Automatic Information Extraction from Piping and Instrumentation

Diagrams

Rohit Rahul, Shubham Paliwal, Monika Sharma and Lovekesh Vig

TCS Research, New Delhi, India

Keywords:

P&ID Sheets, Symbol Classification, Pipeline Code Extraction, Fully Convolutional Network, Tree-structure.

Abstract:

One of the most common modes of representing engineering schematics are Piping and Instrumentation dia-

grams (P&IDs) that describe the layout of an engineering process flow along with the interconnected process

equipment. Over the years, P&ID diagrams have been manually generated, scanned and stored as image files.

These files need to be digitized for purposes of inventory management and updation, and easy reference to

different components of the schematics. There are several challenging vision problems associated with digi-

tizing real world P&ID diagrams. Real world P&IDs come in several different resolutions, and often contain

noisy textual information. Extraction of instrumentation information from these diagrams involves accurate

detection of symbols that frequently have minute visual differences between them. Identification of pipelines

that may converge and diverge at different points in the image is a further cause for concern. Due to these

reasons, to the best of our knowledge, no system has been proposed for end-to-end data extraction from P&ID

diagrams. However, with the advent of deep learning and the spectacular successes it has achieved in vision,

we hypothesized that it is now possible to re-examine this problem armed with the latest deep learning models.

To that end, we present a novel pipeline for information extraction from P&ID sheets via a combination of

traditional vision techniques and state-of-the-art deep learning models to identify and isolate pipeline codes,

pipelines, inlets and outlets, and for detecting symbols. This is followed by association of the detected com-

ponents with the appropriate pipeline. The extracted pipeline information is used to populate a tree-like data

structure for capturing the structure of the piping schematics. We have also evaluated our proposed method on

a real world dataset of P&ID sheets obtained from an oil firm and have obtained extremely promising results.

To the best of our knowledge, this is the first system that performs end-to-end data extraction from P&ID

diagrams.

1 INTRODUCTION

A standardized representation for depicting the equip-

ment and process flow involved in a physical process

is via Piping and Instrumentation diagrams (P&ID).

P&ID diagrams are able to represent complex en-

gineering workflows depicting schematics of a pro-

cess flow through pipelines, vessels, actuators and

control valves. A generic representation includes

fluid input points, paths as pipelines, symbols which

represent control and measurement instruments and,

sink points. Most industries maintain these complex

P&IDs in the form of hard-copies or scanned images

and do not have any automated mechanism for in-

formation extraction and analysis of P&IDs (Arroyo

et al., 2014). Consequently, future analysis and au-

dit for process improvement involves manual involve-

ment which is expensive given the domain expertise

required. It would be of great value if the data present

in P&ID sheets could be automatically extracted and

provide answers to important queries related to the

connectivity of plant components, types of intercon-

nections between process equipments and the exis-

tence of redundant paths automatically. This would

enable process experts to obtain the information in-

stantly and reduce the time required for data retrieval.

Given the variations in resolution, text fonts, low

inter-class variation and the inherent noise in these

documents, this problem has previously been consid-

ered too difficult to address with standard vision tech-

niques. However, deep learning has recently shown

incredible results in several key vision tasks like seg-

mentation, classification and generation of images.

The aim of this paper is to leverage the latest work in

deep learning to address this very challenging prob-

lem, and hopefully improve the state-of-the-art for in-

formation extraction from these P&ID diagrams.

Rahul, R., Paliwal, S., Sharma, M. and Vig, L.

Automatic Information Extraction from Piping and Instr umentation Diagrams.

DOI: 10.5220/0007376401630172

In Proceedings of the 8th International Conference on Pattern Recognition Applications and Methods (ICPRAM 2019), pages 163-172

