Segmentation Algorithm for Machine-Harvested Cotton based on S

and I Regional Features

Lei Li

1, a

, Chengliang Zhang

2

and Xinyu Zheng

1

1

School of Mechanical and Automotive Engineering, Qilu University of Technology (Shandong Academy of Sciences), 3501

Daxue Road, Jinan, China

2

School of Mechanical Engineering, University of Jinan, 336 Nanxinzhuang West Road ,Jinan, China

Keywords: Machine-harvested cotton, Impurities segmentation, Region merging, Color feature.

Abstract: A segmentation method based on regional color information is proposed for the complicated natural

impurities in machine-harvested cotton. The color gradient operation of the filtered machine cotton picking

image is carried out, and the marked image is obtained by extended minimum transformation operation. The

initial segmented image is obtained by using the watershed algorithm on the modified gradient image.

Spatial proximity and color information are considered comprehensively in the process of region merging.

Saturation S and brightness I as color information feature are mainly used in the paper. In order to make the

algorithm more accurately, the information features are updated in the process of merging. The

experimental results show that the average segmentation accuracy of the method for natural impurities is

92%.

1 INTRODUCTION

China is the largest cotton producer and consumer in

the world, as well as the largest textile producer and

exporter, but up to now, a considerable part of the

region still rely on manual picking by manpower.

Due to the increase of labor cost and the large-scale

planting of cotton, the traditional manual picking has

become unsuitable, and mechanical picking of

cotton has become the mainstream trend. The

impurity content of machine-harvested cotton is

much higher than that of manual picking. The

impurities mainly include cotton leaves, cotton

sticks, cotton shells, rigid leaves, dust and other

impurities. Therefore, it is especially important to

clean up the impurities in cotton (Qing, 2013). In the

cleaning of cotton impurities, the types of impurities

cleaned are by different equipment. Some cleaning

machines mainly clean up the leaf debris and other

light impurities, and others cleaning machines

mainly clean bell shell, rigid flap and other heavy

impurities (Anthony, 1995). The classification and

identification of impurities in cotton mining can

provide a reference for the adjustment of operation

parameters of cotton processing equipment, improve

the efficiency of impurity removal, and also provide

a guiding reference for the further improvement of

cotton picker equipment (Zhang, 2016).

At present, most of the researches are aimed at

the identification of the cotton heterosexual fiber

(Wang, 2015 and Jiang, 2015), and relatively few

researches on the machine-produced seed cotton

(Zhang, 2017). Imaging removal methods for cotton

impurities are generally used, such as X-ray

tomography (Pai, 2004), visible-light imaging

(Tantaswadi, 1999 and Yang, 2009), ultraviolet

fluorescence imaging (Mustafic, 2014), infrared

imaging (Jia, 2005), hyperspectral imaging (Zhang,

2016), and so on. The image segmentation is first

performed when the image is processed. Image

segmentation is the premise and foundation of the

image processing of the machine-harvested cotton.

The quality of the segmentation directly affects the

subsequent processing effect. The segmentation of

the image can lead to the difficulty of the

identification of the impurities in the cotton, and

even cause the error judgment. At present, the image

segmentation method is roughly divided into three

categories: the threshold segmentation method, the

edge segmentation method and the region

segmentation method. The region segmentation

method uses the consistency of regions as the

criterion to divide the regions of the image, and the

Li, L., Zhang, C. and Zheng, X.

Segmentation Algorithm for Machine-Harvested Cotton based on S and I Regional Features.

