3D Microfluidic Perfusion Cell Culture System for Concentration

Gradient and Air Bubble Trapping Functions

Dong Hyeok Park

1

, Xuan Don Nguyen

1

, Moon Jeong Kim

1

, Karl Morten

2

and Jeung Sang Go

1

1

School of Mechanical Engineering, Pusan National University, Busandaehak road 63-2, Busan, Republic of Korea

2

Nuffeild Department of Obstetrics & Gynaecology, University of Oxford, Oxford, U.K.

Keywords: Cell Culture, Three Dimensional Culture, Perfusion, Concentration Gradient, Microchannel Mixer, Air

Bubble Trap.

Abstract: This paper presents a cell culture well-plate for three dimensional perfusion cell cultures. A concentration

gradient generator, a microchannel system, is embedded in the plate bottom for not only the perfusion

culture but transfer of reagents with linear concentration gradient to 4 wells of the plate. The concentration

uniformity of gradient generated is guaranteed by adding microchannel mixers at the end of generator.

Sudden expansion reservoirs, air bubble traps, make perfusion cell cultures plate long-term culture without

interruption of perfusion flow caused by injection of air bubbles in the microchannels. The performance of

the developed 3D microfluidic perfusion cell culture system is examined experimentally and compared with

analytical results. Then, it is applied to test the cytotoxicity of cells infected with Ewing’s sarcoma. Cell

death is observed for different concentrations of H

2

O

2

. Finally, the 3D perfusion cell culture well-plate is

presented with not only similar structure to conventional 3×4 well-plate but expansion of concentration

range from a 4 fold of dilution in 4 wells to a 100 fold of dilution in 7 wells.

1 INTRODUCTION

In vitro cell culture has been used for detecting

biomarkers from cell growth with reagents.

Incubating conditions like 37 ℃ of temperature, 5-

10 % of CO

2

control to keep pH condition for media,

relative humidity and sterilization are arranged for in

vitro culture (Schumacher and Strehl, 2002;

Caicedo-Carvajal and Liu, 2011). Even though the

conditions are satisfied, the 2D culture, which

cultures cells onto plates with media and nutrient

factors without circulation of them, could be

understood individual cellular phenomena but is

difficult to capture the physiological behaviour of

cells in vivo (Baker and Chen, 2012).

Differences of the cell morphologies, protein

expressions and cell proliferations are reported

between 2D culture and 3D perfusion culture, which

mimics in vivo environment containing

transportation of cellular growing factors like

oxygen and nutrients, emission of cellular wastes

(Baker and Chen, 2012; Li and Valadez, 2012;

Caicedo-Carvajal and Liu, 2012).

For these reasons, 3D perfusion systems have

been suggested to address closer environment with

in vivo environment (Li and Valadez, 2012; Ong and

Zhang, 2008; Yi and Lin, 2017), but they are needed

to address numerous experiments with varying

concentration of their target reagents or drugs and a

significant gap exists between the producers of

microfluidic technologies (mainly engineer) and

end-user (expert in life sciences) for manipulation

of microfluidic devices (Langelier and Livak-Dahl,

2011).

We present a 3D perfusion cell culture plate

based on microfluidic design with a structure similar

to conventional 2D well-plate for end-user’s favor. It

not only transfers injecting samples like reagents,

media or drugs into cells, but also generates their

concentration gradient for high-throughput

experiments.

Sudden expansion reservoirs arranged in ahead

of microchannel system prevent air bubbles, which

disturb designed microfluidic functions (Sung and

Shuler, 2009), from introduction into the

microchannel system for keeping stable injection of

samples and long-term culture.

Park, D., Nguyen, X., Kim, M., Morten, K. and Go, J.

3D Microfluidic Perfusion Cell Culture System for Concentration Gradient and Air Bubble Trapping Functions.

DOI: 10.5220/0007472001990206

In Proceedings of the 12th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2019), pages 199-206

