Formation Process of Graphene Nano Sheets

Herlince Sihotang

1

, Rikson Siburian

1,2*

, Crystina Simanjuntak

3

, Saur Lumban Raja

1

, Minto Supeno

1

,

Vivi Sukmawati

1

and Zul Alfian

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1, Medan 20155, Indonesia

2

Nano Medicine Center, Universitas Sumatera Utara, Medan, Indonesia

3

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

vsukmawati81@gmail.com, zulalfian16@yahoo.com

Keywords: Graphene Nano Sheets, Magnesium, Epoxide, FTIR, Hummer Method.

Abstract: Formation process of Graphene Nano Sheets (GNS) was described in this paper. The aims of this paper are

to synthesize of GNS and to propose formation process of GNS base on magnesium (Mg) as a reductor

agent. This research is an experiment laboratory research. The modification of Hummer’s method was

chosen to generate GNS. Then, GNS was characterized with FTIR. The results data show that Mg may be

used to reduce epoxide functional groups.

1 INTRODUCTION

Graphene may be applied to many applications

(Geim, 2007; Xu, 2015; Novoselov, 2004; Terrones,

2010; Soldano, 2010). Unfortunately, it cannot be

produced naturally. It is possible to synthesize base

on graphite as a raw material (Choi, 2011; Bhuyan,

2016; Lee, 2016). Generally, GNS may be

synthesized by using CVD (Wang, 2009; Juang,

2010; Bárcenas, 2018; Jacobberger, 2015) and

chemical method (Siburian, 2012, 2013, 2014, 2017;

Ratih, 2018; Supeno, 2018; Sebayang, 2018). GNS

may be generated with facile method. Commonly,

chemical method in term of producing graphene uses

graphite as a raw material (Bhuyan, 2016; Eigler,

2013; Saleem, 2018; Dimiev, 2014). Chemically

method may be expected to large scale graphene

production (Kairi, 2018; Li, 2014; Zhong, 2015;

Parvez, 2015; Park, 2009), and exfoliated graphite

(Gao, 2017). The commercialization of graphene

and its derivatives product will be visible if it may

produce on low cost, best quality, large scale and

green material (Tatarova, 2017; Zhong, 2015).

Therefore, in this paper the formation of GNS base

on chemically method was studied, thereby large

scale production of GNS may be done in future.

2 MATERIALS AND METHODS

2.1 Synthesis of GNS

In this research, GNS was produced with Hummer’s

modified method (Siburian, 2012). Briefly, 1 gram

graphite was mixed with 75 mL H

2

SO

4

96% and 1

gram NaNO

3

, stirred for 4 hours. Then, 5 gram

KMnO

4

gradually was added into solution, stirred 4

hours, T = 20

o

C at ice water bath condition. At the

end of 4 hours, the solution was move from ice

water bath and it was continue stirred for 48 hours at

room temperature to form dark brown solution.

Subsequently, 5 mL H

2

O

2

30% and 100 mL H

2

SO

4

5% was put into solution, respectively, stirred 2

hours to form graphite oxide. After that, graphite

oxide solution was centrifuged at 6500 rotor per

minute (rpm) for 20 minutes to separate between

residue and supernatant. Then, residue was added 10

mL piranha solution and aquades, centrifuged at

6500 rpm for 20 minutes, respectively to form

graphite oxide solution.

100 mL graphite oxide solution was

ultrasonicated on 5060 Hz for 5 hours to form

graphene oxide. Finally, 10 mL graphene oxide

solution was added 0.01 mg magnesium (Mg)

powder, stirred for 72 hours, filtrated and heated at T

= 80 ºC for 24 hours to produce GNS. Graphite,

36

Sihotang, H., Siburian, R., Simanjuntak, C., Raja, S., Supeno, M., Sukmawati, V. and Alfian, Z.

Formation Process of Graphene Nano Sheets.

DOI: 10.5220/0008839400360038

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 36-38

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

graphite oxide, graphene oxide and GNS were

characterized by using FTIR, respectively.

