Characterization of α-Cellulose from Bagasse Cane Bz 132

(Saccharum officinarum)

Tengku Rachmi Hidayani

1,3

, Basuki Wirjosentono

2*

, Darwin Yunus Nasution

2

and Tamrin

2

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

3

Program Studi Agribisnis Kelapa Sawit, Politeknik Teknologi Kimia Industri, Medan, Indonesia

Keywords: Cellulose, α – Cellulose, Bagasse, Okhamafe Method, Extraction.

Abstract: A study concerning the separation of α - cellulose from bagasse were conducted using Okhamafe. The first

stage is the preparation of bagasse powder type Bz 132. Stage second is the separation of α - cellulose from

bagasse is done with the method Okhamafe done by immersion in 3.5 % HNO acid, bleaching with Sodium

Hypochlorite 1.75 % and purification with 17.5 % NaOH. The third stage is the characterization of α -

cellulose from bagasse types Bz 132 showed visible surface with large round -shaped grains are almost the

same size (uniform). This may indicate that the resulting α - cellulose has a form of homogeneous size (as

large). From the analysis of functional groups with the free OH groups visible wave number 4001.50 cm-1

which shows a typical chain of cellulose CH2OH and OH hydrogen bonds with wave number 3437.30 cm-1

as supporting data. Of the thermal test with test results obtained DTA melting point at a temperature of

60oC and 320oC decomposition point.

1 INTRODUCTION

Sugarcane is one of the agricultural commodities

containing lignocellulose so that it has the potential

as a raw material in the manufacture of

biodegradable composites. So far the use of sugar

cane is still limited to the sugar processing industry

by only taking the water, while the pulp of about 35-

40% of the weight of sugarcane milled is only used

as industrial fuel or may be disposed of so that it

becomes waste (Krisna, 2009). Cellulose is the main

constituent part of woody plant tissue. The

ingredients are mainly found in perennials, however,

cellulose is basically found in every type of plant,

including seasonal plants, shrubs and vines, even the

simplest plants. Such as: mushrooms, algae and

mosses (Tarmansyah, 2007). Separation of α-

cellulose from corn cob fiber was carried out by

Okhamafe by taking fine and dry fibers from corn

cobs which were then immersed in 3.5% HNO3

containing a number of NaNO3 at 900C for 2 hours.

The mixture is then soaked and heated with 2%

NaOH and 2% Sodium Sulfite at 50oC for 1 hour,

then bleached with Sodium hypochlorite

(Ohwoavworhua, 2005). Based on the descriptions

above, the researcher was interested in conducting

research on the extraction of α-cellulose from

sugarcane bagasse Bz 132 (Saccharum officinarum).

The results of α-cellulose from sugarcane bagasse

Bz 132 (Saccharum officinarum) were obtained

analyzed by functional groups by Fourier Transform

Infrared Spectroscopy (FTIR) test, analysis of

morphological properties by Spectra Electro

Magnetic (SEM) test, thermal properties analysis

with Differential Thermal Analysis (DTA) test. This

study is expected to provide information about the

analysis of the properties of α-cellulose from

sugarcane bagasse Bz 132 (Saccharum officinarum)

which is expected to be able to increase the

economic value of bagasse waste.

2 MATERIALS AND METHODS

2.1 Research Location

This research was carried out at the Kimia Terpadu

Universitas Sumatera Utara, the SEM test was

174

Hidayani, T., Wirjosentono, B., Nasution, D. and Tamrin, .

Characterization of -Cellulose from Bagasse Cane Bz 132 (Saccharum officinarum).

DOI: 10.5220/0008864601740177

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 174-177

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

conducted at the PPGL Laboratory, the DTA test

was conducted at the Politeknik Teknologi Kimia

Industri (PTKI), the FTIR Test was conducted at the

Bea Cukai Belawan Laboratory.

2.2 Methods

2.2.1 Preparation of Sugarcane Bagasse

Discarded the skin of sugarcane bagasse type Bz

132, milled with a grinder, extraction wet bagasse

from sugarcane waterdir. Wet bagasse washed with

water, soaked in water for 2 hours, dried under the

sun for 6 days, cut to from fine fibers, mashed up

and get dry sugarcane bagasse.