ISBN: 978-989-758-353-7

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

199

2 DESIGN OF THE 3D

MICROFLUIDIC PERFUSION

CELL CULTURE SYSTEM

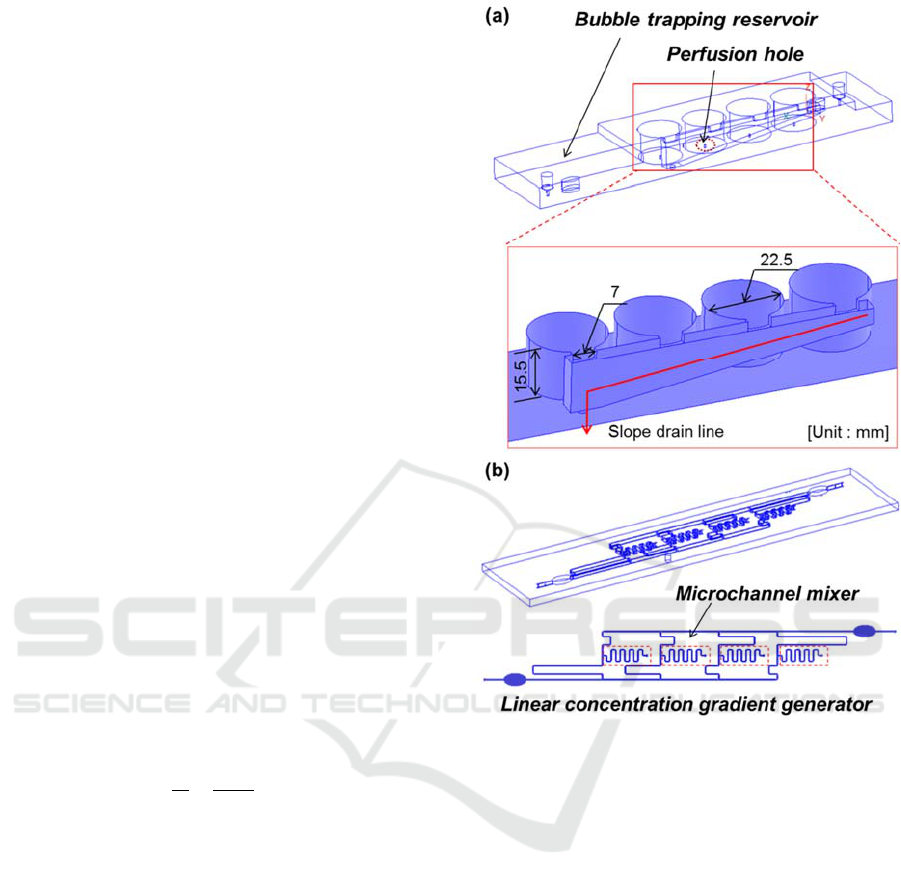

Figure 1 shows the schematic drawing of the 3D

microfluidic perfusion cell culture plate developed

in this study. It consists of two plates, the cell

culture plate and the perfusion channel plate. In the

cell culture plate, the four culture wells are designed

with the same size as the wells in a general 2D 3×4

well-plate and the microfluidic system integrated

with a concentration gradient generator,

microchannel mixers and sudden expansion

reservoirs for trapping injecting air bubbles

embedded in the bottom of the culture plate.

2.1 Concentration Gradient Generator

The concentration gradient generator was designed

for high-throughput sample screening. Concentration

of samples like drugs or reagents could be obtained

by mixing two different liquids with a linear volume

flow rate ratio.

Figure 1(b) shows the linear concentration

gradient generator. The microchannel is bifurcated

into four branch microchannels. To distribute the

volumetric perfusion flow rate, the flow resistance

was considered. Based on the Poiseuille’s law, the

flow resistance can be obtained by dividing the

pressure drop with the perfusion flow rate,

analogous to Kirchhoff’s circuit law in electricity,

and it is expressed in Eq. 1.

=

∆

=

(1)

where

is the flow resistance, ∆ is the

pressure drop, is the perfusion flow rate,

is the

hydraulic diameter, is the dynamic viscosity of a

fluid, and is the channel length. The flow

resistance is proportional to the length and reversely

proportional to the fourth power of the hydraulic

diameter of the branch microchannel. Thus, in the

design of the linear concentration gradient generator,

the length of the branch microchannel was varied to

control the volumetric perfusion flow rate because a

small variation in the diameter as a result of the

fabrication accuracy sensitively affects a large

change in the flow resistance.

In the design, four different concentrations of

40%, 30%, 20% and 10% were considered for the

four perfusion culture wells, which were the linear

concentration gradient.

Figure 1: Proposed 3D microfluidic perfusion cell culture

system. (a) Upper cell culture well plate, (b) bottom

perfusion channel plate.

When a solute and a dilute are introduced

through two inlets, the solute is divided into the four

branch microchannels with a ratio of 40%, 30%,

20% and 10% of the perfusion flow rate and the

dilute is divided with a ratio of 10%, 20%, 30% and

40%. Then, they meet with the ratios of the

volumetric flow rates of 4:1, 3:2, 2:3 and 1:4,

respectively.

2.2 Microchannel Mixer

When the solute and dilute are ejected from the

concentration gradient generator, they are in a

laminar flow region with low Reynolds number

caused by the small hydraulic diameter of the

microchannel. Thus, they are required to be mixed

well to obtain a uniform concentration in the

perfusion culture wells.

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

200

Due to the difficulty of using turbulent mixing as

well as ultrasonic or magnetic stirring in a laminar

flow, the mixing is mainly depended on diffusion of

the solute molecules into the dilute through the

interface of two laminated fluid flows and the

diffusion is occurred along the microchannel. The

channel length,

, to complete the mixing of

the two laminated fluids can be calculated by

multiplying the diffusion time, and the fluid

velocity, and expressed in Eq. 2 (Nguyen and

Wereley, 2006).

= =

(2)

where is the microchannel width and is

diffusive coefficient. The velocity of the fluid flow,

is also obtained by dividing the perfusion flow rate

with the cross-sectional area.

