Case Study on Model-based Application of Machine Learning using

Small CAD Databases for Cost Estimation

Stefan B

¨

orzel

1

and J

¨

org Frochte

2

1

Breuckmann GmbH & Co. KG, Dieselstraße 26-28, 42579 Heiligenhaus, Germany

2

Dept. of Electrical Engineering & Computer Science, Bochum University of Applied Sciences,

Kettwiger Straße 20, 42579 Heiligenhaus, Germany

Keywords:

Cost Estimation, Small Databases, Model-based Approach, Feature Generation from CAD Data.

Abstract:

In many industries, the development is aimed towards Industry 4.0, which is accompanied by a movement

from large to small quantities of individually adapted products in a multitude of variants. In this scenario, it is

essential to be able to provide the price for these small batches fast and without additional costs to the customer.

This is a big challenge in technical applications in which this price calculation is in general performed by local

experts. From the age of expert systems, one knows how hard it is to achieve a formalised model-based on

expert knowledge. So it makes sense to use today’s machine learning techniques. Unfortunately, the small

batches combined with typically small and midsize production enterprises (SMEs) lead to smaller databases

to rely on. This comes along with data which is often based on 3D data or other sources that lead in the

first step to a lot of features. In this paper, we present an approach for such use cases that combines the

advantages of model-based approaches with modern machine learning techniques, as well as a discussion on

feature generation from CAD data and reduction to a low-dimensional representation of the customer requests.

1 INTRODUCTION

In many industries, the development is aimed towards

Industry 4.0, which is accompanied by a movement

from large to small batches of individually adapted

products in a multitude of variants. This is made

possible on the one hand by production machines

equipped with more processors, sensors and radio

links, which allow the machines to achieve a model

of their environment and to communicate with each

other to be more flexible. On the other hand, this

technology alone cannot support the development of

Industry 4.0 - it needs intelligent components for pro-

cess control as a further development of the static

process that often still exists today. This is widely

discussed in different papers like e. g. (Li and Nigge-

mann, 2018), (Kuschicke et al., 2017) or (Windmann

and Niggemann, 2015).

However, the demand for machine learning tech-

niques often starts much earlier than in the produc-

tion itself. A customer first asks for a price for these

small batches. This is a big challenge for small and

medium-sized companies. The question can often be

answered only by few experts in the organisation and

the customers are often not willing to pay for the ini-

tial price estimation. Also, the greater flexibility on

the customer side in Industry 4.0 leads to more vari-

ants being requested because they change their pro-

cesses more quickly as well. Hence it is reasonable

to increase the degree of automation of the price esti-

mation with machine learning techniques. One issue

is the accuracy of the offered price because too cheap

offers lead to loss of profits and too expensive offers

may lead to the loss of customers. The main challenge

for this is the provided amount of data in typical ap-

plication scenarios. In small and medium-sized com-

panies, which produce small batches, comparatively

fewer data is generated per product variant. There-

fore techniques which require huge amounts of data

like deep neural networks are in general not feasible

here. The data situation demands feature engineering

with the goal to come to general features which can

be applied to a broad spectrum of products.

In many application areas, Computer-Aided-

Design (CAD) data, which contain three-dimensional

representations of parts, together with simulation re-

sults are the starting point for a product variant. Cus-

tomers submit CAD data which is essential to calcu-

late the price. For machine learning, this means we

somehow will have to measure the difference between

258

Börzel, S. and Frochte, J.

Case Study on Model-based Application of Machine Learning using Small CAD Databases for Cost Estimation.

DOI: 10.5220/0007979802580265

In Proceedings of the 11th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2019), pages 258-265

ISBN: 978-989-758-382-7

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the CAD data of a new request and existing product

variants in our database. This case study will concen-

trate on CAD data describing forms.

1.1 Related Work

Moulds are indispensable for the repeatable and cost-

effective mass production of various parts or products

in today’s world. This economical production is of-

fered by many foundries worldwide. Due to this wide

range of different foundries, inquiries from compa-

nies are usually sent to several foundries. This sit-

uation causes foundries a lot of work in processing

inquiries and estimating costs for making the neces-

sary moulds and producing the castings. On this oc-

casion, several authors have investigated the question

of cost estimation of moulds in the last two decades.

The publication (Wang et al., 2003) describes a way

for their use in injection moulding to present inquiries

with the customer, part and mould information that

can be stored in a database. Their approach is mainly

a case based principle, which is extended by a neu-

ral network to measure similarity and speed up the

search for similar cases in the database. (Mukher-

jee et al., 2005) list an integrated solution for cal-

culating mould costs. A weighted sum of various

mould costs is calculated and evaluated with the ac-

tual costs. (Chougule and Ravi, 2006) present a para-

metric model for calculating tool costs for casting

steel and grey cast iron. The parameters of the cast-

ing are determined from the volume body. This work

is not using machine learning as such but the pre-

sented analytical model is related to our model-based

approach. The analytical model – mainly a formula –

consists of some parameters which are available from

the request and some which need to be estimated.

The estimation is performed here by expert knowl-

edge and/or simulation. It is an example of existing

models in this application field with free parameters.

