CAD-driven Pattern Recognition in Reverse Engineered Models

S. Gauthier

1,2

, W. Puech

1

, R. B

´

eni

`

ere

2

and G. Subsol

1

1

LIRMM Laboratory, CNRS, Univ. Montpellier, France

2

C4W, Montpellier, France

Keywords:

Reverse Engineering, Beautification, Geometric Constraints.

Abstract:

Today, it has become frequent and relatively easy to digitize the surface of 3D objects and then to reconstruct

a combination of geometric primitives such as planes, cylinders, spheres or cones. However, the given re-

construction contains only geometry, no information of a semantic nature used during the design process is

included. In this paper, we present a robust method to recognize specific geometric structures which are not

explicitly present in an object, such as features and repetitions. These are known as patterns, which are used

in the CAD modeling process. Moreover, the digitization of an object often leads to various inaccuracies,

and therefore inaccurate extracted primitives. We also demonstrate how recognized patterns can be useful as

an application in beautification, which consists of the adjustment of primitive parameters to satisfy geomet-

rical relations such as parallelism and concentricity. Our objective is to design a fast and automatic method,

which is seldom seen in reverse engineering. We show the efficiency and robustness of our method through

experimental results applied on reverse engineered 3D meshes.

1 INTRODUCTION

An industrial reverse engineering application aims to

reconstruct an object as a combination of geometric

primitives, from a digitized 3D mesh or a 3D point

cloud (B

´

eni

`

ere et al., 2013). For example, on manu-

factured objects, we search for planes, spheres, cylin-

ders, cones and tori. A more advanced objective of

the reverse engineering process may also be to re-

trieve the design intent of an object. To do this, we

must take into account CAD modeling rules, which

produce semantics in constructed objects.

In this paper, we propose a method to recognize

specific patterns from a set of primitives. This allows

us to deduce, even for an inaccurate digitized object,

geometrical relations given by the original modeling

process. Then, we show that these patterns can be

used to improve the reconstructed model, for exam-

ple. This is known as a beautification step (Langbein,

2003), which aims to satisfy the geometric relations

between the primitives (e.g. parallelism, orthogonal-

ity) by regularizing the primitive parameters.

We present previous work on this topic in

Section 2. Then, we detail our proposed method in

Section 3. Finally, we present experimental results

on several 3D meshes in Section 4 and conclude in

Section 5.

2 PREVIOUS WORK

During the design process of manufactured parts, par-

ticular geometric structures are often constructed ac-

cording to specific mechanical functions or machin-

ing processes. These structures are commonly called

patterns, and correspond to combinations of primi-

tives which respect some geometrical relations. In re-

verse engineering, recognizing these patterns allows

us to understand relations between the primitives and

to retrieve information about the design or the ma-

chining process of the part. In this section, we focus

on two types of patterns which are features and repe-

titions.

2.1 Feature Recognition

The first type of patterns contains neighboring prim-

itive subsets which define geometrical structures re-

lated to a machining process or a specific tool (Sanfil-

ippo and Borgo, 2016). These structures correspond

to features (Harik, 2007), which can be specific holes

for example. To recognize features, three approaches

seem to be favored (Babic et al., 2008). The first

one consists of the construction and an analysis of

a graph containing relations between the primitives,

which can be neighborhood (Lupinetti et al., 2017)

244

Gauthier, S., Puech, W., Bénière, R. and Subsol, G.

CAD-driven Pattern Recognition in Reverse Engineered Models.

DOI: 10.5220/0007360702440254

In Proceedings of the 14th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2019), pages 244-254

ISBN: 978-989-758-354-4

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

or geometric relations such as parallelism or concen-

tricity (Wu et al., 2003). Then, the pattern recogni-

tion corresponds to a sub-graph detection according

to each feature type. The second approach first de-

composes the part into small convex volumes, then

tries to detect specific volume combinations corre-

sponding to features (Geng et al., 2016). The third

approach groups other methods, which can be based

on hints such as 2D sections of the part for exam-

ple (Muraleedharan et al., 2018). Other methods have

been proposed to recognize patterns, based on neural

networks (Jun et al., 2001) or genetic algorithms (Pal

et al., 2005). However, these approaches require a

large and annotated database, which is out of our

scope. Finally, we highlight methods which use sys-

tems of rules based on three previously described ap-

proaches (Wang and Yu, 2014; Vilmart et al., 2018).

These rule systems can be used to infer new informa-

tion or construct a hierarchical system of features, for

example.

However, existing methods seem to have difficul-

ties correctly separating intersecting features. More-

over, some information used to recognize features are

specific to a feature type, which can be a problem

to extend the method to other features. On the other

hand, rule-based methods have been proposed to im-

prove obtained results, by taking the best of the three

approaches. In current literature, it seems that a few

methods propose to recognize features from primi-

tives extracted from a digitized 3D mesh, which are

often inaccurate. It would be interesting to adapt a

rule-based system and take into account all the infor-

mation deduced from both the 3D mesh and the ex-

tracted primitives.

2.2 Repetition Recognition

The second class of patterns contains repetitions from

a reference geometrical structure, such as a fea-

ture, which can be composed of one or many prim-

itives (Urbanic and Elmaraghy, 2008). This repetition

can then be constructed from a predefined scheme,

for example a line or a circle. The main particu-

larity of these patterns is that their components are

regularly spaced. For example, a circular repetition

places the reference feature duplicated regularly over

360

◦

. To recognize repetitions, a first approach con-

sists in the detection of transformation combinations

of a subset of primitives, such as translation, rotation

or scaling (Pauly et al., 2008). A second approach

is based on a symmetry detection, which allows us

to characterize a pattern by a combination of symme-

try planes (Vilmart et al., 2018). Other approaches

propose to use additional informations such as 2D

sections of the object for example (Urbanic and El-

maraghy, 2008). We note that most of the existing

methods only propose to recognize repetitions from

similar primitive subsets and define the extracted pat-

terns in a reference plane, as in standard CAD model-

ing processes.

However, most of these approaches are designed

for models without inaccuracies. In fact, similarity

and placement of inaccurate primitives are more com-

plex and can generate construction ambiguities, par-

ticularly when the complexity of the parts increases.

Therefore, it seems difficult to use existing methods

on reverse engineered models from inaccurate data in

a generic manner, without taking particular cases into

account.

3 PROPOSED PATTERN

RECOGNITION

In CAD modeling, we often construct some patterns

of primitives according to standard rules. In our con-

text, we need to recognize them from a combination

of geometric primitives. Firstly, we focus on neighbor

primitive sets, which can define features. Secondly,

we propose to recognize repetitions. In the context

of reverse engineering, we also propose an applica-

tion to model beautification (Langbein, 2003), which

regularizes primitive parameters with respect to geo-

metric constraints.

3.1 Feature Recognition

In mechanics, each part can correspond to a specific

function. When we focus on them more locally, we

can also find sub-parts which have their own func-

tions. We call these sub-parts features. These fea-

tures correspond to specific mechanical functions or

machining processes, and give some information con-

cerning geometrical relations between primitives. In

this work, we focus on two features, counterbored and

countersunk holes (see Fig. 1), which essentially im-

ply parallelism and concentricity relations. Since we

do not have any a priori information on the part, we

only analyze the geometry of these structures without

infering associated mechanical functions or machin-

ing processes. To recognize these features, we pro-

pose a rule-based method where the rules are defined

by geometrical relations between primitives. First, we

construct a graph which contains relations between

each pair of primitives: neighborhood, parallelism,

orthogonality and concentricity. Then, we define a

convexity relation between two primitives by analyz-

ing the convexity of their intersections. Finally, our

CAD-driven Pattern Recognition in Reverse Engineered Models

245

feature recognition process consists of extracting a

sub-graph respecting a set of specific rules for each

type of feature.