DOI: 10.5220/0008850503470353

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 347-353

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

347

regions of interest are extracted for further

processing. Compared with threshold segmentation

and edge segmentation, region segmentation has

strong anti-noise ability and good robustness. The

threshold method is generally used to segment

cotton impurities (Kan, 2010), while the regional

segmentation method is less used. In order to

quickly classify and identify the impurities of

machine picking cotton, a method based on S and I

characteristic region is proposed in this paper. In this

paper, the marked image of the image is obtained by

extending the minimum transformation operation,

and the watershed algorithm is used to segment the

image on the modified gradient image of the marked

image. Then, the region after the initial segmentation

is taken as the basic unit of processing, and on the

basis of considering the spatial proximity of the

image, On the basis of the above, the region merging

is mainly carried out with the saturation S and

luminance I feature information.

2 REGIONAL MERGER

Watershed algorithm is a morphological

segmentation method, which associates the object in

the gradient image with the minimum point markers,

which is proposed according to the process of

immersing terrain on the surface of the water. Holes

are drilled at each ponding basin (regional minimum

values) in the natural topography, allowing water to

submerge the whole terrain from low to high. By

constructing the dam to intercept the water in

different ponding basins, the resulting dam boundary

is the dividing line of the watershed. Each catchment

basin is numbered in the order of formation. The

watershed algorithm is simple to operate, but due to

the existence of noise and texture details of the

image itself, the image contains a lot of pseudo-

minimum values, which can easily submerge the

interested targets, resulting in serious watershed

over-segmentation (Li, 2014).

In order to reduce the phenomenon of over-

segmentation, the watershed algorithm is used to

segment the filtered gradient image, and the vector

of color image is used to calculate the gradient

directly. On this basis, the morphological marking

method of extended minimum transform H-minima

operation is introduced to mark the gradient image.

By comparing with the given threshold h, the local

minimum values whose depth is lower than the

threshold value are eliminated and the number of

local minimum points is limited, which is similar to

the process of filling shallow water basins with

irrigation (Soille P, 2008).

2.1 Color Image Gradient Algorithm

There are two general gradient algorithms for color

image gradient algorithm. One is to simply

decompose the color image into three gray images,

solve the gradients of the three gray images

respectively, and then add them together. However,

because the edge direction of the three components

of the image may not be the same, the gradient

synthesis results of the three independent

components are not accurate enough; the other is the

method of finding the gradient directly by the color

image vector used in this paper, which is as follows:

b

x

B

g

x

G

r

x

R

u

(1)

(2)

Assume that , and is the dot product

of u, v, which is:

222

x

B

x

G

x

R

uug

xx

(3)

222

y

B

y

G

y

R

vvg

yy

(4)

y

B

x

B

y

G

x

G

y

R

x

R

vug

xy

(5)

From this, we can get the vector gradient, which

is represented by the angle as follows:

]

)(

2

arctan[

2

1

),(

yyxx

xy

gg

g

yx

(6)

The value of the change rate in the direction θ is

obtained as follows:

1/ 2

1

F( , ) [ ( ) cos 2

2

()2sin2]

xx yy

xx yy xy

xy g g

gg g

(7)

b

y

B

g

y

G

r

y

R

v

xx

g

yy

g

xy

g

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

348

2.2 Extended Minimum

Transformation Operation

The gradient image is subjected to an extended

minimal transformation operation with a depth

threshold of h, that is:

min( )

mark

f

Hfh

(8)

Where

f

is the color gradient image;

mark

f

is

the marked image;

min( )H

represents the

morphological H-minima transform; h is the setting

depth threshold.

The larger the value of the depth threshold h, the

less the number of minimum points to be marked,

the less the number of divided regions, but the

boundary may be inaccurate. The depth threshold

can be set by the specific segmentation object and

the segmentation requirement, and the reasonable

segmentation result can be achieved.

After the marked image is obtained by the

extreme mark, the gradient image is corrected with

the minimum operation of morphology, so that the

local minimum region of the image only appears in

the marked position, and the other pixel values will

be "push-up" as needed in order to delete other local

minimum regions. The corrected gradient image

is:

(9)

Where represents the morphological

minimum calibration operation.

The watershed segmentation operation is carried

out on the modified gradient image, and the initial

segmentation image of machine-harvested cotton is

obtained.