In our work, we will use machine learning to pro-

vide an estimation for these parameters. In the work

(Denkena et al., 2009) inquiry processes of 10 enter-

prises were examined. The explosive nature of the

topic is discussed and a model for rule-based deci-

sion support is presented, which is based on geomet-

ric information of the casting. This leads to a faster

and more accurate calculation possibility. To estimate

the similarity between different CAD entries in our

database our approach is related to (Burrows et al.,

2011) when it comes to defining a metric for CAD

data. In (Burrows et al., 2011) this metric is used to

determine the difference between bridge designs. The

used machine learning technique is unsupervised with

the goal to judge if a design is feasible or not. We pro-

vide approaches for a supervised regression technique

and production application in opposite to bridge con-

struction problems.

1.2 Contribution and Structure

In this work, we . . .

• . . . provide a general process framework for re-

gression problems based on CAD data in scenar-

ios with small data sets.

• . . . perform a case study using this framework for

cost estimation of forms. This case study consists

of

– how features can be generated from CAD data

by computation,

– a feature selection and compression and

– the design and choice of a feasible metric and

regression technique.

Furthermore we emphasis in this work the fact that it

is not necessary to perform a price prediction solely

using Machine Learning. We denote such an ap-

proach – a regression technique to predict the price

based on given features – “model-free” in this work

to distinguish it from our approach, even if in other

circumstances one would like to argue that the trained

neural network or similar eager learner is a model

itself. For transparency issues and to deal with the

given limits concerning the database it makes sense

to just apply the regression technique to some com-

plex estimate factors in a formula – the model – for a

cost estimation instead.

As we will show the estimation of a single or a

few parameters is often a feasible approach. The in-

fluence of the accuracy of the predicted parameters is

also shown by an error propagation of the manufac-

turing costs in this work.

The rest of this paper is organised as follows.

First, Section 2 contains the presentation of the sug-

gested framework. In Section 3 the application case

from High-Pressure-Die-Casting (HPDC) manufac-

turing, including the aspect of manufacturing costs,

is briefly outlined. The next section describes the

feature engineering from CAD data and the assem-

bling of databases. This includes the reduction of

the feature space in order to address small databases.

With this work done we apply in Section 5 different

machine learning approaches and present the results.

Section 6 draws a conclusion.

Case Study on Model-based Application of Machine Learning using Small CAD Databases for Cost Estimation

259

estimated

price

f(x,intuitivefactors)

(once derived by experts)

intuitivefactor

generalized

feature

regression

technique

CAD data

feature

generation

feature

generation

CAD data base

generalized feature

data base

price

request

1.

2.

3.

5.4. 6.

9. 8. 7.

customer

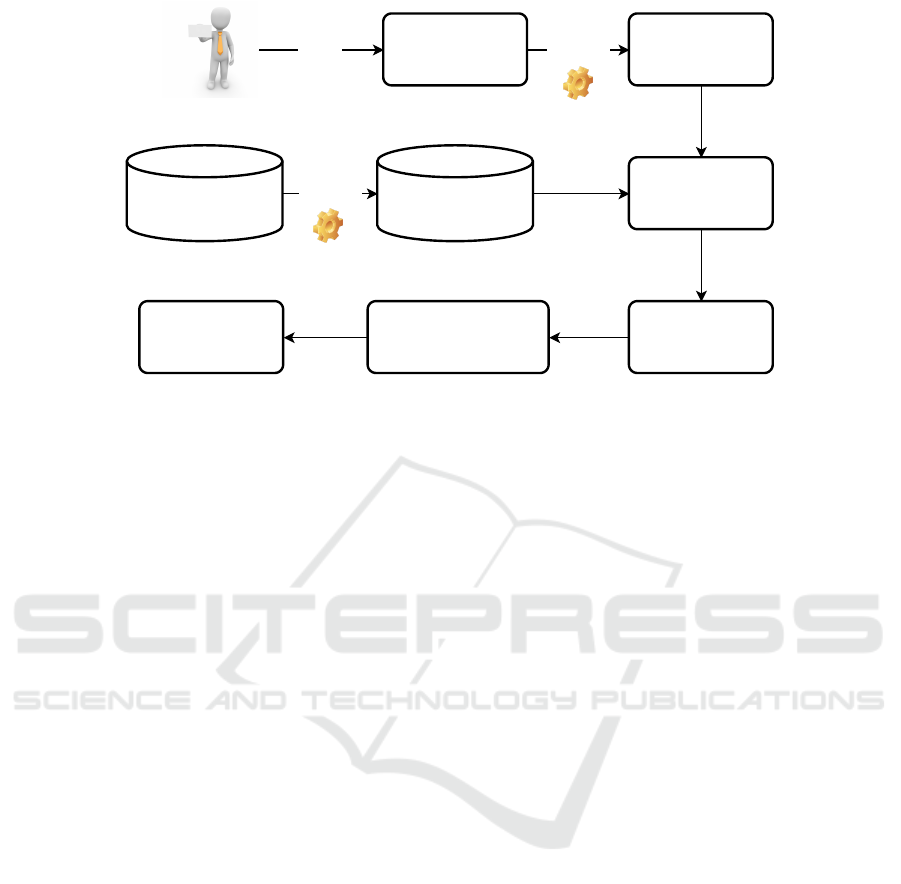

Figure 1: Process overview.