Additionally, to improve the mixing efficiency

and size compactness, the meandered microchannel

mixer was designed and numerically simulated. In

the analysis, diffusion of methanol solution by

referring rhodamine-110, a fluorescent substance,

into water, was considered. Injecting flow rate was

200 μl/min through each inlet. The width and depth

of the microchannel mixer was 0.5 and 2 mm,

respectively. The theoretical length to complete the

diffusion mixing was calculated as 60 mm from Eq.

2. The mixing ratio was evaluated by calculating the

coefficient of variation (hereafter, C.V.) of the solute

concentration on the cross-sectional plane along the

microchannel mixer. The C.V. is defined in Eq. 3.

. . =

100%

(3)

To determine the uniform mixing on the cross-

sectional plane, the mixing was evaluated when the

C.V. was less than 5%. Finally, the concentration

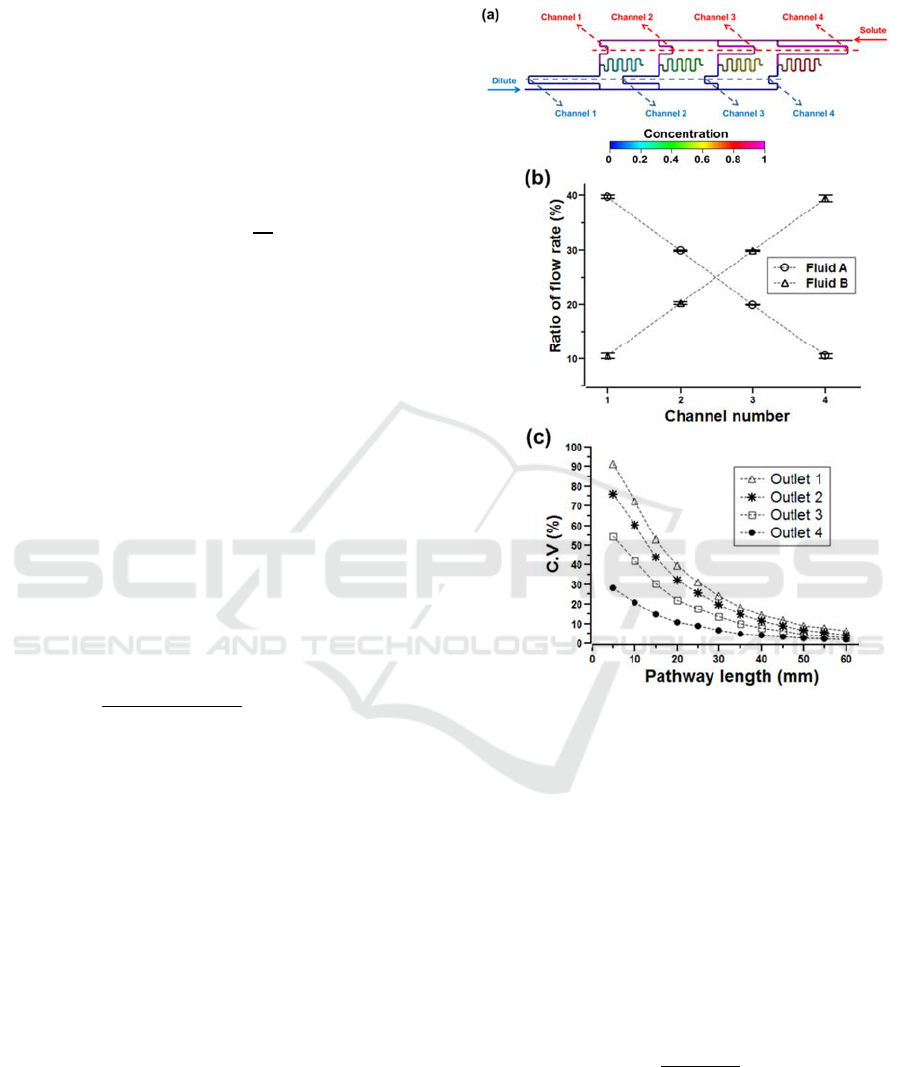

gradient generator was simulated by connecting the

branch microchannels and the meandered

microchannel mixers with a length of 60 mm. Figure

2 shows the linear concentration gradient generator

with ratios of 39.7%, 29.9%, 20.0% and 10.4%. The

error was evaluated to be less than 4% compared

with the design values.

2.3 Sudden Expansion Reservoir

When air bubbles adhere onto the surface of the

microchannels, the designed flow resistance in the

concentration gradient generator couldn’t be kept

their designed value. The sudden expansion

reservoir is a cylindrical shape’s chamber collecting

or trapping air bubbles before their entering into the

microchannel. When air bubbles existed in the

samples

injected through the inlet and reached into

Figure 2: Numerical analysis of the perfusion microfluidic

channel. (a) The concentration gradient generator

integrated with microchannel mixers, (b) linear

distribution of flow rates, (c) coefficient of variations.

the reservoir, they rise due to buoyancy resulting

from the difference in density. To trap air bubbles in

the reservoir, the rising velocity must be higher than

perfusion velocity. The rising velocity of an air

bubble can be calculated from the balance between

the buoyancy force and the drag force acting on the

air bubble expressed in Eq. 4. (Zheng and Yapa,

2000) and the perfusion velocity is also obtained by

dividing the perfusion flow rate with the cross-

sectional area of the channel.

