The Effectiveness of Chitosan as an Antimicrobial on Bacterial

Cellulose-based Scaffold Skin Tissue Engineering

Khatarina Meldawati Pasaribu

1

, Saharman Gea

2*

, Safruddin Ilyas

3

and Tamrin

2

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

3

Department of Biology, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Bacterial Cellulose, Collagen, Chitosan, Antimicrobial, Composite.

Abstract: It is recognized that bacterial cellulose (BC) is used as a scaffold for tissue engineering. However, pristine

BC is not ideal enough to be applied as a scaffold because bacterial cellulose does not have antimicrobial

activity. The aim of this study was to evaluate the antmicrobial activity of bacterial cellulose and their

composites. BC gel, produced by Acetobacter xylinum with HS medium as a carbohydrate resources, was

immersed into chitosan (Ch) and collagen (Co) by ex-situ approach to produce BC/Ch/Col. The same

procedures were repeated for BC/Ch, BC/Col, and BC/Col/Ch. The effectiveness of antimicrobial activity

was carried out using disk paper to inhibit the growth of pathogen bacteria such as Escherichia coli and

Staphylococcus aureus. The results showed that BC/Ch has the highest antimicrobial activity against E. coli

and S. aureus with the inhibition zone of 10.15 mm and 7.9 mm, respectively.

1 INTRODUCTION

Cellulose is the most abundant biopolymer on earth

and has been used for a broad range of

implementations, such as filtration, food, medicine,

healthcare, and cosmetics due to its low-cost, low-

toxicity, hydrophilicity, biocompatibility, and

flexibility. Since cellulose is so commonly used in

biomedical fields and food packaging, it is

appropriate to address its activity against pathogenic

bacteria (Tsai et al., 2017). Unlike cellulose that is

isolated from the plant, BC is more interested in

studying because it is free of other polymers. In

addition to being used as an ideal matrix for medical

devices, it can be dried using freeze drying to mould

it into three-dimensional structures. Its construct can

make BC capable of retaining high water levels,

mechanically resistant and biocompatible. BC has a

nanofibrillary structure that supports cell

regeneration either as an assistance in the healing of

skin lesions 3 or in tissue engineering (Ataide et al.,

2017).

The BC fibrous woven is made of three-

dimensional nanofibres that are well-arranged,

resulting in high surface area and porosity hydrogels

(Esa, Tasirin and Rahman, 2014). Acetobacter

xylinum is regarded as the most researched starter

and the most effective bacteria as a BC producer that

capable to assimilating different sugars and

producing elevated cellulose levels in culture

medium (Esa, Tasirin and Rahman, 2014).

Previous study shows BC can be used as a

scaffolding for the growth of cells such as skin

fibroblast, ligament, cartilage and others that do not

contain blood vessels by in-vitro (Gea et al., 2018).

BC has been demonstrated to be biocompatible with

living tissues. Bacterial cellulose has high

hydrophilic characteristics and never dries, which is

the required property, as it has been shown that

when the wound is constantly moisturized, wounds

cure better and quicker (Kucińska-Lipka, Carayon

and Janik, 2015).

Tissue engineering devices, mainly used as

implantable scaffolding, is usually made from

biomaterials with distinct structures and

characteristics. To this end, many biomaterials –

both synthetic and naturally occurring – have been

used in tissue engineering (TE) applications, where

extra scaffolding material changes such as anchoring

of biologically active entities are generally needed.

Materials such as cellulose, chitosan, hyaluronic

acid and collagen have recently drawn considerable

178

Pasaribu, K., Gea, S., Ilyas, S. and Tamrin, .

The Effectiveness of Chitosan as an Antimicrobial on Bacterial Cellulose-based Scaffold Skin Tissue Engineering.

DOI: 10.5220/0008864701780181

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 178-181

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

interest as prospective materials for TE applications.

(Ozdil and Aydin, 2014). Due to its outstanding

biocompatibility and distinctive physiochemical

characteristics, bacterial cellulose (BC) has appeared

as a promising biomaterial for tissue engineering

applications.

To this end, ex-situ approach for BC production

has been the focus of much research as this approach

can further improve BC characteristics in order to

address the precise requirements for TE applications.