ISBN: 978-989-758-351-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

163

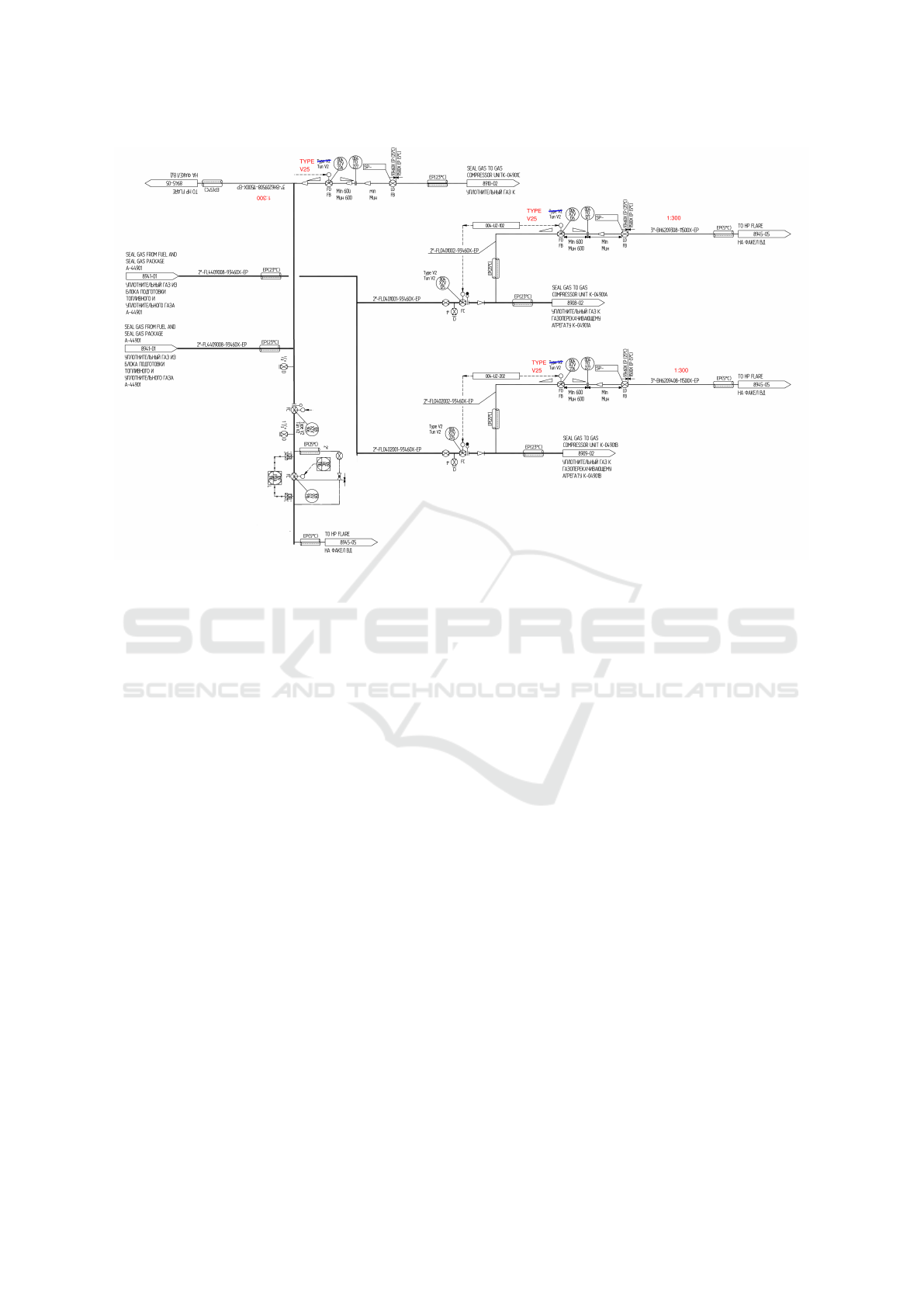

Figure 1: An Example of Piping and Instrumentation Diagram sheet.

The digitization process of P&IDs involves identi-

fication and localization of pipeline codes, pipelines,

inlets, outlets and symbols which is followed by map-

ping of individual components with the pipelines. Al-

though tools for the digitization of engineering draw-

ings in industries are in high demand, this problem

has received relatively little attention in the research

community. Relatively few attempts have been made

in the past to address digitization of complex engi-

neering documents comprising of both textual and

graphical elements, for example: complex receipts,

inspection sheets, and engineering diagrams (Verma

et al., 2016), (Wang et al., 2009), (Arroyo et al.,

2014), (Gupta et al., 2017), (Adam et al., 2000).

We have found that connected component analy-

sis (Koo and Kim, 2013) is heavily employed for

text-segmentation for such documents (Verma et al.,

2016). However, the recently invented Connectionist

Text Proposal Networks (CTPN) (Tian et al., 2016)

have demonstrated the capability to detect text in ex-

tremely noisy scenarios. We utilize a pre-trained

CTPN network to accurately detect the text patches

in a P&ID image. In the literature, symbol detec-

tion is performed by using shape based matching

techniques (Belongie et al., 2002), auto associative

neural networks (Gellaboina and Venkoparao, 2009),

graph based techniques (Yu, 1995). However, detect-

ing symbols in P&ID sheets is quite challenging be-

cause of the low inter-class variation among different

symbols and the presence of text and numbers inside

symbols. To alleviate this issue, we succesfully em-

ploy Fully Convolutional Networks (FCN) which are

trained to segment out the individual symbols.

Thus, our proposed pipeline for information ex-

traction from P&ID sheets uses a combination of

state-of-the-art deep learning models for text and

symbol identification, in combination with low level

image processing techniques for the extraction of dif-

ferent components like inlets, outlets and pipelines

present in the sheets. Moreover, given the paucity of

sufficient real datasets for this domain, automating the

process of information extraction from P&ID sheets

is often harder than in other domains and significant

data augmentation is required to train deep models.

We evaluate the efficacy of our proposed method on

4 sheets of P&IDs, each containing multiple flow di-

agrams, as shown in Figure 1.

To summarize, we have formulated the digiti-

zation process of P&IDs as a combination of (1)

heuristic rule based methods for accurate identifica-

tion of pipelines, and for determining the complete

flow structure and (2) deep learning based models for

identification of text and symbols and (3) rule based

association of detected objects and a tree based rep-

resentation of process flow followed by pruning for

determining correct inlet to outlet path. While formu-

lating the digitization process of P&IDs, we make the

following contributions in this paper:

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

164

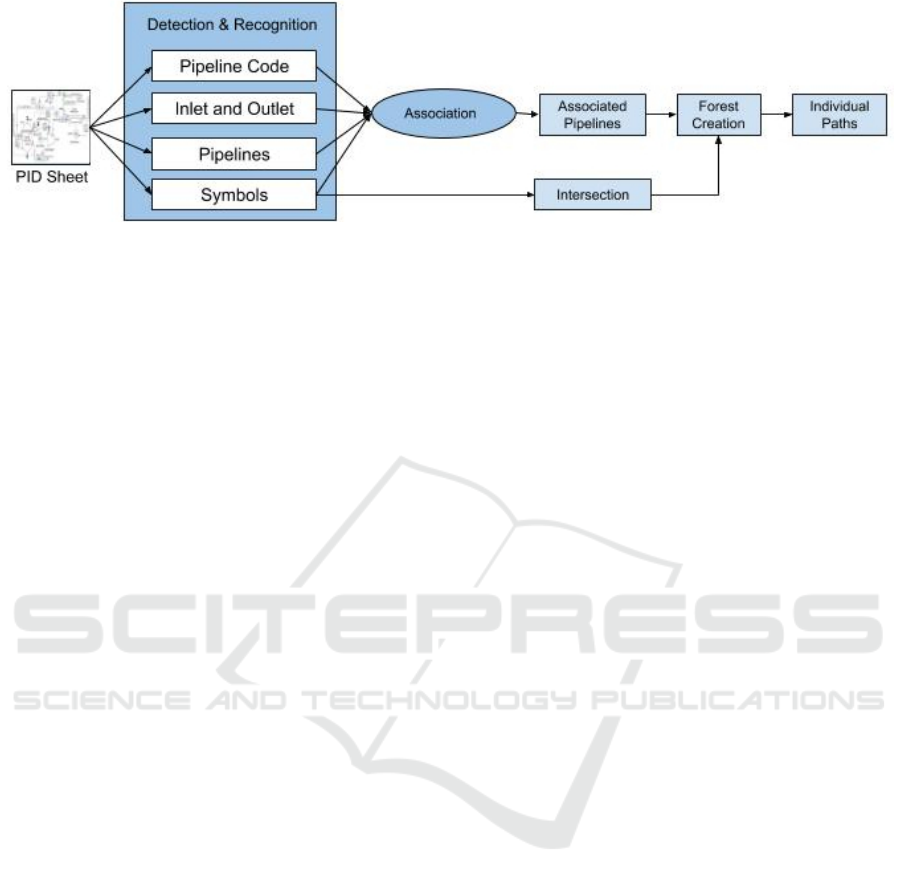

Figure 2: Flowchart showing proposed 2-step process for digitization of Piping and Instrumentation Diagrams. First, P&ID

sheet is fed to a detection and recognition engine which identifies and isolates different components of the process flow like

pipelines, pipeline codes, inlets, outlets and symbols using a combination of traditional vision techniues and deep learning

models. Subsequently, the extracted components are sent to an association module for mapping with the appropriate pipeline.