3 RESULTS AND DISCUSSION

First of all, graphite as a raw material was

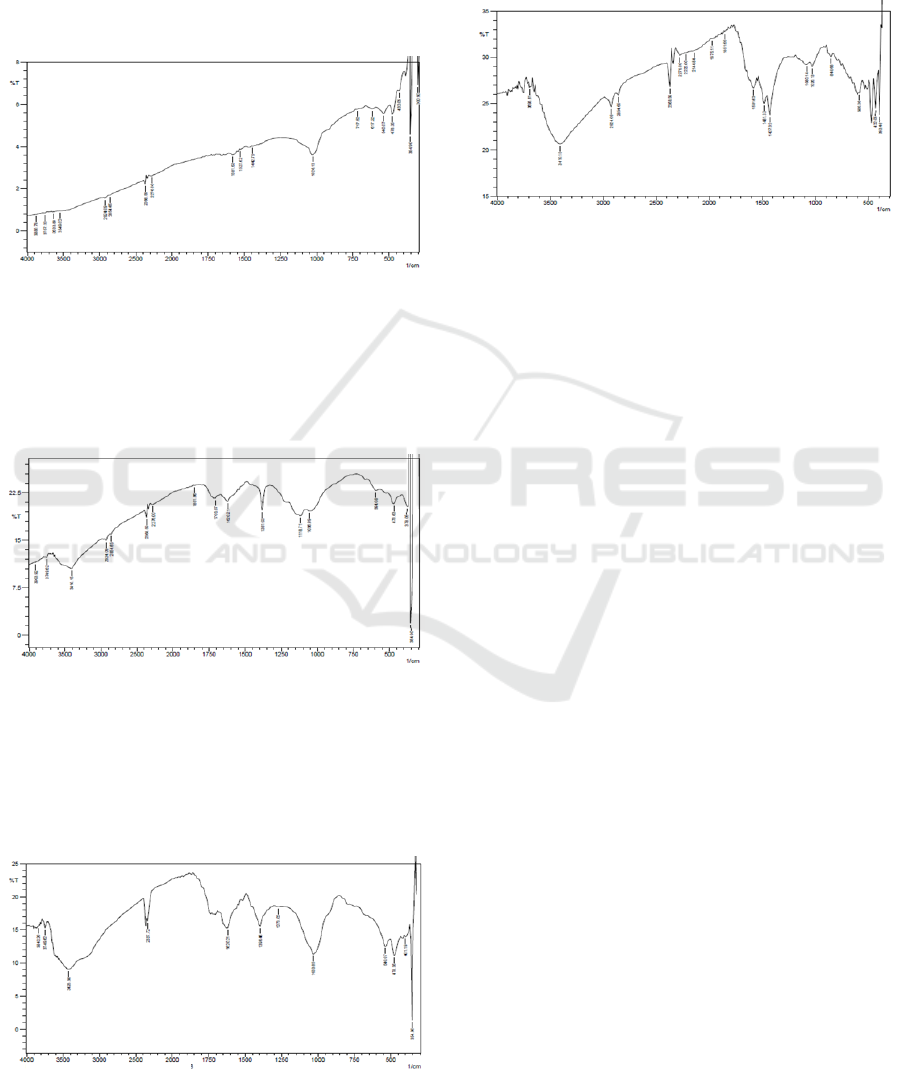

characterized with FTIR (Figure 1).

Figure 1: FTIR spectrum of graphite.

Figure 1 show that there is a weak and broad peak at

1581 cm

-1

, indicating graphite consists of double

bond aromatic carbon. In contrast, FTIR spectra of

graphite oxide is totally different compare to

graphite (Figure 2).

Figure 2: FTIR spectrum of graphite oxide.

FTIR data indicates that graphite oxide has hydroxyl

functional group (-OH) (wave number (υ) = 3,410 cm

-

1

), CH

2

(2,924 cm

-1

), CH

3

(2,854 cm

-1

), C=O

(1,705

cm

-1

), and C-O

(1,118 cm

-1

). Meanwhile, FTIR data of

graphite oxide may be seen in Figure 3.