=

∆

(4)

where,

is the rising velocity of a bubble,

∆ is a difference of density between the

surrounding fluid and the bubble,

is a

diameter of the bubble and is the dynamic

3D Microfluidic Perfusion Cell Culture System for Concentration Gradient and Air Bubble Trapping Functions

201

viscosity of a fluid. From the inequation between the

rising velocity and perfusion velocity, the diameter

of a rising bubble,

can be expressed in Eq. 5.

=

∆

(5)

where, is an area of the cross-sectional plane.

In the perfusion flow condition used for numerical

analysis of the concentration gradient generator, the

minimum diameter of rising bubbles was 8 μm and

bubbles with below 8 μm of diameter is negligible

for clogging microchannel with 0.5 mm of width and

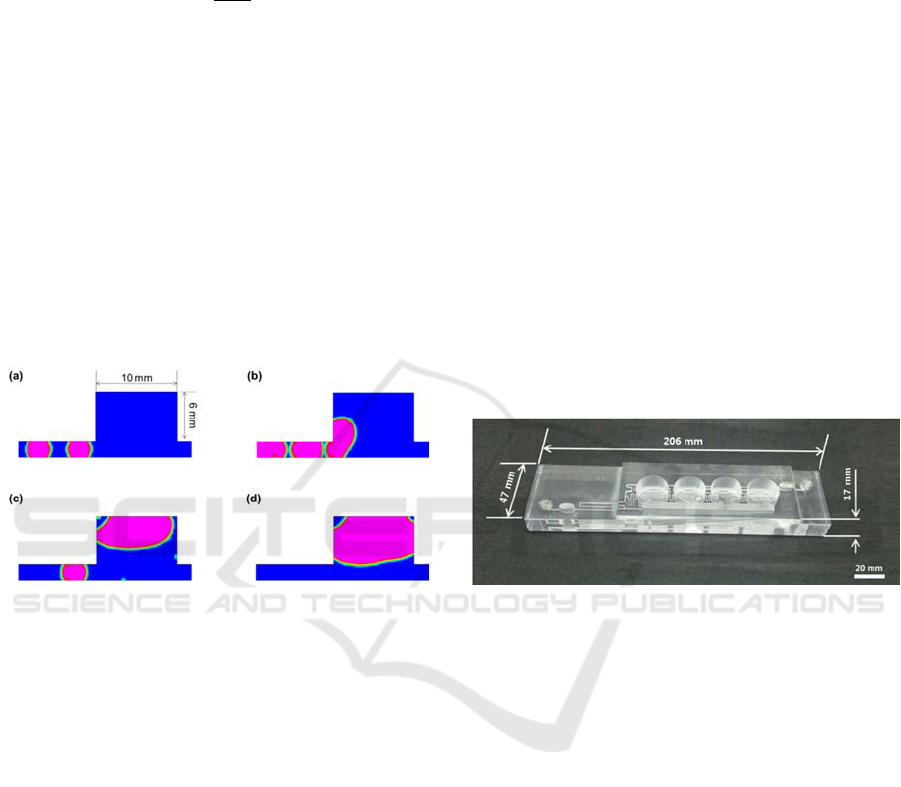

2 mm of depth. Figure 3 shows the behaviour of air

in the sudden expansion reservoir was simulated in

2-dimensional structure. The transient analysis

showed that the air bubbles in the reservoir collected

as much as approximately 55.7 mm

2

, and the

reservoir capacity was 60 mm

2

. This implies that the

trapping capacity of air bubbles is almost equal to

the volume of the sudden expansion reservoir.

Figure 3: CFD simulation of behaviour of air bubbles in

the 2D sudden expansion reservoir.

The reservoir was an elliptic shape with a major

length, minor length and height of 10, 5.5 and 6 mm,

respectively. The trapping capacity of the reservoir

was 260 μl.

3 FABRICATION OF THE 3D

MICROFLUIDIC PERFUSION

CELL CULTURE

The 3D microfluidic perfusion cell culture well plate

was fabricated by using a milling machine and

bonding two plates of biocompatible and transparent

PMMA. The four cell culture wells were fabricated

with the same size as those in the general 2D 3×4

well-plate. Additionally, the size and shape of the

wells were fitted to the scaffolds for the 3D culture

of cells. At the centre of the bottom of each well, a

hole was bored to supply media continuously. The

open drain channel was machined at top side of

wells with an inclined angle of 7

o

to guide the

overflown media from the perfusion culture wells by

gravity.

The linear concentration gradient generator

connected with the meandered microchannel mixers

was machined in the bottom perfusion channel plate.