2 A PROCESS FRAMEWORK

FOR MODEL-BASED PRICE

ESTIMATION BASED ON

SMALL CAD DATABASES

Figure 1 illustrates the suggested process. We first

start with the existing method of price estimation,

which we would like to automate. Now we locate

the parts of this process that need expertise and the

ones that can be derived easily from the request of the

customer. The result is a price model

price = f (x,intuitive factors), (1)

which depends on a vector variable x with known or

easily derivable parameters from the request and on

one or more intuitive factors. With this term, we de-

scribe all aspects of the formula or model that are hard

to formalise or describe in a formal model. In prac-

tice, this means every factor the expert cannot teach

easily non-experts how to estimate. This model rep-

resents step 8 in Figure 1. Once we derived it, it is of

course fixed and only depends on its variables. The

use of such a model brings up the need to estimate

the influence of the intuitive factors we now wish to

compute using a machine learning approach. The rea-

son is, that in general error boundaries between the

predicted and the real price are required, but not for

the factors in the formula. Sometimes this can be

formed by an analytic error analysis and sometimes

it needs some sensitivity analysis, see e. g. (Saltelli

et al., 2008). In this paper, we assume that these intu-

itive factors can be computed based on the informa-

tion provided by CAD data, which comes along with

the request (steps 1 & 2 in Figure 1). Our database

contains products produced in the past together with

their production costs. To compute the distance be-

tween two requests we need to develop a feature gen-

eration process taking us from step 2 to 3 and from

step 4 to 5 in Figure 1. The goal of this feature en-

gineering is a low dimensional space which is able to

capture all the necessary aspects from the data with-

out relying on a special variant of the product. So

the features itself must provide some generalisation.

Using these features we can use a common machine

learning technique for regression in step 6 and pre-

dict values for the intuitive factors. Together with

our model, we can now estimate the price for the re-

quested product.

3 MAIN INFLUENCE OF

MANUFACTURING COSTS

To work out an appropriate offer for a die-cast part,

it is essential to know the design of the mould in

order to produce the it, as this has an influence on

the production of the mould and the later production

process of the cast part. When using standardised

moulds with fixed sizes, the most important quantity

to be determined for each standard is the number of

economically reasonable mould nests n. It describes

how many parts can be produced with one mould at

the same time and is the quantity we want to pre-

dict using machine learning techniques as mentioned

in Section 1. Since parts can only be produced as a

whole with moulds, n is an integer and is different for

each mould standard because of their different dimen-

sions. For reasons of symmetry, this value is in most

KDIR 2019 - 11th International Conference on Knowledge Discovery and Information Retrieval