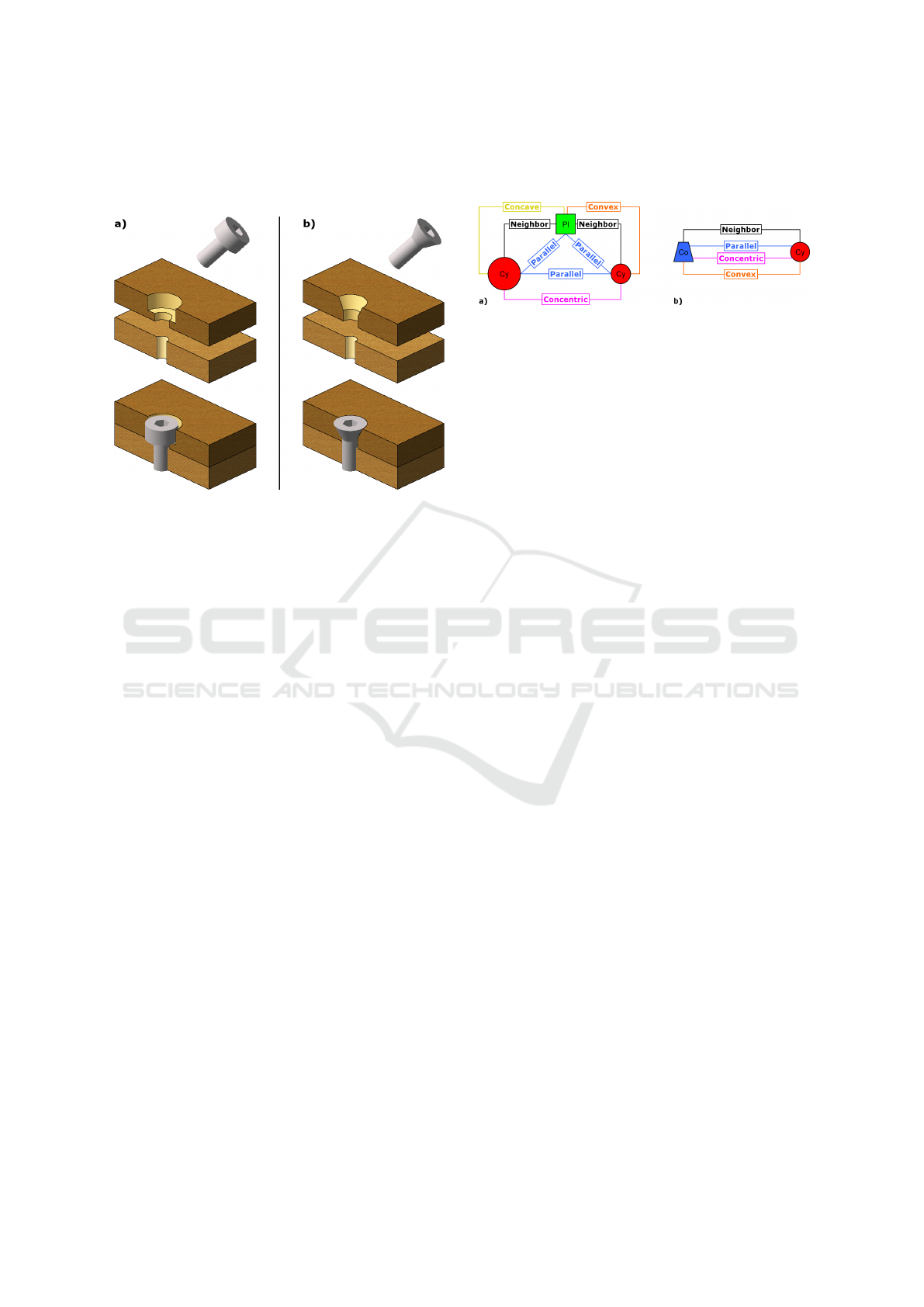

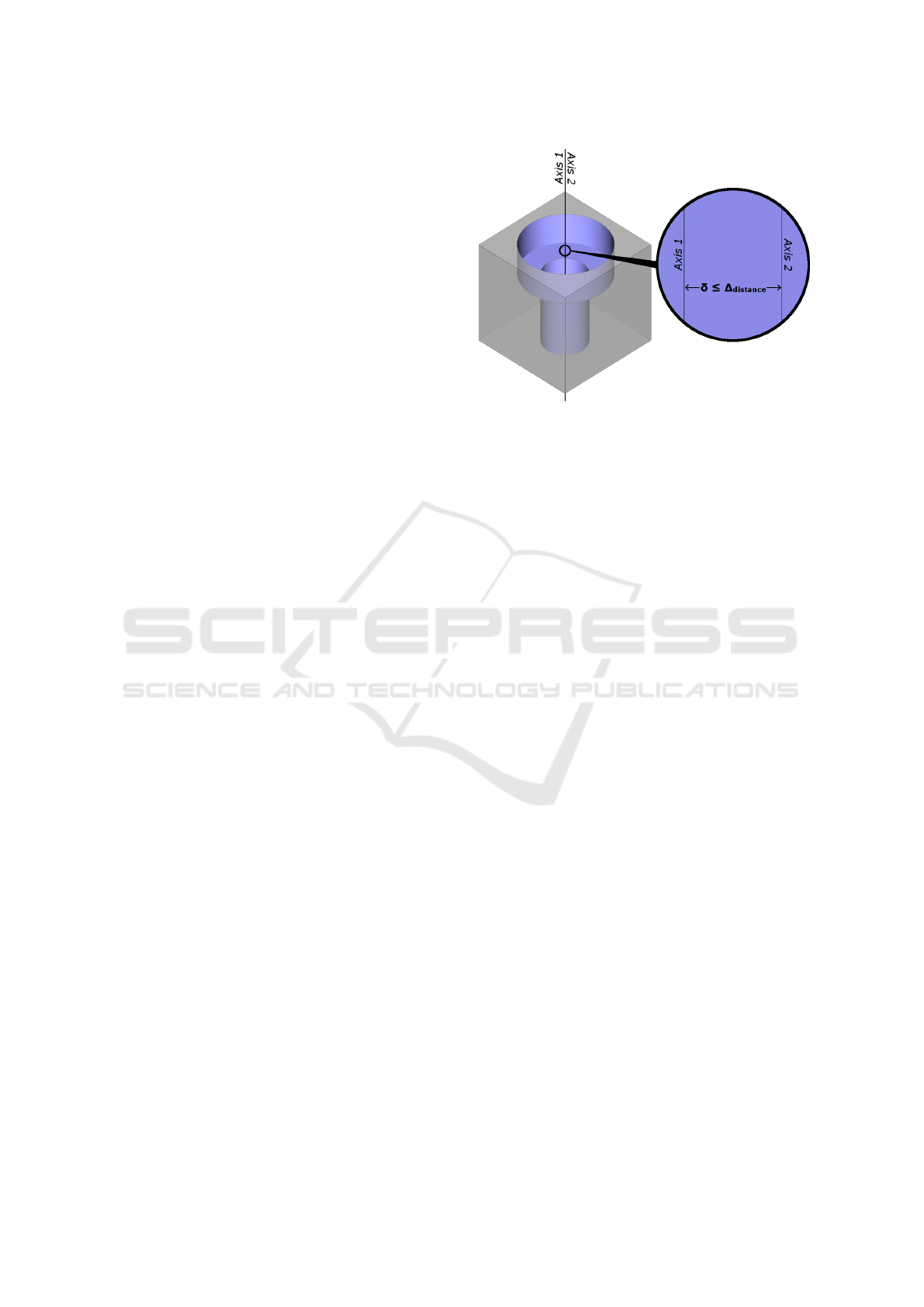

Figure 1: Focus on two features: a) Counterbored hole (or

counterbore), b) Countersunk hole (or countersink).

A counterbored hole, or counterbore, is a specific

type of drilling (Fig. 1.a). Its principal function is

to host and hide a flat head screw, a nut or a ring.