To bond the well plate and the channel plate, a

transparent and UV curable adhesive (MP-4102,

CALO®) was coated onto the bottom of the upper

well plate. After the outlets of the microchannel

mixers were aligned with the holes of the culture

wells and the two plates were bonded physically,

UV was irradiated onto the edges for 5 seconds at 9

Watt and onto the whole surface for 30 minutes at 9

Watt.

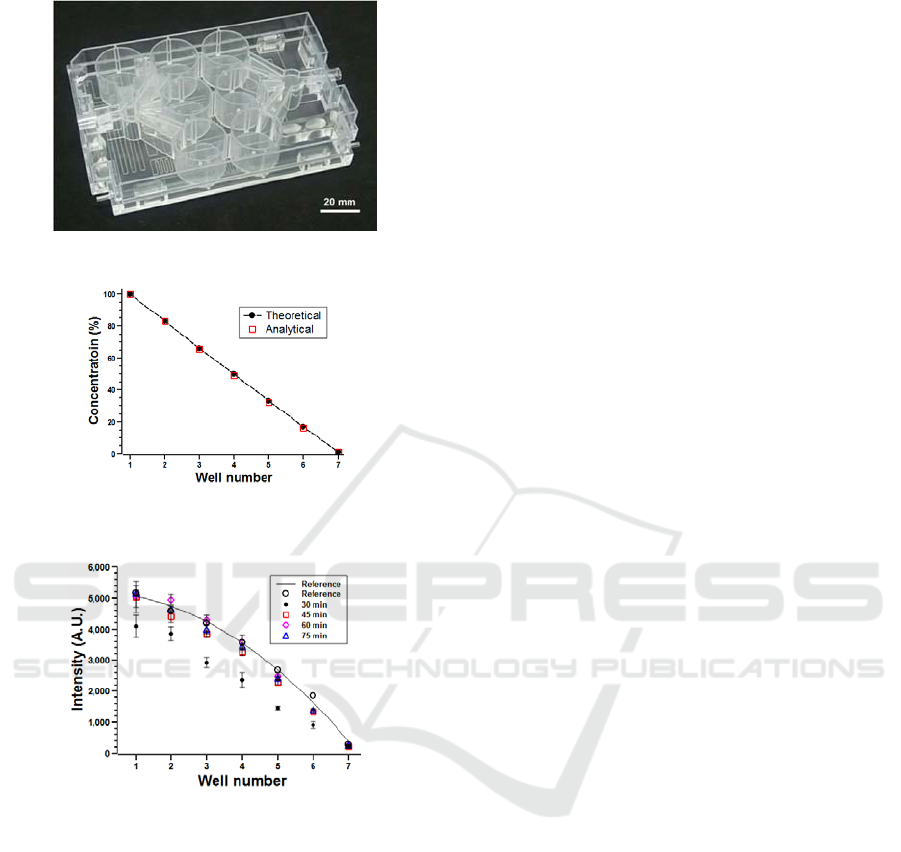

Figure 4 shows the fabricated 3D microfluidic

perfusion cell culture plate. To evaluate the bonding

quality, the blockage of the microchannels due to

adhesive filling and the leakage of the unbound parts

were examined. When water was introduced with a

large flow rate of 500 μl/min, no local blockage was

observed in the microchannels.

Figure 4: The 3D perfusion cell culture plate fabricated

from PMMA.