260

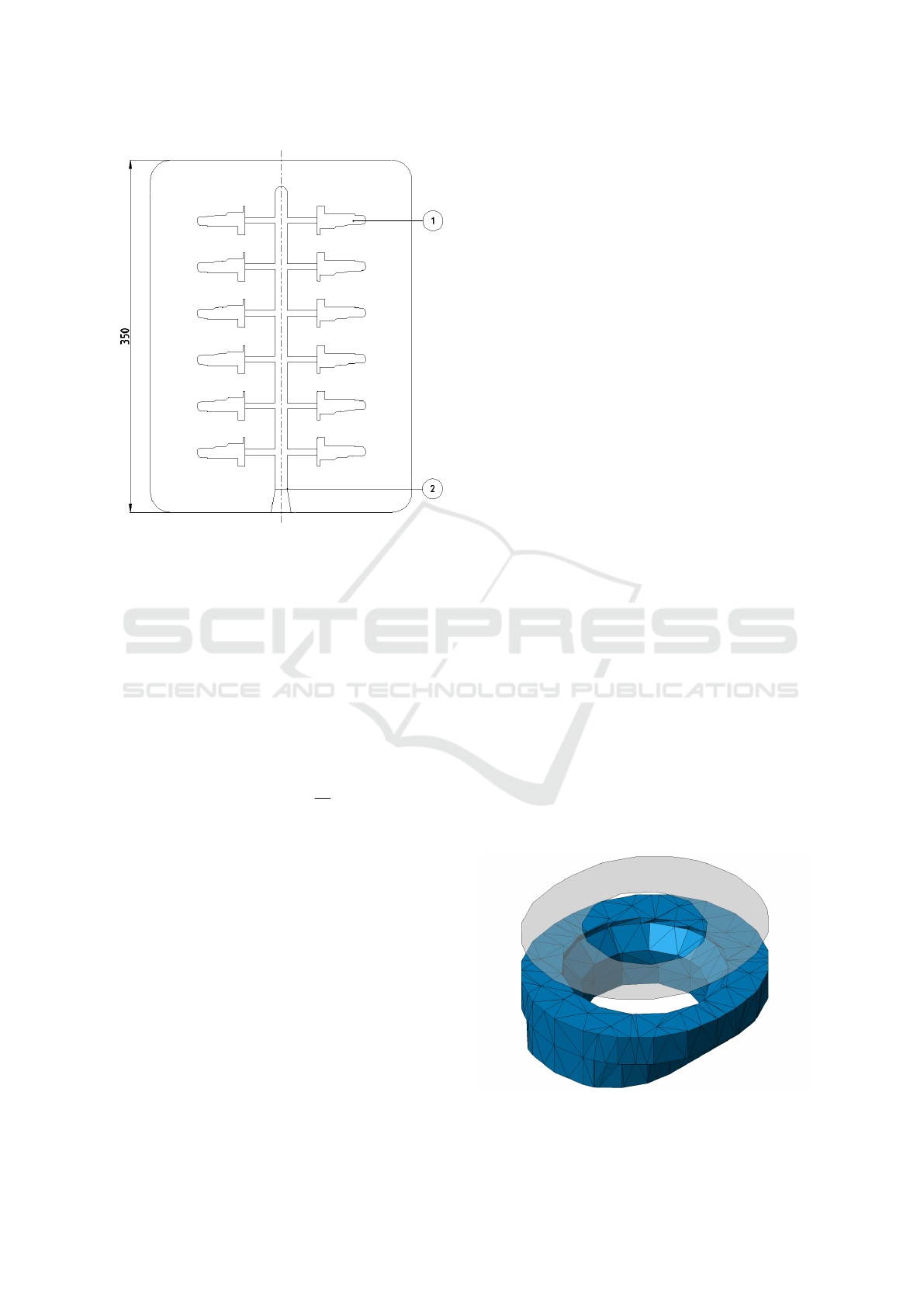

Figure 2: Concept sketch of a mould half of the company

Breuckmann internal mould standard E350 with a simpli-

fied cast tree (2) and 12 mould nests (1).

cases even-numbered. An example for the company

Breuckmann internal mould standard E350 (which is

a coding for its main dimension of 350mm) and its

12 mould nests to produce silicon tombac parts, a

special brass alloy for technically demanding appli-

cations with a tensile strength of over 500 MPa (com-

pared to the often used aluminium alloy Al-226 with

240MPa), is shown in Figure 2. After the mould nests

number n is worked out, the simplified equation (2) is

used to calculate the manufacture costs MC in e/part.

MC = V c

M

+

c

G

n

(2)

The equation is part of the two-step cost price cal-

culation, a business instrument for determining offer

prices. In this formula, V is the volume of the cast-

ing part and n the number of mould nests. Costs that

affect the material, such as raw material costs, burn-

up surcharges and other material surcharges, are sum-

marised to the size c

M

in e/m

3

. Variable costs in-

curred by the die casting mould, the die casting ma-

chine, the casters and other process variables of the

foundry are summarised in e/piece with c

G

. Post-

processing steps such as deburring processes, drilling

and thread cutting processes or coating processes are

neglected for the sake of simplicity. To calculate

the gross sales price, administration and distribution

costs, special costs, profit surcharges, rebates, dis-

counts and taxes would then be included. Since the

goal is to predict the number of mould nests n for a

cost estimate, in opposite to let this parameter been

worked out exactly by a specialist in hours of work,

it is important to know which deviation of the costs

is generally accepted by the market. This acceptance

usually ranges between 10 % and 20 % deviation from

the cost estimate and can be improved by prior con-

sultation with the customer and transparent behaviour.

This specification should serve as a target range for

this work.