A counterbore is composed of: (i) a large cylinder

to host the screw head; (ii) a small cylinder to host

the screw thread; (iii) a plane to support the screw

head. Therefore, we define specific rules allowing us

to recognize the geometric structure of a counterbore

from a set of primitives and geometrical relations (see

Fig. 2.a): (i) the plane is a neighbor of the two cylin-

ders; (ii) the three primitives have parallel orienta-

tions; (iii) the two cylinders are concentric; (iv) the

two cylinders have different radii; (v) the intersection

between the plane and the small cylinder is convex;

(vi) the intersection between the plane and the large

cylinder is concave. A counterbore is then parameter-

ized by a position, an orientation, two radii, a drilling

depth and a counterbore depth. Its position is defined

as the intersection point between the plane and the

common axis of the two cylinders.

A countersunk hole, or countersink, is another

type of drilling (see Fig. 1.b). Its principal function

is to host and hide a tapered head screw. A counter-

sink is composed of: (i) a cone to host the screw head;

(ii) a cylinder to host the screw thread. Therefore, we

define a second set of rules, allowing us to recognize

the geometric structure of a countersink from prim-

itives and their relations (see Fig. 2.b): (i) the cone

and the cylinder are neighbors; (ii) the cone and the

cylinder are concentric; (iii) the intersection between

the cone and the cylinder is convex. A countersink

is then parameterized by a position, an orientation, a

radius, an angle, a drilling depth and a countersink-

ing depth. Its position is defined as the center of the

intersection circle between the cone and the cylinder.

Figure 2: Relation sub-graphs associated to features: a)

Counterbore, b) Countersink.

Therefore, each rule set defines a relation sub-

graph specific to a feature. The feature recognition

is then realized by searching for these specific sub-

graphs in a global relation graph between the primi-

tives.

3.2 Repetitions

In mechanical engineering, we often repeat features

along specific patterns. For example, aligning regu-

larly spaced fixing holes along a line can improve the

global fixation of a large part, increase the production

speed or reduce machining costs. Of course, these

repetitions can be constructed from varied sub-parts,

for economical or esthetic reasons. Consequently,

these repetitions contain semantic information, be-

yond the underlying geometry. In our approach, we

propose to recognize repetitions from a feature set.

Therefore, a repetition is defined by a set of simi-

lar features, regularly spaced along a specific pattern

such as a line or a circle. Unlike features, these rep-

etitions are not limited to neighboring components.

Then, this recognition allows us to determine relative

positions between features.

3.2.1 Feature Similarity

As explained before, a repetition groups similar fea-

tures. However, in the context of reverse engineer-

ing, the corresponding primitives can be inaccurate

since they are extracted from inaccurate data. Conse-

quently, we first need to define the similarity between

two features. To do that, we propose to compare their

parameters, according to predefined tolerances:

• ∆

distance

: distance tolerance defining two similar

positions;

• ∆

angle

: angle tolerance defining two similar orien-

tations.

Then, we define two types of similarity: partial and

integral. The partial similarity consists of the com-

parison of feature dimensions only. For example,

two counterbores are partially similar if their radii

GRAPP 2019 - 14th International Conference on Computer Graphics Theory and Applications

246

and depths are similar according to ∆

distance

. The

integral similarity consists in the comparison of di-

mensions with ∆

distance

and orientations with ∆

angle

.

Hence, integrally similar features are necessarily par-

allel. We note that partial similarity rules can be

adapted by adding or removing conditions, which al-

lows some flexibility in our method. This similar-

ity analysis compares all feature parameters except

their positions. Indeed, these can be defined relatively

when features are grouped in the same repetition.

3.2.2 Alignment Detection

Linear repetitions, along a line, are most frequently

used in CAD modeling. To recognize linear repeti-

tions, we first need to detect aligned features. To do

this, we propose to extract a set of axes and points

directly from the feature parameters, as illustrated in

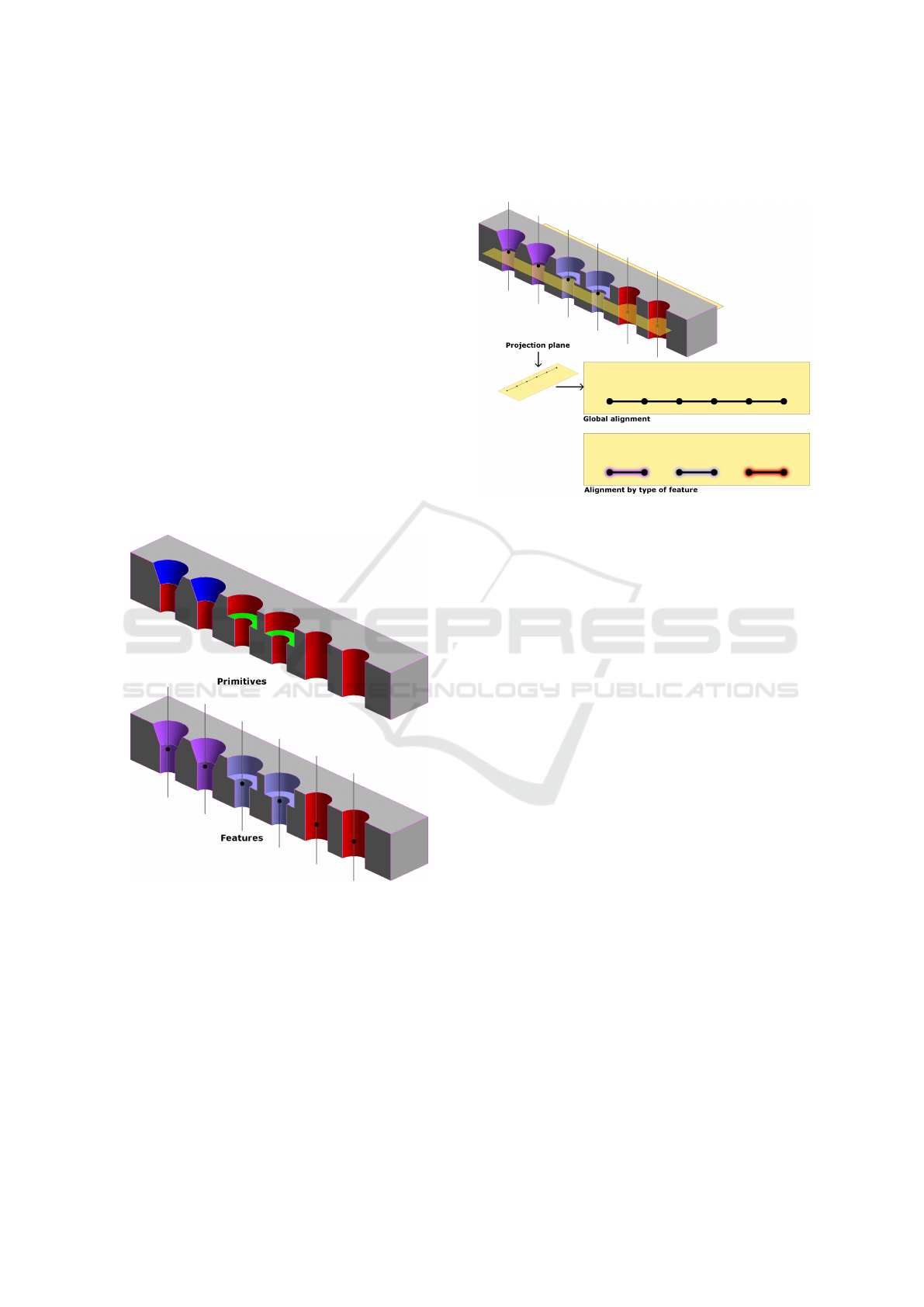

Fig. 3. In this example, we detect six aligned and par-

allel features: two countersinks, two counterbores and

two simple holes.

Figure 3: Axis and point extraction from feature parame-

ters. Each axis or point is then common to all the corre-

sponding primitives.

From these axes and points, it is possible to ex-

tract alignments in multiple directions. In CAD mod-

eling, repetitions are generally constructed from 2D

patterns, designed in a plane. From this observation,

we propose to detect repetitions in such planes. In the

case of parallel axes, we only use the plane which is

orthogonal to these axes, since it allows us to com-

pute orthogonal projection of feature positions. Our

feature alignment detection process is illustrated in

Fig. 4. We can distinguish two types of alignements:

global alignments using partial similarity rules and

alignments by type using integral similarity.

