyah, T. M., Fajarna, F. and Febriani 2018,

'Purification and partial characterisation of α-amylase

produced by a thermo-halophilic bacterium isolate

PLS 75', Biosaintifika 10 (3), 574–580.

Iqbalsyah, T. M., Malahayati, M. Atikah, A. and Febriani,

F. 2019a, 'Cultivation conditions for protease

production by a thermo-halostable bacterial isolate

PLS A', Jurnal Natural 19 (1), 18–23.

Iqbalsyah, T. M., Malahayati, Atikah and Febriani 2019b,

'Purification and partial characterisation of a thermo-

halostable protease produced by Geobacillus sp. strain

PLS A isolated from undersea fumaroles', Journal of

Taibah University for Science 13 (1), 850–857.

Liu, X.D. and Xu, Y. 2008, 'A novel raw starch digesting

α-amylase from a newly isolated Bacillus sp. YX-1:

Purification and Characterisation', Bioresources

Technology 99, 4315–4320.

Malhotra, R., Noorwez, S. and Satyanarayana, T. 2000,

'Production and partial characterisation of

thermostable and calcium‐independent α‐amylase of

an extreme thermophile Bacillus thermooleovorans

NP54', Letters in Applied Microbiology 31, 378–384.

Miller, G. L. 1959, 'Use of Dinitrosalicylic Acid reagent

for determination of reducing sugar', Analytical

Chemistry 31 (3), 426–428.

Moreno, M. de L., Perez, D. and Garcia, M. T. Mellado, E.

2013, 'Halophilic bacteria as a source of novel

hydrolytic enzymes', Life 3, 38–51.

Moshfegh, M., Shahverdi, A. R., Zarrinni, G. and

Faramarzi, M. A. 2013, 'Biochemical characterisation

of an extracellular polyextremophilic α-amylase from

the halophilic archaeon Halorubrum xingjiangense’,

Extremophiles 17, 677–687.

Reddy, N. S., Nimmagadda, A. and Rao, K.R.S.S. 2003,

'An overview of the microbial α-amylase family',

African Journal of Biotechnology 2 (12), 645–648.

Schwieger, F. and Tebbe, C.C. 1998, 'A New Approach to

Utilise PCR-Single Stranded Conformation

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

374

Polymorphism for 16S rRNA Gene-Based Microbial

Community Analysis, Applied Environmental

Microbiology 64, 4870-4876.

Souza, P. M. de and Magalhaes, P. de O. 2010,

Application of microbial α-amylase in industry - A

review’, Brazilian Journal of Microbiology 41, 850–

861.

Sundarram, A. and Murthy, T. P. K. 2014, 'α-Amylase

production and application: A review', Journal of

Applied and Environmental Microbiology 2 (4), 166–

175.

Tamura, K., Stecher, G., Peterson, D., Filipski, A. and

Kumar S. 2013, 'MEGA6: Molecular evolutionary

genetics analysis version 6.0', Molecular Biology and

Evolution 30, 2725–2729.

Zhang, Q., Han, Y. and Xiao, H. 2017, 'Microbial α-

amylase: A biomolecular overview', Process

Biochemistry 53, 88–101.

Growth Conditions for Alpha-amylase-producing Bacterium PLS 75 Strain Isolated from a High Temperature and Saline Area

375