Finally, a tree-like data structure is created to determine the flow from inlet to outlet.

• We propose a novel pipeline consisting of a

two-step process for information extraction from

P&ID diagrams, comprising of a combination of

detection of different components of the process

flow followed by their association with appropri-

ate pipeline and representation in a tree-like data

structure to determine the flow from inlet to outlet.

• We propose the use of conventional image pro-

cessing and vision techniques to detect and rec-

ognize graphic objects (e.g. pipelines, inlets and

outlets) present in P&ID.

• We use a fully convolutional neural network

(FCN) based segmentation for detection of sym-

bols in P&ID sheets at the pixel level because of

very minute visual difference in appearance of dif-

ferent symbols, as the presence of noisy and tex-

tual information inside symbols makes it difficult

to classify based on bounding box detection net-

works like Faster-RCNN (Ren et al., 2015).

• We evaluate our proposed pipeline on a dataset of

real P&ID sheets from an oil firm and present our

results in Section 5.

The remainder of the paper is organized as fol-

lows: Section 2 gives an overview of related work in

the field of information extraction from visual docu-

ments. An overview of the proposed pipeline for auto-

matic extraction of information from P&ID is given in

Section 3. Section 4 describes in detail the proposed

methodology for extracting different P&ID compo-

nents like pipeline code, pipelines and symbols etc.

and their mapping. Subsequently, Section 5 gives de-

tails about the dataset, experiments and a discussion

on the obtained results. Finally, we conclude the pa-

per in Section 6.

2 RELATED WORK

There exists very limited work on digitizing the con-

tent of engineering diagrams to facilitate fast and ef-

ficient extraction of information. The authors (Goh

et al., 2013) automated the assessment of AutoCAD

Drawing Exchange Format (DXF) by converting DXF

file into SVG format and developing a marking algo-

rithm of the generated SVG files. A framework for

engineering drawings recognition using a case-based

approach is proposed by (Yan and Wenyin, 2003)

where the user interactively provides an example of

one type of graphic object in an engineering drawing

and then system tries to learn the graphical knowl-

edge of this type of graphic object from the exam-

ple and later use this learned knowledge to recognize

or search for similar graphic objects in engineering

drawings. Authors of (Arroyo et al., 2015) tried to

automate the extraction of structural and connectiv-

ity information from vector-graphics-coded engineer-

ing documents. A spatial relation graph (SRG) and its

partial matching method are proposed for online com-

posite graphics representation and recognition in (Xi-

aogang et al., 2004). Overall, we observed that there

does not exist much work on information extraction

from plant engineering diagrams.

However, we discovered a significant body of

work on recognition of symbols in prior art. (Adam

et al., 2000) proposed Fourier Mellin Transform fea-

tures to classify multi-oriented and multi-scaled pat-

terns in engineering diagrams. Other models utilized

for symbol recognition include Auto Associative neu-

ral networks (Gellaboina and Venkoparao, 2009),

Deep Belief networks (Fu and Kara, 2011), and con-

sistent attributed graphs (CAG) (Yu, 1995). There are

also models that use a set of visual features which cap-

ture online stroke properties like orientation and end-

point location (Ouyang and Davis, 2009), and shape

Automatic Information Extraction from Piping and Instrumentation Diagrams

165

based matching between different symbols (Belongie

et al., 2002). We see that most of the prior work fo-

cuses on extracting symbols from such engineering

diagrams or flow charts. To the best of our knowl-

edge, there exists no work which has proposed an end-

to-end pipeline for automating the information extrac-

tion from plant engineering diagrams such as P&ID.

In literature, Connected Component (CC) analy-

sis (Koo and Kim, 2013) has been used extensively

for extracting characters (Gupta et al., 2017) from im-

ages. However, connected components are extremely

sensitive to noise and thresholding may not be suit-

able for P&ID text extraction. Hence, we utilize

the recently invented Connectionist Temporal Pro-

posal Network (CTPN) (Tian et al., 2016) to detect

text in the image with impressive accuracy. For line

detection, we utilize Probabilistic hough transform

(PHT) (Kiryati et al., 1991) which is computationally

efficient and fast version of the standard hough trans-

form as it uses random sampling of edge points to

find lines present in the image. We make use of PHT

for determining all the lines present in P&ID sheets

which are possible candidates for pipelines. In our

paper, we propose the use of Fully convolutional neu-

ral network (FCN) based segmentation (Shelhamer

et al., 2016) for detecting symbols because trandi-

tional classification networks were unable to differ-

entiate among different types of symbols due to very

minute inter-class differences in visual appearances

and presence of noisy and textual information present

inside symbols. FCN incorporates contextual as well

as spatial relationship of symbols in the image, which

is often necessary for accurate detection and classifi-

cation of P&ID symbols.

3 OVERVIEW

The main objective of the paper is to extract

the information from the P&ID sheets representing

schematic process flow through various components

like pipelines, valves, actuators etc. The information

is extracted from P&ID and stored in a data struc-

ture that can be used for querying. The P&ID dia-

gram shown in Figure 1 depicts the flow of oil through

pipelines from inlet to outlet, where outlets and in-

lets denote the point of entry and exit of the oil, re-

spectively. Each outlet is unique and may connect to

multiple inlets, forming a one-to-many relationship.

The symbols indicate the machine parts present on

the pipeline to control the flow and to filter the oil in a

specific way. The pipelines are identified by a unique

P&ID code which is written on top of every pipeline.