Figure 4: Axis and point alignments as 2D patterns in a

reference plane.

The proposed alignment detection consists of seven

steps.

1. Construct a plane P with a reference orientation

(according to coordinate system).

2. Project the feature positions {p

i

} on P , to obtain

the positions {p

0

i

}.

3. Construct a line D with a reference orientation

which is orthogonal to that of P .

4. Translate D on a position p

0

i

. This creates an

alignment A.

5. Add to A the positions {p

0

j

} that are a distance

δ 6 ∆

distance

from D.

6. Repeat these steps until all the planes, lines and

features are treated.

7. Keep only alignments of many features, then com-

pute the final alignment lines by a weighted aver-

age. The weights can be given by the area of each

feature.

Each alignment is then parameterized by a position,

a plane orientation, a line orientation and a feature

list. This algorithm retrieves global alignments, but

can be extended to alignments by types of features. To

do this, we can modify the fifth step to retrieve only

positions of the same type or apply integral similarity

rules.

3.2.3 Repetition Recognition

As described in Section 3.2.2, a repetition is an align-

ment of regularly spaced features that are similar.

CAD-driven Pattern Recognition in Reverse Engineered Models

247

In CAD modeling, repetitions are commonly con-

structed from five parameters: (i) a reference plane;

(ii) a 2D pattern belonging to the plane, which can

be a line or a circle for example; (iii) a reference

feature to repeat; (iv) an expected number of feature

copies; (v) the distance between two successive fea-

tures. To generalize the method, we propose to search

for combinations of repetitions, allowing us to recon-

struct complex feature configurations. For example,

a rectangular pattern can be defined as a combina-

tion of four repetitions or as a repetition of two sub-

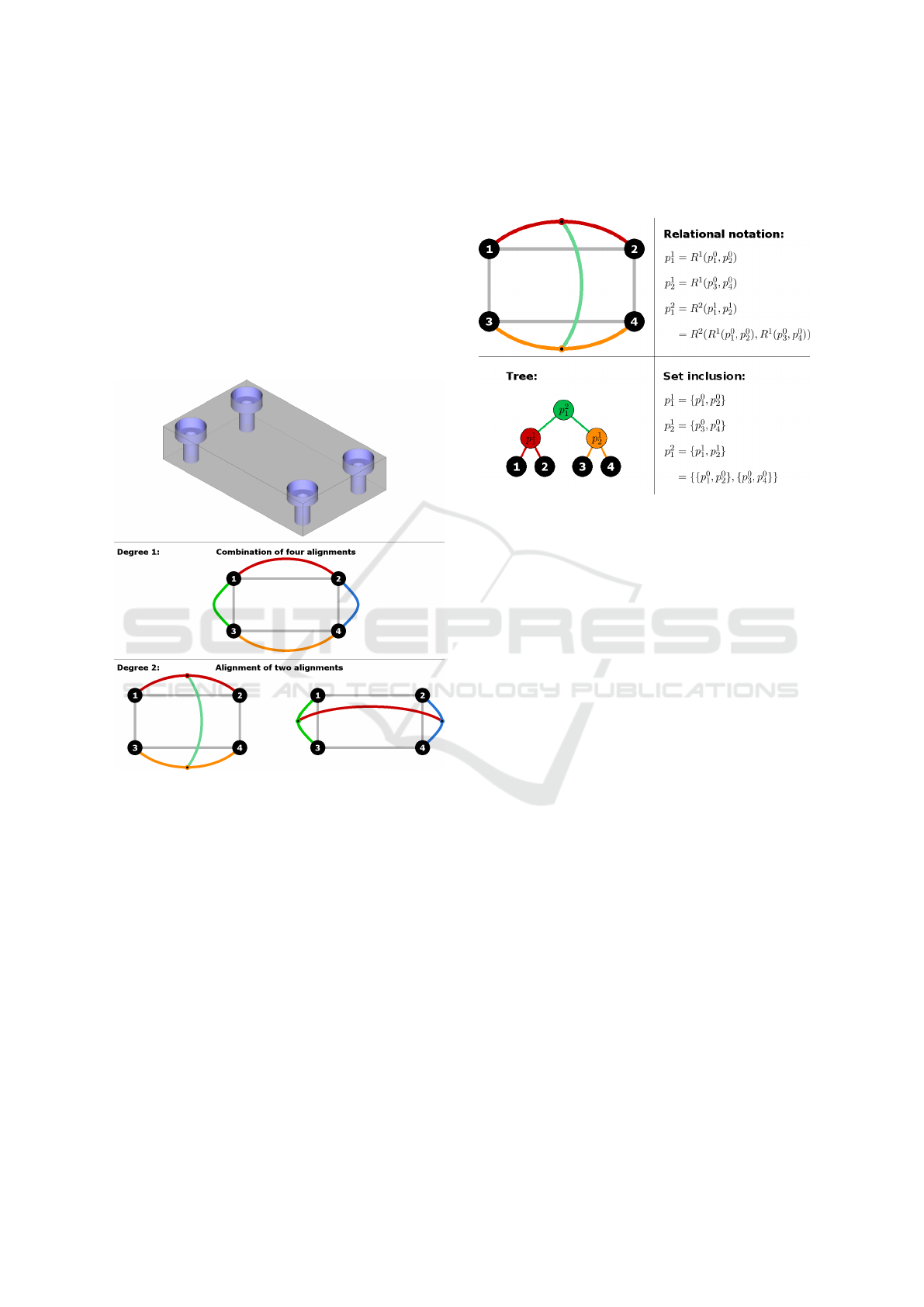

repetitions (see Fig. 5).

Figure 5: Three interpretations of a rectangular pattern.

Black disks correspond to features and colored curves cor-

respond to repetitions.

Therefore, we need to detect repetitions recur-

sively. We then define a new parameter, the degree,

which corresponds to the recursion depth needed to

construct a repetition. We propose to define a rep-

etition p

d

i

, where d corresponds to the degree, as a

relation R

d

between regularly aligned sub-repetitions

of lower degree:

p

d

i

= R

d

(p

d−1

1

... p

d−1

n

) with n > 2. (1)

In our approach, the sub-repetitions

{p

d−1

1

... p

d−1

n

} must be similar and regularly

spaced with a distance δ. The similarity between two

repetitions is then defined by comparing their param-

eters and those of their reference features. According

to the pattern type, other parameters need to be

compared such as orientations for a line or radii for a

circle. Here, a zero-degree repetition corresponds to

a feature. In the following, we could also represent a

repetition with a tree or a set inclusion (see Fig. 6).

Figure 6: Equivalent notations to represent a repetition.

From the rectangular pattern illustrated in Fig. 5,

with a length l and a width w, we can define

two equivalent two-degree repetitions: (i) by re-

peating according to l then w, we obtain the rep-

etition R

2

(R

1

(p

0

1

, p

0

2

), R

1

(p

0

3

, p

0

4

)); (ii) by repeating

according to w then l, we obtain the repetition

R

2

(R

1

(p

0

1

, p

0

3

), R

1

(p

0

2

, p

0

4

)). This equivalence between

repetitions can lead to identification problems. In-

deed, even if these repetitions result in the same final

primitive positions, we do not know which of them

was favored during modeling. Therefore, we propose

a decision algorithm to keep only the most relevant

repetitions. This algorithm is based on a set of prede-

fined rules, which allows for good adaptability. These

rules can be designed, for example, to maximize the

coverage of the object by repetitions or to reduce the

number and degree of repetitions. In our method, four

rules are defined to retrieve the most relevant repeti-

tions. These are based on successive minimizations

and maximizations of the repetition parameters:

1. maximize the total number of grouped features;

2. minimize the degree;

3. maximize the feature number of sub-repetitions;

4. minimize the distance between sub-repetitions.