(10)

Where

()WST

represents the watershed

segmentation operator.

3 REGIONAL MERGER

There are still many over-segmented regions in the

initial segmentation images obtained by marking

watershed method, which need to be merged. In this

paper, three aspect of the spatial proximity,

saturation S and luminance I characteristic

information between regions are considered. In order

to improve the segmentation accuracy, the region

spatial proximity, saturation S and luminance I

feature information are updated iteratively in the

merging process.

Spatial adjacency represents the adjacent

relationship between regions, and only the adjacent

regions can merge when the conditions are satisfied.

In the concrete operation, the image block after the

initial segmentation is marked in the region, and the

adjacent relationship between the regions is

represented in the form of adjacent relation table (Li,

2014). As shown in Fig. 1, assuming that there are 5

segmented regions in the image, such as A, B, C, D,

E, it is necessary to merge the region of the image

according to the spatial proximity.

Figure 1. Image segmentation region sketch map.

The table of adjacent relationships established

according to this is shown in Table 1. ``1'' in the

relational table indicates that two areas are

contiguous, and``0'' means not. In the calculation,

first judge whether the two regions are adjacent

areas according to the numbers``0'' or``1'' in the

adjacent relation table. If adjacent, further judge

whether the areas can be merged according to the

area color information. In the process of merging

two adjacent regions that meet the judgment

conditions, the unified marking numbers of two

regions and the elimination of watershed ridge line

are completed according to the statistics of the

number of marks in the eight neighborhood of pixels

on the watershed ridge line.

Table 1. Adjacency relation table.

Adjacency

relation

Area name

A B C D

Area

name

A 0 1 0 0

B 1 0 1 1

C 0 1 0 1

D 0 1 1 0

ws

f

min( )

ws mark

fIM ff

min( )IM

()

ws ws

f

WST f

Segmentation Algorithm for Machine-Harvested Cotton based on S and I Regional Features

349

The iterative operation of the merging process is

realized by programming. With the progress of the

iterative process, the algorithm updates the

segmented region graph and the adjacent relation

table, and updates the color feature information of

the merged new region at the same time.

Color information feature is a key factor to

determine the regional similarity of machine-

harvested cotton images. In the image of machine

picking cotton, the color information of cotton and

impurity is complex. The preliminary research

shows that the saturation of impurity is generally

higher than that of cotton, and the brightness of

cotton is higher than that of impurity. Therefore, the

characteristic information of saturation S and

brightness I is used to distinguish cotton from

impurity effectively. In the process of programming,

we first judge whether the two regions are adjacent,

then judge whether the region saturation S and

brightness I conform to the threshold setting, and

merge the regions that conform to the threshold.

4 PROCESS OF IMPURITY

DIVISION ALGORITHM

In this paper, the marked watershed algorithm and

the region merging algorithm based on color

information are combined to segment the cotton

impurities. The algorithm has strong anti-noise

ability and good stability. Firstly, the median filter is

carried out to obtain the filtered color gradient

image, the marked image is obtained by extended

minimum transform operation, the gradient image is

modified by morphological forced minimum

operation, the initial segmented image is obtained by

watershed algorithm on the modified gradient image,

and then the segmented region is merged. The

regional adjacent relationship table is established,

the adjacent regions are initially merged by the

brightness threshold, and the rigid lobe and other

regions in the image are merged by the saturation

threshold, so as to obtain the final merged picture. In

this process, the saturation of impurities is generally

higher, the brightness of dark impurities is low, and

the brightness of cotton is higher. The algorithm

flow is shown in Fig. 2.

Figure 2. Flow chart of machine-harvested cotton

impurities segmentation.

