Synthesis and Characterization of Superabsorbent Polymer based on

Carboxymethyl Cellulose, Breadfruit Starch and Aluminum Sulfate

Darwin Yunus Nasution*, Marpongahtun, Dede Ibrahim Muthawali, A. D. Budiman and Zulfikar

Departement of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

zulfikarsimatupang47@gmail.com

Keywords: Superabsorbent Polymer, Carboxymethyl Cellulose, Breadfruit Starch.

Abstract: Superabsorbent polymer is a polymeric material that able to absorb a large amount of water. The purpose of

this study is to synthesize and measure water absorption capacity and study the crosslinking process of

superabsorbent-aluminum-breadfruit starch (Al-CMC-BS). The preparation of Al-CMC-BS was done in two

steps. The first step was reacting CMC with aluminum sulfate so that the aluminum-carboxymethyl

cellulose (Al-CMC) film was produced and then mashed into powder. Al-CMC powder was dissolved in

water and reacted with BS solution to obtain Al-CMC-BS. Furthermore, Al-CMC-BS produced was

determined their water absorption capacity, morphology with SEM, functional group with FTIR and

transition glass temperature with DSC. The results showed that the absorption capacity of water from Al-

CMC-BS reached 2,444.44 %. SEM analysis shows the formation of a more homogeneous Al-CMC-BS

mixture than before mixing. The FTIR spectrum shows the formation of crosslink between Al-CMC and

BS. DSC analysis shows that there is one Tg value of Al-CMC-BS that is on 95.85˚C, which is in between

Tg of BS on 118.72˚C and Tg of CMC on 94.23˚C. This shows that the mixture of Al, CMC and BS is

miscible mixture

1 INTRODUCTION

Polymer superabsorbent (SAP) is the most

interesting study in modern polymer technology

because of its ability to absorb water up to 550 g of

water per gram of dry SAP polymer (Klinpituksa

and Kosaiyakanon, 2017). This ability to absorb

high water causes SAP to be widely used in various

fields of application such as concrete additives

(Mechtcherine, 2016) health supplies, medical

materials (Sadeghi and Soleimani, 2013), sewage

treatment and agriculture(Salavati et al., 2018; Tao

et al., 2018). Essentially SAP is a three-dimensional

crosslinked network polymer that has hydrophilic

characteristics and is not soluble in water. The

hydrophilic nature is caused by the presence of ionic

function groups such as carboxylic and hydroxyl

groups found along the polymer chain so that it

pushes to draw diffuse water into the network (Raju

et al., 2003). The molecular structure of SAP is a

three-dimensional cross link network that experience

swelling and insoluble by solvating water molecules

through the formation of hydrogen bonds. Water

absorption also causes a decrease in SAP entropy,

making it able to experience swelling daninsoluble

(Abdel-raouf, 2019).

Polyacrylate, a synthetic polymer, is the main

base material used in the industry to make SAP.

Polyacrylate is modified into network molecules

using organic crosslinking agents and initiators so

that crosslinked SAP is formed. Polyacrylate is

made from an acrylic acid polymerization reaction.

Acrylic acid is a byproduct in the process of making

ethylene and fuel oil. Therefore, polyacrylate is a

non-renewable material that relies on the

petrochemical industry. In addition, the absorption

of water is still relatively lower compared to SAP

based on natural materials (Chatterjee, 2002).

Lately, it was developed preparation of

biopolymer-based SAPs derived from agricultural

products such as corn starch, cassava starch, sago

starch and cellulose and its derivatives (Chandra

Sutradhar et al., 2015), (Weerawarna, 2009).

Compared to petroleum-based polymers,

biopolymers have advantages due to high

hydrophilicity, renewable, biodegradable and non-

toxic (Weerawarna, 2009), (Nnadi and Brave, 2011).

116

Nasution, D., Marpongahtun, ., Muthawali, D., Budiman, A. and Zulfikar, .

Synthesis and Characterization of Superabsorbent Polymer based on Carboxymethyl Cellulose, Breadfruit Starch and Aluminum Sulfate.

DOI: 10.5220/0008857101160120

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 116-120

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In this study, Al-CMC-BS was synthesized from

carboxymethyl cellulose (CMC), breadfruit starch

(BS) isolated from breadfruit and aluminum sulfate

octadecahydrate as crosslinking agents. Breadfruit is

obtained from breadfruit plants where breadfruit has

a starch content of 19.09 % (Masita, 2017).