To capture all the information from the P&ID

sheets, we propose a two-step process as follows :

• In the first step, we identify all the individual com-

ponents like pipelines, pipeline codes, symbols,

inlets and outlets. We use conventional image

processing and vision techniques like connected

component analysis (Koo and Kim, 2013), proba-

bilistic hough transform (Kiryati et al., 1991), ge-

ometrical properties of components etc. to local-

ize and isolate pipelines, pipeline codes, inlets and

outlets. Symbol detection is carried out by using

fully convolutional neural network based segmen-

tation (Shelhamer et al., 2016) as symbols have

very minute inter class variations in visual appear-

ances. Text detection is performed via a Connec-

tionist Text Proposal Network (CTPN), and the

recognition is performed via the tesseract OCR li-

brary.

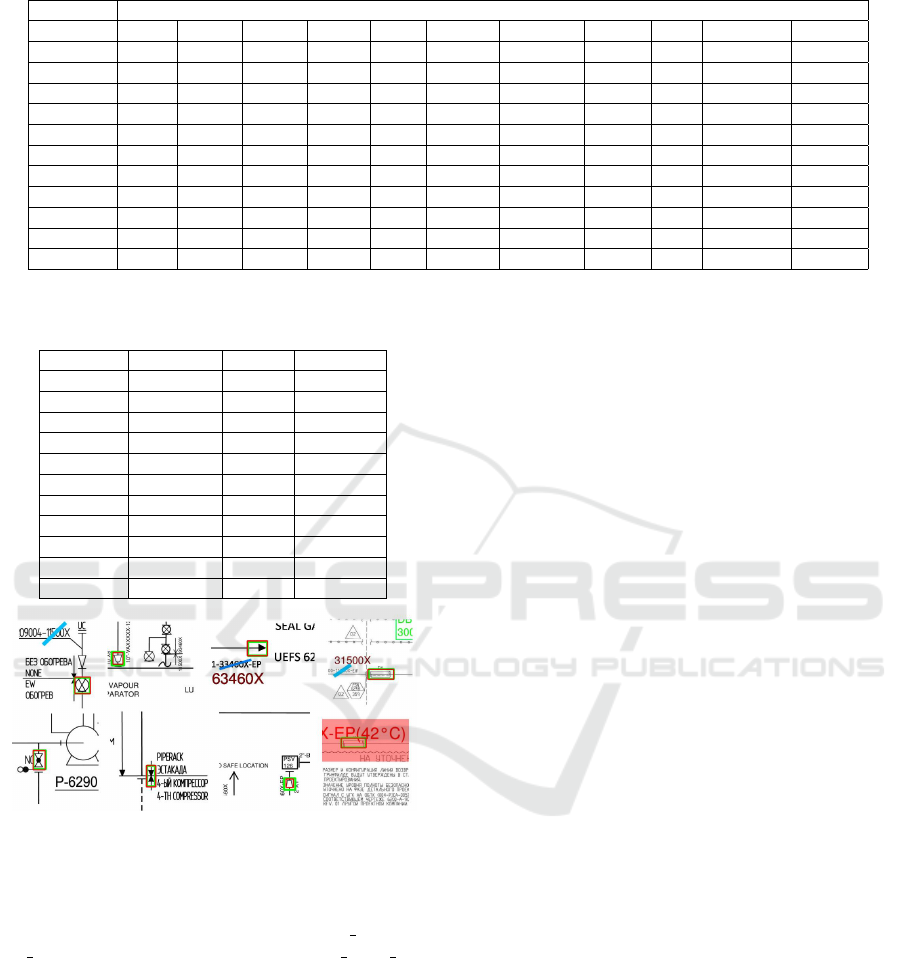

• In the second step, we associate these components

with each other and finally capture the flow of

oil through pipelines by forming a tree-like data

structure. The tree is able to represent one-to-

many relationship where each outlet acts as root

node and each inlet is treated as a leaf node. The

pipelines represent intermediate nodes present in

the tree.

4 PROPOSED METHODOLOGY

In this section, we discuss the proposed methodolody

for extracting information from P&ID sheets in de-

tail. It is a two-step process as shown in Figure 2

in which the first step involves detection and recog-

nition of individual components like pipeline-codes,

symbols, pipelines, inletss and outlet. The second

step involves association of detected components with

the appropriate pipelines followed by formulation of

tree-like data structure for finding the process flow of

pipeline schematics. These steps are detailed as fol-

lows :

4.1 Detection and Recognition

We use vision techniques for extracting different com-

ponents like pipeline-codes, symbols, pipelines, inlets

and outlets present in P&IDs. We divide these com-

ponents into two-types : 1. text containing pipeline-

codes and 2. graphic objects like pipelines, symbols.

As observed from Figure 1, P&ID sheets have text

present which represents pipeline code, side notes,

sometimes as part of a symbol or container / symbol /

tag numbers, we call these text segments as pipeline-

code. The non-text components like pipelines, sym-

bols, inlets and outlets are termed as graphic objects.

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

166

Now, we discuss the detection and recognition meth-

ods for different components as follows :

• Detection of Pipeline Code: The pipeline code

distinctly characterizes each pipeline. Hence, we

first identify the pipeline code. While previous

approaches utilized thresholding followed by

connected components in order to extract the

codes, we utilize a CTPN (Tian et al., 2016)

network pre-trained on a scene-text dataset for

pipeline-code detection, as it was far more robust

to noise / color in the document. CTPN is a

convolutional network which accepts arbitrarily

sized images and detects a text line in an image

by densely sliding a window in the convolutional

feature maps and produces a sequence of text

proposals. This sequence is then passed through

a recurrent neural network which allows the

detector to explore meaningful context informa-

tion of text line and hence, makes it powerful to

detect extremely challenging text reliably. The

CTPN gives us all possible candidate components

for pipeline code with 100 % recall but with

significant number of false positives which are

filtered out in a later step. Subsequently, we

use tesseract (Smith, 2007) for reading each

component detected in the previous step. Since,

pipeline codes have fixed length and structure, we

filter out false positives using regular expressions.

For example, the pipeline code is of the format

N”-AANNNNNNN-NNNNNA-AA where N

denotes a Digit and A denotes an alphabet. This

domain knowledge gives us all the pipeline codes

present in the P&ID sheets.