Figure 3: FTIR spectrum of graphene oxide.

The formation of graphene oxide may be indicated

with υ = 3,410 cm

-1

(-OH), 1,620 cm

-1

(C=O), and

1,273 cm

-1

(C-O). Finally, graphene oxide was

reduced by using Mg to form GNS (Figure 4). In the

presence of Mg, the epoxide functional group may

be replaced by Mg.

Figure 4: FTIR spectrum of graphene.

4 CONCLUSIONS

The formation of graphene occurs when functional

group of graphene oxide was reduced by Mg. Mg

may only reduced epoxy functional group.

REFERENCES

Geim, A. K., Novoselov, K. S., The rise of graphene,

Nature Materials, 2007, 6, 183–191.

Xu, Y., Shi, G., Duan, X., Self-Assembled Three-

Dimensional Graphene Macrostructures: Synthesis

and Applications in Supercapacitors, Acc. Chem. Res.,

.2015, 48, 6, 1666-1675.

Novoselov, K. S., Geim, A. K., Morozov, S. V., Jiang, D.,

Zhang, Y., Dubonos, S. V., Grigorieva, I. V., Firsov,

A. A., Electric Field Effect in Atomically Thin Carbon

Films, Science, 2004, 306 (5696), 666-669.

Terrones, M., Botello-Méndez, A. R., Campos-Delgadoc,

J., López-Urías, F., Vega-Cantúd, Y. I., Rodríguez-

Macías, F. J., Elías, A. L., Munoz-Sandoval, E., Cano-

Márquez, A. G., Charlier, J. C., Terrones, H.,

Graphene and graphite nanoribbons: Morphology,

properties, synthesis, defects and applications, Nano

Today, 2010, 5, 351—372.

Soldano, C., Mahmood, A., Dujardin, E., Production,

properties and potential of graphene, Carbon, 2010, 48

(8), 2127-2150.

Wang, X., You, H., Liu, F., Li, M., Wan, L., Li, S., Li,

Q., Xu, Y., Tian, R., Yu, Z., Xiang, D., and Cheng,

J., Large‐Scale Synthesis of Few‐Layered Graphene

using CVD, Chem. Vap. Deposition 2009, 15, 53–56.

Juang, Z,Y., Wu, C. Y., Lu, A. Y., Su, C. Y., Leou, K. C.,

Chen, F. R., and Tsai, C. H., Graphene synthesis by

chemical vapor deposition and transfer by a roll-to-roll

process, Carbon 48 (2010) 3169 – 3174.

Formation Process of Graphene Nano Sheets

37

Bárcenas, A. M., Perez-Robles, J. F., Vorobiev, Y. V.,

Ornelas-Soto, N., Mexicano, A. and García, A. G.,

Graphene Synthesis Using a CVD Reactor and a

Discontinuous Feed of Gas Precursor at Atmospheric

Pressure, Journal of Nanomaterials, 2018, Article ID

3457263, 1-12.

Jacobberger, R. M., Machhi, R., Wroblewski, J., Taylor,

B., Gillian-Daniel, A. L., and Arnold, M. S., Simple

Graphene Synthesis via Chemical Vapor Deposition,

J. Chem. Educ., 2015, 92, 11, 1903-1907.

Bhuyan, Md. S. A., Uddin, Md. N., Islam, Md. M.,

Bipasha, F. A., and Hossain, S. S., Synthesis of

graphene, International Nano Letters, 2016, 6, 2, 65–

83.

Lee, H. C., Liu., W. W., Chai, S. P., Mohamed, A. R., Lai,

C. W., Khe, C. S., Voon, C. H., Hashim, U., Hidayah,

N. M. S., Synthesis of Single-layer Graphene: A

Review of Recent Development, Procedia Chemistry,

2016, 19, 916-921.

Siburian, R., and Nakamura, J., Formation Process of Pt

Subnano-Clusters on Graphene Nanosheets, J. Phys.

Chem. C, 2012, 116, 43, 22947-22953.