While there has been a current trend in the

expansion of BC implementations in TE, BC major

TE implementations remain in wound dressing and

bone regeneration. However, this is likely to be a

chance, as the full potential of BC as a biomaterial

and in TE is continually being explored (Stumpf et

al., 2018). In this study, the BC is reinforced by

collagen and chitosan to enhance its antimicrobial

activities which can be applied for scaffold material

in skin tissue engineering.

2 METHODS

2.1 Bc Preparation

Acetobacter xylinum as a sort of bacterial strain

used to synthesize BC, was acquired from the

Material and Polymer Postgraduate Labolatorium of

Universitas Sumatera Utara, Indonesia. This aerobic

gram-negative bacteria actively fermented at pH 4.5

and temperature between 25 and 30˚C using

carbohydrate as carbon resources (Esa, Tasirin and

Rahman, 2014). BC production in HS medium

containing glucose (20 g/L), peptone (5 g/L), yeast

extract (5 g/L), citric acid (1.15 g/L), and disodium

hydrogen phosphate (2.7 g/L). The culture medium

pH then was adjusted to 4.5 by using CH3COOH

glacial. The culture medium was then autoclaved to

remove potential contaminants and then permitted to

reach room temperature. The Acetobacter xylinum

starter was then put and inoculated for 7 days inside

the incubator in a static culture medium at 28ºC. The

cellulose fiber would be sythesized by Acetobacter

xylinum during this inoculated period. After that, the

gels obtained was immersed in NaOH (2.5 g/L) for

24 h to purified the BC from the bacteria and culture

medium. The BC gel then bleached overnight in

NaOCl (2.5 mL/L). Finally, the BC gel was washed

by using aquadest until the BC reach neutral pH.

2.2 Production of BC/Ch Composites

The purified BC gel were immersed in 20 mL

aqueous of chitosan (0.2 g/L) in acetic acid solution

1% for 24 h. Then they were dried in freeze dryer

for 24 h. The final composite film have been marked

as BC/Ch.

2.3 Production of BC/Col Composites

The purified BC gel were immersed in 20 mL

aqueous of colagen (0.2 g/L) for 24 h. Then they

were dried in freeze dryer for 24 h. The final

composite film have been marked as BC/Col.

2.4 Production of BC/Ch/Col

Composite

The purified BC gel were immersed in 20 mL

aqueous of chitosan (0.2 g/L) in acetic acid solution

1% for 24 h. BC/Ch composite then immersed in 20

mL aqueous of colagen (0.2 g/L) for 24 h. Then they

were dried in freeze dryer for 24 h. The final

composite film have been marked as BC/Ch/Col.

2.5 Production of BC/Col/Ch

Composite

The purified BC gel were immersed in 20 mL

aqueous of colagen (0.2 g/L) for 24 h. BC/Ch

composite then immersed in 20 mL aqueous of

chitosan (0.2 g/L) in acetic acid solution 1% for 24

h. Then they were dried in freeze dryer for 24 h. The

final composite film have been marked as

BC/Col/Ch.

2.6 Antimicrobial Activity

The antimicrobial activity of BC, BC/Ch, BC/Col,

BC/Ch/Col, BC/Col/Ch composites were assessed

using a technique of disk diffusion against

pathogenic bacteria such as Escherichia coli and

Staphylococcus aureus. The technique of disk

diffusion was conducted on medium nutrient agar in

petri dish. All the samples tested were then shaped

into a 10 mm diameter disk and sterilized for 5 min

on each side using a low-power UV lamp. Then, the

disks were placed on the agar plate inoculated. The

plates were then placed in an incubator of 37 ° C for

24 hours. The efficacy of the inhibitory action of the

evaluated samples on againts the bacterial was

determined by measuring the inhibition zone

diameter.

The Effectiveness of Chitosan as an Antimicrobial on Bacterial Cellulose-based Scaffold Skin Tissue Engineering

179

3 RESULT AND DISCUSSION

Medium culture methods on producing BC would

determine the macrostructure morphology of BC.

Static culture medium would produce a pristine solid

woven fiber gelatinous cellulose film that formed on

the interface of the medium. In agitation culture

medium, cellulose is synthesized spread in medium.

BC gels that produced by agitation medium culture

was usually formed as of fibrous suspensions, pellets

and have ir-regular masses. In this work the BC gels,

that would use to made composites was produced in

static culture medium conditions in HS medium for

7 days. After 7 days BC gels that formed on the

surface of the medium a BC gel film was treated

with NaOH and NaOCl. The treated BC gel film

would form as colorless and transparent gel as

showed at figure 1.