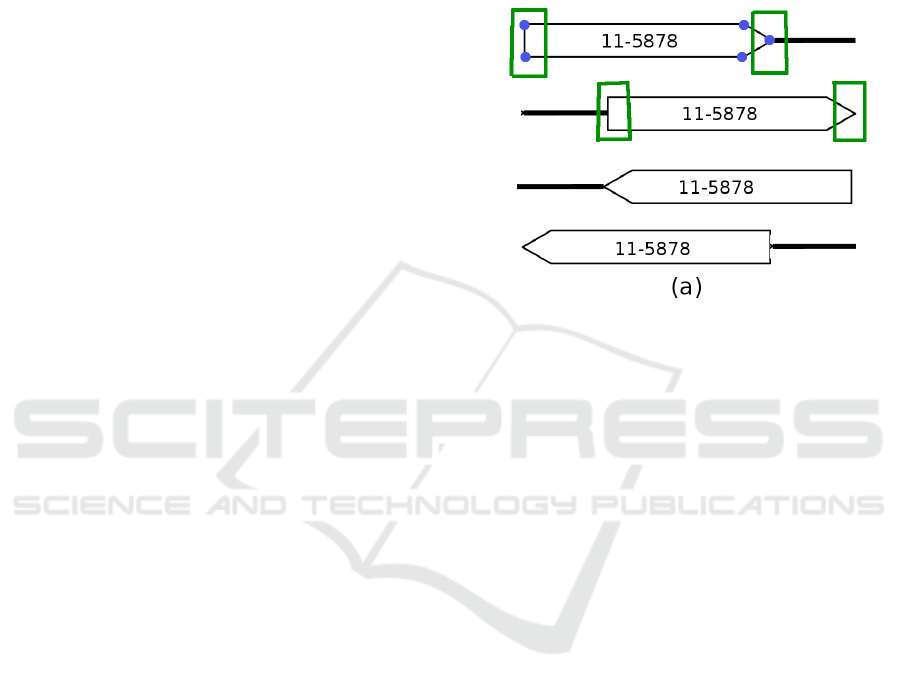

• Detection of Inlet and Outlet: The inlet or outlet

marks the starting or ending point of the pipeline.

There is a standard symbol representing inlet or

outlet. It is a polygon having 5 vertices and the

width of the bounding box is at least thrice its

height. We use this shape property of the symbol

to detect inlet / outlet robustly using heuristics.

For detection of the inlets and outlets, we subtract

the text blobs detected as pipeline codes from

a binarized input image for further processing.

Then, we use Ramer-Douglas algorithm (Fei and

He, 2009) in combination with known relative

edge lengths to identify the polygons. After

detecting each polygon, we find out whether it

is an inlet or an outlet. As can be seen from

Figure 1, there are 4 possible cases of polygons

because there are two types of tags present in

P&ID : left-pointing and right-pointing. Each of

the right-pointing or left-pointing tag can either

be an inlet or an outlet. We find the orientation

of tags from the points given by Ramer-Douglas

knowing the fact that there will be 3 points on one

side and two on another side in a right-pointing

or left-pointing tag, as shown in Figure 3. To

further classify whether the candidate is an

inlet or outlet among them, we take a small

kernel K on either side of the component image

and find out which edge is crossed by a single line.

Figure 3: Figure showing inlets and outlets of P&ID dia-

grams.

• Detection of Pipeline: We remove the detected

text and inlet / outlet tags from the image for

detecting pipelines. We then use probabilistic

hough transform (Kiryati et al., 1991) on the

skeleton (Saha et al., 2016) version of the image

which outputs a set of all lines including lines

that do not correspond to pipelines.

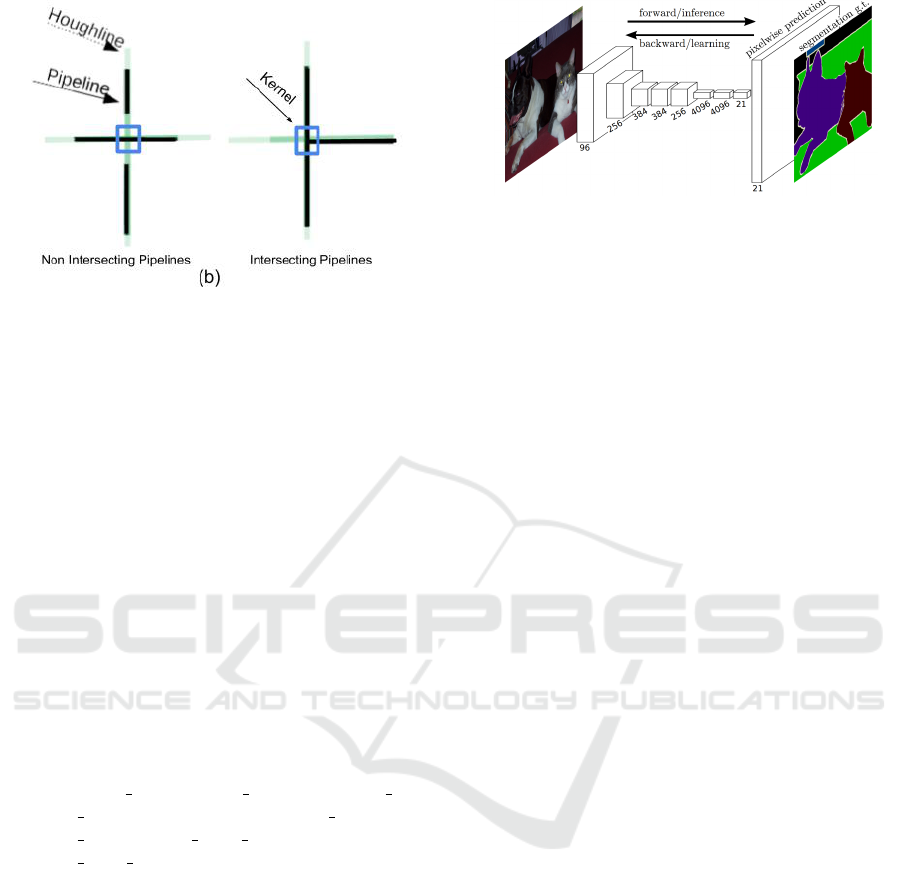

• Detection of Pipeline Intersections: The output

of the hough lines is a set of lines which does

not take into account the gap at the intersections,

as shown in Figure 4. There can be two kinds

of intersections : a valid intersection or an

invalid intersection. We aim to find all the valid

intersections. This is achieved by determining all

the intersections between any two line segments

by solving the system of linear equations. The

solution to the equations is a point which should

lie on both finite pipelines. This assumption en-

sures that the solution is a part of foreground. An

invalid intersection is the intersection where the

solution of the two linear equations for the line

has given us an intersection but there exists no

such intersection in the image. This is indicated

by the gap in one of the lines involved in the

intersection, as shown in Figure 4. To discard

invalid intersections, we draw a square kernel

of size 21 with the center at the intersection and

check for lines intersecting with the edges of the

square. Here, we have two possibilities : (1)

Automatic Information Extraction from Piping and Instrumentation Diagrams

167

Figure 4: Figure showing pipelines in P&ID sheets.

where the intersections are on the opposite edges

of the square and no intersection on other two

edges of the square. This means that there is

no intersection and there is just one line which

passes through the intersection. (2) where there

can be intersection on three or all four edges of

the square. This is the case of valid intersection

between the pipelines. Thus we obtain the

pipeline intersections and store them for use later

to create of a tree-like data structure for capturing

the structure of pipeline schematics.