2.2.2 Extraction of α -Celullose from

Bagasse Cane Bz 132

About 75 gram of Bagasse cane put into beakerglass,

added 1000 mL of HNO

3

with 10 mg of NaNO

2

,

dipped for 2 hours in the water bath, washed and

filtrate, residue was heated with 375 mL NaOH 2%

and 375 mL Na Sulfite 2% with temperature 50oC for

one hour, washed and filtrated, residue was heated

with 500 mL sodium hypochlorite 1,75% for 0,5 hour

with temperature 100

o

C for 0,5 hour, washed and

filtrated until neutral pH. Cellulose (residue) added

500 mL NaOH 17,5% and heated for 80

o

C, washed

and filtrated until neutral pH., wet alpha cellulose

dried with oven 60

o

C, and saved in desiccator,

characterization with FTIR, SEM, and DTA test.

3 RESULTS AND DISCUSSIONS

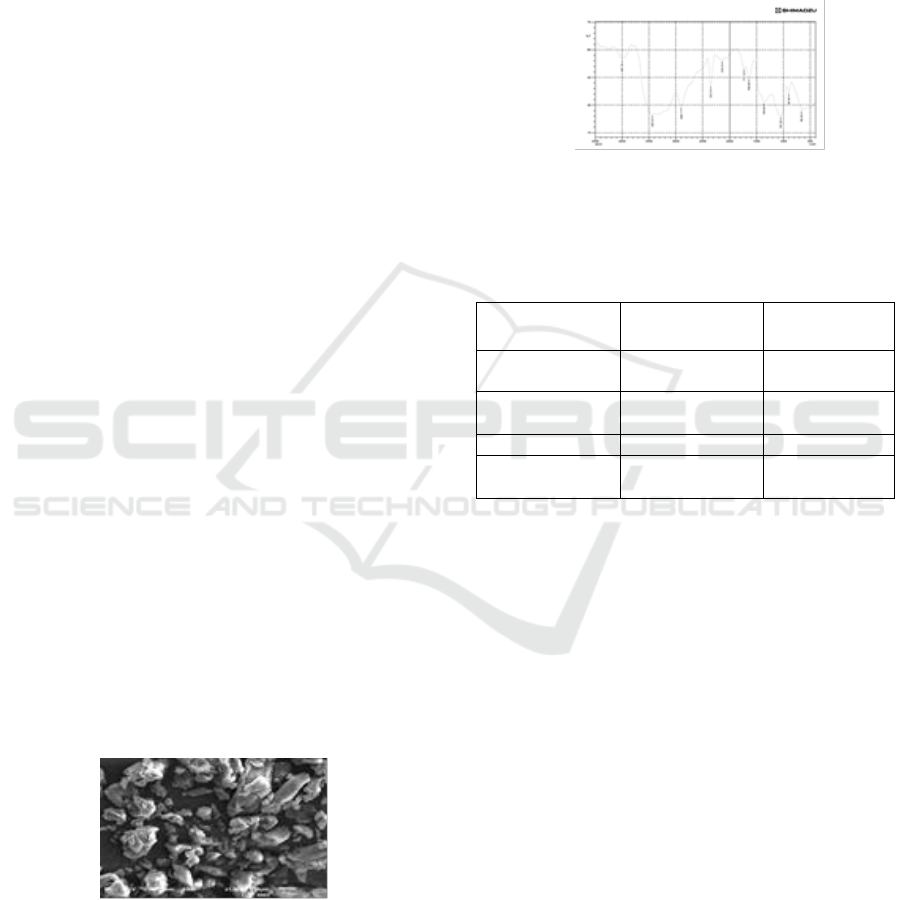

3.1 SEM Analysis of α -Celullose

Bagasse Cane Bz 132 (Saccharum

officinarum)

Figure 1: Test results of α-cellulose SEM from bagasse

pulp Bz 132 (Saccharum officinarum).

Figure 1: is the result of SEM photos of the surface

of α-cellulose from bagasse Bz 132 (Saccharum

officinarum) with a magnification of 1000 times.

Visible round nutiran surface with almost the same

size (uniform). This can show that the resulting α-

cellulose from sugarcane bagasse Bz 132

(Saccharum officinarum) has a homogeneous size.

3.2 the Cross-Linked Al-CMC

The following are the results of α-cellulose FTIR

test from bagasse Bz 132 (Saccharum officinarum).

Figure 2: α-cellulose FTIR Test results from sugarcane

bagasse Bz 132 (Saccharum officinarum).

Table 1: The spectra of FT-IR analysis of α-cellulose from

bagasse Bz 132 (Saccharum officinarum) provide

absorption spectrum peaks with wave numbers.