Breadfruit plants grow a lot in Indonesia, especially

North Sumatra Province.

The purpose of this study was to synthesize and

characterize superabsorbent polymer based on CMC

and breadfruit starch. The resulting Al-CMC-BS was

characterized by measuring water absorption

capacity, FTIR spectrum, morphology with SEM,

glass transition temperature (Tg) with DSC.

2 MATERIALS AND METHODS

2.1 Materials

Breadfruit starch is isolated from ripe breadfruit.

Chemical used, which is sodium carboxymethyl

cellulose and aluminum sulfate octadecahydrate are

purchased from Merck & Co.

2.2 Methods

2.2.1 Isolation of Starch from Breadfruit

Ripe breadfruit is washed with water, peeled, cut

into smaller sizes and then ground. Furthermore,

breadfruit that has been finely filtered to separate the

pulp. Filtrate is left for 24 hours and separated by

decantation. The precipitate (BS) is dried at 70˚C.

2.2.2 Preparation of the Croos-Linked

Al-CMC

About 2.8 g of sodium carboxymethyl cellulose was

dissolved with 100 mL of distilled water, heated on

a hot plate for 1 hour at 70˚C, then added 0.02 g

octadecahydrate cross-linker and stirring continued

for 30 minutes again. The formed solution pour over

the Teflon pan and dry it at 80˚C. The film formed is

then finely ground and the water absorption capacity

(WAC) is determined.

2.2.3 Preparation of Cross-Linked

Al-CMC-BS

Breadfruit starch as much as 0.5 g was dissolved

with aquadest at 80˚C while stirring for 45 minutes

until gelatin was formed, then added 0.5 g Al-CMC

powder while stirring with a magnetic stirrer at 70˚C

for 30 minutes. The mixture formed is then poured

on a mold pan, then dried for 12 hours at 105˚C.

Solids formed are used for examination of WAC,

SEM, FTIR and DSC.

2.3 Characterization

2.3.1 Water Absorption Capacity (WAC)

The WAC of the sample is determined by inserting

the sample into a tea bag, then soaking it in distilled

water for 24 hours and then weighing it down. The

WAC price is calculated using equation:

WAC (%) =

1

21

W

WW −

(1)

W1: Weight of sample after soaking

W2: Weight of dry sample

2.3.2 Fourier Transform Infra-Red (FT-IR)

Spectroscopy

The tool used to record IR spectrum was the

Shimadzu-IR Prestige 21 Spectrometer with

scanning region 400-4000 cm

-1

at 16 cm

-1

resolution.

Samples were mixed with KBr powder and

examined using IR spectrometer.

2.3.3 Scanning Slectron Microscope (SEM)

The morphology of the surface of the Al-CMC-BS

film was discovered by using electron microscope

(Bruker) with a magnification of 500 times under

10.00 kV of voltage

2.3.4 Differential Scanning Calorimetry

(DSC)

To measure Tg, differential scanning calorimetry

(DSC), type METTLER TOLEDO (Switzerland),

model DSC1, temperature range: 25-3000

0

C,

Heating rate:10 K/ min, N

2

gas 50 mL/min.

3 RESULT AND DISCUSSION

3.1 Isolation of Breadfruit Starch

In this study the starch used was breadfruit starch, of

which 600 g of breadfruit produced 60 g of starch.

Synthesis and Characterization of Superabsorbent Polymer based on Carboxymethyl Cellulose, Breadfruit Starch and Aluminum Sulfate