4 EXPERIMENTS

4.1 Performance Evaluation of the

Microfluidic System

4.1.1 Concentration Gradient Generation

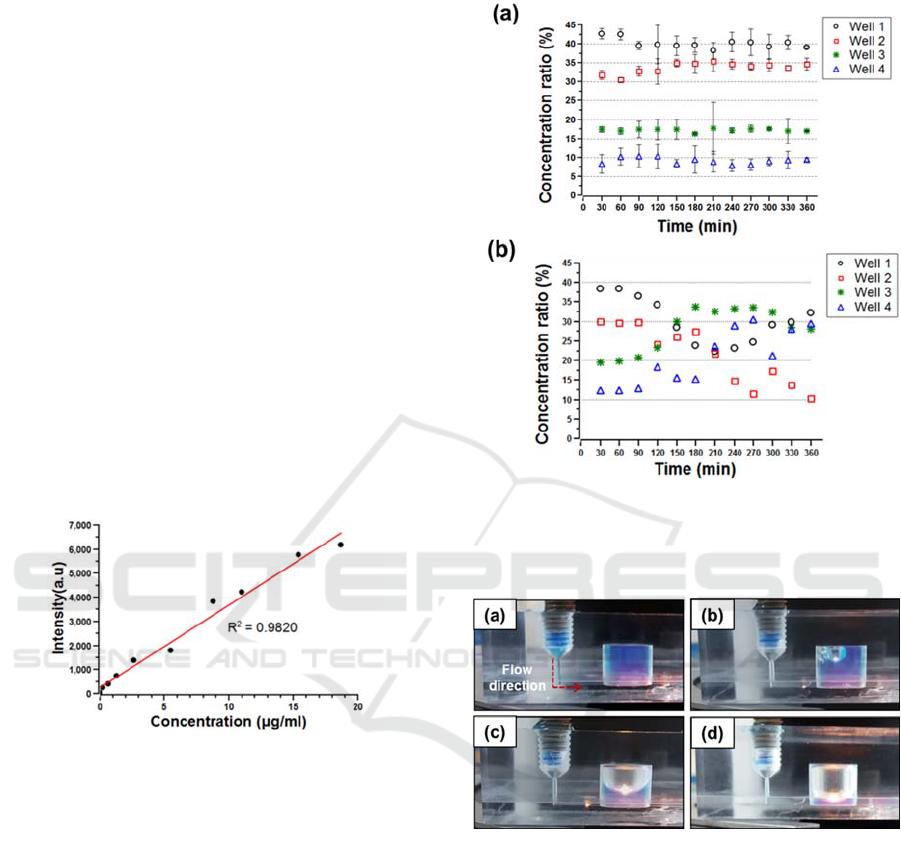

The perfusion flow rate injecting into the 3D

microfluidic perfusion cell culture plate was

controlled by a syringe pump (PHD 2000, Harvard).

First, the concentration gradient generator was

examined. Deionized (DI) water dissolved with

rhodamine-110 molecules was injected into one inlet

while only DI water was injected into the other inlet.

To obtain a reference in fluorescence intensity

versus concentration, rhodamine-110 with a

controlled concentration ranging from 0.0 to 18.7

μg/ml was prepared as shown in figure 5. The

fluorescence intensity of Rhodamine-110 was

measured for the different concentrations with a

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

202

microplate reader (FLUOstar, OPTIMA). The

calibration curve was fitted with an R

2

of 0.9820

shown in figure 5. The inlet flow rate of two samples

was 80 μl/min. The syringes were refilled every 6

hours and three times. During the refilling process of

the water, the air bubbles moving into the perfusion

microchannel were observed. The samples with

volume of 150 μl in each well were taken every 30

minutes. Then the fluorescence intensity of the

samples was measured. Figure 6(a) shows that the

linear concentration gradient of 40%, 30%, 20% and

10% in the four perfusion wells was generated with

an error of 9.7%. The C.V. was calculated to be

1.9% on average by taking samples several times

shown in figure 6(a). Moreover, the performance of

the linear concentration gradient generator was

tested without the air bubble trapping reservoirs. As

soon as air bubbles were introduced into the branch

microchannels, the flow entering the linear

concentration gradient generator was seriously

disturbed and detoured into the rest of the branch

microchannels. As a result, the linear concentration

gradient was no longer consistently maintained

shown in figure 6(b).

Figure 5: Calibration of rhodamine-110 concentration to

fluorescent intensity.

4.1.2 Air Bubble Trap

The trapping capacity of the air bubble trap reservoir

was tested. Initially, the 3D microfluidic perfusion

cell culture plate was filled with blue coloured water

for visualization. Then, air in a syringe was injected

with a flow rate of 50 μl/min. The trapping of the air

bubbles in the reservoir was monitored over time.

Figure 7 shows that the air in the reservoir was

trapped due to buoyancy. The trapping capacity of

the reservoir was measured when the air bubbles

started to enter into the microchannel. It was

measured to be 268 μl, which agrees well with the

designed capacity. The small discrepancy was

caused by the extra volume as a result of the

meniscus of the air bubble.

Figure 6: Concentration gradient of rhdamine-110

generated in 3D microfluidic perfusion cell culture plate.

(a) Perfusion test with sudden expansion reservoir, (b)

without reservoir.

Figure 7: Visualization of trapping air bubbles in the

sudden expansion reservoir. (a) The reservoir filled with

blue coloured water, (b)-(d) injecting air, (d) limitation of

trapping air bubbles.

4.2 Cell Cytotoxicity Test

The 3D microfluidic perfusion cell culture plate was

used for a cytotoxicity test of Ewing’s sarcoma cells,

A-673 (ATCC® CRL-1598™), which are rare

tumour cells and mostly expressed in the bones or

tissues of children. It is not clearly known what

causes Ewing’s sarcoma. However, experimental

reports have shown that the concentration of

hydrogen peroxide, H

2

O

2

, has a key role in cancer

development (Lopez-Lazaro, 2007). Thus, the

3D Microfluidic Perfusion Cell Culture System for Concentration Gradient and Air Bubble Trapping Functions

203

toxicity test of the cells used different concentrations

of H

2

O

2

as a cytotoxic drug.

For the 3D cell perfusion cell culture, scaffolds

were inserted into the four perfusion wells, and the

Ewing’s sarcoma cells were seeded onto the

scaffolds. Then, to mimic an in vivo environment,

the media were warmed in a water bath, and the

temperature was maintained 36

o

C. Moreover, the

3D perfusion cell culture plate was installed in a

warm chamber to acclimate it to a temperature of 36

o

C. By using a peristaltic pump (MNI PULS 3,

Glison®), the nutrient medium and a mixture of the

medium and H

2

O

2

were introduced into the two

inlets, respectively, and the perfusion flow rate was

40 μl/min for each. Specifically, the perfusion flow

rate was selected by considering the designed linear

concentration gradient generator in the four culture

wells and the previous work using a perfusion cell

culture with a perfusion flow rate ranging from 0.1

to 1 ml/min (Cartmell and Porter, 2003)

The perfusion cytotoxicity was assayed for 4

hours. During this time, 100 μl of drained media

were collected every 30 minutes and mixed with 10

μl of propidium iodide (PI). Then, the fluorescence

intensity was analysed. The excitation and emission

wavelengths were 540 and 620 nm, respectively.