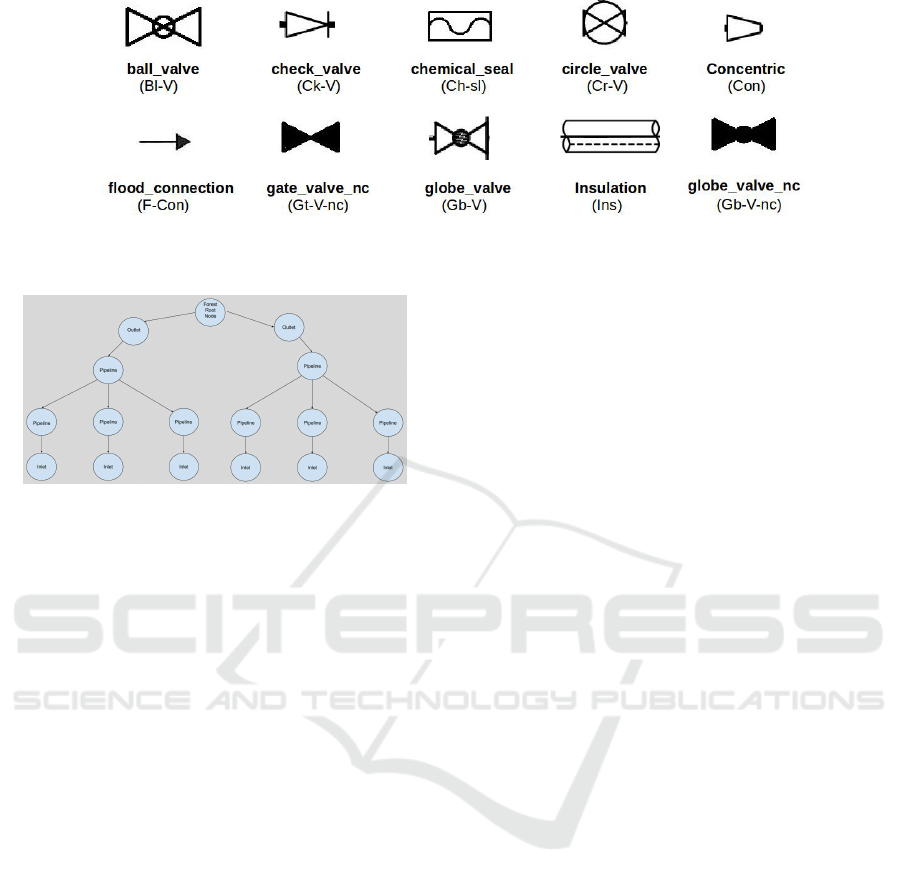

• Detection of Symbols: There are various types of

symbols present in the P&ID sheets which repre-

sent certain instruments responsible for controling

the flow of oil through pipelines and performing

various tasks. In our case, we have 10 classes

of symbols to detect and localise in the sheets,

e.g. ball valve, check valve, chemical seal,

circle valve, concentric, flood connection,

globe valve, gate valve nc, insulation and

globe valve nc. As can be seen in Figure 6, these

symbols have very low inter-class difference in

visual appearances. So, standard deep networks

for classification are not able to distinguish them

correctly. Therefore, we propose to use fully

convolutional neural network (FCN) (Shelhamer

et al., 2016) for detecting symbols. FCNs, as

shown in Figure 5, are convolutional networks

where the last fully connected layer is replaced by

a convolution layer with large receptive field. The

intuition behind using segmentation is that FCN

network has two parts : one is downsampling

path which is composed of convolutions, max

pooling operations and extracts the contextual in-

formation from the image, second is upsampling

path which consists of transposed convolutions,

unpooling operations to produce the output with

size similar to input image size and learns the

Figure 5: Fully convolutional segmentation network taken

from (Shelhamer et al., 2016).

precise spatial location of the objects in the image.

Data Annotation for FCN: For detecting sym-

bols using FCN, we annotated a dataset of real

world P&IDs diagrams from an oil firm. The

original P&ID sheets are of very large size, so we

divided it into smaller patches of size 400 × 400

for annotating the symbols. These patches

contain different classes of symbols and can have

multiple symbols present in a single patch. The

symbols were annotated by masking their pixel

values completely and subsequently, obtaining

the boundaries of the symbol masks representing

the shape of the symbol. To automate this process

of extracting outlines of symbol masks, a filter

was applied for the region containing the masked

shape, i.e, bitwise-and operation was used. This

was followed by thresholding the patches to get

the boundaries / outlines only and then it was

dilated with a filter of size 3 × 3. As the training

dataset was limited, we augmented the images by

performing some transformations on the image

like translation and rotation.

Training Details: We use VGG-19 (Simonyan

and Zisserman, 2014) based FCN for training

symbol detector. An input image of size 400 ×

400 is fed to the network and it is trained using

Adam optimizer with a learning rate of 0.0004 and

batch size of 8.

4.2 Association and Structuring

At this stage, we have detected all the necessary com-

ponents of the P&ID diagrams. Next step is to as-

sociate these components with each other and form a

structure of the pipeline schematics. This is done as

follows :

• Tags to Pipeline Association: We find the line

emerging direction from the orientation of inlet

and outlet. We associate the closest pipeline from

the line emerging point in the direction of pipeline

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

168

Figure 6: Different classes of symbols present in P&ID sheets.

Figure 7: An example of tree-like data structure creation for

capturing the process flow of pipeline schematics of P&ID.

to the tag. The closest pipeline is determined

based upon euclidean distance.