Functional

group

Wavenumber

Shriner.

(2004)

Free O-H group

4001.50 cm

-1

3500 – 4000

O-H hydrogen

bond

3437.30 cm

-1

3330 – 3500

C-H streching

2898.17 cm

-1

2840 – 3000

C-O carbonil

Cyclic ring

1380.84 cm

-1

897.90 cm

-1

1200 – 1400

800 - 900

From the FTIR spectra of α-cellulose from

sugarcane bagasse Bz 132 (Saccharum officinarum)

it is seen that the OH Group is free with wave

numbers 4001.50 cm

-1

which shows the CH chain

that is typical for hydrogen cellulose and OH bonds

with wave numbers 3437.30 cm-1 as supporting

data. And there is a CH stretching at wave number

2898.17 cm

-1

which proves the existence of CH

bonds at the end of cellulose and carbonyl CO at the

wave number 1642.46 cm

-1

which is also a typical

group of cellulose supported by fingerprint region

finger 897.90 cm

-1

which shows a cyclic ring chain.

So it can be concluded that there are cellulose

compounds in the spectra displayed.

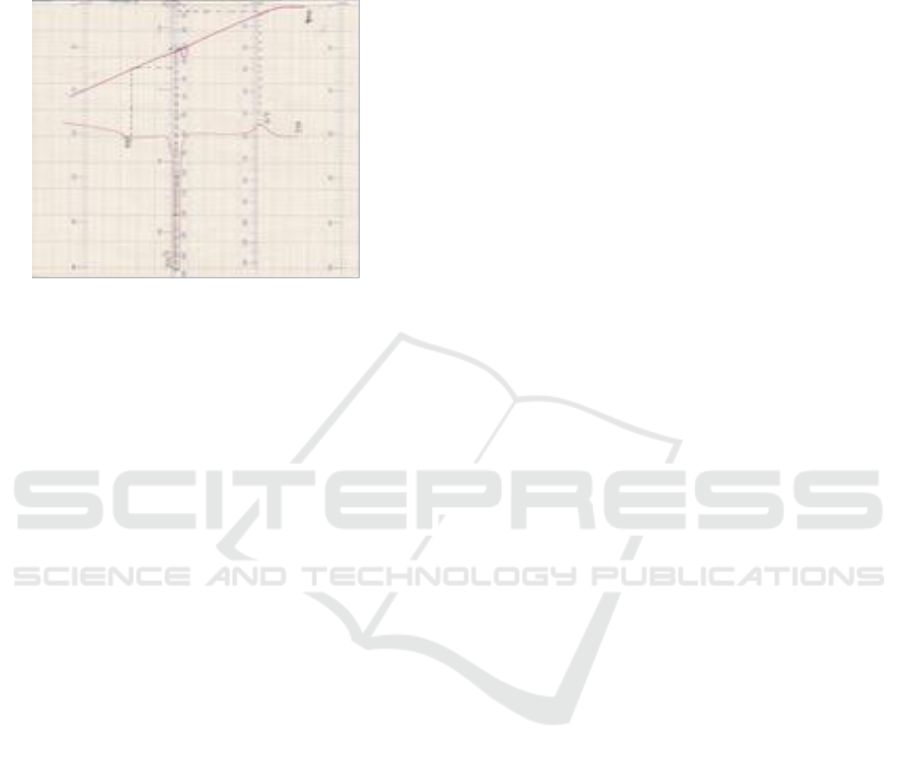

3.3 Result of DTA Test from

α -Cellulose N 132 (Saccharum

officinarum)

The tool used in the DTA test on α-cellulose from

bagasse Bz 132 (Saccharum officinarum) is

termocouple / mv: PR / 15mv brand shimadzu,

japan. The temperature of the experiment is the

Characterization of -Cellulose from Bagasse Cane Bz 132 (Saccharum officinarum)

175

temperature of 20°C - 600°C. MCC used in this test

is 30 gram with DTA range ± 250 µv, heating speed

10°C mm / minute and chard speed 2.5 mm / minute.

The following is a picture of the DTA test

equipment used.

Figure 3: DTA Test.