Figure 1: BC gel film.

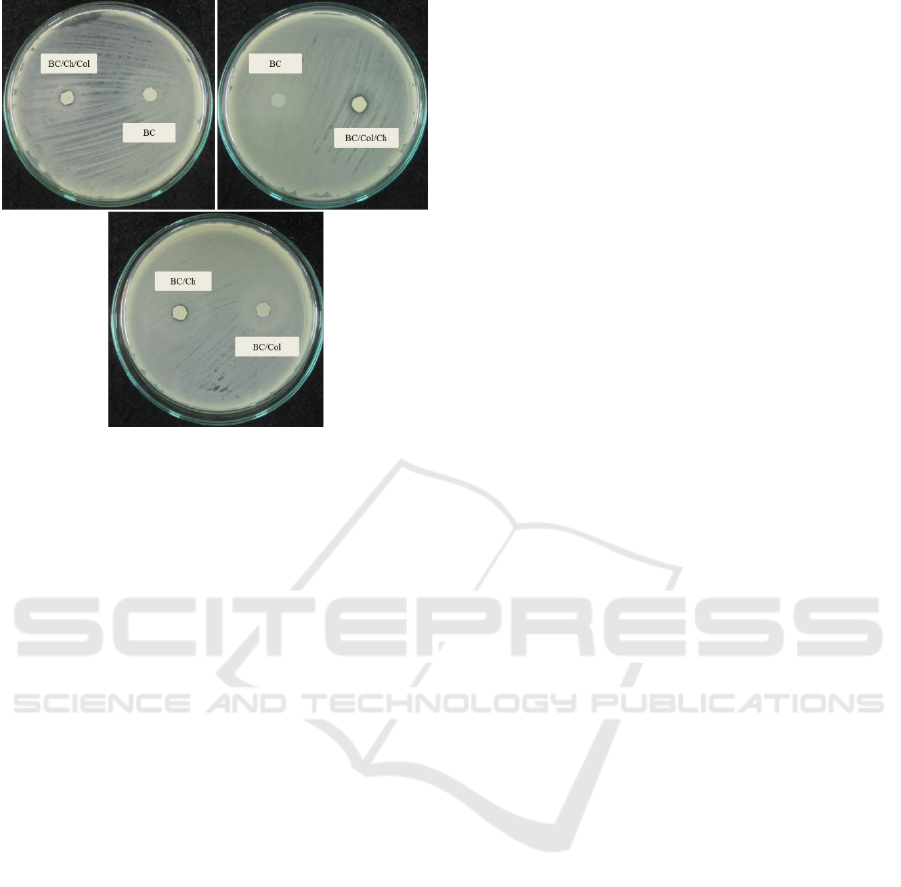

In this study, the disk diffusion method was used

to evaluate the antimicrobial acitivity of the tested

samples, which is known as one of the popular

methods of antimicrobial activity. Since the

inhibition zone can be measured directly.

Antimicrobial properties of the sampels have been

observed to inhibit the growth of Escherichia coli

and Staphylococcus aureus.

Prepared composites were placed on the surface of

the Escherichia coli and Staphylococcus aureus

bacteria lawn. The efficiency of antimicrobial

activity of BC, BC/Ch, BC/Col, BC/Ch/Col,

BC/Ch/Col composites was evaluated by measured

the size of appeared clear zones of inhibition around

the samples after 24 h of exposure.

Figure 2: The inhibition zones of tested samples against

pathogen bacteria Escherichia coli.

Pure BC is known to be a natural scaffolding

material because it can be a suitable cell growth

environment due to higher water retention that

prevents tissue dehydration and cell death, resulting

in faster skin repairs. But pure BC shows no

antimicrobial activity to prevent infection in the

affected area. In our case, pure BC as a control

sample showed no antimicrobial activity where no

inhibition zone was present in Figure 2.