117

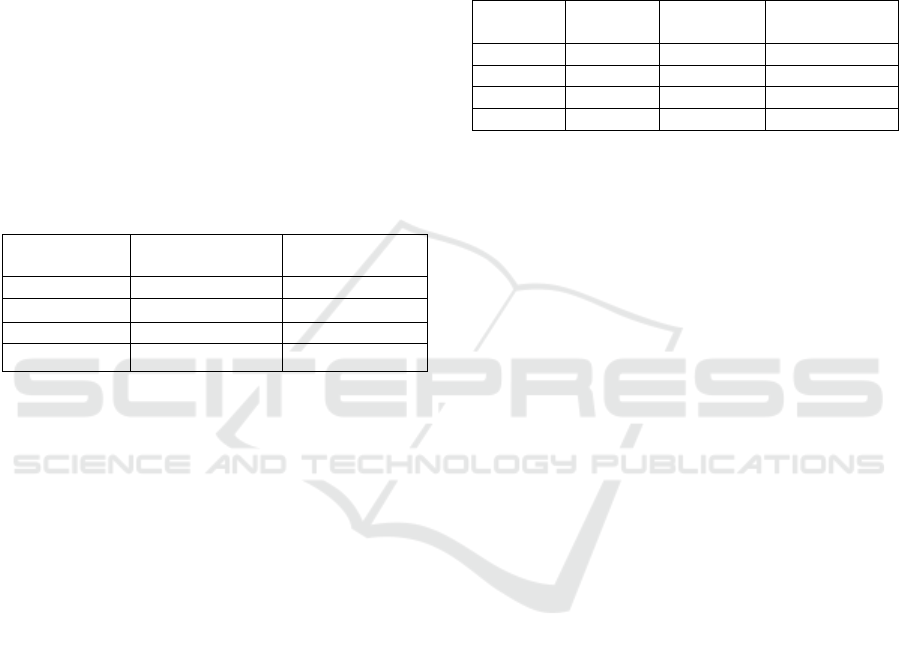

The FT-IR spectrum of breadfruit starch is shown in

Fig.1. The absorption peak at 3387 cm

-1

showed a

stretching group (O-H). The absorption peak of 2924

cm

-1

indicates the presence of a C-H (-CH

2

) group.

Almost the same OH and CH (-CH

2

) absorption

peaks from breadfruit starch were also obtained by

Nurhaeni et.al at wave number 3377.37 cm

-1

at

2927.27 cm

-1

The absorption peak at wave number

1157 cm

-1

was absorption peak of C-O alcohol and

absorption peak at 1018 cm

-1

was the C-O glycosidic

functional group (Nurhaeni et al., 2018). This

spectrum shows that the spectrum in Fig. 1 is a

spectrum of carbohydrate compounds (starch).

3.2 The Cross-Linked Al-CMC

Water absorption capacity from the Cross-Linked

Al-CMC can be seen in Table 1.

Table 1: WAC Values from The Cross-Linked Al-CMC.

Na – CMC

(g)

Al

2

(SO

4

)

3

18 H

2

O

(g)

Al-CMC (%)

2.8

0.0

772.22

2.8

0.2

1911.11

2.8

0.6

1500.01

2.8

0.8

1322.22

The test was carried out by immersing 0.1 g of

Al-CMC in a tea bag which weighed 0.8 g and then

immersed in 20 mL distilled water. Based on table 1,

it can be seen that the WAG value of Na-CMC is the

lowest that is equal to 772.22%.When the the

concentration of the cross-linker is low , it leads to

low degree of cross linking, and it is hard for

network structure to form, so the water absorbency

is low. However, when cross-linker is higher than

2%, there are much more cross-linking points and

the pores become smaller in the network, which

causes the decrease of the water absorbency (Braihi,

2015). The optimum absorption capacity of Al-CMC

is in the ratio of 2.8: 0.2 or (98: 2) % of 1911.11 %

/0.1 g Al-CMC (191.11 g water / g Al-CMC-BS)

3.3 The Cross-Linked Al-CMC-BS

The WAC values from the cross-linked Al-CMC-BS

on various compositions can be seen in table 2. The

cross-linked Al-CMC-BS is made by mixing the

cross-linked Al-CMC that has the optimum WAC

price, which is the ratio of Na- CMC against

aluminum sulfate octadecahydrate 2.8: 0.2 (see table

1) with breadfruit starch. From table 2 it can be seen

that the addition of breadfruit starch gives a very

significant increase in WAC and the optimum WAC

value is in the composition 2.8: 0.2: 0.5. that is equal

to 244.444% / g Al-CMC-BS. Breadfruit starch

serves to increase the number of hydrophilic groups

and form a network structure that is larger than the

Al-CMC network structure so that the absorption of

water increases (Braihi, 2015).