5 EXPERIMENTAL ANALYSIS

5.1 Test Materials and Devices

The image acquisition device, as shown in Fig. 3,

mainly includes cotton storage device, light source

bracket, industrial camera, quartz glass plate, light

source, camera support, shield, dark room and

computer. The experimental materials are machine-

harvested cotton, including leaf chips, rigid leaves,

branches, bell shell, dust and other natural

impurities. When collecting the picture, the machine

picking cotton is stored in the cotton storage device

and pressed on the quartz glass board to take

pictures at a certain pressure.

As shown in Fig. 4, the real object of the

shooting device is shown in Fig. 4. The camera is

selected from the dimension V-EM510C/ M color

area array industrial CCD camera, the resolution is

2456 pixels, 2058 pixels, the CCD size is 2/3 ", the

GigE Gigabit Ethernet output, the industrial lens is

M0824-MPW2, the focal length is 8 mm, and the

light source controller is AFT-ALP2430-02, The

Original image

Image preprocessing

(Median filtering)

Color gradient image

(Calculation of color image vector)

Marking image

(Extended minimum transformation operation)

Regional adjoining judgment

(Establishing an area adjacency matrix)

Initial regional merger

(Brightness I threshold)

Final regional merger

(Saturation S threshold)

Watershed segmentation image

(Watershed algorithm)

Modified gradient image

(Morphological forced minimum operation)

End

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

350

illumination light source is a four-section bar-shaped

LED diffuse light source AFT-WL21244-22W.

Figure 3. Image acquisition device.

1- Cotton storage device 2-Quartz glass plate 3-Light

source 4-Light source bracket 5-Industrial camera 6-

Camera bracket 7-Dark room 8-Shield 9-Computer

Figure 4. Shooting device photo.