4 FEATURE ENGINEERING AND

DATABASE CREATION FROM

CAD DATA

In order to be able to calculate features from 3D data,

these are first meshed and saved in the Stereolithog-

raphy (STL) file format, which is a 3D representa-

tion of the object as a list of triangles. An example

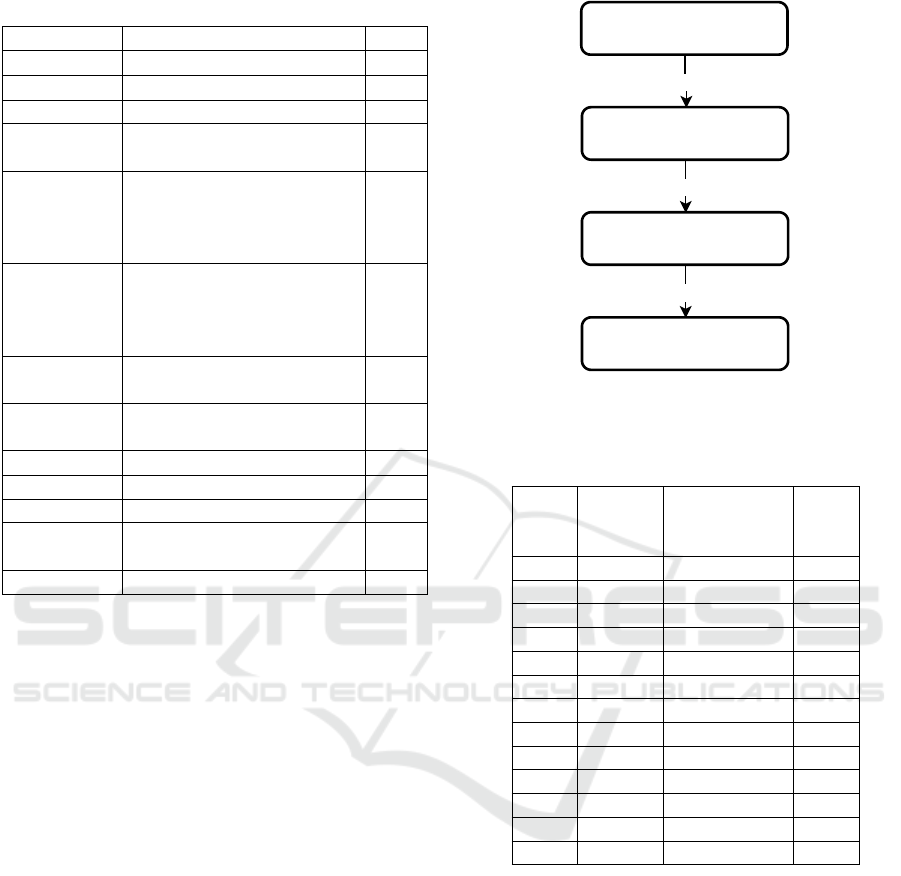

is shown in Figure 3. With this representation, fea-

tures can be derived and calculated using scripts and

analytical equations. A feature to be mentioned, for

example, would be the volume V required to deter-

mine the material requirement for filling the mould

cavity. An efficient way to calculate the volume V

is shown in (Zhang and Chen, 2001). Another fea-

ture is the area projected in direction of demould-

ing S (as shown in Figure 3), against which the hy-

draulic casting pressure acts and attempts to open the

mould. The full list of features can be found in Ta-

ble 1. The database created for this work with a

total of 700 data sets consists of data from die casting

moulds with its id (identifying number), its acronym

for the mould standard, the number of its mould nests

n and the extracted features of the associated cast-

ings. The requests are from the period between early

2014 and late 2018 and were taken from the request-

archive for silicon tombac parts. Of the 700 data

Figure 3: Area projected in direction of demoulding calcu-

lated from meshed CAD part data.

Case Study on Model-based Application of Machine Learning using Small CAD Databases for Cost Estimation

261

Table 1: Extracted Features from CAD Data.

symbol description unit

O surface mm

2

V volume mm

3

M = V /O casting module mm

S area projected in direction

of demoulding

mm

2

a smallest side length of

smallest bounding box

orthogonal to direction of

demoulding

mm

b largest side length of small-

est bounding box orthog-

onal to direction of de-

moulding

mm

h height in direction of de-

moulding

mm

A

b

= a · b area of projected bounding

box

mm

2

V

b

= a · b · h volume of bounding box mm

3

η

A

= S/A

b

occupancy rate of area 1

η

V

= V /V

b

occupancy rate of volume 1

O

g

surface with influence on

demoulding

mm

2

q = O/O

g

demouldability quotient 1

sets, 526 can be assigned to the most common mould

standards: E350 with 240, P360 with 98 and V360

with 188 moulds. Overall, this accounts for about

75 % of all moulds offered. With the small number

of data set, the features must be selected and reduced

in order to fit the regression model as well as possi-

ble. To achieve this, the feature-importances of the

Random-Forest-Regression (RFR) and the Pearson-

Correlation-Coefficient (PCC) between the features

and the number of mould nests n are considered.