Table 2: Values of WAC from the Cross-Linked Al-CMC-

BS

Na – CMC

(g)

Al

2

(SO

4

)

3

18 H

2

O (g)

BS (g)

Al-CMC-BS (%)

2.8

0.2

0.0

772.22

2.8

0.2

0.5

2444.44

2.8

0.2

1.0

2360.00

2.8

0.2

1.5

2356.66

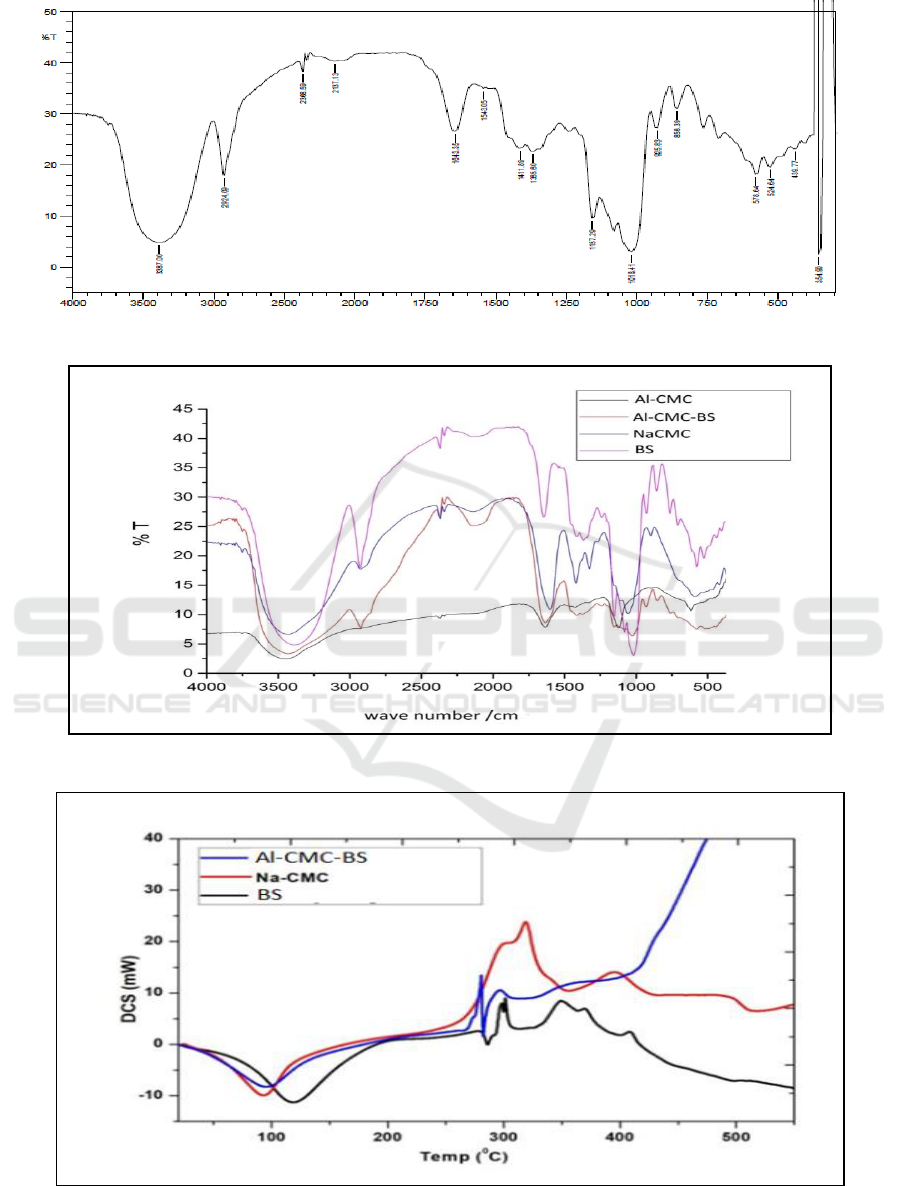

The broad peak at 3300-3450 cm

-1

is presented

by O-H stretching and peak that appears at 2900-

3000 cm

- 1

. is saturated aliphatic C-H group of CMC

The peak around 1060 cm

-1

is due to C-O-C

stretching and peak at 1604.77 cm-1 is assigned to

stretching vibration of the carbonyl group from

COO-.

The small peaks detected at 894.97 cm-1 were

confirmed to β 1-4 glycoside bonds. The existence

of the carbonyl group and its salt that assigned to

carboxymethyl group was observed at 1600-1640

cm

-1

and 1400-1450 cm

-1

(Siregar et al., 2019).This

proves that this spectrum is a spectrum of Na-CMC.