• Pipeline Code to Pipeline Association: Simi-

larly, we assign the pipeline codes to the near-

est pipeline based on the minimum euclidean dis-

tance from any vertex of the bounding box of

nearest to the nearest point on the line.

• Symbols to Pipeline Association: Subsequently,

every detected symbol will be associated to clos-

est pipeline using minimum euclidean distance,

provided it is not separated from the pipeline.

Following this, we represent the structure of

P&ID diagrams in the form of a forest, as shown in

Figure 7. Each outlet is treated as the root node of a

specific tree in the forest and inlets are treated as leaf

nodes. This means that all the lines are intermediate

nodes. Each tree has minimum height of 2, root node

has single child. Trees can have common nodes i.e.,

it can have common pipelines and inlet tags, but a

root node is unique in the forest. At any time, a single

flow path is represented by unique path between

outlet and inlet.

Tree Pruning: The Pruning of tree is required to re-

move the false detections of pipelines by hough lines

transform algorithm. A false positive pipeline is one

which is represented in tree as a leaf node and does

not link to any of the inlets. Therefore, we prune the

tree by starting from the root node and removing all

the nodes that do not lead to any inlet.

5 EXPERIMENTAL RESULTS

AND DISCUSSIONS

In this section, we evaluate the performance of our

proposed end-to-end pipeline for extracting informa-

tion from P&ID sheets. We use a dataset of real world

PID sheets for quantitative evaluation which contains

4 number of sheets consisting of 672 flow diagrams.

Table 1 shows the accuracy of detection and associ-

ation of every component of the pipeline schematics.

Row 1 of Table 1 gives the accuracy of pipeline code

detection by CTPN followed by filtering of false pos-

itives using domain knowledge of standard code for-

mat. 64 codes are successfully detected out of total

71 giving accuracy of 90.1%. We also show the vi-

sual output of CTPN on text detection on a sample

P&ID sheet, as given in Figure 8.

Next, pipelines are detected with an accuracy

of 65.2% because of some random noise such as

line markings and overlaid diagrams. The proposed

heuristics based method for outlet and inlet detection

performed really well giving 100% accuracy of detec-

tion, as given by Row 3 and 4, respectively. During

the association of pipeline codes and outlets with the

appropriate pipe, we were able to successfully asso-

ciate 41 out of 64 pipeline codes and 14 out of 21

outlets, only. This is because of the fact that some-

times pipelines are not detected properly or pipelines

do not intersect with the outlet, which happened in our

case, as evident by pipeline detection accuracy given

in Row 2 of Table 1. However, inlets are associated

quite successfully with the appropriate pipeline, giv-

ing an association accuracy of 96.8%.

Now, we present the results of symbol detection

using FCN in the form of a confusion matrix, as

shown in Table 2. FCN is trained for approx.7400

iterations and we saved the network at 7000 itera-

tions by careful observation of the cross-entropy loss

of train and validation set to prevent the network from

overfitting. There are 10 different classes of symbols

for detection in P&ID sheets. We keep one extra class

Automatic Information Extraction from Piping and Instrumentation Diagrams

169

Figure 8: Figure showing text-detection output of pre-trained CTPN (Tian et al., 2016)on P&ID sheet.

Table 1: Results of proposed pipeline for individual components.

Results of

individual component

Component Successful cases Accuracy

Pipeline-Code Detection 64 / 71 90.1%

Pipeline Detection 47 / 72 65.2%

Outlet Detection 21 / 21 100%

Inlet Detection 32 / 32 100%

Pipeline Code Association 41 / 64 64.0%

Outlet Association 14 / 21 66.5%

Inlet Association 31 / 32 96.8%

Figure 9: Plot showing cross-entropy loss for train and vali-

dation sets during training of FCN (Shelhamer et al., 2016)

for symbol detection.

for training i.e. Others comprising of such symbols

present in the P&ID diagrams that are not of interest

but were creating confusions in detection of symbols

of interest. So, we have total of 11 classes of symbols

for training FCN network for symbol detection.

We experimentally observe that FCN gives en-

couraging results for symbol detection with some

minor confusions. As it is evident from the Fig-

ure 6, symbols such as ball valve, globe valve nc,

gate valve nc, globe valve look visually similar and

have very low inter-class variation in appearance.

Most of the confusion is created among these

classes of symbols only as given in Table 2 with

the exception of gate valve nc being recognised as

flood connection which are not visually similar. For

example, 5 out of 79 ball valve are being recognised

as globe valve, 4 out of 68 globe valve are detected as

ball valve, 3 out of 57 globe valve nc are recognized

as gate valve nc. Symbols such as gate valve nc

and concentric are detected successfully. We pro-

vide some sample examples of symbol detection us-

ing FCN in Figure 10.

We also calculate precision, recall and F1-score

for each class of symbols, as given in Table 3. We

found that FCN detects symbols, even with very low

visual difference in appearances, with impressive F1-

scores of values more than 0.86 for every class. Pre-

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

170

Table 2: Confusion Matrix for Symbol Detection using FCN (Shelhamer et al., 2016) network.

Predictions

Actual Bl-V Ck-V Ch-sl Cr-V Con F-Con Gt-V-nc Gb-V Ins Gb-V-nc Others

Bl-V 74 2 0 0 0 0 0 4 0 0 0

Ck-V 0 64 0 0 4 0 0 0 0 0 0

Ch-sl 0 0 25 0 0 0 0 0 0 0 0

Cr-V 0 0 0 294 0 0 0 0 0 0 0

Con 0 0 0 0 38 0 0 0 0 0 0

F-Con 0 0 0 0 0 41 0 0 0 1 0

Gt-V-nc 0 0 0 0 0 8 36 0 0 3 0

Gb-V 5 0 0 3 0 0 0 64 0 0 0

Ins 0 0 0 0 0 0 0 0 261 0 0

Gb-V-nc 0 0 0 0 0 0 0 0 0 52 0

Others 0 0 3 0 0 0 0 0 4 0 149

Table 3: Performance Measure of FCN (Shelhamer et al.,

2016) on different classes of Symbol Detection.