The last two points are evaluated from a tree leaf,

which corresponds to the reference feature, then by

progressively tracing back to the root (see Fig. 7). We

note that only a subset of these rules can allow us to

decide which repetition to keep. For example, if two

repetitions do not contain the same total number of

features, the first rule is enough to select the most rel-

evant one. If the selection rules do not allow us to de-

GRAPP 2019 - 14th International Conference on Computer Graphics Theory and Applications

248

cide which repetition to keep, for example when they

have identical parameters as in the case of a squared

pattern, then one of the two repetitions is arbitrarily

chosen since it does not change the final results.

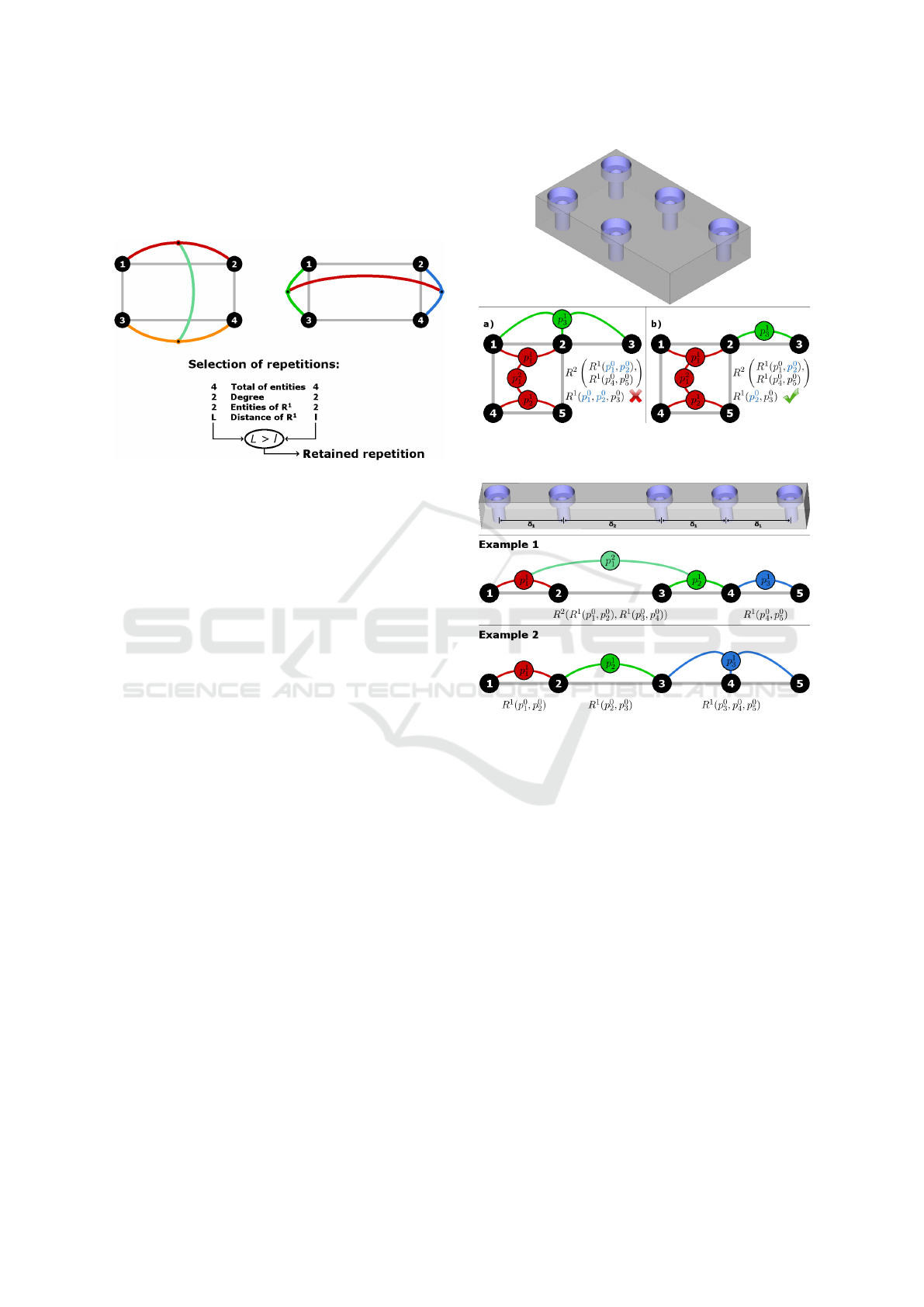

Figure 7: Selection of the most relevant repetition by com-

paring their parameters, according to predefined rules.

To better correspond to a CAD modeling process,

the selected repetitions must not have more than one

feature in common. If we take the example in Fig. 8.a,

two repetitions have been recognized, which means

that the object can be reconstructed in two steps. The

first step consists of the construction of the feature

p

0

1

, then repeating it four times to construct a squared

repetition p

2

1

. Secondly, the feature p

0

1

is repeated

along a line in three times, giving the linear repetition

p

1

3

. However, both these two repetitions construct the

feature p

0

2

whereas we must not construct the same

feature many times. Therefore, we need to remove

repetitions with more than one common features, and

keep at each step the most relevant one according to

our rules. This allows us to obtain the configuration

shown in Fig. 8.b, for example. This one consists

of the repetition of p

0

1

to construct a square, then to

repeat p

0

2

to construct p

0

3

. In this case, we obtain a

unique copy of each feature.

Besides this, some configurations can be ambigu-

ous or composed of many mixed patterns. In this

case, many repetition combinations can reconstruct

the same object. In Fig. 9, we can see two possible

repetition combinations allowing us to reconstruct the

same part. The first example is composed of a two-

degree and a one-degree repetitions. This combina-

tion seems to maximize the total number of grouped

features, and therefore seems to be the most relevant

one according to our four previously described rules.

The second example shows a combination of three

one-degree repetitions. This example seems to mini-

mize the repetition degree. To detect the second com-

bination, we only need to use the last three rules. This

highlights the adaptability of our algorithm.

Figure 8: Repetition overlap removal: a) Two common fea-

tures, b) One common feature.

Figure 9: Pattern example which can be described with dif-

ferent repetition combinations.

To correctly recognize repetitions according to

predefined rules, we need to take into account all pos-

sible combinations of the repetitions which allow us

to reconstruct the part. To do this, we propose an it-

erative algorithm (Algorithm 1). Firstly, we retrieve a

set of features {p

0

1

... p

0

n

}. Then, a feature p

0

1

is defined

as the reference feature in repetition recognition. We

then search for repetitions of two copies, three copies,

up to repetitions of n copies. This recognition is ap-

plied iteratively with each feature p

0

i

, to obtain all the

combinations. These define a set of one-degree repe-

titions {p

1

1

... p

1

k

}. The algorithm is iterated on these

one-degree repetitions, then on the obtained higher

degree repetitions {p

d

1

... p

d

n

}, until no new repetition

can be recognized. Finally, a selection step is applied

on all recognized repetitions to retain only the most

relevant combination. The theoretical complexity of

this algorithm can be relatively high, but according

to our observations, repetitions generally group small

numbers of features.