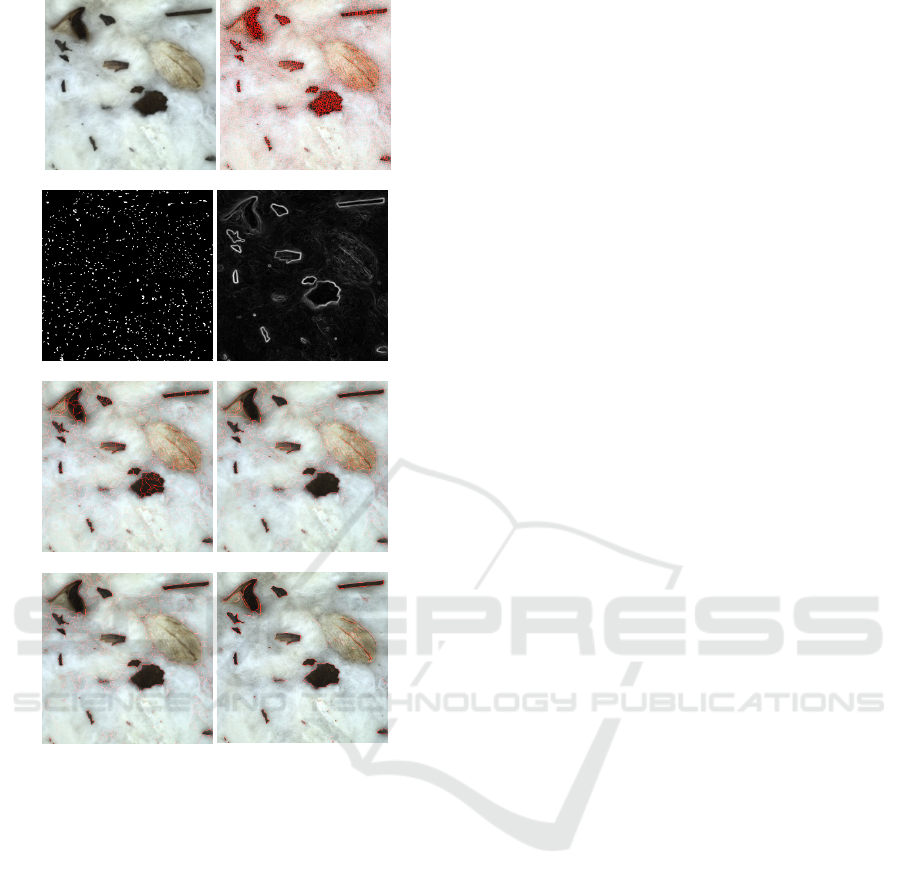

5.2 Example Segmentation Analysis

The pictures were collected and taken by the

experimental device, and the examples of cotton

picking by machine were analyzed. Fig. 5 is the

original image of a typical example, and Fig. 6 (a) is

the image after filtering the median value of the

original image. Because the image contains small

impurities such as dust and miscellaneous, it needs

to be filtered by small window. Fig. 6 (b) is a

segmented image obtained directly by using

watershed algorithm based on color gradient image.

It can be seen that the phenomenon of over-

segmentation is very serious. In order to eliminate

the phenomenon of over-segmentation, the marked

image is obtained by using the minimum expansion

operation, and the modified gradient image is

obtained by the forced minimum operation. The

extended minimum region image and the modified

gradient image are shown in Fig. 6 (c), Fig. 6 (d).

The initial segmentation image is obtained by

watershed operation on the modified gradient image,

as shown in Fig. 6 (e). It can be seen that the

impurity boundary in the image is very clear.

Compared with the watershed method, the

phenomenon of excessive cutting in the marked

watershed image is reduced, but it is still very

serious. Based on this, the region merging is carried

out. Firstly, the image is initially merged by using

the brightness I threshold, and the image as shown in

Fig. 6 (f) is obtained. It can be seen that the shallow

cotton area and the deeper branches, cotton leaves

are completely merged, and there are still many

areas in the rigid flap and boll shell area that have

not been merged. Then the saturation S threshold is

used to merge the rigid lobe, bell shell and other

regions in the image. As can be seen from Fig. 6 (g),

the light color region of rigid lobe and boll shell is

merged, and the dark cotton area is still segmented.

In the natural state, the color information

characteristics of rigid valve are very complex

because of external factors such as wind frosting,

diseases and insect pests. In the process of

segmentation, as long as the outer edge of rigid lobe

is completely divided and complete, it is considered

that the rigid lobe is perfect. In addition, because of

the seed cotton ball and the gap between impurities

and cotton, the cotton in this part of the image is

darker, and the cotton with dark features is

segmented separately.

Fig. 6 (h) is a segmented image obtained by

canny operator. From the segmentation effect, canny

operator can segment the darker color impurities

clearly, but for rigid lobe, bell shell, dark cotton

segmentation effect is not good, and canny operator

cannot close the edge. The algorithm proposed in

this paper has stronger anti-noise ability and higher

accuracy for rigid lobe. In this paper it is assumed

that the complete continuous edge information of

impurities can be segmented, the segmentation is

considered to be correct. In this paper, 80 images are

processed, and the average accuracy of the

segmentation method can be 92%.

Figure 5. Machine-harvested cotton photo.

Segmentation Algorithm for Machine-Harvested Cotton based on S and I Regional Features

351

(a) (b)

(c) (d)

(e) (f)

(g) (h)

Figure 6. Image analysis process.

6 CONCLUSIONS

A natural impurity segmentation method based on S

and I region color information is proposed in this

paper for the impurities in machine-harvested cotton.

In order to reduce the phenomenon of over-

segmentation, the marked watershed algorithm is

used to obtain the initial segmentation image by

extending the minimum transform operation through

the watershed transformation algorithm of color

gradient image. The adjacent relationship among the

regions is established by the adjacent 8-pixel.

Saturation S and brightness I in HSI space are

selected as region color features for region merging,

and feature information is updated iteratively in the

process of merging, which makes the algorithm

faster and has strong robustness. The experimental

results show that the average accuracy of the

segmentation method can be 92% for the natural

impurities such as rigid flap, bell shell, branch, leaf

chip, dust and so on in machine-harvested cotton.