Since the E350 mould standard has the most data

records, as shown in Section 4, the procedures are

demonstrated using it. By using the RFR feature-

importances, the features are ranked as shown in Ta-

ble 2. The placement shows that by accumulating the

first six features about 95 % of the feature importance

is covered. The PCC shows that the features a and

b also seem to be relevant. When testing and training

the models, the first six features of the PCA were used

and some features were removed or exchanged for

testing purposes. It turned out that the mean-relative-

error (mre) could be decreased by about 0.5 % if fea-

ture S is exchanged for a. Based on the described con-

siderations, five features V,O,V

b

,A

b

,b are selected by

their feature-importance and a is chosen instead of

S because the results are more accurate. The result-

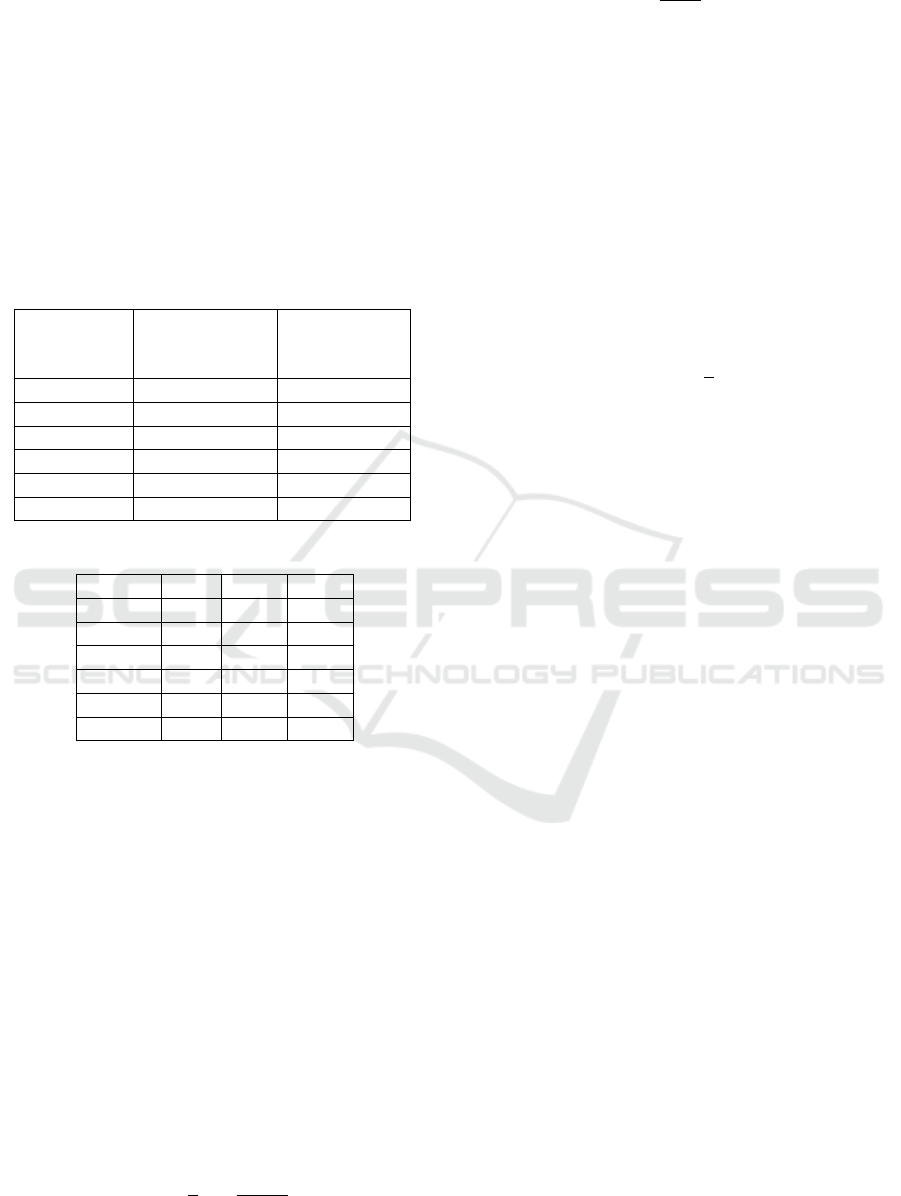

ing workflow, from the CAD data to the composed

features, is shown in Figure 4. Nevertheless, a six-

feature generation

CAD data

feature selection

all features

PCA

most relevant features

composed features

Figure 4: Generation, selection and reduction of features

from CAD data.

Table 2: Features ranked by RFR feature importances and

listed PCCs values.

rank symbol

RFR

importances

/ %

PCC

/ 1

1 A

b

76.6 -0.44

2 S 7 -0.46

3 O 4.4 -0.41

4 V

b

3.8 -0.33

5 b 2.2 -0.61

6 V 1.2 -0.38

7 O

g

1.1 -0.31

8 M 0.9 -0.48

9 η

A

0.8 0.16

10 a 0.7 -0.57

11 η

V

0.6 0.43

12 h 0.4 -0.33

13 q 0.3 0.16

dimensional characteristic space for the given amount

of data is still too large for this application due to the

low data density. This circumstance is also known as

the curse of dimensionality. There the next logical

step is to reduce the feature space keeping as much

information as possible. Two standard approaches

for this process step are using Principal-Component-

Analysis (PCA) assuming a linear model or using

an autoencoder with the option to capture non-linear

relations. Because of the small database, a simple

model is the first choice for a stable composed fea-

ture space. It turned out that with a PCA, the data set

can be reduced to three principal components with a

total variance of approximately 96 %, as shown in Ta-

ble 3. Due to this coverage, the features transformed

into this three dimensional space are used. To ex-

KDIR 2019 - 11th International Conference on Knowledge Discovery and Information Retrieval

262

plore some Details of the PCA its first three Principal-

Components (PC) are listed in Table 4 and discussed.

The first PC PC

1

is made up of equal parts of the se-

lected features. Only the feature b, which describes

the long side of the bounding box contributes a little

less to the first main component 0.33. The feature b

is strongly represented with −0.89 in the second PC

PC

2

and thus significantly determines its direction. In

the third main component PC

3

, the short side of the

bounding box a dominates with −0.69. In addition,

the casting volume V and its surface O are still repre-

sented with 0.5 and 0.41, respectively.

Table 3: PCA on the features A

b

,V

b

,O,V,a,b.

principal

component

explained

variance ratio

/ %

accumulated

/ %

1 79.92 79.92

2 9.88 89.80

3 6.15 95.95

4 2.89 98.84

5 0.88 99.72

6 0.28 100.00

Table 4: The first three PC of the PCA.

symbol PC

1

PC

2

PC

3

A

b

0.44 -0.07 -0.30

V

b

0.43 0.16 0.09

O 0.43 0.19 0.41

V 0.43 0.07 0.50

a 0.39 0.36 -0.69

b 0.33 -0.89 -0.11

5 REGRESSION MODELS AND

RESULTS

The trained regression models are evaluated with a

test set of 20 % of the data set. For validation, the

predicted number of mould nests ˆn of the test set is

compared with the actual number of mould nests n

according to (3) and noted as the mean relative devi-

ation of mould nests ¯n

rel

. Since the machine learning

techniques, due to the small number of data sets and

a few special cases, are forced to generalise as well as

possible, strong relative deviations occur in some sit-

uations. Here those deviations greater than 50 % (see

(4)) are defined as outliers. The outliers are sorted out

before the scoring.

¯n

rel

=

1

k

k

∑

i=1

n

i

− ˆn

i

n

i

(3)

n

rel

=

n − ˆn

n

≥ 50 % (4)

Each regression model is tested using the

Stratified-ShuffleSplit-Cross-Validator (SSSCV)

from sklearn (Pedregosa et al., 2011). This procedure

evaluates the regression models statistically, making

sure that each subset has an approximately equal

distribution that reduces the variance of the estimate.