From thermocouple DTA, α-cellulose from

sugarcane bagasse Bz 132 (Saccharum officinarum)

shows a peak at 60°C, a peak formed on the right

area which shows a decrease in temperature

(endotherm) and a peak on the left at 320°C

indicating there is an increase in temperature

(exotherm). At 60°C α-cellulose from bagasse Bz

132 (Saccharum officinarum) evaporates which is

likely to be the water that is still stored α-cellulose

from bagasse Bz 132 (Saccharum officinarum), and

at 320°C α-cellulose from pulp sugar cane Bz 132

(Saccharum officinarum) burns by showing its

optimum peak.

4 CONCLUSIONS

Separation of α-cellulose from bagasse is done by

the Okhamafe method by extraction which is done

by immersion in 3.5% of HNO

3

acid, bleaching with

Sodium Hipochlorite 1.75% and purification with

NaOH 17.5%. Analysis of the characteristics of the

resulting α-cellulose was obtained from the results

of α-cellulose SEM photos of the surface with a

magnification of 1000 times. Visible spherical-

shaped surfaces with almost the same size (uniform).

This can indicate that the resulting α-cellulose has a

homogeneous size (equal in size). From the

functional group analysis, we can see the free O-H

group with wave number 4001.50 cm

-1

which shows

the CH2OH chain that is typical for cellulose and O-

H hydrogen bonds with wave numbers 3437.30 cm

-1

as supporting data. From the thermal test, the DTA

test obtained the melting point at a temperature of

60

0

C and a decomposition point of 320

0

C according

to the reference cellulose in general.

ACKNOWLEDGEMENTS

This research was carried out funded by Politeknik

Teknologi Kimia Industri Medan.

REFERENCES

Astawan, M., 2008. Kemasan:Pengaman Dan Pengawet

Makanan. Senior:Jakarta

Azubuike, Chukweumeka.P.C., Okhamafe, Augustine. O.,

Falodun, abiodun., 2011. Some Pharma Copocial and

diluent-Binder Properties of MaizeCob-derive from α-

cellulose in Selected Tablet Formulations. Journal of

Chemical and Pharmaceutical research. 481-488.

Eichhorn, S. J., Baillie, C. A., Zafeiropoulos, N.,

Mwaikambo, L. Y., Ansell, M. P., Dufresne, A.,

Entwistle, K. M., Herrera-Franco, P. J., Escamilla, G.

C., Groom, L. and Hughes, M., 2001. Current

international research into cellulosic fibres and

composites. Journal of materials Science, 36(9),

pp.2107-2131.

Kazakova, E. G. and Demin, V. A., 2009. A new procedure

for preparing microcrystalline cellulose. Russian Journal

of Applied Chemistry, 82(3), pp.496-499.

Malau, KM., 2009. Pemanfaatan Ampas Tebu Sebagai

Bahan Baku Dalam Pembuatan Papan Partikel.Skripsi.

Medan: USU.

Leppänen, K., Andersson, S., Torkkeli, M., Knaapila, M.,

Kotelnikova, N. and Serimaa, R., 2009. Structure of

cellulose and microcrystalline cellulose from various

wood species, cotton and flax studied by X-ray

scattering. Cellulose, 16(6), pp.999-1015.

Ohwoavworhua, F. O. and Adelakun, T. A., 2005. Some

physical characteristics of microcrystalline cellulose

obtained from raw cotton of Cochlospermum

planchonii. Tropical Journal of Pharmaceutical

Research, 4(2), pp.501-507.

Ohwoavworhua, F. O. and Adelakun, T. A., 2005.

Phosphoric acid-mediated depolymerization and

decrystallization of α-Cellulose obtained from corn

cob: preparation of low crystallinity cellulose and

some physicochemical properties. Tropical Journal of

Pharmaceutical Research, 4(2), pp.509-516.

Oksman, K., 2007. Extrusion and Mechanical Properties

of Highly Filled Cellulose Fibre-Polypropylene

Composites. Division of Manufacturing and Design of

Wood and Bionano composites. Lulea University of

Technology: Sweden.

Penebar Swadaya., 2000. Pembudidayaan Tebu Dilahan

Sawah dan Tegalan.Penebar Swadaya: Jakarta.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

176

That, T., 2008. Improving the Processing and Properties of

Cellulose fibre Composite. National Research

Council: Canada.

Tarmansyah, U. S., 2007. Pemanfaatan Serat Rami Untuk

Pembuatan Selulosa. STT No.2288.Volume 10 Nomor

18. Tim Puslitbang Indhan Balitbang Dephan: Jakarta.

Characterization of -Cellulose from Bagasse Cane Bz 132 (Saccharum officinarum)

177