Precision Recall F1-Score

Bl-V 0.925 0.936 0.931

Ck-V 0.941 0.969 0.955

Ch-sl 1 0.893 0.944

Cr-V 1 0.989 0.995

Con 1 0.905 0.95

F-Con 0.976 0.837 0.901

Gt-V-nc 0.766 1 0.867

Gb-V 0.888 0.941 0.914

Ins 1 0.985 0.992

Gb-V-nc 1 0.929 0.963

Others 0.955 1 0.977

Figure 10: Examples of symbols detected using FCN. The

green and red colored bounding boxes of symbols repre-

sent ground truth and corresponding predictions by FCN,

respectively.

cision is 100% for symbols like chemical seal, cir-

cle valve, concentric, insulation and globe valve nc.

6 CONCLUSION

In this paper, we have proposed a novel end-to-end

pipeline for extracting information from P&ID sheets.

We used state-of-the-art deep learning networks like

CTPN and FCN for pipeline code and symbol de-

tection, respectively and basic low level image pro-

cessing techniques for detection of inlets, outlets and

pipelines. We formulated a tree-like data structure for

capturing the process flow of pipeline schematics af-

ter associating the detected components with the ap-

propriate pipeline. We performed experiments on a

dataset of real world P&ID sheets using our proposed

method and obtained satisfactory results.

REFERENCES

Adam, S., Ogier, J., Cariou, C., Mullot, R., Labiche, J.,

and Gardes, J. (2000). Symbol and character recog-

nition: application to engineering drawings. Inter-

national Journal on Document Analysis and Recog-

nition.

Arroyo, E., Fay, A., Chioua, M., and Hoernicke, M. (2014).

Integrating plant and process information as a basis

for automated plant diagnosis tasks. In Proceedings

of the 2014 IEEE Emerging Technology and Factory

Automation (ETFA), pages 1–8.

Arroyo, E., Hoang, X. L., and Fay, A. (2015). Automatic

detection and recognition of structural and connectiv-

ity objects in svg-coded engineering documents. In

2015 IEEE 20th Conference on Emerging Technolo-

gies Factory Automation (ETFA), pages 1–8.

Belongie, S., Malik, J., and Puzicha, J. (2002). Shape

matching and object recognition using shape contexts.

IEEE Transactions on Pattern Analysis and Machine

Intelligence, 24(4):509–522.

Fei, L. and He, J. (2009). A three-dimensional dou-

glas–peucker algorithm and its application to auto-

mated generalization of dems. International Journal

of Geographical Information Science, 23(6):703–718.

Fu, L. and Kara, L. B. (2011). Neural network-based sym-

bol recognition using a few labeled samples. Comput-

ers and Graphics, 35(5).

Gellaboina, M. K. and Venkoparao, V. G. (2009). Graphic

symbol recognition using auto associative neural net-

work model. In 2009 Seventh International Confer-

ence on Advances in Pattern Recognition, pages 297–

301.

Goh, K. N., Mohd. Shukri, S. R., and Manao, R. B. H.

(2013). Automatic assessment for engineering draw-

Automatic Information Extraction from Piping and Instrumentation Diagrams

171

ing. In Advances in Visual Informatics, pages 497–

507, Cham. Springer International Publishing.

Gupta, G., Swati, Sharma, M., and Vig, L. (2017). Informa-

tion extraction from hand-marked industrial inspec-

tion sheets. In 2017 14th IAPR International Con-

ference on Document Analysis and Recognition (IC-

DAR), volume 06, pages 33–38.

Kiryati, N., Eldar, Y., and Bruckstein, A. (1991). A

probabilistic hough transform. Pattern Recognition,

24(4):303 – 316.

Koo, H. I. and Kim, D. H. (2013). Scene text detection via

connected component clustering and nontext filtering.

Trans. Img. Proc., 22(6):2296–2305.

Ouyang, T. Y. and Davis, R. (2009). A visual approach to

sketched symbol recognition. In Proceedings of the

21st International Jont Conference on Artifical Intel-

ligence, IJCAI’09, pages 1463–1468, San Francisco,

CA, USA. Morgan Kaufmann Publishers Inc.

Ren, S., He, K., Girshick, R. B., and Sun, J. (2015). Faster

R-CNN: towards real-time object detection with re-

gion proposal networks. CoRR, abs/1506.01497.

Saha, P. K., Borgefors, G., and di Baja, G. S. (2016). A sur-

vey on skeletonization algorithms and their applica-

tions. Pattern Recognition Letters, 76:3 – 12. Special

Issue on Skeletonization and its Application.

Shelhamer, E., Long, J., and Darrell, T. (2016). Fully

convolutional networks for semantic segmentation.

CoRR, abs/1605.06211.

Simonyan, K. and Zisserman, A. (2014). Very deep con-

volutional networks for large-scale image recognition.

CoRR, abs/1409.1556.

Smith, R. (2007). An overview of the tesseract ocr engine.

In Proceedings of the Ninth International Conference

on Document Analysis and Recognition - Volume 02,

ICDAR ’07, pages 629–633, Washington, DC, USA.

IEEE Computer Society.

Tian, Z., Huang, W., He, T., He, P., and Qiao, Y. (2016).

Detecting text in natural image with connectionist text

proposal network. CoRR, abs/1609.03605.

Verma, A., Sharma, M., Hebbalaguppe, R., Hassan, E., and

Vig, L. (2016). Automatic container code recognition

via spatial transformer networks and connected com-

ponent region proposals. In Machine Learning and

Applications (ICMLA), 2016 15th IEEE International

Conference on, pages 728–733. IEEE.

Wang, N., Liu, W., Zhang, C., Yuan, H., and Liu, J. (2009).

The detection and recognition of arrow markings

recognition based on monocular vision. In 2009 Chi-

nese Control and Decision Conference, pages 4380–

4386.

Xiaogang, X., Zhengxing, S., Binbin, P., Xiangyu, J., and

Wenyin, L. (2004). An online composite graphics

recognition approach based on matching of spatial re-

lation graphs. Document Analysis and Recognition,

pages 44–55.

Yan, L. and Wenyin, L. (2003). Engineering drawings

recognition using a case-based approach. In Sev-

enth International Conference on Document Analysis

and Recognition, 2003. Proceedings., pages 190–194

vol.1.

Yu, B. (1995). Automatic understanding of symbol-

connected diagrams. In Proceedings of 3rd Interna-

tional Conference on Document Analysis and Recog-

nition, volume 2, pages 803–806 vol.2.

ICPRAM 2019 - 8th International Conference on Pattern Recognition Applications and Methods

172