Due to the small number of data sets, 100 splits are

performed to get a sense of the true value and its

uncertainty. For each of the 100 passes of the SSSCV,

the mean relative deviation ¯n

rel

is calculated and

the number of outliers o is counted according to the

criterion in (4). This count o is divided by the number

of test records k of each run and noted as the relative

number of outliers

o

rel

=

o

k

. (5)

According to the SSSCV, the 100 pairs of values con-

sisting of ¯n

rel

and o

rel

are used to calculate their mean

value µ and standard deviation σ respectively. The re-

sult of the SSSCV is then listed in Table 5 as µ ± 2σ.

The two standard deviations cover about 95 % of the

test runs and represents the uncertainty of the mean µ.

The regression models RFR, K-nearest-Neighbor-

Regression (KNR) and an ANN are trained and

scored, as described in the paragraph before, for each

mould standard separately. The Implementations of

the RFR and KNR were used from scikit-learn (Pe-

dregosa et al., 2011). All were manually tested and

tuned. In RFR, after 64 trees, there is no significant

change in accuracy and dispersion. The maximum

depth of the trees with eight nodes seems to give a

good generalisation. A change in the default settings

of the KNR does not seem to improve accuracy or

generalisation, so the number of neighbours remains

at five. For the fully connected ANN created with

Keras, two hidden layers with 16 neurons each and

an L2 regularization of 1/1000 proved to be suitable

for a good fit and generalisation of the data. For its

three input neurons for the composed features and its

hidden layer, the Rectified-Linear-Units (ReLU) acti-

vation function is used. For the regression purpose,

the activation function of its one output neuron was

set to linear. The results from the described training

and the used regression models, which are trained for

each mould standard detached, are shown in Table 5.

The results in Table 5 shows the relative number

of outliers o

rel

and the mean relative deviation of the

number of mould nests ¯n

rel

for each mould standard

and regression model. One can see that the RFR has

the lowest outlier rate, taking into account all three

mould standards. With the P360 mould standard,

the ANN has difficulties in estimating the number of

Case Study on Model-based Application of Machine Learning using Small CAD Databases for Cost Estimation

263

Table 5: Training results. Each mould standard has been

trained and tested with its own RFR, KNR and ANN. The

results for o

rel

and ¯n

rel

are noted as µ ± 2σ.

mould model o

rel

/ % ¯n

rel

/ %

E350 RFR 7.6 ± 6.6 15.7 ± 3.1

E350 KNR 9.1 ± 7.2 16.0 ± 3.2

E350 ANN 7.4 ± 6.4 15.7 ± 3.5

P360 RFR 12.2 ± 13.7 15.9 ± 6.1

P360 KNR 13.3 ± 13.6 15.8 ± 5.8

P360 ANN 12.7 ± 16.0 20.9 ± 4.9

V360 RFR 8.3 ± 7.5 16.1 ± 3.7

V360 KNR 9.2 ± 8.6 16.0 ± 3.5

V360 ANN 9.9 ± 9.7 17.8 ± 3.6

mould nests n due to the small number of data sets of

98 moulds, as listed in Section 4, with 20.9 % mean

relative deviation. For the mean relative deviation, the

KNR is close to the results of the RFR, but has more

relative outliers o

rel

. With this consideration, the RFR

wins with a slight advantage over the KNR and ANN.

n

regression method

no

outlier?

price model

estimated price

yes

n

expert

Figure 5: Process to deal with outliers.

To simplify the further discussion about outliers,

only the RFR results for the E350 mould standard are

considered. In the 100 runs of the SSSCV, 27 out

of the 240 parts for this mould standard have been

identified and counted as outliers. At this point, the

character of the SSSVC method should once again

be pointed out. Not every part appears equally often

in the test set during 100 runs. However, the counts

clearly show which parts are noticeable as outliers

and how they can be identified. 11 of these parts are

counted only one to five times. There are no special

characteristics to be proven for these parts. Here one

can assume outliers due to the character of the SSSCV

method and the small database. 13 parts have multiple

features that deviate about two to five times from the

mean value, e. g. the volume, the surface or its dimen-

sions. These parts stand out so clearly from typical

silicon tombac castings that they will also require an

individual consideration by an expert for the prepara-

tion of an offer in the future. The remaining three out-

lier parts can be justified due to atypical mould con-

struction work.

In order to check the influence of a misjudgment

of the number of mould nests on the manufacturing

costs, an error-propagation is carried out. To perform

the error propagation, the simplified equation (2),

which is explained in Section 3, is used to calculate

the manufacture costs MC. Furthermore, the param-

eters of interest must be derived partially. As this is

in our case only the number of mould nests n, this is

done according to (6). Since only one quantity is de-

rived, the uncertainty of the production costs u

MC

can

be calculated as presented in (7) and its relative un-

certainty u

MC,rel

as shown in (9). With (8) the mean

relative deviation of the mould nests number ¯n

rel

from

Table 5 is used to calculate the uncertainties of the

mould nest numbers u

n

.

∂MC

∂n

=

−c

G

n

2

(6)

u

MC

=

∂MC

∂n

u

n

(7)

u

n

= n · ¯n

rel

(8)

u

MC,rel

=

u

MC

MC

(9)

Based on the database described in Section 4 and

the mean relative deviations of the mould nest num-

ber ¯n

rel

of the results from the RFR given in Table 5,

the relative uncertainties of the manufacturing costs

u

MC,rel

were calculated for data sets of the respective

mould standards E350, P360 and V360. In Table 6,

these are given as the mean value µ and twice the

standard deviation σ of the respective mould standard.