The gain value was set as 1800. The intensity of the

PI relates the degree of cell death. The degree of cell

death was measured for the four different

concentrations of H

2

O

2

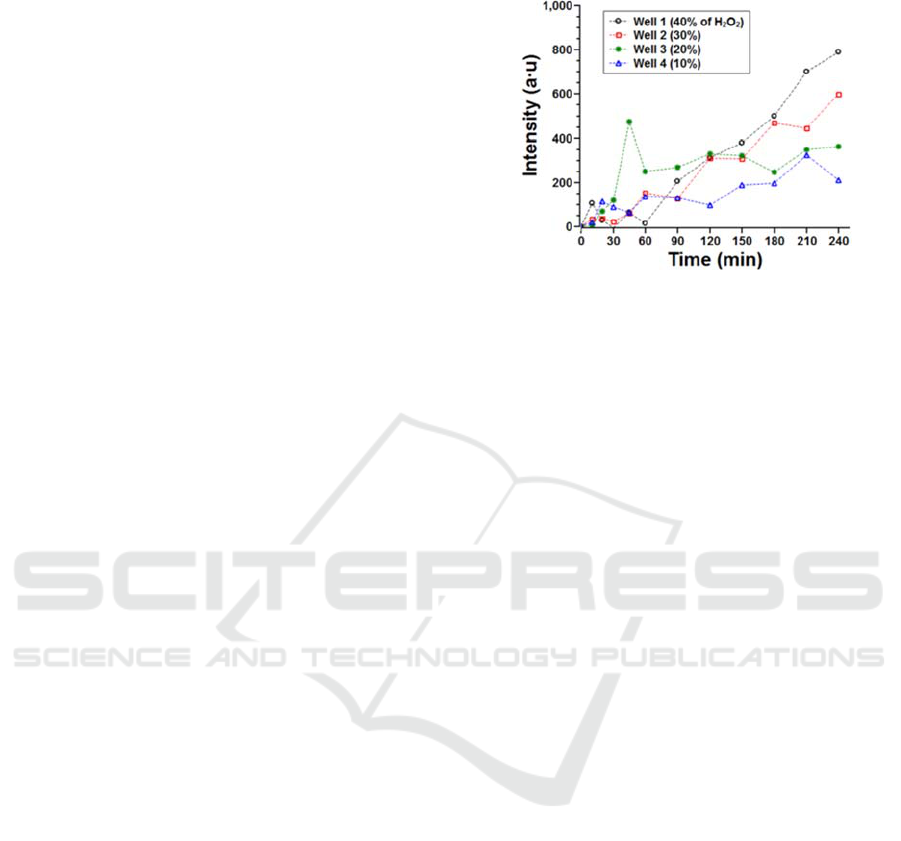

. Figure 8 shows that cell

death increased continuously until up to 240 minutes,

while the specific threshold concentration of the cell

death was not found. Moreover, more cells were

killed at the higher concentration. A higher PI signal

was observed at a higher concentration of H

2

O

2

, and

there were less cell proteins on the scaffold. To

conduct long-term culture assays using the perfusion

cell culture system, the 3D microfluidic perfusion

cell culture plate needs to increase its capacity for air

bubble trapping, after which, it needs to be

compared with a 2D static cell culture of the same

cells.

5 APPLICATION OF THE 3D

MICROFLUIDIC PERFUSION

SYSTEM

In this study the 3D microfluidic perfusion cell

culture plate with a 4 fold dilution of concentration

gradient is presented. The designed 4 fold dilution of

screening shows the feasibility of our design and

application to cell culture processes. Even though

the well size is similar to the general 3×4 well-

Figure 8: Result of PI stained DNAs from Ewing’s

sarcoma cells.

plate’s one, the structure is quite different size with

the general 3×4 well-plate. Most microplate reading

tools are for fixed to general well-plate size, so the

well-plates can be inserted on the reading tools

directly. Thus, the structure is improved to have

similar size with the general 3×4 well-plate for

simplifying cell culture processes, increasing high-

throughput rate of sample screening as well as

compatibilities with general measuring tools as

shown in figure 9.

The concentration range is expanded from a 4

fold dilution of 10-40% to a 100 fold dilution of 1-

100% based on the design. Figure 10 shows the

detail concentration gradient for 7 wells with a

hundred fold dilution and figure 11 shows a

performance of generating concentration gradient by

injecting rhodamine-110 into the improved 3D

microfluidic perfusion well-plate. From the result of

perfusion of rhodamine-110 in the improved well-

plate, after 30 minutes of perfusion the intensity

corresponding to concentration of rhodamine-110 is

close to reference samples, which are concentration

fabricated manually to comparison with perfusion

sample.