After 24 h exposure diameters of inhibition

zones measured as 10.15 mm, 6.4 mm, 7.9 mm and

8.8 mm for BC/Ch, BC/Col, BC/Ch/Col, BC/Co/Ch

respectively. The best antibacterial activities are

carried out by BC / Ch. The findings acquired

showed that composite BC / Ch has great

antimicrobial activity against Escherichia coli. This

result also indicated that BC/Ch have better

antimicrobial activities rather than Ag/BC, where

showed bacterial colony-forming clear zone about

6.5 mm, which is in this range, it can be said that its

good enough as an antimicrobial substrate (Pal et al.,

2017).

This finding was also supported by another study

that showed that the composite of BC/AgNPs

displayed clear inhibition areas against both model

bacteria tested (i.e. 2 mm for E. coli. and 9 mm for

S. aureus), while no inhibition area for pristine BC

was reported (Stumpf et al., 2018).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

180

Figure 3: The inhibition zones of tested samples against

pathogen bacteria Staphylococcus aureus.

Chitosan has been previously reported have

antimicrobial effects against some pathogens such as

E. coli and S. aureus. The polymers in BC films

have been reported to be susceptible to colonization

by bacteria. BC alone does not have antimicrobial

activity, but the incorporation of chitosan into the

BC films could prevent bacterial adhesion. After 24

h exposure diameters of inhibition zones measured

as 7.9 mm, 6.5 mm, 7.1 mm and 7.4 mm for BC/Ch,

BC/Col, BC/Ch/Col, BC/Co/Ch respectively.

4 CONCLUSIONS

In summary, bacterial cellulose based biocomposites

for scaffold material had been prepared and the

antimicrobial activity had been investigated. The

results showed that BC/Ch has the highest

antimicrobial activity against E. coli and S. aureus

with the inhibition zone of 10.15 mm and 7.9 mm,

respectively. As it have antimicrobial activity and

did not contain hazardous chemical contamination, it

can be concluded that the BC, BC/Ch, BC/Ch/Co

and BC/Co/Ch was the potential scaffold material

for skin tissue engineering.

ACKNOWLEDGEMENTS

This work is completely financed under PMDSU

2019 research scheme by Ministry of Research,

Technology, and Higher Education

(KEMENRISTEK DIKTI), Republic of Indonesia.

REFERENCES

Ataide, J. A. et al. (2017) ‘Bacterial Nanocellulose Loaded

with Bromelain: Assessment of Antimicrobial,

Antioxidant and Physical-Chemical Properties’,

Scientific Reports, 7(1), pp. 2–10. doi:

10.1038/s41598-017-18271-4.

Esa, F., Tasirin, S. M. and Rahman, N. A. (2014)

‘Overview of Bacterial Cellulose Production and

Application’, Agriculture and Agricultural Science

Procedia. Elsevier Srl, 2, pp. 113–119. doi:

10.1016/j.aaspro.2014.11.017.

Gea, S. et al. (2018) ‘Enhancing the quality of nata de

coco starter by channeling the oxygen into the

bioreactor through agitation method’, in AIP

Conference Proceedings. doi: 10.1063/1.5082469.

Kucińska-Lipka, J., Carayon, I. and Janik, H. (2015)

‘Bacterial cellulose in the field of wound healing and

regenerative medicine of skin: recent trends and future

prospectives’, POLYMER BULLETIN, 72(9), pp.

2399–2419.

Ozdil, D. and Aydin, H. M. (2014) ‘Polymers for medical

and tissue engineering applications’, Journal of

Chemical Technology and Biotechnology, 89(12), pp.

1793–1810. doi: 10.1002/jctb.4505.

Pal, S. et al. (2017) ‘Silver-Functionalized Bacterial

Cellulose as Antibacterial Membrane for Wound-

Healing Applications’, ACS Omega, 2(7), pp. 3632–

3639. doi: 10.1021/acsomega.7b00442.

Stumpf, T. R. et al. (2018) ‘In situ and ex situ

modifications of bacterial cellulose for applications in

tissue engineering’, Materials Science and Engineering

C. Elsevier B.V, 82, pp. 372–383. doi:

10.1016/j.msec.2016.11.121.

Tsai, T. T. et al. (2017) ‘Antibacterial cellulose paper

made with silver-coated gold nanoparticles’, Scientific

Reports. Springer US, 7(1), pp. 1–10. doi:

10.1038/s41598-017-03357-w.

The Effectiveness of Chitosan as an Antimicrobial on Bacterial Cellulose-based Scaffold Skin Tissue Engineering

181