The specification of the two standard deviations cover

about 95 % of the data sets and serve as an uncertainty

for the mean value. With a mean relative uncertainty

u

MC,rel

of about 10 % to 14 % of the manufacturing

costs, with the framework shown in this work, it is

possible to prepare quick target price quotations with

a high degree of automation which satisfies the accep-

tance of uncertainties of a cost estimate between 10 %

and 20 %, as explained in Section 3. If methods are

also used to support quotation creation, as shown in

(Wang et al., 2003), uncertainties can be further re-

duced. Additional post-processing steps also may re-

duce the relative uncertainties in unit costs. The pre-

sented procedure was implemented and was able to

reduce the average processing time . The process step

KDIR 2019 - 11th International Conference on Knowledge Discovery and Information Retrieval

264

Table 6: Mean relative Uncertainty of Manufacturing costs

u

MC,rel

noted as µ ± 2σ.

mould standard u

MC,rel

/ %

E350 10.4 ± 3.9

P360 14.0 ± 1.5

V360 13.0 ± 2.3

for determining the number of mould nests could on

average be reduced on average by a factor of 4.

6 CONCLUSIONS

To recap, the initial CAD data is too complex and our

database too small to be processed directly to a learn-

ing approach. These kind of databases are quite com-

mon for production processes in Industry 4.0 scenar-

ios, especially in SMEs. With our work, we introduce

a framework on how to deal with such use cases. The

starting point is to reduce the CAD data to a lower di-

mensional feature space using expert knowledge. De-

pending on the number of features that are suggested

by the expert, we process using feature selection and

reduction. To reduce the complexity of the regres-

sion task even further, we proposed the use of a price

model with just some missing factors. We were able

to show that using a random forest model about 500

data records are sufficient to develop a price predic-

tion which meets the requirements. Results that do

not meet the requirements are easy to spot as outliers.

These still require the expert to perform a price pre-

diction by hand. It is reasonable to assume that the

number of outliers will decrease over time the system

is used because the database will increase. Indeed,

the methodology comprises nine distinct steps, where

we have evaluated different approaches. One aspect

that comes along with the smaller data sets is that in

these application cases expert knowledge needs to be

combined with machine learning techniques in many

steps like the generation of the data or the building of

the model for the estimation. But unlike expert sys-

tems, the result is a self-learning method which is able

to improve itself without consuming additional time

from the experts. This illustrates that small databases

even with a high variety, which comes along with

small batches in Industry 4.0, is a challenge that can

be mastered using the presented framework.

REFERENCES

Burrows, S., Stein, B., Frochte, J., Wiesner, D., and M

¨

uller,

K. (2011). Simulation data mining for supporting

bridge design. In Proceedings of the Ninth Aus-

tralasian Data Mining Conference-Volume 121, pages

163–170. Australian Computer Society, Inc.

Chougule, R. and Ravi, B. (2006). Casting cost estimation

in an integrated product and process design environ-

ment. International Journal of Computer Integrated

Manufacturing, 19(7):676–688.

Denkena, B., Lorenzen, L.-E., and Sch

¨

urmeyer, J. (2009).

Rule-based quotation costing of pressure die casting

moulds. Production Engineering, 3(1):87–94.

Kuschicke, F., Thiele, T., Meisen, T., and Jeschke, S.

(2017). A data-based method for industrial big data

project prioritization. In Proc. of the Int. Confer-

ence on Big Data and Internet of Thing, BDIOT2017,

pages 6–10, New York, NY, USA. ACM.

Li, P. and Niggemann, O. (2018). A data provenance based

architecture to enhance the reliability of data analy-

sis for industry 4.0. In 2018 IEEE 23rd Int. Confer-

ence on Emerging Technologies and Factory Automa-

tion (ETFA), volume 1, pages 1375–1382. IEEE.

Mukherjee, N., Ravi, B., et al. (2005). An integrated frame-

work for die and mold cost estimation using design

features and tooling parameters. The international

journal of advanced manufacturing technology, 26(9-

10):1138–1149.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V.,

Thirion, B., Grisel, O., Blondel, M., Prettenhofer,

P., Weiss, R., Dubourg, V., Vanderplas, J., Passos,

A., Cournapeau, D., Brucher, M., Perrot, M., and

Duchesnay, E. (2011). Scikit-learn: Machine learning

in Python. Journal of Machine Learning Research,

12:2825–2830.

Saltelli, A., Ratto, M., Andres, T., Campolongo, F., Cari-

boni, J., Gatelli, D., Saisana, M., and Tarantola, S.

(2008). Global sensitivity analysis: the primer. John

Wiley & Sons.

Wang, H., Ruan, X.-Y., and Zhou, X. (2003). Research on

injection mould intelligent cost estimation system and

key technologies. The International Journal of Ad-

vanced Manufacturing Technology, 21(3):215–222.

Windmann, S. and Niggemann, O. (2015). Data-driven as-

sistance functions for industrial automation systems.

In Journal of Physics: Conference Series, volume

659, page 012045. IOP Publishing.

Zhang, C. and Chen, T. (2001). Efficient feature extraction

for 2d/3d objects in mesh representation. In Proceed-

ings 2001 International Conference on Image Pro-

cessing (Cat. No. 01CH37205), volume 3, pages 935–

938. IEEE.

Case Study on Model-based Application of Machine Learning using Small CAD Databases for Cost Estimation

265