The system performance is expected to be stable

by connecting three sudden expansion reservoirs in a

row at each inlet side.

Polycarbonate is chosen for fabrication of the

improved 3D perfusion well-plate considering the

biocompatibility and feasibility of autoclave

sterilizations.

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

204

Figure 9: Improved 3D microfluidic perfusion well-plate.

Figure 10: Result of numerical analysis of expanded

concentration gradient range.

Figure 11: Fluorescent intensity with a concentration of

rhodamine-110.

6 CONCLUSIONS

A 3D microfluidic perfusion cell culture system

consisting of concentration gradient generators to

provide a linear concentration integrated meandered

micromixers for nutrients or drugs and air bubble

trapping reservoirs was developed in this study to

examine cell cultures with a closer relevance to in

vivo microenvironments.

The performance of the concentration gradient

generator connected with the microchannel mixer

was designed by considering flow resistances of

microchannels and examined by measuring the

fluorescence intensity of rhodamine-110 in the

perfusion cell culture wells. The linear concentration

in the wells had a 4 fold of dilution. Additionally,

the trapping capacity of the sudden expansion

reservoir for air bubbles was determined by transient

numerical analysis and visualization. Both methods

showed that the incoming air bubbles float upward

in the sudden expansion trapping reservoir due to the

buoyancy force and gathered until the reservoir was

full. The maximum trapping capacity of the

reservoir was determined to be the same volume as

the sudden expansion reservoir. In addition, the

linear gradient concentration in the wells was stably

maintained for a long-term cell culture with the air

bubble trapping reservoir, while the concentration in

the wells without it was seriously disturbed.

Finally, the 3D microfluidic perfusion well-plate

was improved for compatibilities with measuring

tools like microplate-readers increase of high

throughput rate by expanded concentration range

from a 4 fold of dilution to a 100 fold dilution. Also,

the improved well-plate was fabricated from

polycarbonates for the biocompatibility and

processing the autoclave sterilization.

The suggested 3D microfluidic perfusion cell

culture plate is potentially applicable to high

throughput screening of drugs, nutrients, and growth

factors. For future works, its comparison with a 2D

static cell culture well plate should be done for a

specific targeted cell.

ACKNOWLEDGEMENT

This work was supported by the National Research

Foundation of Korea (NRF) grant funded by the

Korea government (MSIP) (No.

2017R1A2B2006264).

REFERENCES

Schumacher, K., Strehl, R., 2012. Advanced Technique

for Long Term Culture of Epithelia in a Continous

Luminal-Basal Medium Gradient. Biomaterials.

Caicedo-Carvajal, C., Liu, Q., 2011. Cancer Tissue

Engineering: A Novel 3D Polystyrene Scaffold for In

Vitro Isolation and Amplification of Lymphoma

Cancer Cells from Heterogeneous Cell Mixtures.

Journal of Tissue Engineering.

Baker, B., Chen, C., 2012. Deconstructing the Third

Dimension – How 3D Culture Microenvironments

Alter Cellular Cues. Journal of Cell Science.

Li, X., Valadez, A., 2012. Microfluidic 3D Cell Culture:

Potential Application for Tissue-Based Bioassays.

Bioanalysis.

3D Microfluidic Perfusion Cell Culture System for Concentration Gradient and Air Bubble Trapping Functions

205

Caicedo-Carvajal, C., Liu, Q., 2012. Using a Novel 3D

Perfusion bioreactor to Culture β-actin-RFP Reporter

Osteosarcoma. Biowire Spring.

Ong, S., Zhang, C., 2008. A Gel-Free 3D Microfluidic

Cell Culture System. Biomaterials.

Yi, L., Lin, J., 2017. Development and Applications of

Microfluidic Devices for Cell Culture in Cell Biology.

Molecular Biology.

Langelier, S., Livak-Dahl, E., 2011. Flexible Casting of

Modular Self-Aligning Microfluidic Assembly Blocks.

Lab on a Chip.

Sung, J., Shuler, M., 2009. Prevention of Air Bubble

Formation in a Microfluidic Perfusion Cell Culture

System Using a Microscale Bubble Trap. Lab on a

Chip.

Nguyen, N., Wereley, S., 2006. Fundamentals and

Applications of Microfluidics, ARTECH HOUSE.

Boston, London, 2

nd

edition.

Zheng, L., Yapa, P., 2000. Buyant Velocity of Spherical

and Non-Spherical Bubbles/ Droplets. Journal of

Hydraulic Engineering.

Lopez-Lazaro, M., 2007. Dual Role of Hydrogen Peroxide

in Cancer: Possible Relevance to Cancer

Chemoprevention and Therapy. Cancer Letters.

Cartmell, S., Porter, B., 2003. Effects on Medium

Perfusion Rate on Cell-Seeded Three-Dimensional

Bone Constructs in Vitro. Tissue Engineering.

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

206