ACKNOWLEDGEMENTS

This work was supported in part by the Shandong

Province Natural Science Foundation of China under

Grant ZR2017LEE010, Grant ZR2019MEE113, in

part by the Shandong Provincial Key Research and

Development Plan of China under Grant

2017CXGC0215, Grant 2017CXGC0810, Grant

2018CXGC0908, and in part by the Shandong

Province Agricultural Machinery Equipment

Research and Development Innovation Plan Project

under Grant 2017YF047, Grant SD2019NJ012.

REFERENCES

Anthony W S, 1995. Impact of cotton gin machinery

sequences on fiber value and quality. Applied

Engineering in Agriculture, 12(3):351-363.

Jia D Y & Ding T H, 2005. Novel method of detecting

foreign fibers's infrared absorption characteristic.

J.Infrared Millim. Waves, 24(2):147-150.

Jiang Y & Li C Y, 2015. mRMR-based feature selection

for classification of cotton foreign matter using

hyperspectral imaging. Computers and Electronics in

Kan D H, Li D L, Yang W Z & Zhang X, 2010. Cotton

image segmentation method for online foreign fiber

inspection. Transactions of the Chinese Society for

Agricultural Machinery, 26(S2): 11-15.

Li J B, Peng Y K, Huang W Q, Zhang B H & Wu J

T,2014. Watershed segmentation method for

segmenting defects on peach fruit surface.

Transactions of the Chinese Society for Agricultural

Machinery, 45(8): 288-293.

Li Z B, Yang E W, Li J W, 2014. Color image

segmentation based on improved marked watershed

transform and region merging. Computer Engineering

and Design, 35(7): 2458-2461.

Mustafic A, Li C & Haidekker M, 2014. Blue and UV

LED-induced fluorescence in cotton foreign matter.

Journal of Biological Engineering, 1(1): 8-29.

Pai A,Sari-Sarraf H, Hequet E F, 2004. Recognition of

cotton contaminants via X-ray microtomographic

image analysis. IEEE Transactions on Industry

Applications, 40(1) : 77–85.

Qing H, Ma Y H, Zhang J X & Wang X N, 2013. Patent

analysis and discussion of cotton mechanized picking

technology in China. Agricultural mechanization in

Xinjiang, (1): 25-28.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

352

Soille P, 2008. Morphological image analysis: Principles

and applications, Tsinghua University Press. Beijing,

2nd edition.

Tantaswadi P, Vilainatre J & Tamaree N, 1999. Machine

vision for automated visual inspection of cotton

quality in textile industries using color

isodiscrimination contour. Computers & Industrial

Engineering, 37(1-2): 347-350.

Wang X, Li D L,Yang W Z & Li A B, 2015. Lint cotton

pseudo-foreign fiber detection based on visible

spectrum computer vision. Transactions of the Chinese

Society for Agricultural Machinery, 46(8): 7-14.

Yang W Z, Li D L, Wei X H, Kang Y G & Li F T, 2009.

AVI system for classification of foreign fibers in

cotton. Transactions of the Chinese Society for

Agricultural Machinery, 40(12): 177-181.

Zhang C l, Li L, Dong Q C & Ge R Y, 2017. Detection

method for machine-harvested cotton impurities based

on region color segmentation. Journal of Textile

Research, 38(7):135-141.

Zhang C l, Li L, Dong Q C & Ge R Y, 2016. Recognition

method for machine-harvested cotton impurities based

on color and shape features. Transactions of the

Chinese Society of Agricultural Machinery, 47(7):28-

34.

Zhang H, Qiao X, Li Z B & Li D L, 2016. Hyperspectral

image segmentation method for plastic films in ginned

cotton.Transactions of the Chinese Society of

Agricultural Engineering, 32(13): 161-167.

Segmentation Algorithm for Machine-Harvested Cotton based on S and I Regional Features

353