At Al-CMC-BS there is a change in the ether (CH2

O CH2) group at wave number 1327.03 cm-1 after

addition of starch. This is due to the presence of a

strong absorption band on carbonil groups of

1635.64 cm-1 where the absorption band has a

strong influence on the strain of strong carbonil

bonds so that a large dipole moment is needed.

Wave number 1118.71 cm-1 with the C-O-C group

is a weak asymmetric strecthing bond at wave

number 848.64 cm-1. At wave number 2924.09 cm-

1 with the C-H group with the stretching group CH2,

the wave number 1373.32 cm-1 is a wave number

which indicates a bending of the -OH vibration.

Figure 3 is a DSC thermogram from samples.

Investigation with DSC aims to determine whether

Al-CMC-BS is a miscible polymer mixture. The

presence of one Tg price indicates that the polymer

mixture is miscible and if two Tg prices indicate the

polymer mixture is immiscible. Curve shows that

there is one glass transition value (Tg) on Al-CMC-

BS that is at 95.85˚C, which is between Tg from BS

at 118.72˚C and Tg from CMC at 94.23˚C. This

shows that the mixture of CMC and BS is miscible

or Al-CMC-BS is a miscible mixture (Braihi, 2015).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

118

Figure 1: FTIR Spectrum of Breadfruit Fruit Starch.

Figure 2: Increasing FT-IR Spectrum BS, Na-CMC, Al-CMC and Al-CMC-BS

Figure 3: Termogram DSC of Al-CMC-BS, Na-CMC and BS.

Synthesis and Characterization of Superabsorbent Polymer based on Carboxymethyl Cellulose, Breadfruit Starch and Aluminum Sulfate

119

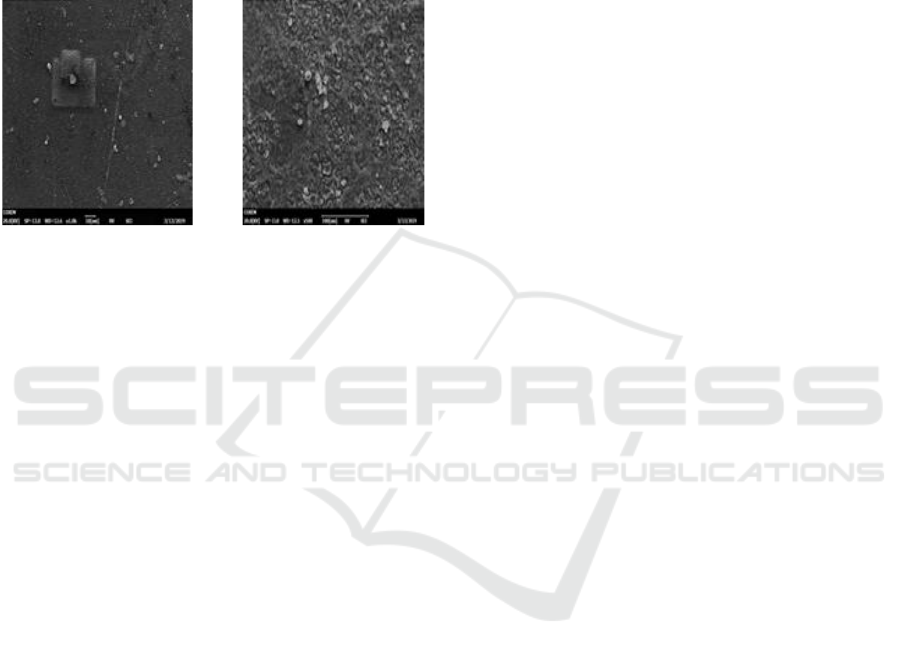

Figure 4.is a SEM photo of Na-CMC and Al-CMC-

BS with optimum WAG. SEM photos showed that

Al-CMC-BS had a coarser and more porous surface

observed compared to surface SEM photos from Na-

CMC. This shows the formation of polymeric

networks that are intertwined and interact with each

other. Larger pore presence in the AL-CMC-BS will

facilitate more water absorption and retention

(Pourjavadi et al., 2007)(Ma et al., 2015)

(a) (b)