Siburian, R., Kondo, T., and Nakamura, J., Size Control to

a Sub-Nanometer Scale in Platinum Catalysts on

Graphene, J. Phys. Chem. C., 2013, 117, 7, 3635-

3645.

Siburian, R., Support Material Effect for Pt Catalytic

Activity at Cathode, International Research Journal of

Pure and Applied Chemistry, 2014, 4, 5, 541-550.

Siburian, R., Sebayang, K., Supeno, M. and Marpaung, H,

Effect of Platinum loading on Graphene Nano Sheets

at Cathode, Orient. J. Chem., 2017, 33, 1, 134-140.

Supeno, M., and Siburian, R., New route: Convertion of

coconut shell tobe graphite and graphene nano sheets,

Journal of King Saud University – Science, 2018,

https://doi.org/10.1016/j.jksus.2018.04.016

Sebayang, K., Siburian, R., and Supeno, M., Graphene

Nanosheets Effect to Improve CO-Tolerance of

Pt/Graphene Nanosheets Catalyst, Orient. J. Chem.,

2018, 34, 6, 2814-2818.

Ratih, D., Siburian, R., and Andriayani, The performance

of graphite/N-graphene and graphene/N-graphene as

electrode in primary cell batteries, Rasayan J. Chem.,

2018, 11, 4, 1649-1656.

Bhuyan, Md. S. A., Uddin, Md. N., Islam, Md. M.,

Bipasha, F. A., Hossain, S. S., Synthesis of graphene,

International Nano Letters, 2016, 6 (2), 65–83.

Eigler, S., Heim, M. E., Grimm, S., Hofmann, P., Kroener,

W., Geworski, A., Dotzer, C., Röckert, M., Xiao, J.,

Papp, C., Lytken, O., Steinrück, H. P., Müller, P.,

Hirsch, A., Wet Chemical Synthesis of Graphene,

Advanced Materials, 2013, 25 (26), 3583-3587.

Saleem, H., Haneef, M., Abbasi, H. Y., Synthesis route of

reduced graphene oxide via thermal reduction of

chemically exfoliated graphene oxide, Materials

Chemistry and Physics, 2018, 204, 1-7.

Dimiev, A. M., Tour, J. M., Mechanism of Graphene

Oxide Formation, ACS Nano, 2014, 8 (3), 3060-3068.

Kairi, M. I., Dayou, S., Kairi, N. I., Bakar, S. A., Vigolo

B., Mohamed, A. R., Toward high production of

graphene flakes – a review on recent developments in

their synthesis methods and scalability, J. Mater.

Chem. A, 2018, 6, 15010-15026.

Li, Y., Chopra, N., Progress in Large-Scale Production of

Graphene. Part 1: Chemical Methods, Journal of the

Minerals, Metals & Materials Society, 2014, 67 (1),

34-43.

Zhong, Y. L., Tian, Z., Simon, G. P., Li, D., Scalable

production of graphene via wet chemistry: progress

and challenges, Materials Today, 2015, 18 (2), 73-78.

Parvez, K., Yang, S., Feng, X., Müllen, K., Exfoliation of

graphene via wet chemical routes, Synthetic Metals,

2015, 210, 123–132.

Park, S., Ruoff, R. S., Chemical methods for the

production of graphenes, Nature Nanotechnology,

2009, 4, 217–224.

Gao H., Zhu K., Hu, G., Xue, C., Large-scale graphene

production by ultrasound-assisted exfoliation of

natural graphite in supercritical CO

2

/H

2

O medium,

Chemical Engineering Journal, 2017, 308, 872–879.

Tatarova, E., Dias, A., Henriques, J., Abrashev, M.,

Bundaleska, N., Kovacevic, E., Bundaleski, N.,

Cvelbar, U., Valcheva, E., Arnaudov, B., Botelho do

Rego, A. M., Ferraria, A. M., Berndt, J., Felizardo, E.,

Teodoro, O. M. N. D., Strunskus, Th., Alves, L. L.

Gonçalves, B., Towards large-scale in free-standing

graphene and N-graphene sheets, Sci Rep., 2017, 7,

10175.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

38