CAD-driven Pattern Recognition in Reverse Engineered Models

249

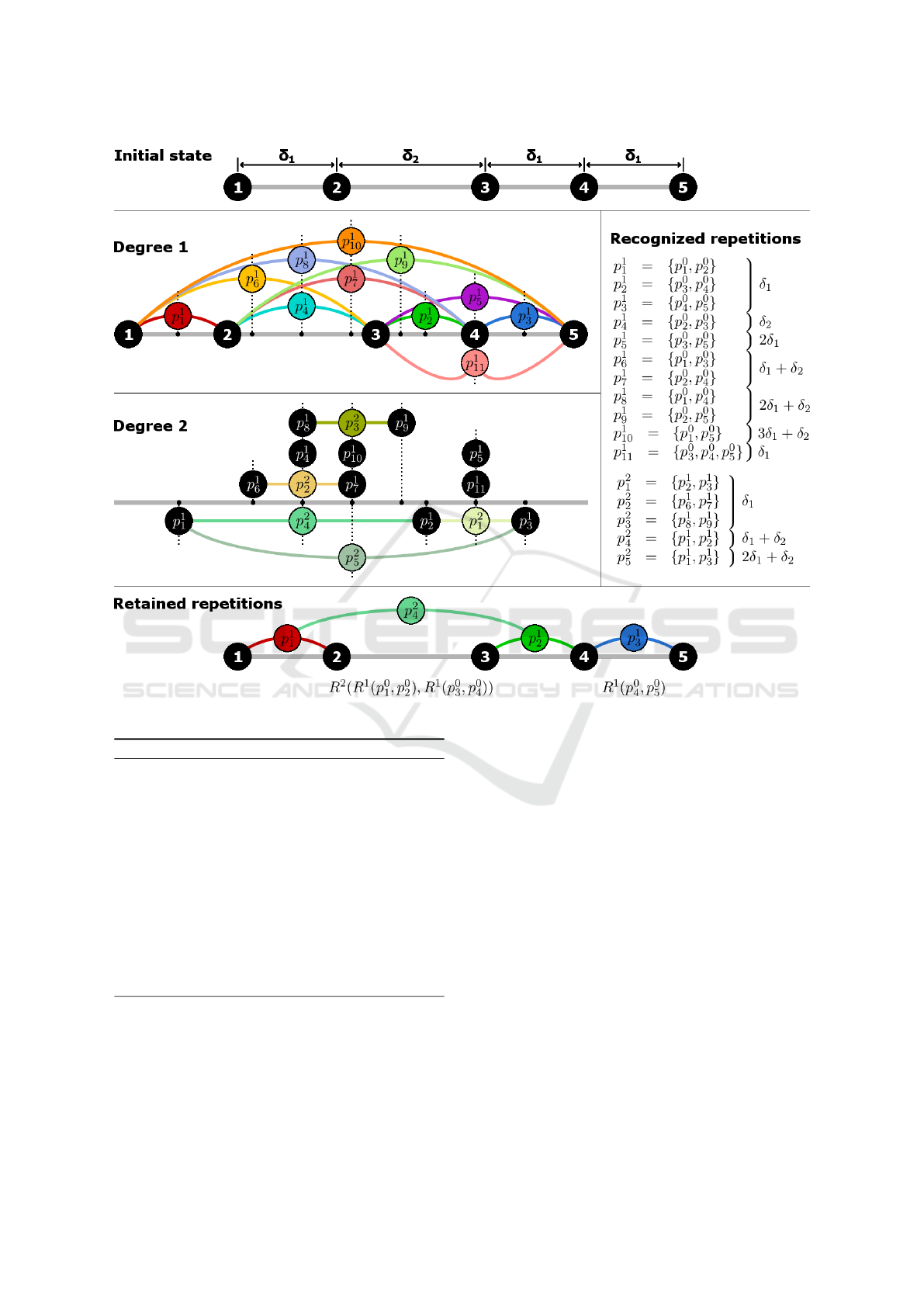

Figure 10: Recognition of all repetition combinations, for each degree, from the object illustrated in Fig. 9.

Algorithm 1: Recognition of repetitions combinations.

Input data: A set of features {p

0

1

... p

0

n

}

We define a set of repetitions R ← {p

0

1

... p

0

n

}

We define a repetition degree d ← 0

repeat

for all repetition p

d

i

∈ {p

d

1

... p

d

n

} ⊆ R do

for all number of copies m ∈ [2;n] do

R ← R ∪ Set of repetitions {p

d+1

1

... p

d+1

k

} com-

posed of m copies of p

d

i

end for

end for

d ← d + 1

until no new repetition can be recognized

R ← Selection of the most relevant repetitions from R

return R

Fig. 10 illustrates the progress of this algorithm

on the object from Fig. 9. During the one-degree

analysis, eleven repetitions are recognized, with only

one which contains three regularly spaced features.

During the two-degree analysis, five new repetitions

are recognized by grouping similar one-degree repe-

titions. No three-degree repetition are recognized so

the algorithm stops. Indeed, the detected two-degree

repetitions are not parameterized by similar distances,

and so cannot be grouped.

Finally, the relevant repetition selection analyzes

the sixteen obtained repetitions. Our first rule con-

sists of the maximization of the total number of fea-

tures included in each repetition. So, the algorithm re-

tains the repetitions {p

2

2

, p

2

3

, p

2

4

, p

2

5

}, which group four

features each. Our second rule does not allow us to

eliminate some of these, since they are all two-degree

repetitions. In the same way, our third rule also re-

tains these four repetitions since their sub-repetitions

group two features each. Our last rule compares the

distances between successive features, for each de-

gree. Firstly, the one-degree repetitions which min-

imize this distance are p

1

1

, p

1

2

and p

1

3

. Then, two-

degree repetitions are compared if they contain these

retained one-degree repetitions, i.e., p

2

4

and p

2

5

. Fi-

nally, the repetition p

2

4

minimizes the distance and so

is retained. During the second iteration, only the rep-

GRAPP 2019 - 14th International Conference on Computer Graphics Theory and Applications

250

etitions {p

1

3

, p

1

5

, p

1

9

, p

1

10

} do not have more than one

feature in common with p

2

4

. Again, the last rule,

which compares distances, allows us to retain the rep-

etition p

1

3

. The selection algorithm finally retains the

repetitions p

2

4

and p

1

3

, which corresponds to the first

combination example in Fig. 9.

In this example, we note that the repetition p

2

1

is

equivalent to the repetition p

1

11

. Indeed, these two

repetitions are parameterized by a unique distance δ

1

.

Moreover, the sub-repetitions of p

2

1

have a common

feature. This notion of equivalence could allow us,

for example, to reduce the algorithm complexity.

3.3 Application for Beautification

Pattern recognition groups together similar primi-

tives, features and repetitions. However, a reverse

engineering process generally approximates primi-

tive parameters from noisy data, such as digitized

3D meshes. In this case, data inaccuracies impact

these parameters which are then not exactly identi-

cal. Therefore, it seems appropriate to beautify the

reconstructed model, i.e., to regularize primitive and

pattern parameters.

3.3.1 Feature Regularization

As explained in Section 3.1, a feature is defined by

some parameters such as orientation, position and di-

mensions. However, the corresponding primitives can

be inaccurate. In this case, they do not exactly re-

spect the geometrical relations induced by the feature

design process. We note that in our work, we first

regularize orientation parameters to get exactly paral-

lel axes and simplify further analyses (see (Gauthier

et al., 2018)). For example, a counterbore can con-

tain two distinct axes, directly extracted from its two

cylinders which are approximatively concentric (see

Fig. 11). In this case, we need to correctly define the

feature parameters, especially when these parameters

are common to many primitives. In fact, a counter-

bore axis can be computed with a weighted mean of

two axes with weights corresponding to cylinder ar-

eas, for example. We compute a countersink axis in

the same way from its cylinder and its cone. The

other parameters of these two features are dimen-

sions, which are independant and can be directly ex-

tracted from the corresponding primitives. Finally,

feature parameters can be regularized according to

predefined modeling rules, for example. The corre-

sponding primitives are then regularized according to

the regularized feature.

Figure 11: Example of an inaccurate counterbore with two

distinct axes from its cylinders.

3.3.2 Repetition Regularization

As described in Section 3.2.3, a repetition is defined

by parameters such as a reference feature and the

distance between two successive features. However,

these parameters can also be impacted by inaccuracies

in primitive parameters (see Fig. 12). Indeed, a repe-

tition groups similar features, but not exactly identical

ones. Moreover, the distance between successive fea-

tures can vary when a repetition groups at least three

features. In this case, we need to correct the repetition

parameters. Therefore, the reference feature param-

eters can be regularized according to all the grouped

features, with a weighted mean, for example. Further-

more, the distance between successive features can be

computed from all the different distances contained in

the recognized repetition. Finally, repetition parame-

ters can be regularized according to predefined mod-

eling rules, for example. Then, the corresponding fea-

tures and primitives are made uniform according to

the regularized repetition.