Figure 4: (a) Photograph SEM (a) Na-CMC and (b) Al-

CMC-

4 CONCLUSIONS

A super absorbent polymer material from CMC,

Aluminum sulfate octadecahydrate and BS called

Al-CMC-BS superabsorbent polymer has been

successfully synthesized. The existence of readfruit

starch is very influential in increasing the absorption

of it to water which reaches 244.4 g of water / g Al-

CMC-BS. Al-CMC-BS super absorbent polymer is a

miscible porous blend

ACKNOWLEDGEMENTS

Author would like to thank to Rector of University

of Sumatera Urara for the funding from the project

of PD-TALENTA 2019

REFERENCES

Abdel-raouf, M.E., 2019. Guar gum based hydrogels for

sustained water release applications in agriculture, a

review. Curr. Res. Biopolym. 2, 1–15.

Braihi, A.J., 2015. Proposed Cross-Linking Model for

Carboxymethyl Cellulose /Starch Superabsorbent

Polymer Blend. Int. J. Mater. Sci. Appl. 3, 363.

Chandra Sutradhar, S., Mizanur, M., Khan, R., 2015.

Synthesis of superabsorbent polymer from

carboxymethylcellulose/acrylic acid blend using

gamma radiation and its application in agriculture

Electrolyte preperation View project. Artic. J. Phys.

Sci. 26, 23–39.

Chatterjee, P.K., 2002. Absorbent Technology, Textile

Science and Technology.

Klinpituksa, P., Kosaiyakanon, P., 2017. Superabsorbent

Polymer Based on Sodium Carboxymethyl Cellulose

Grafted Polyacrylic Acid by Inverse Suspension

Polymerization. Int. J. Polym. Sci.

Ma, G., Yang, Q., Ran, F., Dong, Z., Lei, Z., 2015. High

performance and low cost composite superabsorbent

based on polyaspartic acid and palygorskite clay.

Appl. Clay Sci.

Masita, S., 2017. Characteristics Of Physico Chemical

Properties Of Breadfruit Flour (Artocarpus altilis)

With Toddo’puli Varieties. J. Pendidik. Teknol.

Pertanian, 3, 234–241.

Mechtcherine, V., 2016. Use of superabsorbent polymers

(SAP) as concrete additive. RILEM Tech. Lett.

Nnadi, F., Brave, C., 2011. Environmentally friendly

superabsorbent polymers for water conservation in

agricultural lands. J. Soil Sci. Environ. Manag.

Nurhaeni, Pratiwi, D., Prismawiryanti, 2018. Modified

Breadfruit (Artocarpus altilis) Starch Using Acetic

Acid Anhydride and Its Application for Noodles

Production. Kovalen J. Ris. Kim. 4, 33–40.

Pourjavadi, A., Amini-Fazl, M.S., Ayyari, M., 2007.

Optimization of synthetic conditions CMC-g-poly

(acrylic acid)/Celite composite superabsorbent by

Taguchi method and determination of its absorbency

under load. Express Polym. Lett. 1, 488–494.

Raju, K.M., Raju, M.P., Mohan, Y.M., 2003. Synthesis of

superabsorbent copolymers as water manageable

materials. Polym. Int.

Sadeghi, M., Soleimani, F., 2013. Synthesis and

Characterization Superabsorbent Hydrogelsfor Oral

Drug Delivery Systems. Int. J. Chem. Eng. Appl.

Salavati, S., Valadabadi, S.A., Parvizi, K. H., Sayfzadeh,

S., Hadidi Masouleh, E., 2018. The effect of super-

absorbent polymer and sowing depth on growth and

yield indices of potato (Solanum tuberosum L.) in

Hamedan Province, Iran. Appl. Ecol. Environ. Res.

Siregar, F.K., Muis, D. Y. N. Y., Kaban, D. Y., 2019.

Preparation And Characterization Of Antibacterial

Film Based On Carboxymethylcellulose From Gebang

Leaf ( Coryphautan ), POLYVINYL ALCOHOL

ANDCITRIC ACID 12, 554–564.

Tao, J., Zhang, W., Liang, L., Lei, Z., 2018. Effects of

eco-friendly carbohydrate-based superabsorbent

polymers on seed germination and seedling growth of

maize. R. Soc. Open Sci.

Weerawarna, S.A., 2009. ( 2 ) Patent Application

Publication ( 10 ) Pub . No .: US 2009 / 0014391 A1 1

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

120