4 EXPERIMENTAL RESULTS

In this section, we present experimental results con-

cerning our pattern recognition in reverse engineered

models. From complex digitized 3D point clouds or

3D meshes, a reverse engineering process extracts a

set of geometric primitives such as planes, cylinders,

cones and spheres. We then apply our pattern recog-

nition to this set of primitives.

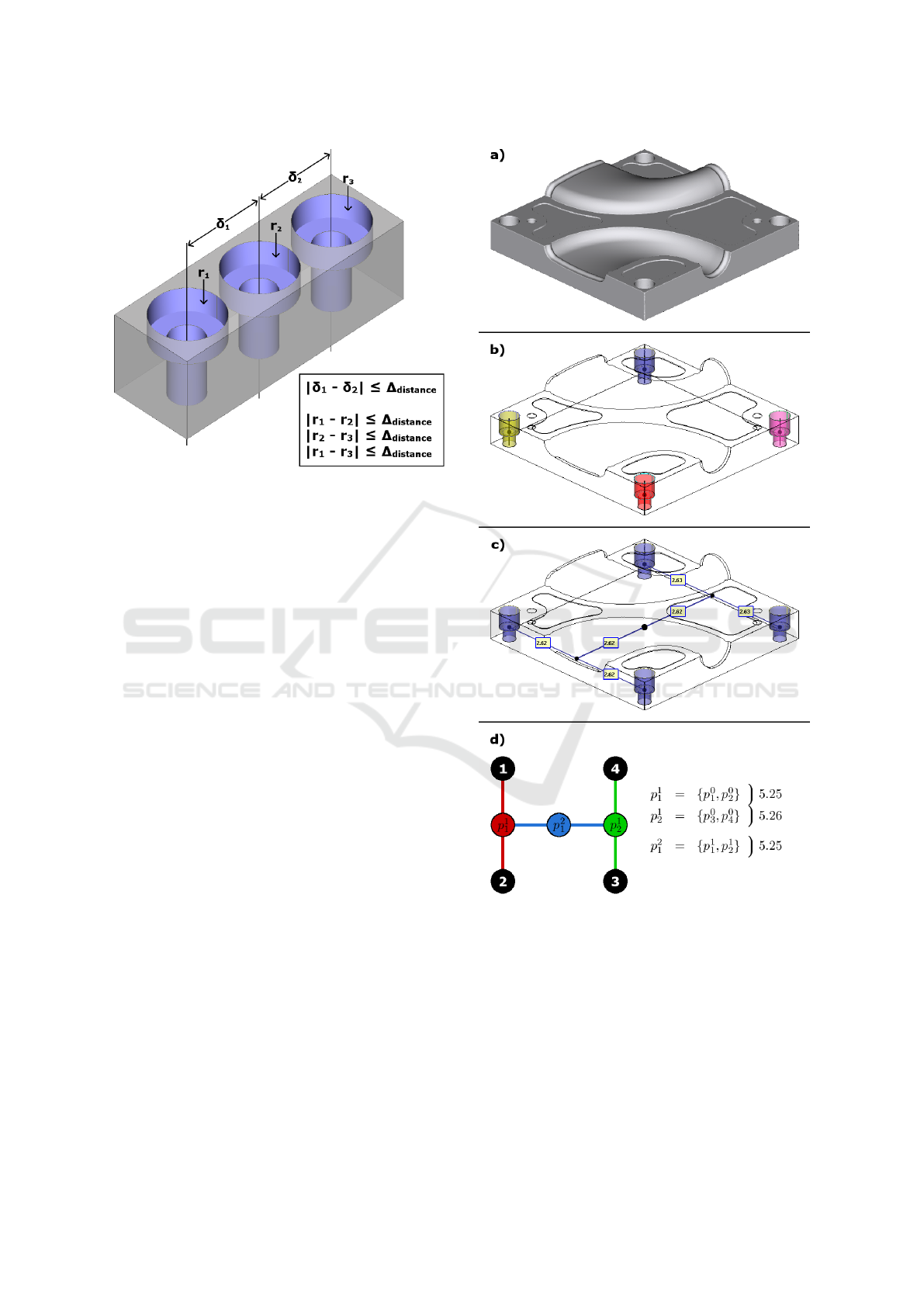

In Fig. 13.a, we can see the Moldy object. From

this object, the reverse engineering process extracts

30 primitives (18 planes, 10 cylinders and 2 freeform

surfaces). As illustrated in Fig. 13.b, our process

extracts four features from these primitives. These

CAD-driven Pattern Recognition in Reverse Engineered Models

251

Figure 12: Example of an inaccurate repetition with a vari-

able distance between its features.

four features are parallel counterbores, each defined

by two radii and two depths. The four counterbores

are parameterized by a drilling radius of 0.187mm and

a chambering radius of 0.287mm. The correspond-

ing depths are respectively defined in the ranges of

[0.363;0.364] and [0.506; 0.508]. Since the four fea-

tures are similar, it is then possible to group them into

repetitions. The recognition and selection processes

give only one relevant repetition, with a degree of two

(see Fig. 13.c). This repetition consists in the align-

ment of two one-degree repetitions, which group two

counterbores each (see Fig. 13.d). We also notice that

these four counterbores are placed in a square pattern,

which certainly corresponds to the original design of

the part. Moreover, the center of the obtained repe-

tition is close to the center of the part, which allows

us to regularize the repetition position. Finally, all the

grouped primitives are regularized at the same time,

according to a unique parameter defining the length

of the side of the squared pattern. In this result, this

length seems to be equal to 5.25mm.

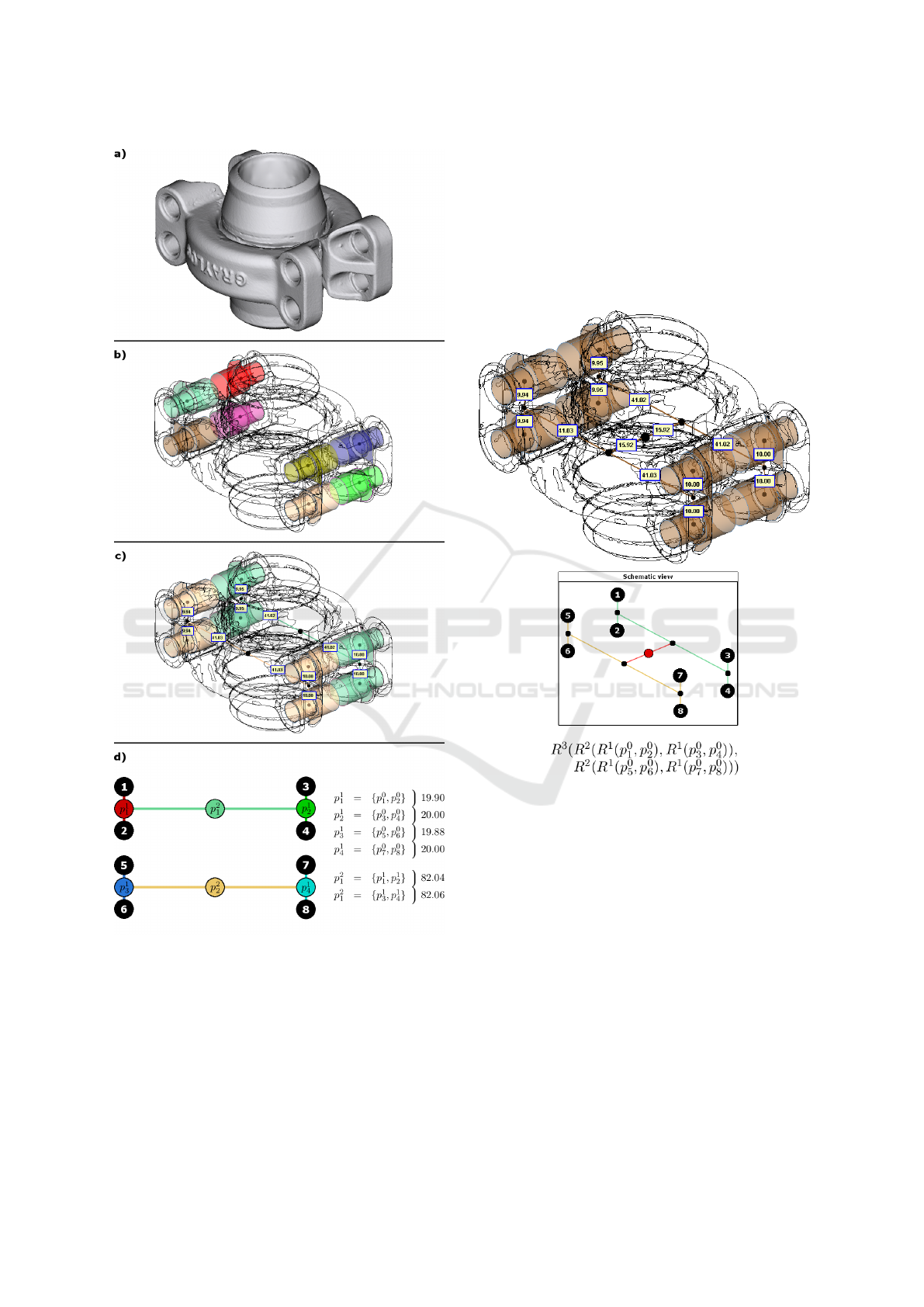

Fig. 14 shows our results on the Watertight ob-

ject, which is composed of 106 primitives (52 planes,

38 cylinders, 12 cones and 4 torii). This part con-

tains eight parallel counterbores (see Fig. 14.b). The

drilling radii are in the range of [4.95;4.97] and the

chambering radii are in the range of [6.59;6.96].

Concerning the depths, we find the ranges of

[10.23;10.47] and [12.27; 13.05]. Since the eight

counterbores are similar, two two-degree repetitions

are recognized. These repetitions group four coun-

terbores each, according to a rectangular pattern (see

Fig. 14.c). Fig. 14.d illustrates the obtained repeti-

tions with a schematic representation. The obtained

Figure 13: Features and repetitions extracted from Moldy

object: a) 3D object composed of 30 primitives, b) Features,

c) Repetitions, d) Schematic representation.

distance parameters suggest that these repetitions cor-

respond to two rectangles with a length of 82mm and

a width of 20mm. The grouped feature positions can

then be regularized according to the repetition centers

and distances. Moreover, we notice that the two rep-

etition centers are approximatively aligned with the

parts center, allowing us to regularize them.

However, these two repetitions are not grouped to-

GRAPP 2019 - 14th International Conference on Computer Graphics Theory and Applications

252

Figure 14: Features and repetitions extracted from Water-

tight object: a) 3D object composed of 106 primitives, b)

Features, c) Repetitions, d) Schematic representation.

gether, whereas they seem similar. Indeed, only their

orientation are different, and in this case they are anti-

collinear. In fact, it corresponds to a mirror-type de-

sign process, which consists in repeating a sub-part of

the object with a planar symmetry. We then propose

to adapt our repetition recognition rules to detect this

configuration. To do this, we just need to define a

new partial similarity rule, which allows us to detect

an orientation inversion. Finally, we obtain a three-

degree repetition, illustrated in Fig. 15. We note that

the center of this repetition is close to the center of the

part. In this case, we can regularize all the grouped

primitives according to the parts center and three dis-

tance parameters.

Figure 15: Mirror-type repetition recognized from repeti-

tions of Watertight object, which are illustrated in Fig. 14.

5 CONCLUSION

In this paper, an efficient method has been proposed

to analyze a set of geometric primitives and recognize

standard CAD patterns. We especially focus on two

types of patterns, these are features and repetitions.

We chose to work on primitives extracted from a dig-

itized 3D mesh, using a reverse engineering process.

The particularity of these primitives is that their pa-

rameters can be inaccurate. Indeed, fabrication and

digitization processes are not perfect, and can intro-

duce noisy data.

Our proposed pattern recognition allows us to de-

duce geometric relations and relative placement be-

tween inaccurate primitives. Then, we show that our

CAD-driven Pattern Recognition in Reverse Engineered Models

253

proposed analysis can be applied to a beautification

step, which consists of the regularization of primitive

parameters to better correspond to the original CAD

model. Our experimental results suggest that our ap-

proach is robust enough to analyze and correct primi-

tives from a complex digitized part.

Our proposed method is a first step towards a

fully automatic reverse engineering process, retriev-

ing the original design intent of a digitized manufac-

tured part. However, it can be difficult to take into

account all the primitive placement possibilities in

an object, i.e., all distances and proportions possibly

used during the modeling process. Therefore, our al-

gorithm is designed to be adaptive and easily exten-

sible, by adding or removing some rules concerning

geometrical relations, features and repetitions.

REFERENCES

Babic, B., Nesic, N., and Miljkovic, Z. (2008). A review of

automated feature recognition with rule-based pattern

recognition. Computers in Industry, 59(4):321–337.

B

´

eni

`

ere, R., Subsol, G., Gesqui

`

ere, G., Le Breton, F., and

Puech, W. (2013). A comprehensive process of re-

verse engineering from 3D meshes to CAD models.

Computer-Aided Design, 45(11):1382–1393.

Gauthier, S., Puech, W., B

´

eni

`

ere, R., and Subsol, G.

(2018). Orientation beautification of reverse engi-

neered model. In GRAPP: International Confer-

ence on Computer Graphics Theory and Applications,

pages 91–100.

Geng, W., Chen, Z., He, K., and Wu, Y. (2016). Feature

recognition and volume generation of uncut regions

for electrical discharge machining. Advances in Engi-

neering Software, 91:51–62.

Harik, R. (2007). Sp

´

ecifications de fonctions pour un

syst

`

eme d’aide

`

a la g

´

en

´

eration automatique de gamme

d’usinage: application aux pi

`

eces a

´

eronautiques de

structure, prototype logiciel dans le cadre du pro-

jet RNTL USIQUICK. PhD thesis, Universit

´

e Henri

Poincar

´

e-Nancy I.

Jun, Y., Raja, V., and Park, S. (2001). Geometric feature

recognition for reverse engineering using neural net-

works. The International Journal of Advanced Manu-

facturing Technology, 17(6):462–470.

Langbein, F. C. (2003). Beautification of reverse engineered

geometric models. PhD thesis, Cardiff University.

Lupinetti, K., Giannini, F., Monti, M., and Pernot, J.-P.

(2017). Identification of functional components in me-

chanical assemblies. Procedia CIRP, 60:542–547.

Muraleedharan, L. P., Kannan, S. S., Karve, A., and

Muthuganapathy, R. (2018). Random cutting plane

approach for identifying volumetric features in a CAD

mesh model. Computers & Graphics, 70:51–61.

Pal, P., Tigga, A., and Kumar, A. (2005). Feature extraction

from large CAD databases using genetic algorithm.

Computer-Aided Design, 37(5):545–558.

Pauly, M., Mitra, N. J., Wallner, J., Pottmann, H., and

Guibas, L. J. (2008). Discovering structural regular-

ity in 3D geometry. ACM transactions on graphics

(TOG), 27(3):43.

Sanfilippo, E. M. and Borgo, S. (2016). What are features?

An ontology-based review of the literature. Computer-

Aided Design, 80:9–18.

Urbanic, R. and Elmaraghy, W. (2008). Design recovery of

internal and external features for mechanical compo-

nents. Virtual and Physical Prototyping, 3(2):61–83.

Vilmart, H., L

´

eon, J.-C., and Ulliana, F. (2018). From

CAD assemblies toward knowledge-based assem-

blies using an intrinsic knowledge-based assembly

model. Computer-Aided Design and Applications,

15(3):300–317.

Wang, Q. and Yu, X. (2014). Ontology based automatic

feature recognition framework. Computers in Indus-

try, 65(7):1041–1052.

Wu, Y., Shah, J. J., and Davidson, J. K. (2003). Computer

modeling of geometric variations in mechanical parts

and assemblies. Journal of Computing and Informa-

tion Science in Engineering, 3(1):54–63.

GRAPP 2019 - 14th International Conference on Computer Graphics Theory and Applications

254